Content Menu

● Overview of Extrusion Production Technician Role

● Salary Overview

>> Average Salary

>> Hourly Wage

>> Salary by Experience Level

● Factors Influencing Salary

>> 1. Geographic Location

>> 2. Industry Type

>> 3. Company Size and Reputation

● Career Advancement Opportunities

● Job Outlook

● Essential Skills for Extrusion Production Technicians

>> 1. Mechanical Aptitude

>> 2. Attention to Detail

>> 3. Problem-Solving

>> 4. Communication Skills

>> 5. Technical Proficiency

● Training and Certifications

● Challenges Faced by Extrusion Production Technicians

● The Role of Technology in Extrusion Processes

>> 1. Advanced Machinery

>> 2. Automation

● Conclusion

● FAQs

>> 1. What is the average salary of an extrusion production technician?

>> 2. What factors influence the salary of an extrusion technician?

>> 3. Are there opportunities for career advancement in this field?

>> 4. What skills are important for an extrusion technician?

>> 5. What industries employ extrusion production technicians?

● Citations:

Extrusion production technicians play a vital role in the manufacturing sector, particularly in industries that rely on extrusion processes to create products from materials such as plastics and metals. Understanding their earnings can provide insights into the job market and the value of skills in this field. This article will explore the salary ranges, factors influencing pay, and career prospects for extrusion production technicians.

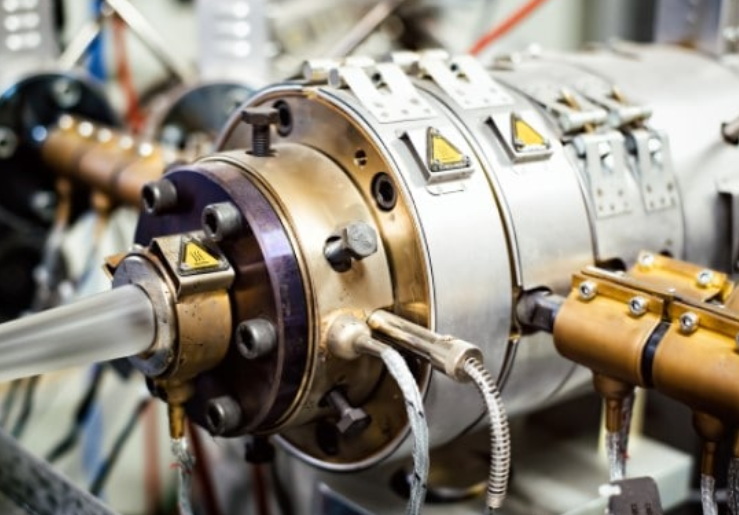

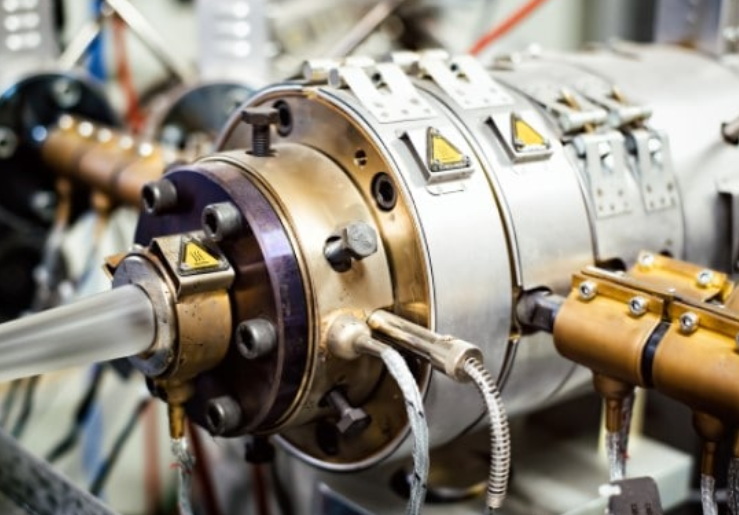

Overview of Extrusion Production Technician Role

Extrusion production technicians are responsible for operating and maintaining extrusion machinery. Their duties typically include:

- Setting up and calibrating machines

- Monitoring production processes

- Conducting quality control inspections

- Troubleshooting equipment issues

- Ensuring compliance with safety standards

The skills required for this role often include mechanical aptitude, attention to detail, and the ability to work under pressure.

Salary Overview

The salary of an extrusion production technician varies based on several factors, including experience, location, and the specific industry. Here's a breakdown of what extrusion production technicians can expect to earn:

Average Salary

- The average annual salary for extrusion operators in the United States is approximately $36,571, with entry-level positions starting around $30,019 and experienced technicians earning up to $45,000 annually.

Hourly Wage

- Hourly wages for extrusion operators typically range from $17.58 to $22.00, depending on experience and location. The national average hourly wage is about $18.00.

Salary by Experience Level

- Entry-Level (0-2 years): Approximately $30,019

- Mid-Career (3-6 years): Approximately $36,571

- Senior-Level (7-12 years): Approximately $43,704

Factors Influencing Salary

Several factors can impact the earnings of extrusion production technicians:

1. Geographic Location

Salaries can vary significantly by state. For instance:

- Connecticut: Highest average salaries for extrusion operators.

- Kansas: Average hourly rate around $18.61.

- Louisiana: Average hourly rate around $19.11.

2. Industry Type

Extrusion operators in different industries may earn varying salaries. Industries that typically pay higher wages include:

- Manufacturing

- Utilities

- Aerospace

3. Company Size and Reputation

Larger companies or those with a strong reputation in the industry often offer higher salaries and better benefits compared to smaller firms.

Career Advancement Opportunities

Extrusion production technicians can advance their careers through additional training and certifications. Opportunities for advancement include:

- Senior Technician roles

- Supervisory positions

- Quality Control Manager roles

Continuing education in areas such as mechanical engineering or industrial technology can also enhance career prospects.

Job Outlook

The job outlook for extrusion production technicians remains positive due to the ongoing demand for manufactured goods. As industries continue to grow, skilled technicians will be needed to operate advanced machinery.

Essential Skills for Extrusion Production Technicians

To succeed as an extrusion production technician, individuals should cultivate a range of skills that enhance their effectiveness on the job:

1. Mechanical Aptitude

A strong understanding of machinery and its components is fundamental. Operators must be able to troubleshoot and solve mechanical issues quickly.

2. Attention to Detail

Precision is key in ensuring that products meet exact specifications. Operators must consistently monitor the extrusion process and make fine adjustments as needed.

3. Problem-Solving

The ability to identify and address issues promptly is critical for maintaining production efficiency.

4. Communication Skills

Operators often work in teams; therefore, clear communication is necessary to ensure that production runs smoothly and issues are addressed collectively.

5. Technical Proficiency

Familiarity with computer systems used for monitoring machine performance can significantly enhance productivity.

Training and Certifications

Most extrusion operators begin their careers with on-the-job training lasting from a few months to a year. This training covers machine operation, safety protocols, and basic troubleshooting techniques.

Certifications such as the Certified Extrusion Operator (CEO) can enhance an operator's career prospects by covering advanced topics like equipment maintenance, safety standards, and process optimization.

Challenges Faced by Extrusion Production Technicians

While working as an extrusion production technician can be rewarding, it also comes with challenges:

- The role can be physically demanding due to long hours spent on one's feet.

- Operators must adhere strictly to safety protocols due to potential hazards associated with machinery.

- The need for precision means that even minor mistakes can lead to significant product defects or waste.

The Role of Technology in Extrusion Processes

Technological advancements have significantly impacted the extrusion process:

1. Advanced Machinery

Modern extrusion machines are equipped with advanced control systems that allow for precise adjustments and monitoring. These technologies enhance efficiency and quality.

2. Automation

The integration of automation has increased productivity and consistency in manufacturing processes, allowing operators to focus on more complex tasks while automated systems handle repetitive ones.

Conclusion

In summary, extrusion production technicians earn a competitive salary that reflects their skills and the demand for their work across various industries. With opportunities for advancement and specialization, this career path can be rewarding both financially and professionally.

FAQs

1. What is the average salary of an extrusion production technician?

The average salary is approximately $36,571 per year or about $18 per hour.

2. What factors influence the salary of an extrusion technician?

Factors include geographic location, industry type, experience level, and company size.

3. Are there opportunities for career advancement in this field?

Yes, technicians can advance to senior roles or supervisory positions with additional training and experience.

4. What skills are important for an extrusion technician?

Key skills include mechanical aptitude, attention to detail, problem-solving abilities, and knowledge of safety standards.

5. What industries employ extrusion production technicians?

Industries include manufacturing, aerospace, automotive, and utilities.

Citations:

[1] https://www.indeed.com/cmp/Aerotek/salaries/Extrusion-Operator

[2] https://www.rssinc.com/blog/understanding-the-role-of-an-extrusion-operator/

[3] https://www.zippia.com/extrusion-operator-jobs/skills/

[4] https://www.zippia.com/extrusion-operator-jobs/trends/

[5] https://www.salary.com/research/salary/alternate/extrusion-machine-operator-ii-salary

[6] https://www.1medicalextrusion.com/careers/senior-extrusion-technician/

[7] http://www.amesburytruth.com/careers/documents/Extrusion%20Technician%20-%20Dec18.pdf

[8] https://www.rssinc.com/blog/what-is-an-extrusion-machine-operator/

[9] https://www.indeed.com/cmp/Westlake-Corporation/salaries/Extrusion+Operator/McPherson,+KS

[10] https://www.indeed.com/career-advice/finding-a-job/what-does-extrusion-operator-do

[11] https://bdcustommfg.com/extrusion-technician-job-description/

[12] https://resumegenerator.io/career-paths-a-job-seekers-guide-for-extruding-and-drawing-machine-setters-operators-and-tenders-metal-and-plastic/

[13] https://www.careeronestop.org/Toolkit/Careers/Occupations/occupation-profile.aspx?location=Alabama&onetcode=51-4021.00

[14] https://customprofiles.com/extrusion-technician/

[15] https://www.linkedin.com/advice/3/how-do-you-become-extrusion-operator-skills-manufacturing-ucy4e

[16] https://www.zippia.com/extrusion-line-operator-jobs/trends/

[17] https://www.ziprecruiter.com/career/Extrusion-Technician/What-Is-How-to-Become

[18] https://careers.dupont.com/us/en/job/242355W/Extrusion-Operator

[19] https://www.talent.com/salary?job=extrusion+technician

[20] https://www.ziprecruiter.com/Salaries/What-Is-the-Average-Extrusion-Technician-Salary-by-State

[21] https://ca.indeed.com/career-advice/finding-a-job/extruder-operator

[22] https://www.bls.gov/ooh/architecture-and-engineering/industrial-engineering-technicians.htm