Content Menu

● Introduction to Fastec Aluminum Extrusion

● The Manufacturing Process

● Applications and Industries

● Design Considerations and Engineering Specifications

● Quality Control and Testing Procedures

● Sustainability and Environmental Considerations

● Conclusion

● Frequently Asked Questions

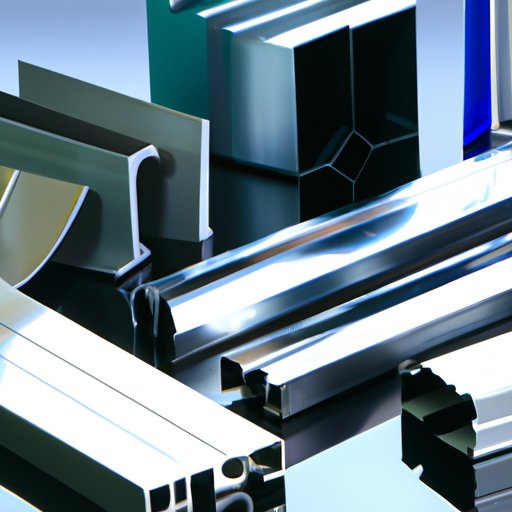

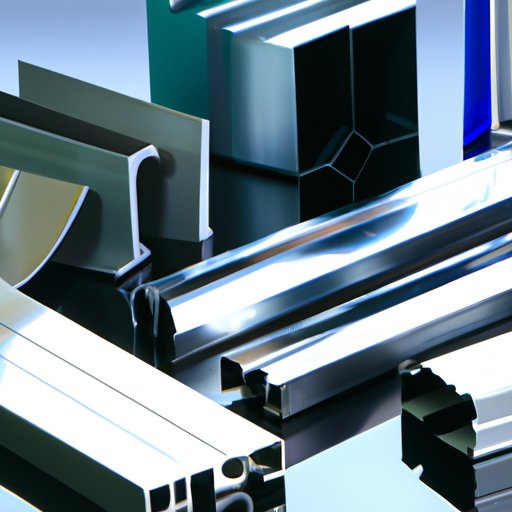

Introduction to Fastec Aluminum Extrusion

Fastec Aluminum Extrusion represents a cutting-edge manufacturing process that has revolutionized various industries through its versatility and efficiency. This sophisticated technology involves forcing aluminum alloy material through a die with a specific cross-sectional profile, resulting in complex shapes and designs that serve numerous industrial and commercial applications. The process combines precision engineering with advanced metallurgical principles to create products that meet the most demanding specifications in terms of strength, durability, and dimensional accuracy. Understanding the fundamental aspects of aluminum extrusion is crucial for professionals in manufacturing, construction, and design industries who seek to optimize their production processes and enhance product quality.

The Manufacturing Process

The manufacturing process of Fastec Aluminum Extrusion involves several critical stages, each contributing to the final product's quality and performance. The process begins with selecting high-grade aluminum alloy, typically 6063 series, known for its excellent extrudability and mechanical properties. The material undergoes careful preparation, including heating to specific temperatures to achieve optimal plasticity for extrusion. Advanced die technology and precise temperature control systems ensure consistent product quality throughout the manufacturing process. Quality control measures are implemented at each stage, from raw material selection to final product inspection, ensuring that every extrusion meets the required specifications and industry standards.

Applications and Industries

Fastec Aluminum Extrusion finds extensive applications across diverse industries, demonstrating its versatility and adaptability. In the construction sector, these profiles are essential components in building facades, window systems, and structural frameworks. The automotive industry utilizes aluminum extrusions for lightweight vehicle components, contributing to improved fuel efficiency and performance. In the renewable energy sector, these profiles are crucial for solar panel mounting systems and wind energy components. The technology sector benefits from aluminum extrusions in electronic enclosures and thermal management systems. Each application showcases the material's unique combination of strength, lightweight properties, and corrosion resistance.

Design Considerations and Engineering Specifications

The design phase of aluminum extrusion requires careful consideration of various technical parameters to ensure optimal performance. Engineers must account for factors such as wall thickness, cross-sectional geometry, and structural requirements. The design process involves sophisticated computer-aided design (CAD) software to create precise specifications that meet both functional and aesthetic requirements. Material selection plays a crucial role, with different aluminum alloys offering varying properties suitable for specific applications. Understanding thermal characteristics, stress distribution, and load-bearing capabilities is essential for creating efficient and effective designs.

Quality Control and Testing Procedures

Quality assurance in Fastec Aluminum Extrusion involves comprehensive testing procedures and strict adherence to international standards. The testing process includes dimensional verification, surface finish inspection, and mechanical property testing. Advanced equipment and technologies are employed to ensure consistent quality across production batches. Regular maintenance of equipment and continuous monitoring of process parameters help maintain high-quality standards. Documentation and traceability systems are implemented to track each product from raw material to finished goods, ensuring complete quality control throughout the manufacturing process.

Sustainability and Environmental Considerations

Fastec Aluminum Extrusion demonstrates strong commitment to environmental sustainability through various initiatives. The aluminum extrusion process is inherently environmentally friendly due to the material's recyclability and long service life. Energy-efficient manufacturing processes and waste reduction strategies are implemented to minimize environmental impact. The use of recycled aluminum in the production process significantly reduces carbon footprint compared to primary aluminum production. Sustainable practices extend to packaging and transportation methods, ensuring minimal environmental impact throughout the supply chain.

Conclusion

Fastec Aluminum Extrusion represents a crucial technology in modern manufacturing, offering versatile solutions across multiple industries. The combination of advanced manufacturing processes, quality control measures, and sustainable practices positions it as a leading choice for various applications. As technology continues to evolve, the future of aluminum extrusion promises even greater innovations and applications.

Frequently Asked Questions

Q1: What are the main advantages of Fastec Aluminum Extrusion?

A: The main advantages include lightweight properties, excellent strength-to-weight ratio, corrosion resistance, design flexibility, and sustainability through recyclability.

Q2: What industries commonly use aluminum extrusions?

A: Key industries include construction, automotive, aerospace, renewable energy, electronics, and architectural applications.

Q3: How does the aluminum extrusion process work?

A: The process involves heating aluminum billets and forcing them through a die with a specific cross-sectional profile, creating complex shapes and designs.

Q4: What are the typical quality control measures in aluminum extrusion?

A: Quality control includes dimensional inspection, surface finish testing, mechanical property verification, and comprehensive documentation of production parameters.

Q5: How does aluminum extrusion contribute to sustainability?

A: Aluminum extrusion supports sustainability through material recyclability, energy-efficient processing, and the production of durable, long-lasting products.