Content Menu

● Introduction to Aluminum MK8 Extruders

>> Advantages of Aluminum MK8 Extruders

● How HICTOP Aluminum MK8 Extruders Improve Filament Feeding

● Installation of HICTOP Aluminum MK8 Extruder

● Choosing the Right HICTOP Aluminum MK8 Extruder

● Comparison with Stock Extruders

>> Enhanced Filament Control

>> Material Compatibility

>> Unlocking Precision Printing

>> Simplified Installation and Maintenance

● Advanced Features and Customizations

>> Support for Flexible Filaments

>> Enhanced Bowden Tube Fittings

● Conclusion

● FAQ

>> 1. What are the benefits of using an aluminum MK8 extruder over a plastic one?

>> 2. Is it difficult to install a HICTOP aluminum MK8 extruder?

>> 3. Will upgrading to an aluminum extruder void my printer's warranty?

>> 4. Can I use an aluminum MK8 extruder with flexible filaments?

>> 5. How does an aluminum extruder improve print quality?

● Citations:

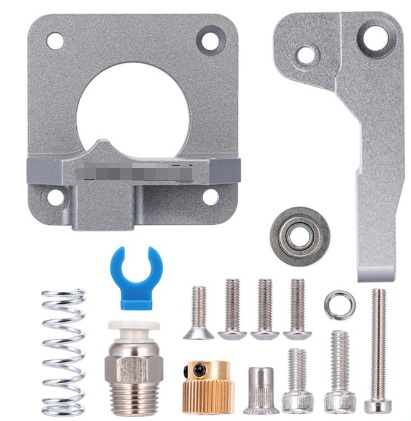

The HICTOP Upgraded Replacement Aluminum MK8 Extruder Drive Feed is a popular upgrade for many 3D printers, particularly those in the Creality series like the Ender 3 and CR-10. This article will delve into the benefits of using an aluminum MK8 extruder, focusing on how it improves filament feeding, and explore its installation and operation.

Introduction to Aluminum MK8 Extruders

Aluminum MK8 extruders are designed to replace the stock plastic extruders found in many budget-friendly 3D printers. These upgrades offer several advantages over their plastic counterparts, including enhanced durability, improved filament control, and better temperature resistance.

Advantages of Aluminum MK8 Extruders

1. Durability: Aluminum is more robust than plastic, capable of withstanding higher mechanical stress without cracking or warping, ensuring a longer lifespan for your extruder.

2. Improved Filament Control: The design of aluminum extruders provides a better grip on the filament, reducing slippage and ensuring consistent extrusion.

3. Higher Temperature Resistance: Aluminum can handle higher temperatures, making it suitable for printing with a wide range of filaments, including ABS and PETG.

4. Precision Printing: Aluminum extruders contribute to better layer adhesion and reduced stringing, resulting in smoother surfaces and finer details in printed objects.

5. Ease of Installation: Most MK8 aluminum extruders come as DIY kits that are easy to install, requiring minimal technical knowledge.

How HICTOP Aluminum MK8 Extruders Improve Filament Feeding

The HICTOP Upgraded Replacement Aluminum MK8 Extruder Drive Feed is specifically designed to enhance filament feeding in several ways:

1. Better Grip on Filament: The aluminum construction provides a more aggressive grip on the filament, reducing slippage and ensuring consistent extrusion.

2. Improved Heat Dissipation: Aluminum is an excellent conductor of heat, which helps maintain a consistent temperature in the extruder, ensuring that the filament melts evenly and flows smoothly through the nozzle.

3. Reduced Jamming: The robust design and improved heat dissipation reduce the likelihood of filament jams, which often occur when the filament does not melt properly or cools down too quickly.

4. Increased Pressure: The MK8 extruder's design allows for a tighter grip on the filament, increasing the pressure applied to the filament as it moves through the extruder, which helps push the filament more consistently.

Installation of HICTOP Aluminum MK8 Extruder

Installing the HICTOP Aluminum MK8 Extruder is relatively straightforward and can be done with basic tools. Here's a step-by-step guide:

1. Prepare the Printer: Ensure the printer is turned off and the filament is removed from the extruder.

2. Disassemble the Stock Extruder: Remove the screws holding the stock extruder in place and gently pull it away from the printer frame.

3. Assemble the Aluminum Extruder: Follow the instructions provided with the kit to assemble the aluminum extruder. This typically involves attaching the drive gear, spring, and bushing.

4. Mount the Aluminum Extruder: Secure the assembled extruder to the printer frame using the provided screws.

5. Connect the Bowden Tube: Attach the Bowden tube to the extruder and ensure it is securely fitted.

Choosing the Right HICTOP Aluminum MK8 Extruder

When selecting an aluminum MK8 extruder, consider the following factors:

1. Compatibility: Ensure the extruder is compatible with your 3D printer model.

2. Material Support: Choose an extruder that supports the types of filaments you plan to use.

3. Price and Quality: Balance cost with quality, as cheaper options may lack durability or performance.

Comparison with Stock Extruders

Stock extruders, often made from plastic, are prone to wear and tear. Over time, the constant pressure and friction from the filament can cause them to crack or warp. This leads to inconsistent extrusion and a decline in print quality. Aluminum extruders, on the other hand, are built to last. The robust metal construction can withstand significant mechanical stress without showing signs of wear. This not only extends the lifespan of your extruder but also ensures consistent performance over time.

Enhanced Filament Control

One of the most common issues with stock extruders is their inability to maintain a consistent grip on the filament. This can result in slippage, under-extrusion, and inconsistent layer adhesion. The MK8 aluminum extruder is designed with a more aggressive grip that firmly holds the filament, providing better control during the printing process. This enhanced grip minimizes slippage and ensures a steady flow of filament, resulting in more accurate and reliable prints.

Material Compatibility

Stock extruders often struggle with high-temperature filaments like ABS and nylon. The plastic components can soften or deform under extreme heat, leading to extrusion problems and potentially damaging the extruder itself. Aluminum extruders excel in high-temperature environments due to their superior heat resistance. This allows you to confidently print with a wide range of materials, including high-performance filaments that require elevated temperatures.

Unlocking Precision Printing

Achieving high-quality prints requires precise control over the extrusion process. Inconsistent extrusion can lead to a variety of issues, such as stringing, blobs, and poor layer adhesion. The MK8 aluminum extruder offers superior precision compared to stock extruders. Its consistent filament feeding and stable temperature control contribute to smoother layers, reduced stringing, and overall improved print quality. Whether you're printing intricate models or functional parts, an aluminum extruder can help you achieve exceptional results.

Simplified Installation and Maintenance

Upgrading your extruder might seem like a daunting task, but most MK8 aluminum extruder kits are designed for easy installation. These kits typically include all the necessary components, along with clear instructions that guide you through the process. Additionally, aluminum extruders require minimal maintenance compared to their plastic counterparts. Their durable construction and resistance to wear ensure long-lasting performance with little need for repairs or replacements.

Advanced Features and Customizations

Some advanced MK8 extruder kits, like the FlexiPLUS model, offer additional features such as stainless steel drive gears and improved Bowden tube fittings. These upgrades provide even better support for flexible filaments and easier loading mechanisms, making them ideal for users who frequently work with TPU or similar materials.

Support for Flexible Filaments

Flexible filaments, such as TPU, require a more precise grip and control to prevent slippage and ensure consistent extrusion. The HICTOP Aluminum MK8 Extruder, with its robust design and optional stainless steel gears, is well-suited for handling these types of filaments. The improved grip and control allow for smoother feeding, reducing the likelihood of jams and under-extrusion.

Enhanced Bowden Tube Fittings

The HICTOP Aluminum MK8 Extruder often includes upgraded Bowden tube fittings that prevent slippage and ensure a secure connection. This feature is particularly important for maintaining consistent filament flow and preventing issues like under-extrusion or over-extrusion.

Conclusion

The HICTOP Upgraded Replacement Aluminum MK8 Extruder Drive Feed is a valuable upgrade for enhancing filament feeding in 3D printing. Its durability, improved filament control, and ability to handle higher temperatures make it an excellent choice for both hobbyists and professionals. Whether you're looking to improve print consistency or expand your material options, this extruder is a worthwhile investment.

FAQ

1. What are the benefits of using an aluminum MK8 extruder over a plastic one?

- Answer: Aluminum extruders offer better durability, improved filament control, higher temperature resistance, and enhanced print quality compared to plastic extruders.

2. Is it difficult to install a HICTOP aluminum MK8 extruder?

- Answer: No, installation is relatively easy and can be done with basic tools. Most kits come with instructions and necessary components for a straightforward assembly process.

3. Will upgrading to an aluminum extruder void my printer's warranty?

- Answer: It may void your warranty, depending on the manufacturer's policies. It's advisable to check with the manufacturer before making any modifications.

4. Can I use an aluminum MK8 extruder with flexible filaments?

- Answer: Yes, aluminum MK8 extruders are suitable for printing with flexible filaments like TPU, as they provide better grip and control over the filament.

5. How does an aluminum extruder improve print quality?

- Answer: It improves print quality by providing consistent filament flow, better layer adhesion, and reduced stringing, resulting in smoother surfaces and finer details in printed objects.

Citations:

[1] https://www.metalpartmaker.com/product/4921/hictop-upgraded-replacement-aluminum-mk8-extruder-drive-feed-for-creality-3d-printer-ender-3-3pro-cr-10-cr-10s-cr-10-s4-and-cr-10-s5

[2] https://www.yjing-extrusion.com/why-should-you-choose-an-mk8-extruder-aluminum-over-stock-extruders.html

[3] https://www.youtube.com/watch?v=TPyTiZ6-_jM

[4] https://macewen3d.com/products/mk8-extruder-aluminum-drive-feed-for-cr-10-cr-10-s4-and-cr-10-s5

[5] https://www.yjing-extrusion.com/how-does-the-creality-mk8-aluminum-extruder-improve-filament-flow.html

[6] https://www.hictop3dprinter.com/products/hictop-3d-printer-extruder-kit-original-replacement-parts-full-assemble-mk8-extruder-hot-end-kits-fit-for-creality-3d-printing-cr-10-cr-10s-s4-s5-mini

[7] https://www.reddit.com/r/ender3/comments/dfnv0w/so_you_need_a_working_printer_to_make_a_filament/

[8] https://www.reddit.com/r/ender3v2/comments/193nzb0/i_upgraded_to_the_all_metal_extruder_and_now_the/

[9] https://www.kosovo.ubuy.com/en/product/R8ADRB8-hictop-cr-10-hotend-full-assemble-mk8-extruder-fit-for-creality-3d-printer-cr-10-cr-10s-mini-3d-printer-original-replacement-parts

[10] https://reprap.org/forum/read.php?406%2C769424

[11] https://www.aliexpress.com/item/1005006523519131.html

[12] https://www.u-buy.com.ng/product/R8ADRB8-hictop-cr-10-hotend-full-assemble-mk8-extruder-fit-for-creality-3d-printer-cr-10-cr-10s-mini-3d-printer-original-replacement-parts

[13] https://www.ubuy.ug/en/product/472446DZO-hictop-upgraded-replacement-aluminum-mk8-extruder-drive-feed-for-creality-3d-printer-ender-33pro-cr-10-cr-10s-cr-10-s4-and-cr-10-s5

[14] https://www.yeggi.com/q/hictop+extruder/

[15] https://www.a.ubuy.com.kw/en/product/R8ADRB8-hictop-cr-10-hotend-full-assemble-mk8-extruder-fit-for-creality-3d-printer-cr-10-cr-10s-mini-3d-printer-original-replacement-parts

[16] https://www.hictop3dprinter.com/collections/3d-printers-parts

[17] https://grobotronics.com/bowden-extruder-feed-kit-mk8-silver-1.75mm-aluminum.html?sl=en

[18] https://www.reddit.com/r/ender5plus/comments/n02dbn/reason_to_upgrade_to_an_all_metal_mk8_extruder/

[19] https://www.youtube.com/watch?v=UtemZqFJ5rY

[20] https://www.nepal.ubuy.com/en/product/472446DZO-hictop-upgraded-replacement-aluminum-mk8-extruder-drive-feed-for-creality-3d-printer-ender-33pro-cr-10-cr-10s-cr-10-s4-and-cr-10-s5