Content Menu

● Introduction to Dual Extrusion

>> Types of Dual Extruders

● Aluminum Extruders

>> Benefits of Aluminum Extruders

● Dual Extruder Aluminum Extrusion

>> Advantages of Dual Extruder Aluminum Extrusion

● Applications of Dual Extruder Aluminum Extrusion

● Challenges and Limitations

● Future Developments

● Conclusion

● FAQ

>> 1. What are the main benefits of using dual extruder aluminum extrusion?

>> 2. How does dual extruder aluminum extrusion improve print quality?

>> 3. What are the limitations of dual extruder aluminum extrusion?

>> 4. What types of projects benefit most from dual extruder aluminum extrusion?

>> 5. How does IDEX technology enhance dual extruder printing?

Dual extruder aluminum extrusion is a technology that combines the benefits of dual extrusion 3D printing with the durability and consistency of aluminum extruders. This article will explore how this technology enhances print quality, its applications, and the advantages it offers over traditional single extruder systems.

Introduction to Dual Extrusion

Dual extrusion in 3D printing involves using two extruders to print with different materials simultaneously. This can be particularly useful for creating complex models that require support structures, multi-color prints, or combining different materials for enhanced properties. The ability to print with two materials at once allows for a wide range of creative possibilities, from functional prototypes to artistic sculptures.

Types of Dual Extruders

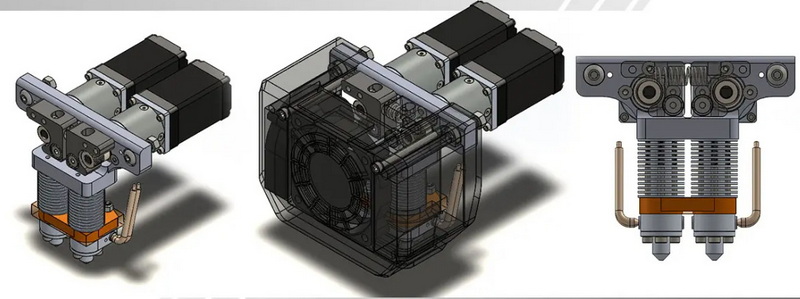

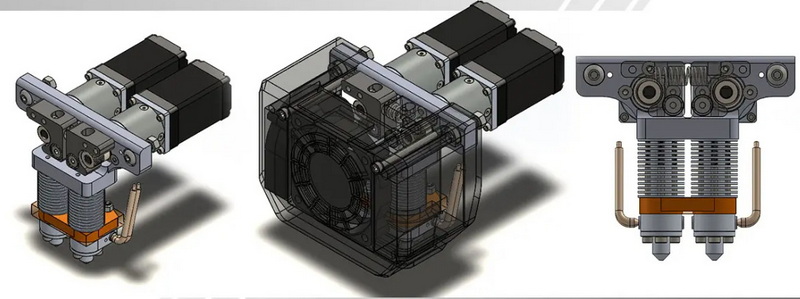

There are primarily two types of dual extruder setups:

1. Dependent Dual Extruders: These extruders are connected and move together, often sharing the same print head. While they are simpler and less expensive, they can be limited in their ability to print complex models without interference. This setup is ideal for basic dual-color prints or simple support structures.

2. Independent Dual Extruders (IDEX): Each extruder moves independently, allowing for more complex prints, mirror printing, and duplication modes. This setup is more versatile but also more complex and expensive. IDEX systems are particularly useful for high-volume production or when printing multiple identical parts simultaneously.

Aluminum Extruders

Aluminum extruders are designed to improve upon the limitations of plastic extruders by offering increased durability and consistency in filament feeding. They are particularly beneficial when working with abrasive filaments or high-temperature materials. The rigidity of aluminum ensures that filaments are fed smoothly and consistently, reducing the likelihood of jams and improving overall print quality.

Benefits of Aluminum Extruders

- Durability: Aluminum is more resistant to wear and tear compared to plastic, extending the extruder's lifespan. This is especially important for heavy-duty printing applications where the extruder is in constant use.

- Consistent Filament Feeding: The rigidity of aluminum ensures that filaments are fed consistently, reducing jams and improving print quality. Consistent feeding is crucial for achieving smooth layer transitions and preventing defects.

- Higher Temperature Resistance: Aluminum extruders can handle higher temperatures, allowing for a wider range of filament types. This includes materials like polycarbonate and ABS, which require higher extrusion temperatures.

Dual Extruder Aluminum Extrusion

Combining dual extrusion with aluminum extruders enhances print quality by allowing for the use of different materials, such as soluble supports, while maintaining the consistency and durability provided by aluminum. This setup is particularly beneficial for printing complex models that require both structural integrity and aesthetic appeal.

Advantages of Dual Extruder Aluminum Extrusion

1. Improved Support Structures: Using one extruder for soluble supports (like PVA or HIPS) reduces post-processing time and prevents damage to the print. Soluble supports dissolve in water, leaving no residue and preserving the print's surface quality.

2. Multi-Material Printing: Combining materials with different properties (e.g., rigid and flexible) enhances the structural integrity and functionality of prints. For instance, using a rigid material for the main structure and a flexible material for joints can create functional prototypes that mimic real-world applications.

3. Enhanced Aesthetics: Dual extruders enable multi-color printing without the need for post-processing, making prints more visually appealing. This is particularly useful for artistic models or educational tools where color differentiation is important.

4. Increased Efficiency: Independent dual extruders allow for faster printing through features like mirror and duplication modes. In mirror mode, two identical parts are printed simultaneously, reducing overall print time by half. Duplication mode allows for printing multiple identical parts at once, significantly increasing production efficiency.

Applications of Dual Extruder Aluminum Extrusion

This technology is particularly useful in industries requiring complex prototypes or models with specific material properties. For instance:

- Educational Models: Using different colors to highlight specific parts can enhance learning experiences. For example, in anatomy models, different colors can be used to differentiate between various tissues or organs.

- Product Design: Combining materials for prototypes allows designers to test both form and function more effectively. This can include testing the durability of a product by using materials with different strengths or flexibility.

- Artistic Creations: The ability to print with multiple colors and materials opens up new possibilities for artistic expression. Artists can create complex sculptures with intricate details and color schemes that would be difficult or impossible to achieve with traditional techniques.

Challenges and Limitations

While dual extruder aluminum extrusion offers many benefits, it also presents some challenges:

- Higher Cost: The initial investment in a dual extruder system with aluminum extruders is higher. This can be a barrier for hobbyists or small businesses with limited budgets.

- Complexity: Calibration and maintenance are more complex compared to single extruder systems. Users need to ensure that both extruders are properly aligned and calibrated to avoid print defects.

- Build Volume: The presence of two extruders often reduces the available build volume. This can limit the size of prints that can be produced, although some printers are designed to minimize this impact.

Future Developments

As technology continues to evolve, we can expect to see further advancements in dual extruder aluminum extrusion. This may include improvements in extruder design for better heat management, more efficient cooling systems, and enhanced software support for complex print configurations. Additionally, advancements in material science could lead to new filaments that take full advantage of the capabilities offered by dual extruder systems.

Conclusion

Dual extruder aluminum extrusion significantly improves print quality by combining the versatility of dual extrusion with the durability and consistency of aluminum extruders. This technology is ideal for applications requiring complex models with multiple materials or colors. However, it also comes with a higher cost and increased complexity. As the technology continues to evolve, we can expect to see even more innovative applications across various industries.

FAQ

1. What are the main benefits of using dual extruder aluminum extrusion?

Dual extruder aluminum extrusion offers improved support structures, multi-material printing capabilities, enhanced aesthetics, and increased efficiency. Aluminum extruders provide durability and consistent filament feeding.

2. How does dual extruder aluminum extrusion improve print quality?

By allowing for the use of soluble supports and combining different materials, dual extruder aluminum extrusion reduces post-processing time and enhances the structural integrity and visual appeal of prints.

3. What are the limitations of dual extruder aluminum extrusion?

The main limitations include a higher initial cost, increased complexity in setup and maintenance, and a reduced build volume due to the presence of two extruders.

4. What types of projects benefit most from dual extruder aluminum extrusion?

Projects that require complex models with multiple materials or colors, such as educational models, product prototypes, and detailed art pieces, benefit significantly from this technology.

5. How does IDEX technology enhance dual extruder printing?

IDEX technology allows each extruder to move independently, enabling features like mirror and duplication modes, which significantly increase printing efficiency and versatility.