Content Menu

● Introduction to Ceramic Extrusion

>> Process Overview

● Advantages of Ceramic Extrusion Equipment

>> High Precision

>> Efficiency and Cost Savings

>> Enhanced Properties

● Innovations in Ceramic Extrusion Equipment

>> Advanced Materials and Technologies

>> Energy Efficiency and Sustainability

● Applications of Ceramic Extrusion Equipment

>> Construction

>> Electronics and Aerospace

>> Automotive and Industrial

● Future Trends and Challenges

>> Customization and Agility

>> Sustainability and Energy Efficiency

● Additive Manufacturing and Ceramic Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using ceramic extrusion equipment?

>> 2. How does ceramic extrusion equipment improve mechanical properties?

>> 3. What role does automation play in ceramic extrusion?

>> 4. How does ceramic extrusion contribute to sustainability?

>> 5. What future trends can be expected in ceramic extrusion technology?

● Citations:

Ceramic extrusion equipment plays a pivotal role in enhancing the quality of ceramic products by leveraging advanced technologies and precision engineering. This article delves into the mechanisms by which ceramic extrusion equipment improves product quality, exploring its applications, innovations, and future trends.

Introduction to Ceramic Extrusion

Ceramic extrusion is a process where ceramic materials are shaped into precise forms using an extruder. This technique is widely used in the production of various ceramic products, from simple tiles to complex components for industries like electronics and aerospace.

Process Overview

The ceramic extrusion process involves several key steps:

1. Material Preparation: Ceramic powders are mixed with water and additives to create a consistent paste.

2. Extrusion: The paste is fed into an extruder, where it is forced through a die to achieve the desired shape.

3. Shaping and Cutting: The extruded material is then cut to the required length and detailed if necessary.

4. Drying and Sintering: The product is dried and then sintered at high temperatures to achieve its final properties.

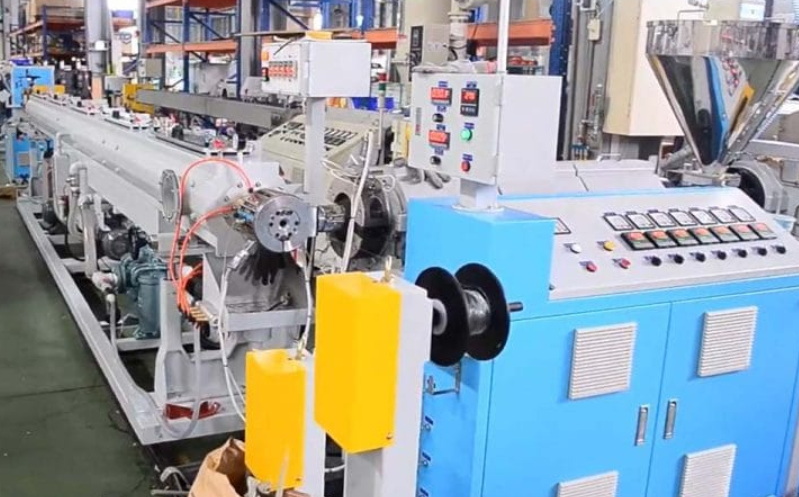

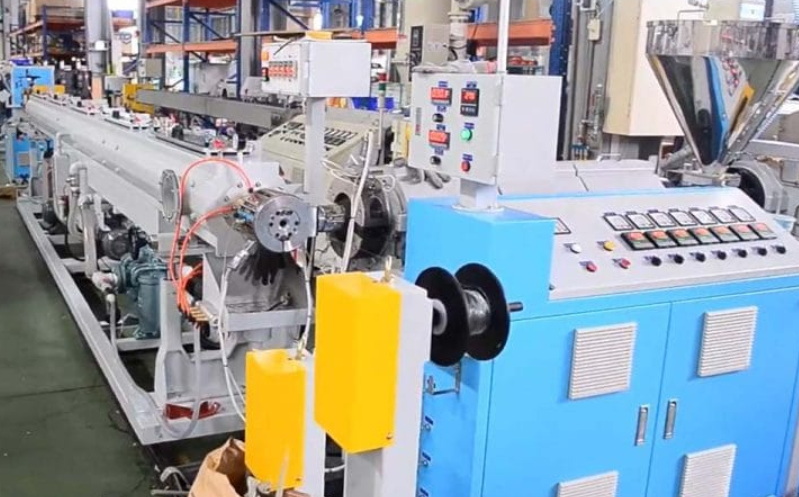

Ceramic extrusion equipment is essential for ensuring maximum precision and quality during these processes. The machines are designed to handle delicate ceramic materials without damage, ensuring that the final products have tight tolerances and a smooth finish.

Advantages of Ceramic Extrusion Equipment

Ceramic extrusion equipment offers several advantages that contribute to improved product quality:

High Precision

- Tight Tolerances: Ceramic extrusion equipment allows for the production of components with tight tolerances, ensuring uniformity and precision in the final product.

- Smooth Finish: The high precision processing techniques used in ceramic extrusion result in a smooth finish, enhancing the aesthetic appeal and functionality of the products.

Efficiency and Cost Savings

- High-Volume Production: Ceramic extrusion enables high-volume production, reducing costs and increasing efficiency.

- Low Production Costs: The process minimizes waste and reduces production costs, making it a cost-effective method for manufacturing ceramics.

Enhanced Properties

- Improved Mechanical Properties: The extrusion process can enhance certain mechanical properties of ceramic products, such as tensile strength.

Innovations in Ceramic Extrusion Equipment

Recent innovations in ceramic extrusion equipment have further improved product quality and expanded its applications:

Advanced Materials and Technologies

- Integration of AI and Machine Learning: Modern ceramic extrusion machines can integrate AI and machine learning to optimize production processes, predict maintenance needs, and enhance overall efficiency.

- Automation and Digitalization: Automation and digitalization have streamlined operations, reduced human error, and improved production rates.

Energy Efficiency and Sustainability

- Energy-Efficient Designs: New machines are designed to minimize energy consumption while improving output, making them more environmentally friendly.

- Recycling and Waste Reduction: Ceramic extrusion machines can reuse waste materials, reducing environmental impact.

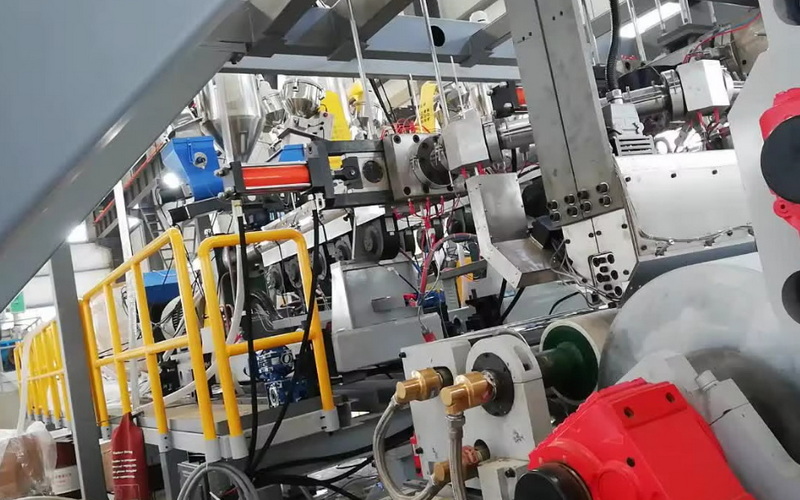

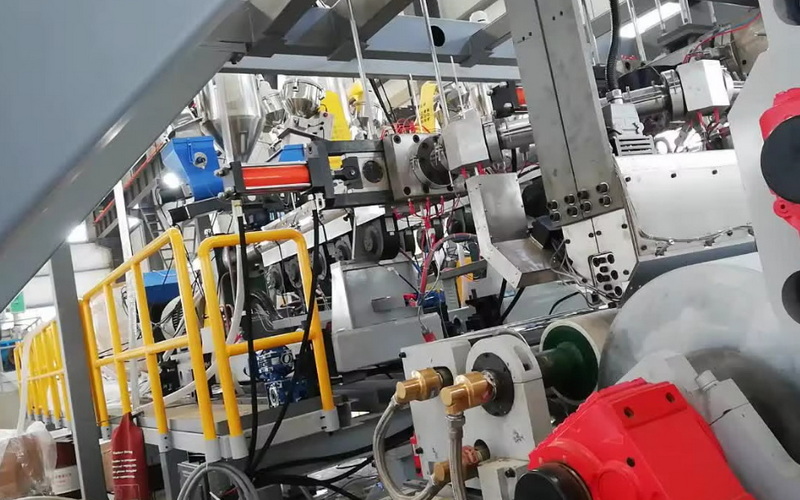

The ceramic extrusion machine market is undergoing rapid transformation, driven by technological advancements and industry collaborations. Trends include the use of 3D extrusion technology, digital twin technology, and collaborative ventures between manufacturers and research institutions. These advancements enhance precision, enable complex geometries, and facilitate real-time monitoring and optimization of extrusion processes[3].

Applications of Ceramic Extrusion Equipment

Ceramic extrusion equipment is used across various industries:

Construction

- Tiles and Bricks: Ceramic extrusion machines produce structural materials like tiles and bricks, essential for infrastructure development.

Electronics and Aerospace

- Precision Components: These machines manufacture precision parts used in electronic devices and aerospace components.

Automotive and Industrial

- Honeycomb Ceramics: Extrusion is used to produce honeycomb ceramics, which are crucial for automotive exhaust emissions systems.

Advanced ceramics, such as alumina, silicon carbide, silicon nitride, and zirconia, are high-strength materials with excellent wear resistance, chemical resistance, and high toughness. They are used in various industrial processes, including extrusion dies, where their thermal stability and hardness are invaluable[4].

Future Trends and Challenges

As technology advances, ceramic extrusion equipment is expected to play a more significant role in meeting the demands of evolving industries:

Customization and Agility

- On-Demand Manufacturing: The trend towards customization and on-demand manufacturing requires ceramic extrusion machines to be more agile and adaptable.

Sustainability and Energy Efficiency

- Green Building Practices: Ceramic extrusion machines contribute to sustainable building practices by producing energy-efficient materials.

The ceramic extrusion machine market is set to witness robust growth over the next decade, driven by technological innovations, increasing demand for sustainable materials, and expanding industrial applications. By 2034, the market is expected to reach a valuation of USD 2.1 billion, with Asia Pacific emerging as a key growth region[3].

Additive Manufacturing and Ceramic Extrusion

Additive manufacturing, particularly material extrusion, is becoming increasingly relevant in the ceramic industry. This method allows for the creation of complex shapes and high-density ceramics, which are crucial for aerospace, biomedical, and electronic applications. However, challenges such as layer thickness and material compatibility remain, requiring further research and development[5][7].

Conclusion

Ceramic extrusion equipment significantly enhances product quality by offering high precision, efficiency, and cost-effectiveness. With ongoing innovations in technology and sustainability, these machines are poised to continue playing a crucial role in various industries.

Frequently Asked Questions

1. What are the primary benefits of using ceramic extrusion equipment?

Ceramic extrusion equipment offers high precision, efficiency, and cost savings. It allows for the production of components with tight tolerances and smooth finishes, enhancing both aesthetic appeal and functionality.

2. How does ceramic extrusion equipment improve mechanical properties?

The extrusion process can enhance certain mechanical properties of ceramic products, such as tensile strength, by ensuring uniformity and consistency in the material structure.

3. What role does automation play in ceramic extrusion?

Automation in ceramic extrusion machines streamlines operations, reduces human error, and improves production rates. It also enables real-time monitoring and adjustments, ensuring consistent quality across large batches.

4. How does ceramic extrusion contribute to sustainability?

Ceramic extrusion machines contribute to sustainability by enabling the production of energy-efficient materials and allowing the reuse of waste materials, thus minimizing environmental impact.

5. What future trends can be expected in ceramic extrusion technology?

Future trends include the integration of AI and machine learning for process optimization, increased focus on energy efficiency, and the development of more agile machines for on-demand manufacturing.

Citations:

[1] https://www.paganoni.it/en/articles-blog/ceramic-extrusion-process-advantages-and-innovations/

[2] https://library.imaging.org/admin/apis/public/api/ist/website/downloadArticle/print4fab/32/1/art00094_1

[3] https://sites.google.com/view/thinkhaven/top-industry-report/ceramic-extrusion-machine-market-analysis-current-landscape-and-future-out

[4] https://www.syalons.com/2023/03/14/enduring-high-temperatures-in-industry-with-advanced-ceramics/

[5] https://pmc.ncbi.nlm.nih.gov/articles/PMC11173494/

[6] https://www.preciseceramic.com/blog/five-processing-methods-of-advanced-ceramics-with-pictures.html

[7] https://www.sciopen.com/article/10.13957/j.cnki.tcxb.2024.05.002

[8] https://media.utilityglobal.com/news/utility-installs-ceramic-extruder-at-its-advanced-technology-center

[9] https://www.syalons.com/2022/08/19/wear-industry-advanced-ceramic-case-studies/

[10] https://www.innovations-report.com/engineering/materials-sciences/extremely-thin-ceramic-components-made-possible-by-extrusion/

[11] https://www.mdpi.com/2073-4352/14/7/623

[12] https://ceramics.onlinelibrary.wiley.com/doi/full/10.1111/jace.20043

[13] https://www.marketresearchintellect.com/blog/ceramic-extrusion-machines-the-unsung-heroes-of-modern-manufacturing-and-construction/

[14] https://ceramics.onlinelibrary.wiley.com/doi/10.1111/ijac.14935?af=R

[15] https://wzr-ceramic.de/en/materialextrusion-2/

[16] https://www.frontiersin.org/articles/10.3389/fceic.2023.1137377/full

[17] https://www.voxelmatters.com/discover-the-top-companies-driving-the-future-of-ceramic-additive-manufacturing/

[18] https://www.mdpi.com/1996-1944/17/11/2779

[19] https://www.corning.com/worldwide/en/innovation/materials-science/ceramics/how-it-works--extrusion.html

[20] https://www.frontiersin.org/journals/ceramics/articles/10.3389/fceic.2023.1136720/full