Content Menu

● Introduction to Cast Film Extrusion

>> Key Components of Cast Film Extrusion Equipment

● Process Overview

>> Video: Cast Film Extrusion Process

● Advantages of Cast Film Extrusion Equipment

● Common Applications of Cast Film

● Technological Advancements in Cast Film Extrusion

>> Market Trends and Growth

● Troubleshooting Common Issues

>> Video: Troubleshooting Tips for Cast Film Extrusion

● Customization and Flexibility

● Global Market Players

● Conclusion

● FAQ

>> 1. What are the main components of cast film extrusion equipment?

>> 2. How does the cooling process in cast film extrusion differ from blown film extrusion?

>> 3. What are the advantages of using cast film extrusion equipment?

>> 4. What are common applications of cast films?

>> 5. How can common issues in cast film extrusion be addressed?

● Citations:

Cast film extrusion equipment is a critical component in the production of plastic films, widely used in packaging, labeling, and laminating industries. This process involves melting thermoplastic materials and extruding them through a flat die onto a chilled roller, where they cool and solidify into a uniform film. In this article, we will delve into the details of how cast film extrusion equipment works, its advantages, and common applications.

Introduction to Cast Film Extrusion

Cast film extrusion is a popular method for producing plastic films due to its efficiency and environmental sustainability. It is used by approximately 70-80% of the industry globally for creating films with high clarity and consistent thickness. The process can produce both monolayer and multilayer films, with a maximum of five layers, making it versatile for various applications.

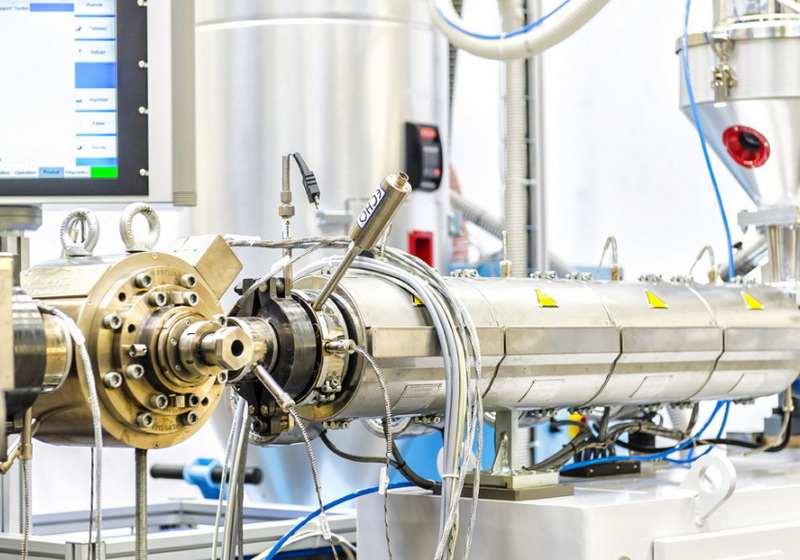

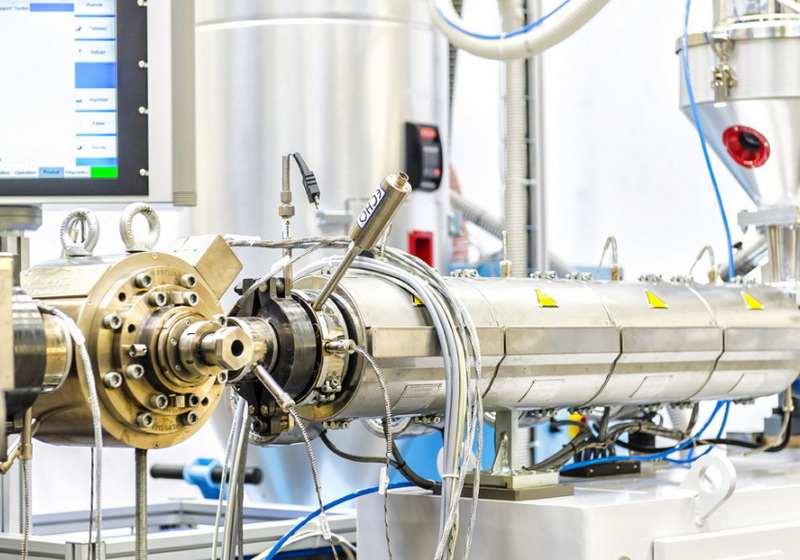

Key Components of Cast Film Extrusion Equipment

1. Extruder: The extruder is responsible for melting and mixing the plastic materials. It consists of a heated barrel and a rotating screw that ensures a homogeneous mixture of the molten polymer.

2. Flat Die System: The flat die system is crucial for shaping the molten polymer into a thin film. It includes a coextrusion feedblock and melt transfer adapters that deliver different molten resins to the die.

3. Cooling Unit: The cooling unit consists of a primary roll, secondary roll, and sometimes an air knife or vacuum box. These components rapidly cool and solidify the film, enhancing its mechanical properties and clarity.

4. Automatic Gauge Control System: This system ensures consistent film thickness by measuring and adjusting the film as it passes through the machine.

5. Winder: The winder transforms the extruded film into rolls, maintaining its quality and dimensions for downstream operations.

Process Overview

The cast film extrusion process involves three main steps:

1. Melting the Thermoplastic Materials: Plastic pellets are fed into an extruder, where they are melted and mixed into a consistent mixture. The most commonly used materials for cast film extrusion are polyethylene (PE) and polypropylene (PP).

2. Flattening and Solidifying: The molten polymer is extruded through a flat die onto a chilled roller, where it cools and solidifies into a thin film. The thickness of the film might range from less than 10 microns to 200 microns. The use of an air knife or vacuum box helps in rapid cooling and solidification, improving the film's mechanical features and clarity.

3. Trimming and Rolling: The film is then passed through a series of rollers to refine its thickness and surface characteristics before being wound into rolls.

Video: Cast Film Extrusion Process

To better understand the process, watch this video:

Advantages of Cast Film Extrusion Equipment

Cast film extrusion offers several advantages over other methods:

- High Clarity and Consistency: Cast films have superior optical clarity and consistent thickness, making them ideal for applications requiring high-quality appearance.

- Efficiency and Sustainability: The process is faster and more environmentally friendly compared to blown film extrusion, contributing to reduced production costs and carbon footprint.

- Flexibility and Versatility: Cast films can be easily integrated with laminating, coating, embossing, and printing units, allowing for a wide range of finishes and applications.

Common Applications of Cast Film

Cast films are used in various industries due to their versatility:

- Packaging: High-clarity films for food packaging and medical packaging.

- Labeling and Laminating: Smooth surface ideal for printing and laminating.

- Stretch and Cling Films: Easy to stretch and provides a classic two-sided cling.

Technological Advancements in Cast Film Extrusion

The global cast film extrusion machines market is experiencing robust growth, driven by technological advancements that improve film quality, increase production speeds, and reduce energy consumption. Innovations in automation and digitalization are streamlining production processes, enhancing efficiency, and reducing operational costs. The integration of Industry 4.0 technologies, such as machine learning and predictive maintenance, is improving overall equipment effectiveness (OEE) and optimizing production output[2].

Market Trends and Growth

The cast film extrusion machines market is projected to grow significantly, driven by the increasing demand for flexible packaging across diverse sectors like food, medical, and hygiene. The market is expected to reach approximately $4 billion by 2033, with a Compound Annual Growth Rate (CAGR) of 6% from 2025 to 2033[2]. The rising adoption of sustainable materials and processes is also a key driver, as companies invest in research and development to create more sustainable and efficient extrusion machines and films[2].

Troubleshooting Common Issues

In cast film extrusion, common issues include gels, un-melts, and melt fractures. These can be addressed by adjusting melt temperatures, inspecting extruder components, and ensuring proper material handling. For instance, uneven transverse thickness can be resolved by adjusting the die lip gap, ensuring even temperature distribution, and maintaining clean die cavities[3].

Video: Troubleshooting Tips for Cast Film Extrusion

For more detailed troubleshooting, watch this video:

Customization and Flexibility

Cast film extrusion lines can be tailored to meet specific customer requirements, allowing for the production of films with varying widths, thicknesses, and compositions. This flexibility is crucial for catering to diverse market needs and evolving consumer preferences[5].

Global Market Players

The cast film extrusion machines market is competitive, with established players like Reifenhauser, Windmöller & Hölscher, and SML, alongside emerging players vying for market share. Regional growth varies, with Asia-Pacific showing significant potential due to expanding manufacturing sectors and rising consumer demand[2].

Conclusion

Cast film extrusion equipment plays a vital role in producing high-quality plastic films with consistent thickness and clarity. Its efficiency, sustainability, and versatility make it a preferred choice for various applications. Understanding how this equipment works and troubleshooting common issues can help optimize production processes.

FAQ

1. What are the main components of cast film extrusion equipment?

Cast film extrusion equipment includes an extruder, flat die system, cooling unit, automatic gauge control system, and winder. Each component is crucial for producing films with consistent quality.

2. How does the cooling process in cast film extrusion differ from blown film extrusion?

Cast film extrusion uses a chilled roller to cool the film, while blown film extrusion relies on air cooling the inflated bubble. This difference affects the clarity and strength of the final product.

3. What are the advantages of using cast film extrusion equipment?

Cast film extrusion offers superior optical clarity, consistent thickness, faster production speeds, and environmental sustainability compared to other methods.

4. What are common applications of cast films?

Cast films are commonly used in packaging, labeling, laminating, and for stretch and cling films due to their clarity and flexibility.

5. How can common issues in cast film extrusion be addressed?

Common issues like gels and melt fractures can be addressed by adjusting melt temperatures, inspecting extruder components, and ensuring proper material handling.

Citations:

[1] https://europlas.com.vn/en-US/blog-1/cast-film-extrusion-process-the-ultimate-guide

[2] https://www.datainsightsmarket.com/reports/cast-film-extrusion-machines-50475

[3] https://www.gsextruder.com/cast-film-extrusion-troubleshooting-and-operation-tips/

[4] https://www.verifiedmarketreports.com/product/cast-film-extrusion-line-market/

[5] https://www.blessonextrusion.com/cast-film-lines/

[6] https://www.gsextruder.com/an-ultimate-guide-to-cast-film-extrusion-process-what-is-cast-film-extrusion/

[7] https://diamat.com/technology/flat-film-production/

[8] https://pmc.ncbi.nlm.nih.gov/articles/PMC9920539/

[9] https://www.datainsightsmarket.com/reports/cast-film-extrusion-machines-50579

[10] http://hbfilmmachine.com

[11] https://www.oliverhcp.com/news-and-resources/packtalk/understanding-the-differences-between-cast-and-blown-extrusion-in-film-production

[12] https://www.northerngrafics.com/vare/mastercast/

[13] https://www.jwellmachine.com/how-do-you-optimize-the-production-process-of-a-cpp-cast-film-line-to-ensure-the-highest-quality-output/

[14] https://www.fortunebusinessinsights.com/polyethylene-cast-film-market-104225

[15] https://davis-standard.com/converting_system/cast-film/

[16] https://chalvo.com/cast-film-extrusion-process-a-complete-guide/

[17] https://www.extrusion-info.com/news/1061

[18] https://davis-standard.com/custom_blog/cast-film-troubleshooting-tips/

[19] https://www.databridgemarketresearch.com/reports/global-cast-films-market

[20] https://www.euro-machinery.com/product-category/extrusion-lines/used-cast-film-extruders/