Content Menu

● Introduction

● Properties of Aluminum Square Tubes

>> Lightweight Yet Strong

>> Corrosion Resistance

>> Versatility in Design

● How Anodizing Works

● Benefits of Anodizing Aluminum Square Tubes

>> Enhanced Corrosion Resistance

>> Improved Wear Resistance

>> Aesthetic Appeal

>> UV Resistance

>> Low Maintenance

● Applications of Anodized Aluminum Square Tubes

>> Structural Applications

>> Non-Structural Applications

>> Automotive Industry

>> Aerospace Industry

>> Marine Applications

● Conclusion

● Related Questions

>> 1. What is the difference between anodized and untreated aluminum square tubes?

>> 2. Can anodized aluminum square tubes be painted?

>> 3. How long does the anodizing process take?

>> 4. Is anodized aluminum environmentally friendly?

>> 5. How do I clean anodized aluminum square tubes?

Introduction

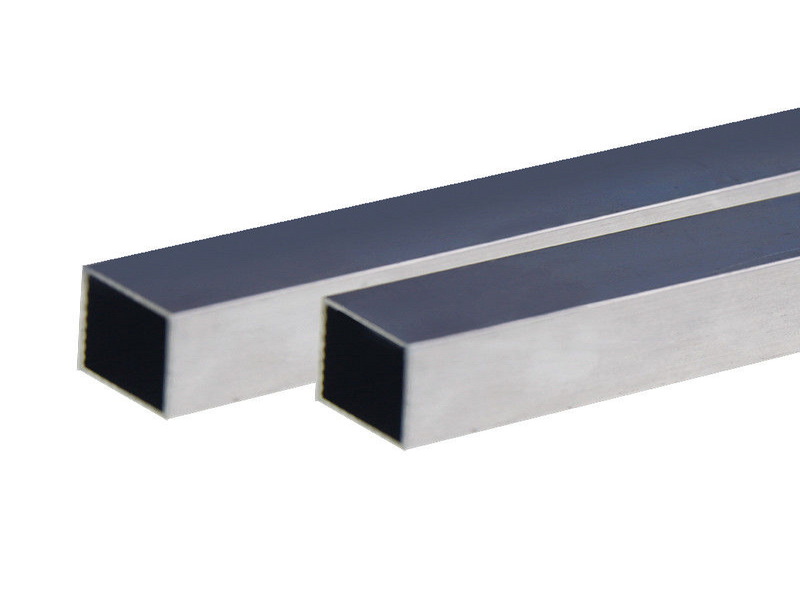

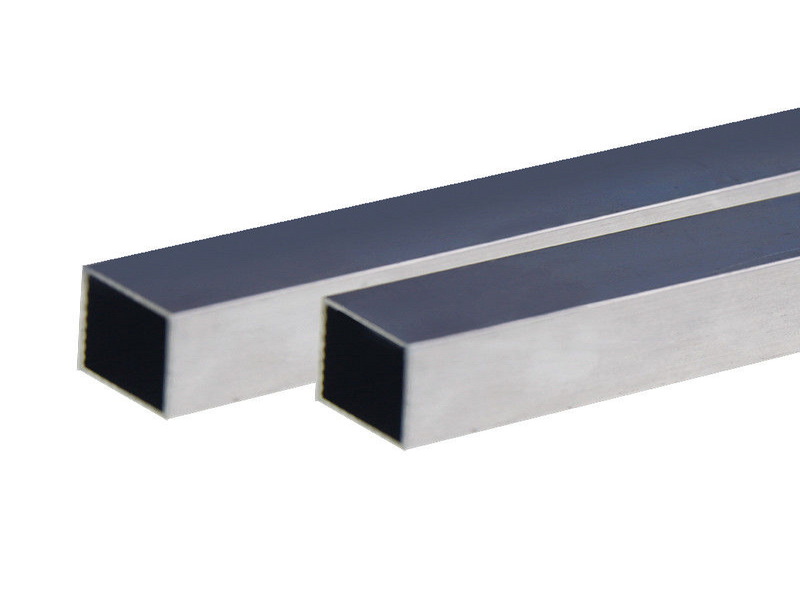

Aluminum square tubes are widely used in various industries due to their lightweight, strength, and versatility. One of the most significant processes that enhance the durability of aluminum square tubes is anodizing. Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. This article explores how anodizing enhances the durability of aluminum square tubes, the benefits of using anodized aluminum, and its applications in different sectors.

Properties of Aluminum Square Tubes

Aluminum square tubes possess several inherent properties that make them ideal for construction and manufacturing. They are lightweight yet strong, providing a high strength-to-weight ratio that is essential for structural applications. Additionally, aluminum is naturally resistant to corrosion, which is a significant advantage in various environments.

Lightweight Yet Strong

The lightweight nature of aluminum square tubes allows for easy handling and installation. This property is particularly beneficial in construction, where reducing the weight of materials can lead to lower transportation costs and easier assembly. Despite their lightness, aluminum square tubes maintain excellent structural integrity, making them suitable for load-bearing applications.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent corrosion. However, this layer can be thin and may not provide sufficient protection in harsh environments. Anodizing enhances this natural corrosion resistance by thickening the oxide layer, making it more robust and effective against environmental factors.

Versatility in Design

Aluminum square tubes can be easily fabricated into various shapes and sizes, allowing for a wide range of applications. They can be cut, welded, and formed to meet specific design requirements, making them a popular choice in architectural and industrial projects.

How Anodizing Works

Anodizing involves immersing aluminum square tubes in an electrolytic solution and passing an electric current through the solution. This process causes the aluminum to oxidize, forming a thicker and more durable oxide layer on the surface. The anodized layer is not only thicker than the natural oxide layer but also more uniform and adherent, providing superior protection against wear and corrosion.

Benefits of Anodizing Aluminum Square Tubes

Anodizing aluminum square tubes offers numerous benefits that enhance their durability and performance in various applications.

Enhanced Corrosion Resistance

The primary benefit of anodizing is the significant increase in corrosion resistance. The thicker anodized layer protects the underlying aluminum from moisture, chemicals, and other corrosive elements. This is particularly important in outdoor applications, where aluminum square tubes are exposed to the elements.

Improved Wear Resistance

Anodized aluminum square tubes exhibit improved wear resistance compared to untreated aluminum. The anodized surface is harder and more durable, making it less susceptible to scratches, dents, and other forms of damage. This property is crucial in applications where the aluminum square tubes are subject to abrasion or mechanical wear.

Aesthetic Appeal

Anodizing also enhances the aesthetic appeal of aluminum square tubes. The process allows for various color finishes, providing options for architectural and decorative applications. Anodized aluminum can be dyed in a range of colors, allowing designers to achieve the desired look while maintaining the material's durability.

UV Resistance

Anodized aluminum square tubes are resistant to ultraviolet (UV) radiation, which can cause fading and degradation in untreated aluminum. This property makes anodized aluminum an excellent choice for outdoor applications, ensuring that the material retains its appearance and structural integrity over time.

Low Maintenance

Anodized aluminum square tubes require minimal maintenance compared to other materials. The anodized surface is easy to clean and does not require regular painting or sealing. This low-maintenance characteristic is particularly advantageous in commercial and industrial settings, where reducing upkeep costs is essential.

Applications of Anodized Aluminum Square Tubes

Anodized aluminum square tubes are used in various applications across multiple industries due to their enhanced durability and aesthetic appeal.

Structural Applications

In construction, anodized aluminum square tubes are commonly used for framing, supports, and reinforcements. Their lightweight nature and high strength make them ideal for structural components in buildings, bridges, and other infrastructure projects.

Non-Structural Applications

Beyond structural uses, anodized aluminum square tubes are also employed in non-structural applications such as furniture, decorative elements, and signage. The aesthetic versatility of anodized aluminum allows designers to create visually appealing products that are also durable.

Automotive Industry

The automotive industry utilizes anodized aluminum square tubes for various components, including frames, supports, and decorative trim. The lightweight nature of aluminum contributes to fuel efficiency, while the anodized finish enhances durability and resistance to environmental factors.

Aerospace Industry

In the aerospace sector, anodized aluminum square tubes are used for structural components and interior fittings. The combination of lightweight and high strength is critical in aerospace applications, where every ounce counts.

Marine Applications

Anodized aluminum square tubes are also popular in marine applications due to their corrosion resistance. Boats and other marine vessels benefit from the durability of anodized aluminum, which can withstand harsh saltwater environments.

Conclusion

Anodizing significantly enhances the durability of aluminum square tubes, making them a preferred choice in various industries. The process improves corrosion resistance, wear resistance, and aesthetic appeal while requiring minimal maintenance. As a result, anodized aluminum square tubes are widely used in construction, automotive, aerospace, and marine applications. Their versatility and performance make them an excellent investment for any project requiring durable and reliable materials.

Related Questions

1. What is the difference between anodized and untreated aluminum square tubes?

Anodized aluminum square tubes have a thicker, more durable oxide layer that enhances corrosion and wear resistance, while untreated aluminum has a thinner natural oxide layer that may not provide sufficient protection.

2. Can anodized aluminum square tubes be painted?

Yes, anodized aluminum can be painted, but it is essential to use the right type of paint and primer designed for aluminum surfaces to ensure proper adhesion.

3. How long does the anodizing process take?

The anodizing process can take anywhere from a few hours to a day, depending on the thickness of the anodized layer required and the specific process used.

4. Is anodized aluminum environmentally friendly?

Yes, anodizing is considered an environmentally friendly process. It uses non-toxic chemicals, and the anodized layer is stable and does not release harmful substances into the environment.

5. How do I clean anodized aluminum square tubes?

Anodized aluminum square tubes can be cleaned with mild soap and water. For tougher stains, a non-abrasive cleaner can be used, but harsh chemicals and abrasive materials should be avoided to prevent damage to the anodized surface.