Content Menu

● Introduction to Automatic Plastic Yoghurt Cup Extrusion Machines

>> Key Components of the Machine

● Operational Principle

● Benefits of Automatic Plastic Yoghurt Cup Extrusion Machines

● Automatic Plastic Yoghurt Cup Extrusion for Sale

>> Tips for Purchasing

● Market Trends and Developments

● Integration with Other Packaging Solutions

● Conclusion

● FAQs

>> 1. What Materials Can Automatic Plastic Yoghurt Cup Extrusion Machines Handle?

>> 2. How Do I Choose the Right Machine for My Production Needs?

>> 3. What Are the Benefits of Using Automatic Plastic Yoghurt Cup Extrusion Machines?

>> 4. Can These Machines Be Customized for Specific Production Requirements?

>> 5. What Kind of Maintenance Does an Automatic Plastic Yoghurt Cup Extrusion Machine Require?

● Citations:

The production of plastic yoghurt cups involves a complex process that requires precision, efficiency, and reliability. Automatic plastic yoghurt cup extrusion machines are designed to meet these demands by integrating advanced technology with streamlined manufacturing processes. In this article, we will delve into the workings of these machines, exploring their components, operational principles, and benefits.

Introduction to Automatic Plastic Yoghurt Cup Extrusion Machines

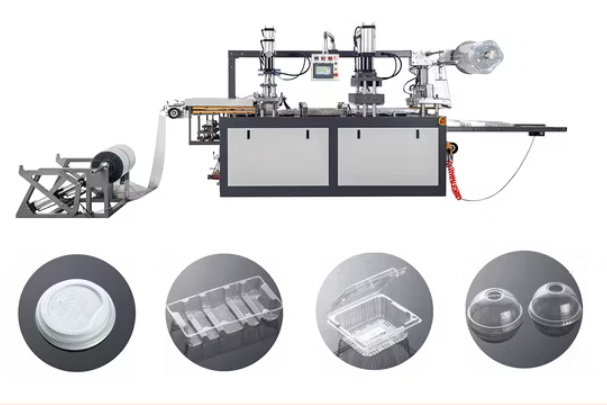

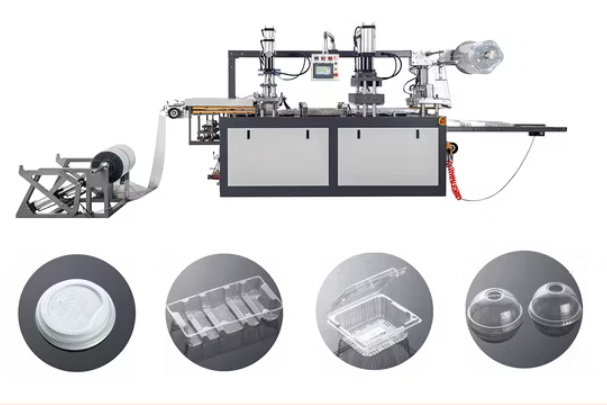

Automatic plastic yoghurt cup extrusion machines are specialized equipment used in the food packaging industry. They utilize thermoforming technology to produce yoghurt cups from plastic sheets. The process involves heating the plastic to make it pliable, then shaping it into the desired form using molds. These machines are crucial for mass production due to their high speed and accuracy.

Key Components of the Machine

1. Material Feeding System: This component ensures continuous and precise feeding of plastic sheets into the machine. It is designed to handle various types of plastic materials, including PP, PS, and PET, which are commonly used in yoghurt cup production.

2. Heating Oven: The oven heats the plastic sheets to the required temperature for forming. Advanced machines often use intelligent energy consumption management systems to optimize heating processes, reducing energy waste and environmental impact.

3. Mold: The mold gives the plastic its shape. It is designed to produce cups of various sizes and shapes. The mold's design is critical, as it must ensure that the cups can be easily stacked without sticking together, while also maintaining rigidity to prevent bending when filled.

4. Forming Station: This is where the heated plastic is formed into cups using vacuum or pressure. The forming station is equipped with hydraulic systems to ensure precise molding and uniform cup walls.

5. Cutting and Trimming: After forming, excess plastic is cut and trimmed to create the final product. This process is automated to minimize waste and ensure consistent product quality.

6. Stacking and Packaging: The finished cups are stacked and prepared for packaging. This stage involves conveyor belts and robotic arms to efficiently handle large volumes of cups.

Operational Principle

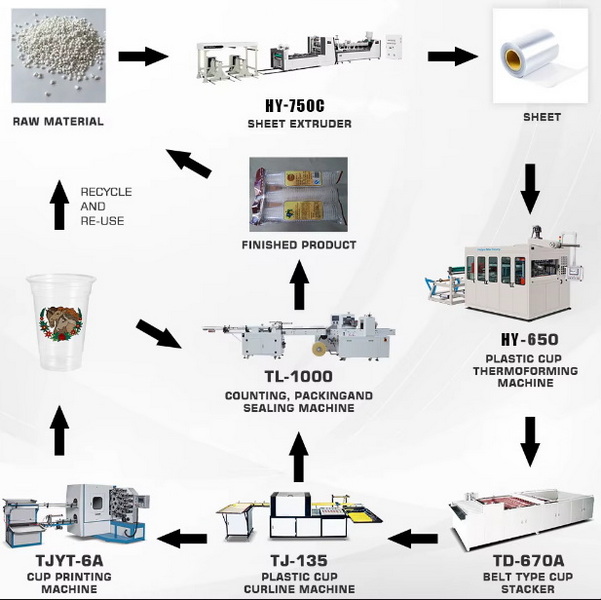

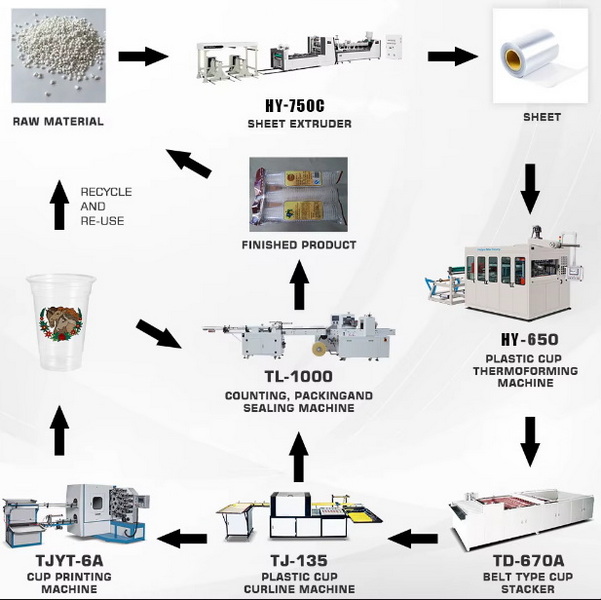

The operational principle of an automatic plastic yoghurt cup extrusion machine involves several stages:

1. Material Preparation: Plastic sheets are fed into the machine. The material feeding system ensures that the sheets are aligned properly and fed at a consistent rate.

2. Heating: The sheets are heated in the oven until they become pliable. This stage is crucial, as the temperature must be precisely controlled to achieve the desired flexibility without overheating.

3. Forming: The heated plastic is placed over a mold and formed into cups using vacuum or pressure. The hydraulic control system ensures that each cup is formed with high accuracy, resulting in uniform cup mouths and walls.

4. Cooling and Hardening: The formed cups are cooled and hardened to maintain their shape. This process is essential to prevent deformation during handling and packaging.

5. Cutting and Trimming: Excess plastic is removed. This stage is automated to minimize waste and ensure consistent product quality.

6. Stacking and Packaging: Cups are stacked and prepared for distribution. This stage involves conveyor belts and robotic arms to efficiently handle large volumes of cups.

Benefits of Automatic Plastic Yoghurt Cup Extrusion Machines

These machines offer several benefits, including:

- High Efficiency: They can produce a large number of cups per hour, making them ideal for mass production. For example, some machines can produce up to 120,000 cups per hour, significantly reducing production cycles and increasing overall productivity.

- Precision and Consistency: Each cup is formed with high accuracy, ensuring uniformity in size and shape. This consistency is crucial for maintaining product quality and ensuring that cups can be stacked efficiently without sticking together.

- Energy Efficiency: Modern machines are designed to reduce energy consumption while maintaining productivity. They often include intelligent energy management systems that optimize heating and cooling processes, reducing waste and environmental impact.

- Flexibility: They can produce cups of various sizes and shapes by changing molds. This flexibility allows manufacturers to quickly adapt to market changes and produce different types of packaging as needed.

Automatic Plastic Yoghurt Cup Extrusion for Sale

For businesses looking to invest in automatic plastic yoghurt cup extrusion for sale, it's essential to consider factors such as production capacity, material compatibility, and after-sales support. Suppliers often provide customized solutions to meet specific needs, ensuring that the machine integrates well with existing production lines.

Tips for Purchasing

1. Assess Production Needs: Determine the required production volume and cup specifications. This involves evaluating the types of yoghurt cups needed, including size, shape, and material.

2. Material Compatibility: Ensure the machine can handle the desired plastic materials. Common materials include PP, PS, and PET, each with its own advantages and applications.

3. After-Sales Support: Look for suppliers offering comprehensive support and maintenance services. This includes training for operators, spare parts availability, and technical assistance to minimize downtime.

4. Energy Efficiency: Consider machines with advanced energy-saving features. These can significantly reduce operational costs and environmental impact over time.

5. Modular Design: Opt for machines with modular designs that allow for easy mold changes. This flexibility is crucial for adapting to different production needs and market trends.

Market Trends and Developments

The market for plastic extrusion machines, including those used for yoghurt cup production, is experiencing significant growth. This is driven by increasing demand for efficient and sustainable manufacturing processes across various industries, including food packaging. Technological advancements, such as intelligent manufacturing technologies and real-time monitoring systems, are enhancing machine efficiency and productivity.

Moreover, there is a growing emphasis on sustainability, with manufacturers integrating eco-friendly attributes into their production lines. This includes the use of recycled materials and energy-efficient designs to reduce environmental impact.

Integration with Other Packaging Solutions

In addition to yoghurt cup production, these machines can be integrated with other packaging solutions to create a comprehensive production line. For example, form-fill-seal machines can be used to fill and seal cups inline, while carton sleeving machines can apply protective sleeves to packaged cups. This integration enhances efficiency and reduces labor costs by automating multiple stages of the packaging process.

Conclusion

Automatic plastic yoghurt cup extrusion machines are vital for efficient and high-quality yoghurt cup production. By understanding their operational principles and benefits, businesses can make informed decisions when investing in these machines. Whether you're looking for automatic plastic yoghurt cup extrusion for sale, it's crucial to consider factors like production capacity, material compatibility, and after-sales support to ensure optimal performance.

FAQs

1. What Materials Can Automatic Plastic Yoghurt Cup Extrusion Machines Handle?

Automatic plastic yoghurt cup extrusion machines can handle a variety of plastic materials, including PP, PS, PET, and PVC. These materials are commonly used in yoghurt cup production due to their durability and food-grade safety.

2. How Do I Choose the Right Machine for My Production Needs?

Choosing the right machine involves assessing your production volume, desired cup size and shape, and the type of plastic material you plan to use. It's also important to consider the machine's energy efficiency and after-sales support offered by the supplier.

3. What Are the Benefits of Using Automatic Plastic Yoghurt Cup Extrusion Machines?

The benefits include high production efficiency, precision in cup formation, flexibility in producing different sizes and shapes, and energy efficiency. These machines are designed to reduce labor costs while maintaining high-quality output.

4. Can These Machines Be Customized for Specific Production Requirements?

Yes, many suppliers offer customization options for automatic plastic yoghurt cup extrusion machines. This can include modifying the machine to handle specific plastic materials, adjusting production speeds, or integrating with existing production lines.

5. What Kind of Maintenance Does an Automatic Plastic Yoghurt Cup Extrusion Machine Require?

Regular maintenance involves cleaning the machine, checking for wear and tear on moving parts, and ensuring that all electrical and pneumatic components are functioning properly. Suppliers often provide maintenance guides and technical support to help extend the machine's lifespan.

Citations:

[1] https://www.litaimachine.com/latest-news/yogurt-cup-thermoforming-machine

[2] https://www.extrusion-info.com/articles/683

[3] https://www.mdpi.com/2624-862X/3/3/46

[4] https://www.eliter-packaging.com/types-yogurt-packaging-machines

[5] https://www.alliedmarketresearch.com/plastic-extrusion-machine-market

[6] https://pmc.ncbi.nlm.nih.gov/articles/PMC9323499/

[7] https://stdcdesigner.en.made-in-china.com/product/HQhpvtWbaiRV/China-Food-Packaging-Plastic-Extruder-Thermoforming-Machines-Line-for-Yogurt-Cup-Making.html

[8] https://sinoplast.en.made-in-china.com/product/eXYQBNWMEbhJ/China-Automatic-Plastic-Yogurt-Cup-Thermoforming-Machine.html

[9] https://repositum.tuwien.at/retrieve/22912

[10] https://www.alibaba.com/product-detail/Disposable-PP-Automatic-Single-Use-Plastic_1601295879720.html

[11] https://sayeahmachine.en.made-in-china.com/product/caIYpldbXuVe/China-Automatic-Plastic-Yoghurt-Cup-Making-Thermoforming-Machine-on-Sale.html

[12] https://www.youtube.com/watch?v=LVxd_izsg7k

[13] https://www.alibaba.com/showroom/plastic-cold-cups-machine.html

[14] https://www.rmthermoform.com/showroom/plastic-machine-extruder/

[15] https://customcupfactory.com/blogs/news/how-are-plastic-cups-made-understanding-the-process-of-disposable-cup-production

[16] https://zj-wylong.en.made-in-china.com/product/QmFUalfYohRE/China-Plastic-Cup-Making-Machine-Pet-Cups-Sheet-Making-Extrusion-Machine-APET-Cups-Sheet-Extruder-Making-Plant-Plastic-Extruder-Machines.html

[17] https://www.tradeindia.com/rajkot/plastic-cup-making-machine-city-214195.html

[18] https://www.youtube.com/watch?v=OOaP39ho3Oc

[19] https://vb.nweurope.eu/media/14010/case-study-report-haval-good-practice-of-circular-economy-business-models.pdf

[20] https://www.maximizemarketresearch.com/market-report/global-plastic-extrusion-machine-market/30066/