Content Menu

● Understanding Aluminum Extrusion Frames

>> Benefits of Aluminum Extrusion Frames

● The Role of Vacuum Pressing in Guitar Making

>> How Vacuum Pressing Works

● Advantages of Using an Aluminum Extrusion Frame in Vacuum Pressing

>> 1. Enhanced Structural Integrity

>> 2. Improved Pressure Distribution

>> 3. Temperature Control

>> 4. Quick Setup and Adjustability

● Applications in Guitar Making

● Conclusion

● FAQs

>> 1. What types of guitars benefit most from using an aluminum extrusion frame in vacuum pressing?

>> 2. Can I build my own aluminum extrusion frame for vacuum pressing?

>> 3. How does temperature affect the vacuum pressing process?

>> 4. Is it necessary to use a vacuum pump with an aluminum extrusion frame?

>> 5. What maintenance does an aluminum extrusion frame require?

● Citations:

The art of guitar making is a delicate balance of craftsmanship, material selection, and technology. Among the tools that have revolutionized this craft is the vacuum press, particularly when combined with an aluminum extrusion frame. This article will explore how an aluminum extrusion frame enhances the vacuum pressing process for guitar tops, detailing its benefits, applications, and the science behind its effectiveness.

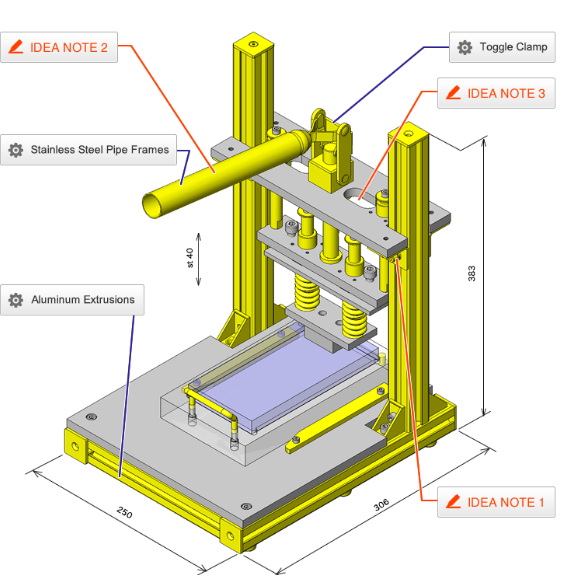

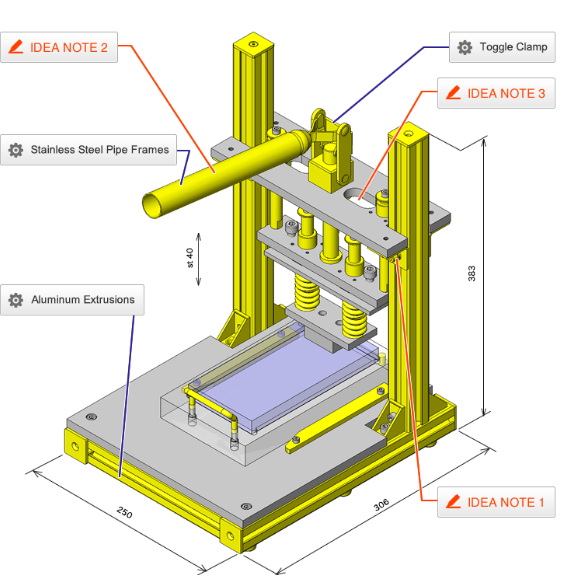

Understanding Aluminum Extrusion Frames

Aluminum extrusion is a manufacturing process that involves forcing aluminum through a shaped die to create long sections with a consistent cross-section. This process allows for the creation of complex shapes that are lightweight yet strong, making aluminum extrusion frames ideal for various applications, including vacuum presses used in guitar making.

Benefits of Aluminum Extrusion Frames

- Lightweight and Durable: Aluminum is significantly lighter than steel, which reduces the overall weight of the vacuum press without sacrificing strength or durability. This lightweight nature makes it easier to handle and maneuver during the pressing process.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that resists corrosion. This property is particularly beneficial in humid environments often encountered in woodworking and guitar making.

- Customizability: The extrusion process allows for a high degree of customization. Frames can be designed to accommodate different sizes and shapes of guitar tops, ensuring a perfect fit for various projects.

- Ease of Assembly: Aluminum extrusion frames can be easily assembled and disassembled. This modularity allows luthiers to adapt their equipment to different tasks without needing specialized tools.

The Role of Vacuum Pressing in Guitar Making

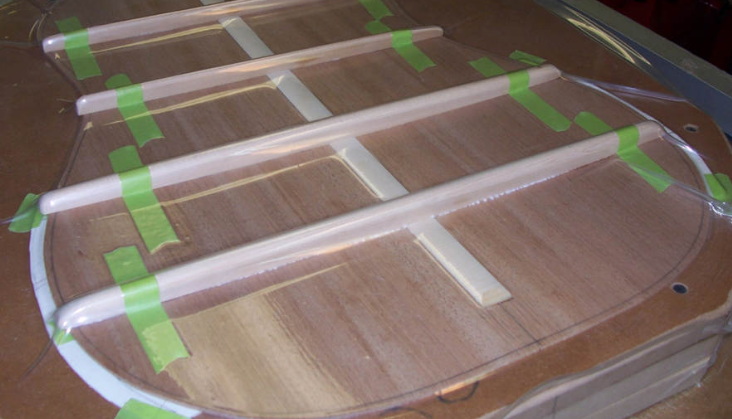

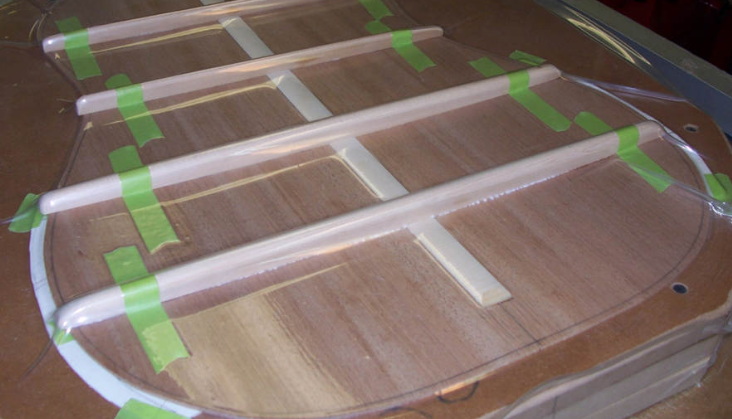

Vacuum pressing is a technique used to apply even pressure across a surface by removing air from a sealed environment. In guitar making, this method is particularly useful for laminating wood layers together to form the top of the instrument. The even pressure ensures that the glue bonds effectively without gaps or bubbles.

How Vacuum Pressing Works

1. Preparation: The guitar top pieces are arranged in the desired configuration, often with glue applied between layers.

2. Sealing: The assembly is placed inside a vacuum bag or press, which is then sealed tightly to prevent air from entering.

3. Evacuation: A vacuum pump removes air from the sealed environment, creating negative pressure that forces the layers together.

4. Curing: The glue cures under pressure, resulting in a strong bond between the layers.

Advantages of Using an Aluminum Extrusion Frame in Vacuum Pressing

1. Enhanced Structural Integrity

The rigidity provided by an aluminum extrusion frame minimizes flexing during the vacuum process. This rigidity is crucial when pressing delicate materials like guitar tops, as it ensures that pressure is evenly distributed across the surface.

2. Improved Pressure Distribution

An aluminum frame can be designed with specific geometries that enhance pressure distribution across the entire surface area being pressed. This design capability helps avoid localized pressure points that could lead to warping or damage to the guitar top.

3. Temperature Control

Aluminum has excellent thermal conductivity, allowing it to dissipate heat effectively during the pressing process. This property helps maintain consistent temperatures within the press, which is vital when using heat-activated adhesives.

4. Quick Setup and Adjustability

The modular nature of aluminum extrusions means that luthiers can quickly adjust their setups based on project requirements. Whether working on different guitar sizes or experimenting with various wood types, an aluminum frame allows for rapid modifications without extensive downtime.

Applications in Guitar Making

Aluminum extrusion frames are increasingly being adopted in various aspects of guitar construction:

- Laminating Tops: They provide a stable platform for laminating multiple layers of wood into a single top piece, improving acoustic properties and aesthetic appeal.

- Bracing Installation: When installing braces on guitar tops or backs, an aluminum frame ensures even pressure is applied while allowing for precise alignment.

- Custom Shapes: Luthiers can create custom molds using aluminum frames to shape unique designs or curves in their guitars.

Conclusion

The integration of an aluminum extrusion frame into the vacuum pressing process has transformed how luthiers approach guitar top construction. Its lightweight nature, durability, resistance to corrosion, and ease of customization make it an invaluable tool in modern guitar making. By ensuring even pressure distribution and enhancing structural integrity during pressing, aluminum frames significantly improve both the efficiency and quality of finished instruments.

FAQs

1. What types of guitars benefit most from using an aluminum extrusion frame in vacuum pressing?

Guitars with complex shapes or those requiring precise lamination techniques benefit significantly from using aluminum extrusion frames due to their stability and customizability.

2. Can I build my own aluminum extrusion frame for vacuum pressing?

Yes! Many luthiers choose to build their own frames using standard aluminum extrusions available from suppliers. There are many resources online that provide guidance on how to construct these frames effectively.

3. How does temperature affect the vacuum pressing process?

Temperature plays a crucial role in adhesive curing times and effectiveness; maintaining optimal temperatures ensures strong bonds without damaging sensitive materials like wood.

4. Is it necessary to use a vacuum pump with an aluminum extrusion frame?

Yes, a vacuum pump is essential for removing air from the sealed environment created by your setup; this negative pressure is what allows even pressure distribution across your workpiece.

5. What maintenance does an aluminum extrusion frame require?

Regular cleaning and inspection for any signs of wear or damage are recommended to ensure optimal performance over time; however, due to its corrosion resistance, maintenance needs are minimal compared to other materials like steel.

Citations:

[1] https://olsonguitars.com/the-artisan/jims-shop/tooling-for-backs-and-tops/

[2] https://www.alineautomation.com/3-benefits-aluminum-extrusion-frames-over-welded-steel/

[3] https://www.projectguitar.com/forums/topic/48247-vacuum-system-for-gluing-guitar-top/

[4] https://www.youtube.com/watch?v=emaAg568qdo

[5] https://guitarmaking.co.uk/community/hints-tips/using-the-vacuum-bagpress/

[6] https://davelers.com/Workshop/Veneering/Presses/1731.html

[7] https://veneersystems.com/product/flip-top-frame-49-inch-by-121-inch/

[8] https://simmal.com/10-surprising-uses-for-aluminium-extrusion-you-didnt-know/

[9] https://www.joewoodworker.com/veneering/visitorspress2.htm

[10] https://www.roarockit.com/woodworking/tap-luthier-kit/

[11] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[12] https://www.youtube.com/watch?v=1Z11MIgTJF8

[13] http://www.anzlf.com/viewtopic.php?t=7883

[14] https://tri-stateal.com/blog/aluminum-extrusions-guide/

[15] https://www.vacupress.com/vacupress-fliptop-table-press-frame-systems/

[16] https://community.carbide3d.com/t/filling-aluminum-extrusions/67952

[17] https://qualityvak.com/frame.html

[18] https://www.cnczone.com/forums/diy-cnc-router-table-machines/156130-cnc.html

[19] https://www.youtube.com/watch?v=g0fStnfrDTE

[20] https://www.reddit.com/r/vandwellers/comments/12lpej5/aluminium_extrusion_8020_vs_wood/

[21] https://guitarmaking.co.uk/community/hints-tips/using-the-vacuum-bagpress/

[22] https://shop.machinemfg.com/5-uses-of-aluminium-extrusions/

[23] https://www.youtube.com/watch?v=W6G3jBHxQZU

[24] https://www.instagram.com/p/Ctb_KgXsJeP

[25] https://www.youtube.com/watch?v=kD4xLWUJ9Dc

[26] https://www.instagram.com/ryan_guitars/reel/C0rZlPRLssv/

[27] https://www.joewoodworker.com/veneering/visitorspress2.htm

[28] https://www.desktopmetal.com/products/studio

[29] https://www.jazzguitar.be/forum/builders-bench/99504-guitar-scanning-cad-formas-veneers-vacuum-pressing.html

[30] https://www.youtube.com/watch?v=kSVTh6-j5ok

[31] https://acousticguitarconstructionforum.com/viewtopic.php?t=817

[32] https://qualityvak.com/angc.html

[33] https://www.youtube.com/watch?v=dG1tc-6mvEg

[34] http://www.vacuum-press.com/table.html

[35] https://www.youtube.com/watch?v=8dNCQGarMxU