Content Menu

● What is Aluminum Extrusion?

● The Aluminum Extrusion Process

● Importance of Aluminum Extrusion in Ball Ground, GA

● Applications of Aluminum Extrusions

>> Detailed Applications Across Industries

● Benefits of Aluminum Extrusion

● Comparison with Other Manufacturing Techniques

● Visual Representation of the Process

● Challenges in Aluminum Extrusion

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What types of products can be made through aluminum extrusion?

>> 2. How does temperature affect the aluminum extrusion process?

>> 3. What are some advantages of using aluminum over other materials?

>> 4. Can you recycle extruded aluminum?

>> 5. What industries benefit from aluminum extrusions?

● Citations:

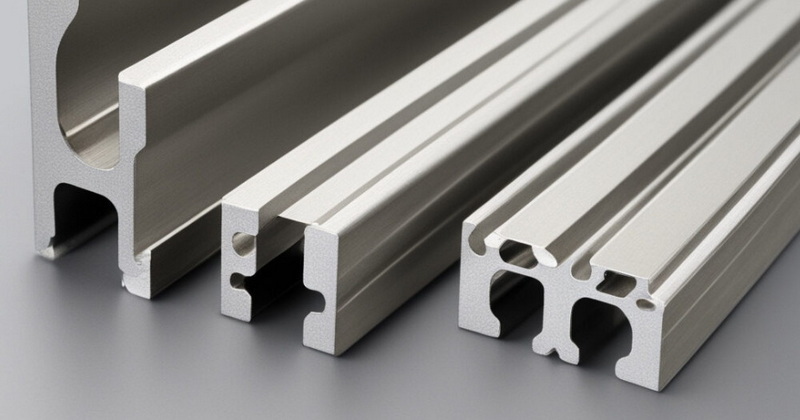

Aluminum extrusion is a vital manufacturing process that shapes aluminum alloy into a wide array of profiles and components. This technique is particularly significant in Ball Ground, Georgia, where several companies specialize in aluminum extrusion, contributing to various industries such as automotive, aerospace, and construction. This article will delve into the intricacies of aluminum extrusion, the specific processes involved, and the significance of this manufacturing method in Ball Ground, GA.

What is Aluminum Extrusion?

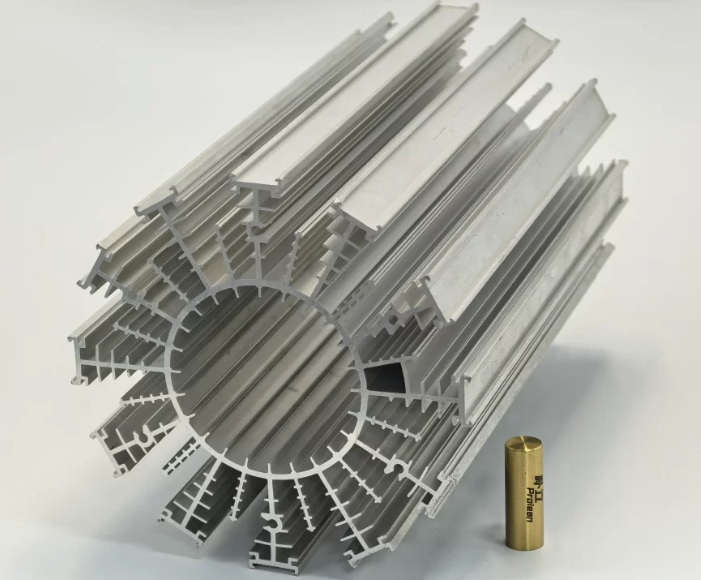

Aluminum extrusion involves forcing aluminum alloy material through a die with a specific cross-sectional profile. The process transforms solid aluminum billets into complex shapes that are essential for numerous applications. The extrusion process can be likened to squeezing toothpaste from a tube; as pressure is applied, the material emerges in the shape defined by the die.

The Aluminum Extrusion Process

The aluminum extrusion process can be broken down into several key steps:

1. Preparation of the Die and Billet:

- The die must be preheated to temperatures between 450°F and 500°F to enhance its lifespan and ensure smooth metal flow.

- The aluminum billet is also preheated to make it malleable enough for extrusion.

2. Loading the Billet:

- Once preheated, the billet is placed into an extrusion press where it will be subjected to high pressure.

3. Extrusion:

- A hydraulic ram applies pressure to the billet, forcing it through the die. As the aluminum material fills the container, it is pressed against the die opening and emerges as a fully formed profile.

4. Cooling:

- After exiting the die, the extruded material is cooled using quenching methods such as water baths or air fans to stabilize its properties.

5. Stretching:

- To correct any twisting that may have occurred during extrusion, the profiles are mechanically stretched.

6. Cutting:

- Finally, the extrusions are cut to specified lengths using a finish saw.

Each of these steps is crucial for ensuring that the final product meets specific standards and requirements.

Importance of Aluminum Extrusion in Ball Ground, GA

Ball Ground, GA, is home to several notable companies specializing in aluminum extrusion, including Universal Alloy Corporation and Awnex Inc. These companies utilize advanced technology and skilled labor to produce high-quality extruded products tailored to customer specifications.

- Universal Alloy Corporation (UAC): Located in Canton, GA, UAC operates one of North America's largest indirect extrusion presses. Their facility focuses on aerospace applications but also serves various other sectors by providing custom extrusions that meet stringent quality standards.

- Awnex Inc.: This company specializes in architectural branding elements and aluminum fabrication. Their state-of-the-art manufacturing facility includes multiple CNC controlled fabrication stations that ensure precision and quality in their extruded products.

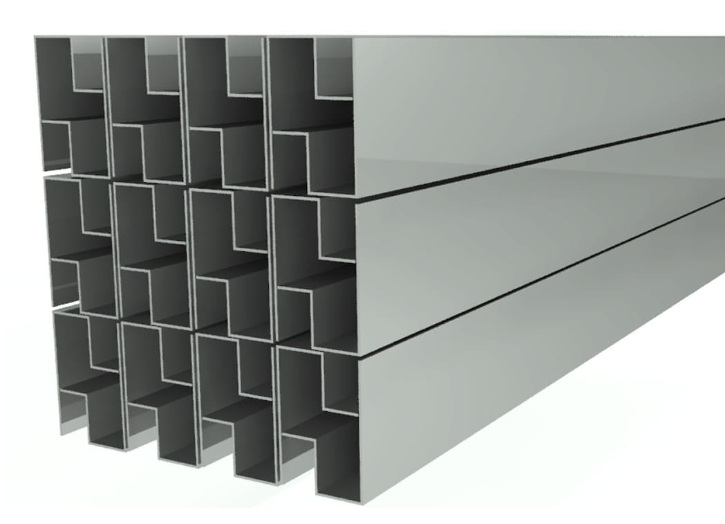

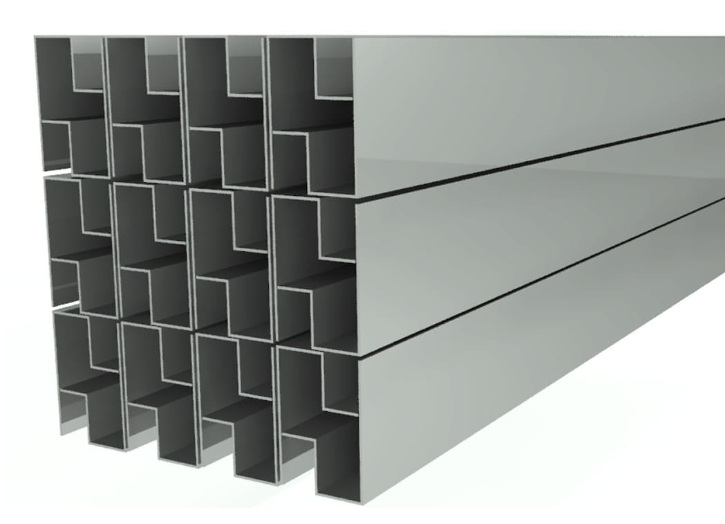

Applications of Aluminum Extrusions

Aluminum extrusions are widely used across different industries due to their lightweight nature and strength. Some common applications include:

- Construction: Used for window frames, door frames, and structural components.

- Automotive: Employed in manufacturing parts like heat sinks and chassis components.

- Aerospace: Critical for creating lightweight yet durable aircraft components.

- Electronics: Used for heat sinks and housing for electronic devices.

- Medical Devices: Utilized for frames and casings due to their corrosion resistance and lightweight nature.

Detailed Applications Across Industries

Aluminum extrusions have become indispensable across various sectors due to their versatility:

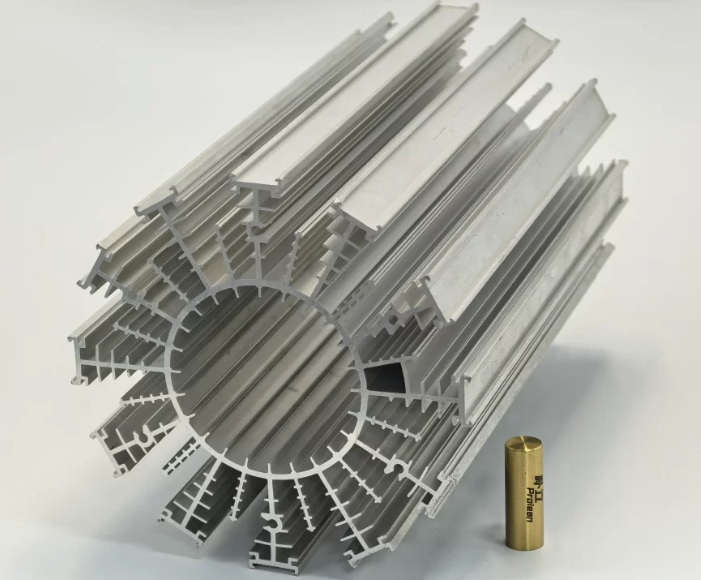

Electronics Industry:

- Heat sinks for CPUs and GPUs

- Enclosures for electronic devices

- Frames for LED panels

- Racks for server equipment

The thermal conductivity of aluminum (approximately 237 W m$$^{-1}$$ K$$^{-1}$$) makes it ideal for managing heat generated by electronic devices[2].

Medical Applications:

- Frames for hospital beds

- Casings for medical instruments

- Structural components for surgical tables

The lightweight nature of aluminum reduces physical strain on healthcare providers when moving medical equipment[2].

Consumer Goods:

- Frames for bicycles and scooters

- Handles for kitchenware

- Lighting fixtures

Aluminum's durability combined with design flexibility makes it an excellent choice for consumer products[2].

Benefits of Aluminum Extrusion

The benefits of using aluminum extrusion include:

- Versatility: Capable of producing complex shapes with precision.

- Cost-Effectiveness: Reduces waste during production compared to other manufacturing methods.

- Strength-to-Weight Ratio: Aluminum offers excellent strength while remaining lightweight.

- Sustainability: Aluminum is recyclable without losing its properties.

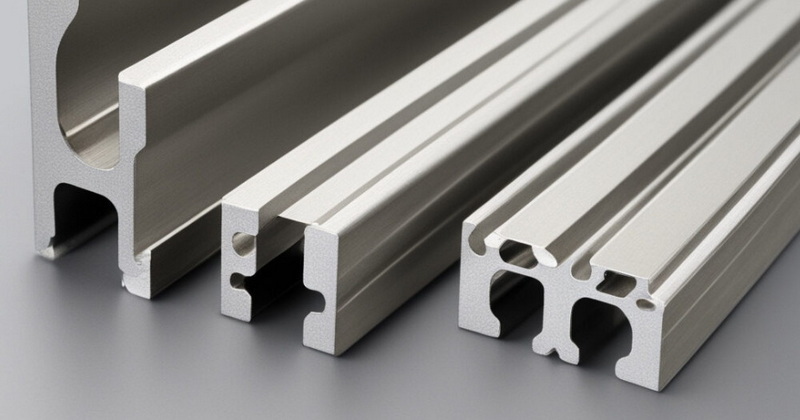

Comparison with Other Manufacturing Techniques

When comparing aluminum extrusion with other manufacturing methods such as CNC machining, it becomes evident that each has its strengths:

| Feature | Aluminum Extrusion | CNC Machining |

| Production Volume | High volume production | Low to medium volume |

| Complexity of Shapes | Complex shapes easily | Intricate details possible |

| Material Waste | Minimal waste | Higher waste potential |

| Cost Efficiency | Cost-effective for mass | More expensive per part |

| Lead Time | Short lead times | Longer lead times |

Aluminum extrusion excels in producing long sections with uniform cross-sections efficiently while CNC machining allows for intricate details but at a higher cost[7][8].

Visual Representation of the Process

To better understand aluminum extrusion, visual aids such as diagrams or videos can be beneficial. Here's a brief description of what you might find:

- Diagrams illustrating each step of the extrusion process from heating billets to cutting finished profiles.

- Videos showcasing real-time extrusion processes at facilities like UAC or Awnex Inc., highlighting machinery and techniques used.

Challenges in Aluminum Extrusion

Despite its many advantages, aluminum extrusion does come with challenges:

- Die Design Complexity: Creating dies can be expensive and time-consuming; intricate designs may require multiple iterations before achieving optimal results.

- Material Limitations: Not all aluminum alloys are suitable for every application; selecting the right alloy is crucial for performance.

- Surface Finish Requirements: Depending on the application, additional processes may be necessary to achieve desired surface finishes (e.g., anodizing or powder coating).

Future Trends in Aluminum Extrusion

As technology advances, several trends are emerging within the field of aluminum extrusion:

1. Increased Automation: Companies are investing in automated systems that improve efficiency and reduce labor costs.

2. Sustainable Practices: There's a growing emphasis on sustainable practices within manufacturing processes; recycling scrap materials has become more common.

3. Innovative Alloys: Research is ongoing into developing new aluminum alloys that offer enhanced properties such as improved strength or corrosion resistance.

4. Customization Demand: As industries evolve, there's an increasing demand for customized solutions that meet specific needs across various applications.

5. Integration with Advanced Technologies: The incorporation of technologies like AI and IoT can enhance monitoring processes during production, leading to better quality control.

Conclusion

Aluminum extrusion plays a pivotal role in modern manufacturing, particularly in Ball Ground, GA. With companies like Universal Alloy Corporation and Awnex Inc., this region has become a hub for high-quality aluminum products that serve various industries. The intricate process of transforming solid aluminum billets into versatile profiles not only enhances product performance but also contributes significantly to economic growth within the area.

FAQ

1. What types of products can be made through aluminum extrusion?

Aluminum extrusion can produce a wide range of products including window frames, structural components for buildings, automotive parts, heat sinks for electronics, and more.

2. How does temperature affect the aluminum extrusion process?

Temperature plays a critical role; both the die and the aluminum billet need to be preheated to ensure malleability and prevent sticking during extrusion.

3. What are some advantages of using aluminum over other materials?

Aluminum offers a high strength-to-weight ratio, corrosion resistance, recyclability, and versatility in design compared to other metals like steel or plastic.

4. Can you recycle extruded aluminum?

Yes! Aluminum is highly recyclable without loss of properties, making it an environmentally friendly choice for manufacturers.

5. What industries benefit from aluminum extrusions?

Industries such as construction, automotive, aerospace, electronics, medical devices, and consumer goods all benefit from the use of aluminum extrusions for their lightweight yet durable properties.

Citations:

[1] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[2] https://proleantech.com/aluminum-extrusion-applications-across-industries/

[3] https://flowstore.com/understand-aluminium-extrusion-modern-manufacturing/

[4] https://www.thomasnet.com/suppliers/georgia/all-cities/aluminum-extrusions-26890400

[5] https://www.aloki.hu/pdf/1402_125135.pdf

[6] https://aec.org/aluminum-extrusion-process

[7] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[8] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[9] https://aluminum-extrusions.net/category/georgia/

[10] https://www.lightmetalage.com/news/industry-news/extrusion/aluminum-extrusion-epds-and-the-push-for-decarbonization/

[11] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[12] https://simmal.com/industries-that-benefit-from-aluminium-extrusion/

[13] https://simmal.com/the-advantages-of-aluminium-extrusion-in-manufacturing/

[14] https://www.mapquest.com/us/georgia/universal-alloy-corporation-548703105

[15] https://aec.org/sustainability

[16] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[17] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[18] https://aec.org/features-benefits

[19] https://clutch.co/logistics/manufacturing-companies/aluminum/georgia

[20] https://taberextrusions.com/not-just-a-new-years-resolution-aluminum-extrusion-sustainability/