Content Menu

● Understanding Aluminum Extrusion Fabrication

● Advantages of Aluminum Extrusion Fabrication

>> Design Flexibility

>> Enhanced Material Properties

>> Cost-Effectiveness

>> Sustainability

● Quality Control in Aluminum Extrusion Fabrication

● Applications of Aluminum Extrusion Fabrication

● The Future of Aluminum Extrusion Fabrication

● Conclusion

● FAQ: Frequently Asked Questions About Aluminum Extrusion Fabrication

>> 1. What is aluminum extrusion fabrication?

>> 2. What are the main advantages of aluminum extrusion fabrication?

>> 3. How does aluminum extrusion fabrication improve product quality?

>> 4. What industries benefit from aluminum extrusion fabrication?

>> 5. What quality control measures are used in aluminum extrusion fabrication?

● Citations:

Aluminum extrusion fabrication has revolutionized numerous industries by providing a versatile and efficient method for producing high-quality components. This process involves forcing aluminum alloy material through a die to create specific cross-sectional shapes, enabling the manufacture of complex and precise parts. The benefits of aluminum extrusion fabrication extend to enhanced product quality through several mechanisms, including superior material properties, design flexibility, and efficient production processes. This article explores these advantages in detail, highlighting how aluminum extrusion fabrication enhances product quality.

Understanding Aluminum Extrusion Fabrication

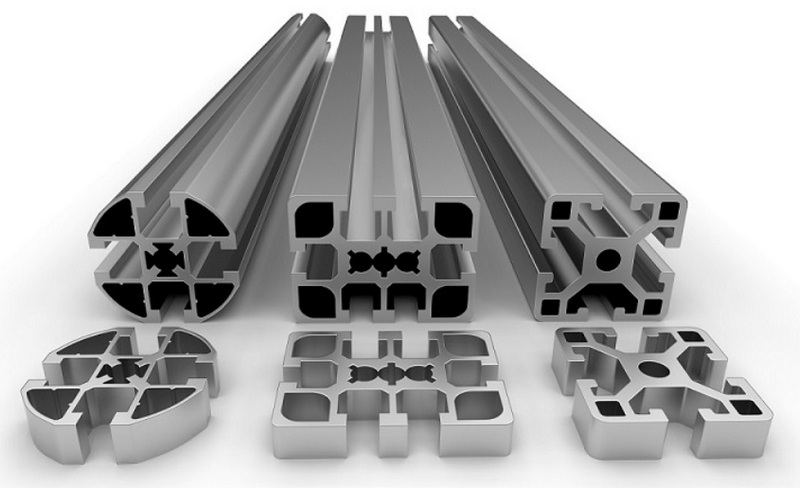

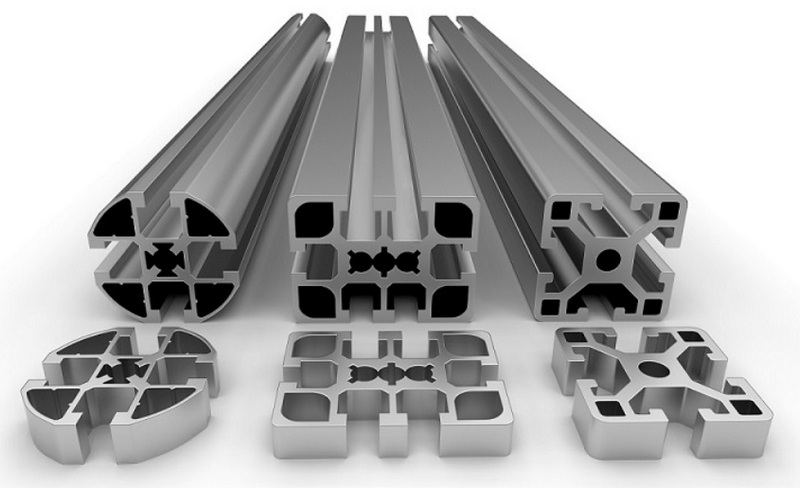

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create a specific shape. This process begins with a cylindrical length of aluminum alloy, known as a billet, which is heated to make it malleable[9]. The heated billet is then loaded into an extrusion press, where a hydraulic ram applies significant pressure, pushing the aluminum through the die[4][11]. The opening in the die determines the final shape of the extruded aluminum[9].

The process can be broken down into several key steps[5]:

1. Die Preparation: The die is preheated to between 450-500 degrees Celsius to maximize its life and ensure even metal flow[5].

2. Billet Preheating: An aluminum billet is preheated in an oven to between 400-500 degrees Celsius, making it malleable enough for extrusion but not molten[5].

3. Extrusion: The heated billet is loaded into the extrusion press, and pressure is applied, forcing the aluminum through the die[9].

4. Emergence: The extruded material emerges from the die in the shape of the fully formed profile[5].

5. Quenching: The extrusion is cooled uniformly using water or fans on a runout table[5].

6. Cutting and Finishing: The cooled bars are cut to the specified length and aged to enhance their mechanical properties[6].

There are two main types of aluminum extrusion:

- Hot Extrusion: Performed at temperatures around 900°F (482°C), allowing for more complex shapes and larger cross-sections[1].

- Cold Extrusion: Done at room temperature or slightly elevated temperatures, typically used for smaller, simpler shapes with tighter tolerances[1][2].

Advantages of Aluminum Extrusion Fabrication

Aluminum extrusion fabrication offers several advantages that contribute to improved product quality. These include design flexibility, enhanced material properties, cost-effectiveness, and sustainability[1][7].

Design Flexibility

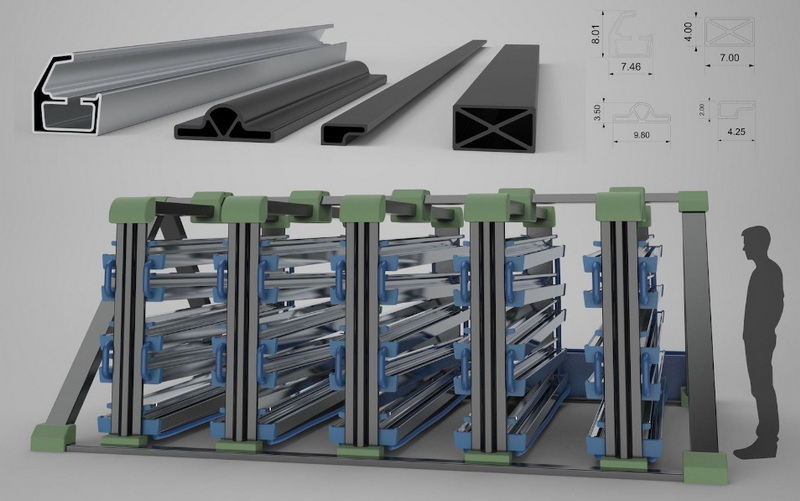

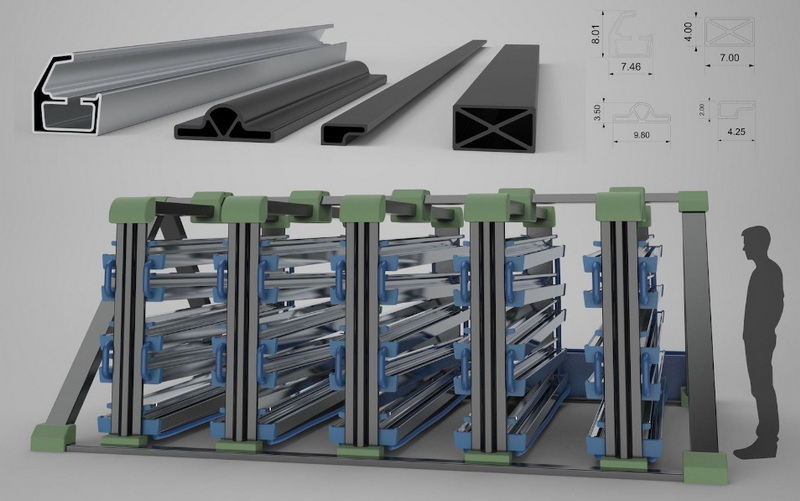

One of the most significant advantages of aluminum extrusion is its unparalleled design flexibility[1]. The process allows for the creation of complex shapes and profiles that would be difficult or impossible to achieve through other manufacturing methods[1]. This flexibility enables designers to optimize product performance and aesthetics simultaneously[1].

- Complex Geometries: Aluminum extrusion enables the production of elaborate and sophisticated geometries that conventional manufacturing processes may find challenging[7].

- Customization: The ability to create custom dies means that aluminum extrusions can be tailored to meet specific application requirements[1].

- Aesthetic Appeal: Designers have the freedom to develop and make more aesthetically pleasing and functional goods[7].

Enhanced Material Properties

Aluminum extrusion fabrication enhances the material properties of the final product, resulting in increased strength, corrosion resistance, and improved surface finish[1][2].

- Strength-to-Weight Ratio: Aluminum extrusion offers an excellent strength-to-weight ratio, making extruded aluminum components ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries[1].

- Corrosion Resistance: Extruded aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. This characteristic ensures the longevity of the product, even in harsh environments[1].

- Increased Strength: Products made by aluminum extrusion typically have increased strength and wear resistance because the material is formed under pressure to produce a homogeneous structure with no cavities, chips, or pores[2].

- Surface Finish: Aluminum extrusion can produce components with excellent surface finishes right out of the die, reducing or eliminating the need for additional finishing processes, saving time and resources[1].

- Dimensional Accuracy: The extrusion process allows for high precision and consistency in the production of components. This precision is crucial in industries where tight tolerances are required, such as aerospace and electronics[1].

Cost-Effectiveness

Despite its numerous benefits, aluminum extrusion remains a cost-effective manufacturing solution[1]. The efficiency of the process, combined with aluminum's abundance and recyclability, keeps production costs competitive[1].

- Material Usage: The extrusion process is highly efficient in terms of material usage. Unlike subtractive manufacturing methods, extrusion minimizes material waste, as the aluminum is shaped rather than cut away[1].

- Production Time: Compared to other manufacturing methods, aluminum extrusion offers faster production times. The process can produce complex shapes in a single step, eliminating the need for multiple manufacturing stages[1].

- Reduced Waste: Aluminum extrusion's adaptability eliminates the need for auxiliary processes, lowering manufacturing costs. The method also produces less waste, which aligns with efficient and economical production methods[7].

Sustainability

Aluminum extrusion contributes to sustainability through its efficient use of materials, the recyclability of aluminum, and the energy efficiency of the process[1].

- Recyclability: Aluminum is 100% recyclable without any loss of quality. Recycling aluminum requires only about 5% of the energy needed to produce new aluminum[1].

- Energy Efficiency: Many aluminum extrusion plants implement energy recovery systems to capture and reuse heat generated during the extrusion process, improving overall energy efficiency[1].

- Sustainable Practices: Many aluminum extrusion plants also implement sustainable practices such as recycling scrap and using energy recovery systems[1].

Quality Control in Aluminum Extrusion Fabrication

Quality control measures are paramount in aluminum extrusion manufacturing to ensure the production of high-quality, reliable, and conforming products[3]. These measures cover every aspect of the production process, from raw material inspection to post-extrusion inspection[3].

- Raw Material Inspection: Verifying the quality and composition of the aluminum alloy before extrusion[3].

- Process Monitoring and Control: Continuously tracking process parameters such as temperature, pressure, and extrusion speed to identify deviations from optimal conditions and make necessary adjustments in real-time[3].

- In-Line Checks: Conducting regular inspections during the extrusion process to detect any defects or inconsistencies[3].

- Post-Extrusion Inspection: Performing final checks on the extruded products to ensure they meet the required specifications and standards[3].

- Documentation: Maintaining detailed records of all quality control activities to ensure traceability and accountability[3].

Modern aluminum extrusion plants utilize advanced technologies to enhance product quality and production efficiency[1]:

1. Computer-Controlled Extrusion Presses: These presses ensure precise control over the extrusion process, resulting in consistent product quality[1].

2. Automated Material Handling Systems: These systems improve efficiency by reducing manual labor and minimizing the risk of damage to the extruded products[1].

3. In-Line Quality Control Systems: Advanced quality control systems, including laser measurement tools and X-ray inspection equipment, ensure that each extruded product meets the required specifications[1].

4. Energy Recovery Systems: Many aluminum extrusion plants implement energy recovery systems to capture and reuse heat generated during the extrusion process, improving overall energy efficiency[1].

Applications of Aluminum Extrusion Fabrication

Aluminum extrusion fabrication is used across various industries due to its versatility and ability to produce high-quality components[1].

- Automotive Industry: Aluminum extrusions are used in automotive manufacturing for lightweighting, improving fuel efficiency, and enhancing structural integrity[1].

- Aerospace Industry: In aerospace, aluminum extrusions are used for aircraft structures, providing high strength-to-weight ratios and corrosion resistance[1].

- Electronics Industry: The electronics industry benefits from aluminum extrusions in the form of heat sinks and enclosures. The excellent thermal conductivity of aluminum helps in efficient heat dissipation[1].

- Construction Industry: Aluminum extrusions are used in construction for window and door frames, curtain walls, and structural components, offering durability and aesthetic appeal[1].

The Future of Aluminum Extrusion Fabrication

The future of aluminum extrusion looks promising, with ongoing developments in alloy technology, manufacturing processes, and sustainability practices[1]. As industries continue to seek lightweight, durable, and cost-effective solutions, aluminum extrusion will undoubtedly play a crucial role in shaping the future of manufacturing[1].

- Alloy Technology: Ongoing research into new aluminum alloys is expected to yield materials with even higher strength, improved corrosion resistance, and enhanced extrudability[1].

- Manufacturing Processes: Advances in extrusion techniques, such as hot and cold extrusion, will enable the production of more complex shapes with tighter tolerances[1].

- Sustainability Practices: Continued emphasis on recycling, energy efficiency, and waste reduction will further enhance the sustainability of aluminum extrusion[1].

Conclusion

Aluminum extrusion fabrication significantly enhances product quality through its design flexibility, enhanced material properties, cost-effectiveness, and sustainability. The process allows for the creation of complex shapes with high precision, combined with the inherent properties of aluminum, making it an ideal choice for a wide range of applications. By implementing stringent quality control measures and adopting advanced technologies, manufacturers can ensure the production of high-quality, reliable, and conforming products. As industries continue to evolve and demand more efficient, durable, and sustainable solutions, aluminum extrusion fabrication will remain at the forefront of modern manufacturing.

FAQ: Frequently Asked Questions About Aluminum Extrusion Fabrication

1. What is aluminum extrusion fabrication?

Aluminum extrusion fabrication is a manufacturing process where aluminum alloy is forced through a die to create a specific shape. This process is used to produce a wide variety of components with complex cross-sectional profiles[4][6].

2. What are the main advantages of aluminum extrusion fabrication?

The main advantages of aluminum extrusion fabrication include design flexibility, enhanced material properties such as high strength-to-weight ratio and corrosion resistance, cost-effectiveness due to efficient material usage, and sustainability through the recyclability of aluminum[1][7].

3. How does aluminum extrusion fabrication improve product quality?

Aluminum extrusion fabrication improves product quality by allowing for high precision and consistency in production, enhancing strength along the length of the profile, and producing excellent surface finishes that reduce the need for additional finishing processes[1][2].

4. What industries benefit from aluminum extrusion fabrication?

Many industries benefit from aluminum extrusion fabrication, including the automotive, aerospace, electronics, and construction sectors. These industries utilize aluminum extrusions for various applications, such as lightweighting, structural components, heat sinks, and architectural elements[1].

5. What quality control measures are used in aluminum extrusion fabrication?

Quality control measures in aluminum extrusion fabrication include raw material inspection, continuous monitoring of process parameters, in-line checks during extrusion, post-extrusion inspection to ensure products meet specifications, and detailed documentation of all quality control activities[3].

Citations:

[1] https://www.yjing-extrusion.com/how-does-aluminum-extrusion-improve-product-quality-and-efficiency.html

[2] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[3] https://aluphant.com/quality-control-measures-in-aluminum-extrusion-manufacturing-a-comprehensive-overview/

[4] https://www.rapiddirect.com/blog/aluminum-extrusion-process/

[5] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[6] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[7] https://flowstore.com/understand-aluminium-extrusion-modern-manufacturing/

[8] https://www.alamy.com/stock-photo/aluminum-extrusion.html

[9] https://www.youtube.com/watch?v=iiGlq7408ME

[10] https://www.alamy.com/stock-photo/aluminum-extrusion-manufacturing.html

[11] https://www.nomexfelt.com/list-news/the-aluminum-extrusion-process-in-10-steps-video-clips/

[12] https://www.howardprecision.com/the-advantages-of-aluminum-extruded-products/

[13] https://www.yjing-extrusion.com/how-does-an-aluminum-billet-to-sheet-extruder-enhance-product-quality.html

[14] http://scaluminum.com/2022/02/benefits-of-aluminum-extrusion-vs-other-types-of-production/

[15] https://sinoextrud.com/quality-assurance-aluminium-production/

[16] https://www.richardsonmetals.com/innovations-in-aluminum-extrusion-pioneering-precision-and-quality/

[17] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[18] https://dl.acm.org/doi/abs/10.1109/MITP.2024.3438545

[19] https://sinoextrud.com/quality-inspection-aluminum-profiles/

[20] https://www.yuhfield.net/en/news/aluminum-extrusion/aluminum-machining-benefits-applications

[21] https://www.alexandriaindustries.com/content-library/demand-innovation/aluminum-extrusion-increases-options-optimize-supply-chain/

[22] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[23] http://scaluminum.com/2022/08/quality-extrusion-maximize-the-benefits-of-aluminum-products/

[24] https://www.shutterstock.com/search/aluminium-extrude

[25] https://aluminum-extrusions.net/fabricated-aluminum-extrusions/

[26] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[27] https://bonnellaluminum.com

[28] https://www.uniqueextrusions.com/photo-gallery/

[29] https://www.youtube.com/watch?v=Olytr4PEDPs

[30] https://rextrusion.en.made-in-china.com/product/JXfnbaAKqWUe/China-Best-Aluminium-Extrusion-Die-Images.html

[31] https://www.istockphoto.com/photos/aluminum-extrusion

[32] https://www.youtube.com/watch?v=baM5hNnBcT8

[33] https://starext.com/news/aluminums-unique-properties-and-custom-aluminum-fabrication

[34] https://www.shutterstock.com/search/aluminium-extrusion

[35] https://www.youtube.com/watch?v=ELgtjeJyFw8

[36] https://www.unisontek.com.tw

[37] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[38] https://hitopindustrial.com/aluminum-extrusion-process/

[39] https://www.otalum.com/quality-optimisation-and-increased-production-of-aluminium-extruded-profiles.html

[40] https://starext.com