Content Menu

● Overview of No Drying Extrusion Compound Fertilizer Production Lines

>> Key Features

● Components of No Drying Extrusion Compound Fertilizer Production Lines

● The Production Process

>> 1. Raw Material Handling

>> 2. Crushing

>> 3. Mixing

>> 4. Extrusion Granulation

>> 5. Screening

>> 6. Coating (Optional)

>> 7. Packaging

● Advantages of No Drying Extrusion Compound Fertilizer Production Lines

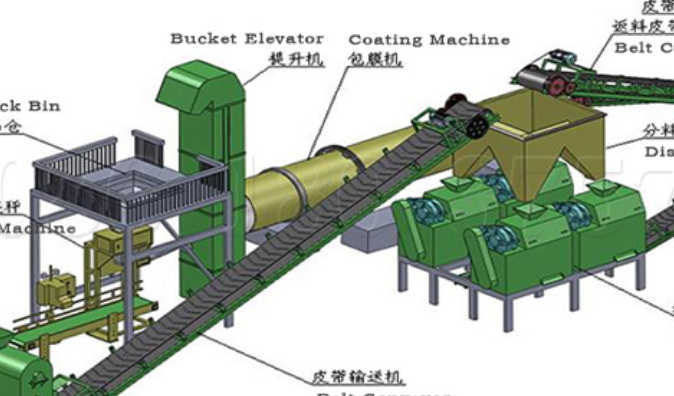

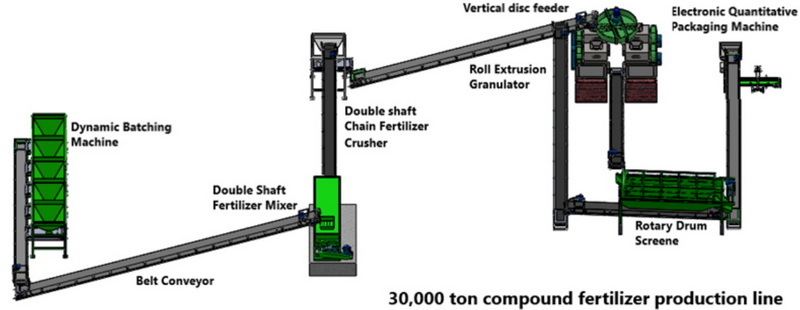

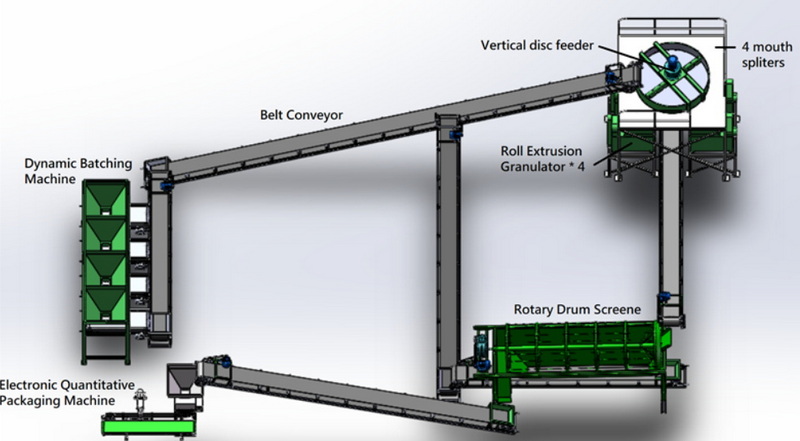

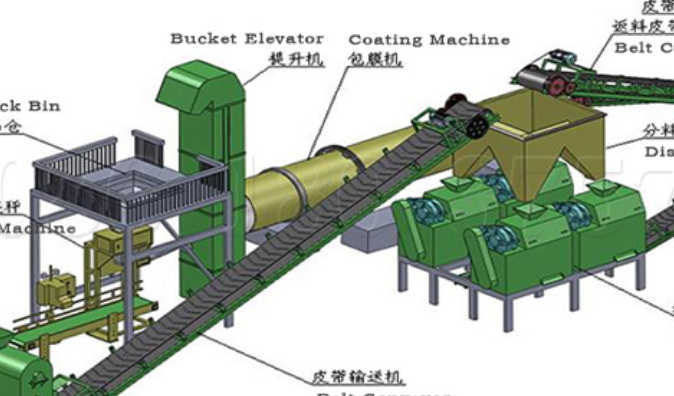

● Visual Representation

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What types of fertilizers can be produced using no drying extrusion technology?

>> 2. How does the absence of a drying process benefit production?

>> 3. What are the raw materials used in no drying extrusion compound fertilizer production?

>> 4. How does the roller extrusion granulator work?

>> 5. What is the typical output capacity of a no drying extrusion compound fertilizer production line?

● Citations:

The production of compound fertilizers is essential for modern agriculture, providing the necessary nutrients to enhance crop yield and soil health. Among various methods of fertilizer production, the "no drying extrusion compound fertilizer production line" stands out due to its efficiency and environmental benefits. This article explores the workings of this innovative production line, its components, advantages, and frequently asked questions.

Overview of No Drying Extrusion Compound Fertilizer Production Lines

No drying extrusion compound fertilizer production lines utilize a process known as extrusion granulation, which allows for the creation of fertilizer granules without the need for drying. This method significantly reduces energy consumption and operational costs while maintaining high product quality.

Key Features

- Energy Efficiency: The absence of a drying process leads to lower energy requirements.

- Environmental Impact: Reduced emissions and waste generation compared to traditional methods.

- Versatility: Capable of producing various types of compound fertilizers tailored to different crops.

Components of No Drying Extrusion Compound Fertilizer Production Lines

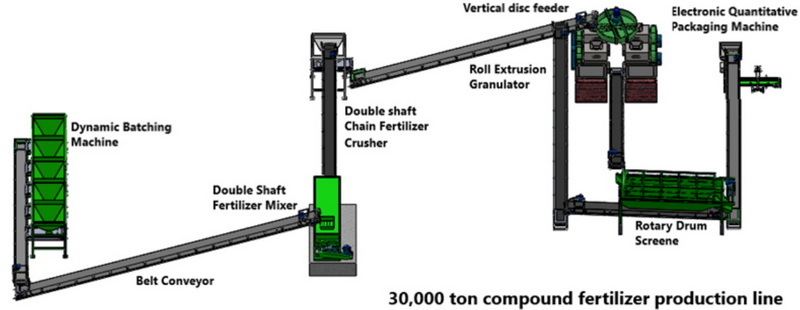

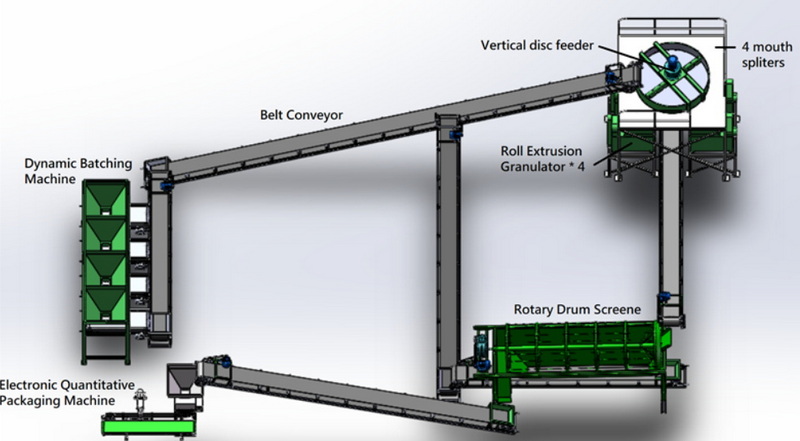

A typical no drying extrusion compound fertilizer production line consists of several key components that work together seamlessly:

1. Dynamic Batching Machine

- Automatically feeds raw materials according to specified formula ratios.

- Ensures high accuracy and efficiency in ingredient measurement.

2. Double Shaft Fertilizer Mixer

- Mixes raw materials thoroughly using a cycloid needle wheel reducer.

- Ensures uniformity in the mixture, crucial for consistent fertilizer quality.

3. Roller Extrusion Granulator

- Compresses the mixed materials into granules through high pressure.

- The rollers can be designed in various shapes to produce different granule sizes.

4. Rotary Drum Screener

- Screens extruded granules to separate qualified from unqualified particles.

- Ensures that only properly sized granules proceed to packaging.

5. Electronic Quantitative Packaging Machine

- Weighs and packages the finished granules automatically.

- Enhances efficiency in the final stages of production.

The Production Process

The no drying extrusion compound fertilizer production process involves several stages:

1. Raw Material Handling

Raw materials, including nitrogen, phosphorus, potassium (NPK), and other organic or inorganic substances, are collected and prepared for processing.

2. Crushing

The raw materials are crushed into smaller pieces to facilitate mixing.

3. Mixing

Crushed materials are blended using a double shaft mixer to achieve a homogeneous mixture.

4. Extrusion Granulation

The mixed materials are fed into the roller extrusion granulator, where they are compressed into granules under high pressure.

5. Screening

The extruded granules are screened to remove any oversized or undersized particles, ensuring uniformity in product size.

6. Coating (Optional)

If required, a protective coating is applied to prevent caking and improve storage life.

7. Packaging

The final step involves packaging the granules into bags or containers for distribution.

Advantages of No Drying Extrusion Compound Fertilizer Production Lines

- Cost-Effectiveness: Lower investment costs due to the elimination of drying equipment.

- High Granulation Rate: Achieves a high rate of granulation, often exceeding 90%.

- Environmentally Friendly: Minimal waste generation and reduced energy consumption contribute to a lower carbon footprint.

- Quality Control: The process allows for precise control over nutrient ratios, ensuring high-quality fertilizer products.

Visual Representation

To provide a clearer understanding of how no drying extrusion compound fertilizer production lines operate, consider the following diagram:

No Drying Extrusion Compound Fertilizer Production Line

Conclusion

No drying extrusion compound fertilizer production lines represent a significant advancement in fertilizer manufacturing technology. By combining efficiency with environmental responsibility, these production lines not only meet the growing demands of modern agriculture but also contribute positively to sustainable farming practices. As the agricultural sector continues to evolve, embracing such innovative solutions will be crucial for achieving food security and environmental sustainability.

Frequently Asked Questions (FAQ)

1. What types of fertilizers can be produced using no drying extrusion technology?

No drying extrusion technology can produce various types of compound fertilizers, including NPK fertilizers and organic-inorganic blends tailored for specific crops.

2. How does the absence of a drying process benefit production?

Eliminating the drying process reduces energy consumption and operational costs while minimizing emissions and waste generation.

3. What are the raw materials used in no drying extrusion compound fertilizer production?

Common raw materials include nitrogen sources (urea, ammonium nitrate), phosphorus sources (DAP, MAP), potassium sources (potassium chloride), and organic materials (manure).

4. How does the roller extrusion granulator work?

The roller extrusion granulator compresses mixed materials into granules by applying high pressure through specially designed rollers without adding water or binders.

5. What is the typical output capacity of a no drying extrusion compound fertilizer production line?

Output capacity can vary widely depending on equipment specifications but typically ranges from 10,000 tons per year to over 200,000 tons per year based on demand and operational scale.

Citations:

[1] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-line-product/

[2] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-line-5-product/

[3] https://agrofertimac.com/production_line/compound-fertilizer-plant.html

[4] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-lines/

[5] https://organicfertilizermachine.com/faqs

[6] https://www.youtube.com/watch?v=vquLRNDB7P0

[7] https://www.cementl.com/npk-compound-fertilizer-production-line-overview/

[8] https://www.syfert.net/resources/compound-fertilizer-granulation-methods-process.html

[9] https://agrofertimac.com/index.html

[10] https://www.cementl.com/npk-compound-fertilizer-production-line-overview/

[11] https://fertilizerequipmentmanufacturer.com/fertilizer-roller-extrusion-granulation-line/

[12] https://fertilizermanufacturingsolutions.com/roller-press-granulator/

[13] https://www.wastetofertilizer.com/compound-fertilizer-production-line/

[14] https://fertilizerplantdesigner.com/npk-fertilizer-production-line/

[15] https://fertilizer-machine.com/product/Fertilizer_Production_Line/No-drying_Extrusion_Fertilizer_Productio.html

[16] https://fertilizergranulatormanufacturer.com/npk-fertilizer-production-process/

[17] https://fertilizer-machinery.com/production_line/compound-fertilizer-plant/extrusion-granulator-production-line.html

[18] https://www.linkedin.com/pulse/drying-dual-mode-extrusion-cylindrical-granulator-organic-yu-

[19] https://fertilizer-machine.com/product/Fertilizer_Production_Line/mini-compound-fertilizer-production-line.html

[20] https://fertilizer-machinery.com/production_line/compound-fertilizer-plant/pan-granulator-production-line.html

[21] http://fertilizerindustryleader.com/video

[22] https://fertilizerequipmentmanufacturer.com/fertilizer-granulation-equipment-video/

[23] https://www.youtube.com/watch?v=CJ6GBJYFjVM

[24] https://www.youtube.com/watch?v=O9KbJnQVPhQ

[25] https://agcrops.osu.edu/sites/agcrops/files/imce/fertility/Most%20Asked%20Agronomic%20Questions,%20Bulletin%20760,%20Chapter%206_%20Fertilizer%20Application.pdf

[26] https://fertilizerplantequiment.com/faq/

[27] https://fertilizermanufacturingsolutions.com/f-a-q/

[28] https://www.researchgate.net/topic/Fertilizers

[29] https://fertilizerequipmentmanufacturer.com/npk-fertilizer-production-line/

[30] https://www.yjing-extrusion.com/where-is-there-a-drying-extrusion-compound-fertilizer-production-line.html

[31] https://fertilizer-machine.net/solution_and_market/compound-fertilizer-production-line.html

[32] https://organicfertilizermachines.com/compound-fertilizer-production-line/

[33] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-line-product/

[34] https://www.cementl.com/solution/npk-compound-fertilizer-production-line/

[35] https://cornsouth.com/articles/fertilization-q-and-a/