Content Menu

● Understanding T-Slot Aluminum Extrusions

>> Benefits of Using 2020 T-Slot Aluminum Extrusions

● Factors to Consider When Choosing 2020 T-Slot Aluminum Extrusions

>> Project Requirements

>> Dimensions and Profile

>> Load Capacity

>> Accessories and Fasteners

>> Surface Finish

>> Budget

● Assembly Tips for 2020 T-Slot Aluminum Extrusions

>> Plan Your Design

>> Gather Tools and Materials

>> Start with the Base

>> Add Vertical Supports

>> Incorporate Accessories

>> Double-Check Measurements

>> Finish with End Caps

● Common Applications of 2020 T-Slot Aluminum Extrusions

>> Robotics

>> Custom Furniture

>> Industrial Automation

>> Display Stands

>> Enclosures and Guards

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between 2020 and 2040 T-slot aluminum extrusions?

>> 2. Can I cut T-slot aluminum extrusions to size?

>> 3. Are T-slot aluminum extrusions suitable for outdoor use?

>> 4. What types of projects are best suited for 2020 T-slot aluminum extrusions?

>> 5. How do I ensure my assembly is stable?

Understanding T-Slot Aluminum Extrusions

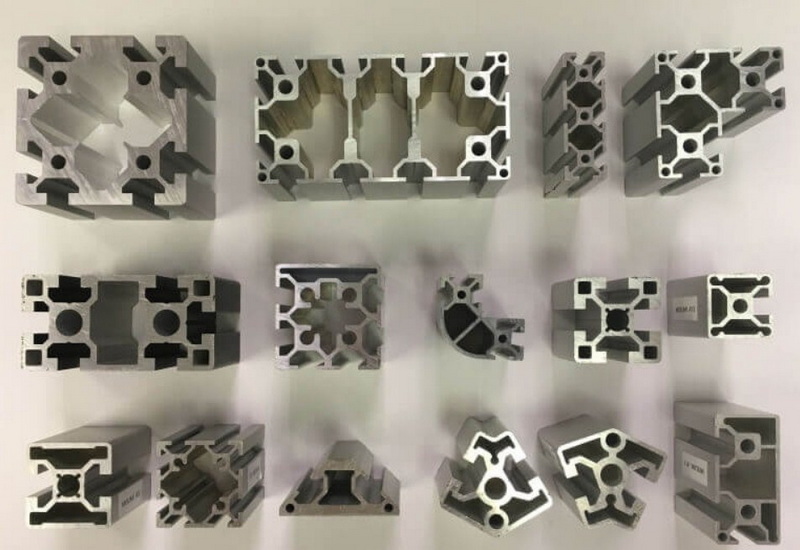

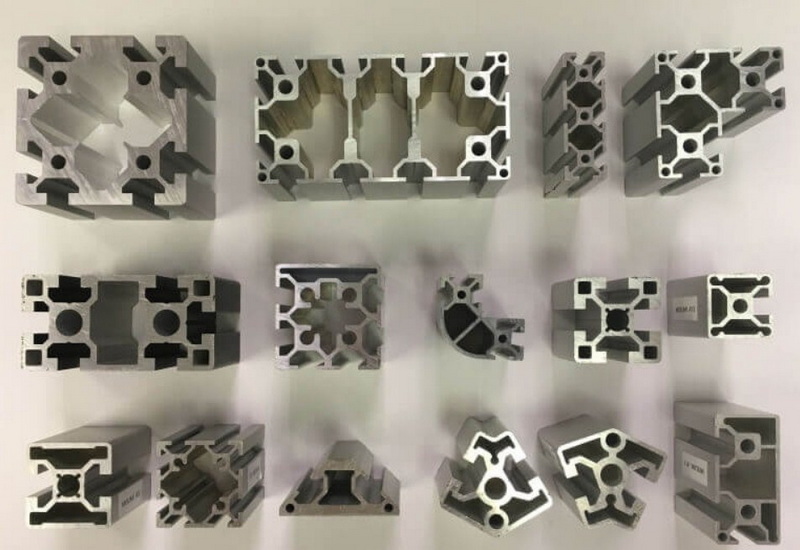

T-slot aluminum extrusions are aluminum profiles with a unique cross-sectional shape that allows for easy assembly and modification. The "T-slot" design features grooves along the length of the extrusion, enabling users to attach various components, such as brackets, panels, and other extrusions, without the need for welding or complex fasteners.

Benefits of Using 2020 T-Slot Aluminum Extrusions

1. Versatility: The 2020 T-slot aluminum extrusion can be used in a wide range of applications, including robotics, furniture, and industrial automation.

2. Lightweight: Aluminum is a lightweight material, making it easy to handle and transport.

3. Strength: Despite its light weight, aluminum is strong and durable, providing excellent structural integrity.

4. Corrosion Resistance: Aluminum naturally resists corrosion, making it suitable for both indoor and outdoor applications.

5. Ease of Assembly: The T-slot design allows for quick and easy assembly, enabling users to create complex structures without specialized tools.

Factors to Consider When Choosing 2020 T-Slot Aluminum Extrusions

When selecting the right 2020 T-slot aluminum extrusion for your project, consider the following factors:

Project Requirements

Before choosing an extrusion, clearly define the requirements of your project. Consider the following questions:

- What is the intended use of the structure?

- What loads will the structure need to support?

- Will the structure be stationary or mobile?

- Are there any specific environmental conditions to consider (e.g., exposure to moisture or chemicals)?

Dimensions and Profile

The 2020 T-slot aluminum extrusion has a standard dimension of 20mm x 20mm. However, it is essential to consider the length and profile of the extrusion. Longer extrusions can provide greater stability, while shorter pieces may be more suitable for compact designs. Additionally, consider whether you need a standard profile or a custom shape for your project.

Load Capacity

Understanding the load capacity of the extrusion is critical for ensuring the safety and stability of your project. The load capacity will depend on several factors, including the length of the extrusion, the type of load (static or dynamic), and the method of support. Consult manufacturer specifications to determine the load limits for the specific extrusion you are considering.

Accessories and Fasteners

To maximize the functionality of your 2020 T-slot aluminum extrusion, consider the accessories and fasteners you will need. Common accessories include:

- Brackets: Used to connect extrusions at various angles.

- End Caps: Provide a finished look and protect the ends of the extrusion.

- Corner Brackets: Allow for secure connections at corners.

- Sliding Nuts: Fit into the T-slots to provide a secure attachment point for other components.

Surface Finish

Aluminum extrusions can come in various surface finishes, including anodized, powder-coated, or mill finish. Anodized finishes provide additional corrosion resistance and a more aesthetically pleasing appearance, while powder-coated finishes offer a wide range of colors. Choose a finish that aligns with your project's aesthetic and functional requirements.

Budget

Finally, consider your budget when selecting 2020 T-slot aluminum extrusions. Prices can vary based on the supplier, length, and finish of the extrusion. It is essential to balance quality and cost to ensure you get the best value for your project.

Assembly Tips for 2020 T-Slot Aluminum Extrusions

Once you have selected the right 2020 T-slot aluminum extrusion for your project, the next step is assembly. Here are some tips to help you assemble your structure effectively:

Plan Your Design

Before starting assembly, create a detailed plan or drawing of your design. This will help you visualize the final product and ensure you have all the necessary components. Consider using design software or sketching your ideas on paper to clarify your vision.

Gather Tools and Materials

Ensure you have all the required tools and materials on hand before starting assembly. Common tools include:

- Allen wrenches

- Screwdrivers

- Measuring tape

- Level

- Saw (for cutting extrusions to size)

Start with the Base

Begin assembly by constructing the base of your structure. This will provide a stable foundation for the rest of the assembly. Use corner brackets to secure the connections and ensure everything is level. A solid base is crucial for the overall stability of your project.

Add Vertical Supports

Once the base is complete, add vertical supports to create the framework of your structure. Use sliding nuts and bolts to secure the connections within the T-slots. Ensure that the vertical supports are plumb and aligned with the base to maintain structural integrity.

Incorporate Accessories

As you build, incorporate any necessary accessories, such as shelves, panels, or additional supports. Ensure that all components are securely attached and aligned. This is also the time to add any features that will enhance the functionality of your structure, such as cable management systems or mounting brackets for additional equipment.

Double-Check Measurements

Throughout the assembly process, regularly check your measurements to ensure accuracy. This will help prevent any misalignments or structural issues. Using a level can help ensure that your structure is straight and true, which is especially important for larger projects.

Finish with End Caps

Once the assembly is complete, add end caps to the exposed ends of the extrusions for a polished look and added safety. End caps can help prevent injuries from sharp edges and give your project a more finished appearance.

Common Applications of 2020 T-Slot Aluminum Extrusions

The versatility of 2020 T-slot aluminum extrusions makes them suitable for a wide range of applications. Here are some common uses:

Robotics

In the field of robotics, 2020 T-slot aluminum extrusions are often used to create frames for robotic arms, mobile robots, and other automated systems. Their lightweight yet sturdy nature allows for the construction of complex structures that can support various components, such as motors, sensors, and control systems.

Custom Furniture

DIY enthusiasts frequently use 2020 T-slot aluminum extrusions to build custom furniture, such as desks, shelving units, and workbenches. The ability to easily modify and expand designs makes aluminum extrusions an excellent choice for creating functional and aesthetically pleasing furniture.

Industrial Automation

In industrial settings, 2020 T-slot aluminum extrusions are commonly used to build machine frames, conveyor systems, and workstations. Their strength and adaptability make them ideal for creating structures that can withstand the rigors of manufacturing environments.

Display Stands

Retailers and exhibitors often use 2020 T-slot aluminum extrusions to create display stands for products and promotional materials. The modular nature of T-slot systems allows for easy reconfiguration and customization to suit different display needs.

Enclosures and Guards

T-slot aluminum extrusions can also be used to create enclosures and safety guards for machinery. These structures can help protect operators from moving parts while providing easy access for maintenance and operation.

Conclusion

Choosing the right 2020 T-slot aluminum extrusion for your project involves careful consideration of various factors, including project requirements, dimensions, load capacity, and budget. By understanding the benefits of T-slot aluminum extrusions and following the assembly tips provided, you can create a robust and functional structure tailored to your needs.

Frequently Asked Questions

1. What is the difference between 2020 and 2040 T-slot aluminum extrusions?

The primary difference is the dimensions; 2020 extrusions are 20mm x 20mm, while 2040 extrusions are 20mm x 40mm. The 2040 extrusions offer greater load capacity and stability for larger projects.

2. Can I cut T-slot aluminum extrusions to size?

Yes, T-slot aluminum extrusions can be cut to the desired length using a miter saw or a band saw. Ensure you have the proper tools and safety equipment when cutting.

3. Are T-slot aluminum extrusions suitable for outdoor use?

Yes, aluminum is naturally resistant to corrosion, making T-slot aluminum extrusions suitable for outdoor applications. However, consider using anodized or powder-coated finishes for added protection.

4. What types of projects are best suited for 2020 T-slot aluminum extrusions?

2020 T-slot aluminum extrusions are ideal for a variety of projects, including custom furniture, robotics, machine frames, and display stands.

5. How do I ensure my assembly is stable?

To ensure stability, use appropriate fasteners, check load capacities, and regularly verify that all components are securely attached and aligned during assembly.