Content Menu

● Introduction to Aluminum Extrusion

● The Role of Aluminum Extrusion Equipment in Modern Manufacturing

● Custom Aluminum Profiles: Tailoring Solutions for Every Industry

>> Applications of Custom Aluminum Profiles:

● The Power of Hydraulic Extrusion Presses

● Industrial Aluminum Processing: From Billet to Final Product

>> Key Steps in Industrial Aluminum Processing:

● The Critical Role of Extrusion Die Manufacturers

● High-Volume Aluminum Production: Meeting Global Demand

● Automated Extrusion Systems: The Future of Manufacturing

>> Benefits of Automated Extrusion Systems:

● Aluminum Profile Suppliers: Bridging Manufacturers and End-Users

● Extrusion Press Maintenance: Ensuring Longevity and Performance

● Advanced Aluminum Fabrication: Beyond Extrusion

● The Global Impact of Aluminum Extrusion Press Manufacturers

● Conclusion: The Future of Aluminum Extrusion

● Frequently Asked Questions

>> 1. What is the typical lifespan of an aluminum extrusion press?

>> 2. How does the size of an extrusion press affect its capabilities?

>> 3. What are the environmental benefits of aluminum extrusion?

>> 4. How do Aluminum Extrusion Press Manufacturers contribute to innovation in other industries?

>> 5. What factors should be considered when choosing an Aluminum Extrusion Press Manufacturer?

Introduction to Aluminum Extrusion

Aluminum extrusion is a cornerstone process in modern manufacturing, enabling the creation of complex profiles and shapes from this versatile metal. At the heart of this industry are the Aluminum Extrusion Press Manufacturers, companies that design and produce the sophisticated machinery essential for transforming raw aluminum into a myriad of products used across various sectors.

The Role of Aluminum Extrusion Equipment in Modern Manufacturing

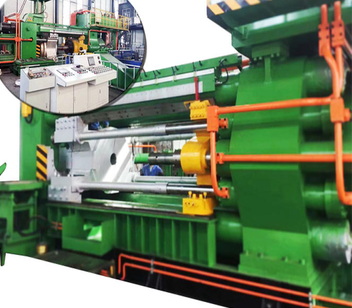

Aluminum Extrusion Equipment forms the backbone of numerous industries, from construction to aerospace. These powerful machines, crafted by specialized Aluminum Extrusion Press Manufacturers, are capable of producing everything from simple rods to intricate custom profiles. The process involves forcing heated aluminum through a die, shaping it into the desired form with precision and efficiency.

The image above showcases a typical large-scale aluminum extrusion press, highlighting the robust construction and complex hydraulic systems that are hallmarks of high-quality Aluminum Extrusion Equipment.

Custom Aluminum Profiles: Tailoring Solutions for Every Industry

One of the most significant advantages offered by modern Aluminum Extrusion Press Manufacturers is the ability to create Custom Aluminum Profiles. These bespoke solutions cater to the unique needs of various industries, from automotive parts to architectural components. The flexibility of aluminum extrusion allows for the production of shapes that would be impossible or prohibitively expensive to manufacture through other methods.

Applications of Custom Aluminum Profiles:

1. Automotive: Lightweight structural components

2. Aerospace: Fuselage and wing parts

3. Construction: Window frames and curtain walls

4. Electronics: Heat sinks and casings

5. Renewable Energy: Solar panel frames and wind turbine components

The Power of Hydraulic Extrusion Presses

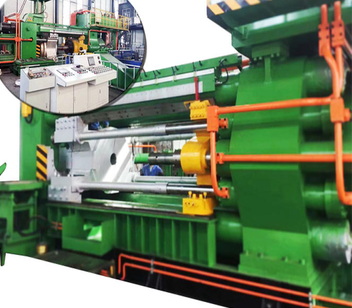

At the core of most modern extrusion facilities are Hydraulic Extrusion Presses. These marvels of engineering, produced by leading Aluminum Extrusion Press Manufacturers, utilize high-pressure hydraulic systems to generate the immense force required to shape aluminum. The precision and power of these presses enable manufacturers to achieve tight tolerances and consistent quality across high-volume production runs.

This image illustrates a state-of-the-art hydraulic extrusion press, showcasing the scale and complexity of these machines designed for High-Volume Aluminum Production.

Industrial Aluminum Processing: From Billet to Final Product

The journey from raw aluminum to finished product is a testament to the capabilities of modern Industrial Aluminum Processing. Aluminum Extrusion Press Manufacturers play a crucial role in this process by providing the equipment necessary for each stage of production.

Key Steps in Industrial Aluminum Processing:

1. Billet preparation and preheating

2. Extrusion through custom dies

3. Cooling and stretching

4. Cutting to length

5. Heat treatment (if required)

6. Surface finishing

Each of these steps relies on specialized machinery, often sourced from the same Aluminum Extrusion Press Manufacturers that provide the core extrusion equipment.

The Critical Role of Extrusion Die Manufacturers

While the press itself is crucial, the dies used in the extrusion process are equally important. Extrusion Die Manufacturers work closely with Aluminum Extrusion Press Manufacturers to create dies that can withstand the extreme pressures and temperatures involved in the extrusion process. These precision-engineered tools are the unsung heroes of the industry, enabling the creation of complex shapes with remarkable accuracy.

High-Volume Aluminum Production: Meeting Global Demand

As the demand for aluminum products continues to grow worldwide, High-Volume Aluminum Production has become increasingly important. Aluminum Extrusion Press Manufacturers have responded to this need by developing larger, faster, and more efficient presses capable of producing vast quantities of extruded aluminum profiles.

This image shows a high-capacity aluminum extrusion press designed for High-Volume Aluminum Production, illustrating the scale of equipment required to meet global demand.

Automated Extrusion Systems: The Future of Manufacturing

The integration of automation into the extrusion process represents a significant leap forward in efficiency and consistency. Automated Extrusion Systems, developed by forward-thinking Aluminum Extrusion Press Manufacturers, incorporate advanced sensors, robotics, and artificial intelligence to optimize every aspect of the extrusion process.

Benefits of Automated Extrusion Systems:

1. Increased productivity

2. Improved quality control

3. Reduced labor costs

4. Enhanced safety

5. Real-time process monitoring and adjustment

These systems represent the cutting edge of aluminum extrusion technology, allowing manufacturers to achieve unprecedented levels of efficiency and quality.

Aluminum Profile Suppliers: Bridging Manufacturers and End-Users

Aluminum Profile Suppliers play a vital role in the industry ecosystem, acting as intermediaries between Aluminum Extrusion Press Manufacturers and end-users. These suppliers often work closely with extrusion companies to develop new profiles and bring innovative solutions to market. Their expertise in both the technical aspects of extrusion and the needs of various industries makes them invaluable partners in the aluminum supply chain.

Extrusion Press Maintenance: Ensuring Longevity and Performance

The sophisticated machinery produced by Aluminum Extrusion Press Manufacturers requires regular maintenance to ensure optimal performance and longevity. Extrusion Press Maintenance is a specialized field that combines mechanical, hydraulic, and electrical expertise. Proper maintenance not only extends the life of the equipment but also ensures consistent product quality and minimizes downtime.

This image depicts a technician performing maintenance on an aluminum extrusion press, highlighting the importance of regular upkeep for these complex machines.

Advanced Aluminum Fabrication: Beyond Extrusion

While extrusion is a critical process, Advanced Aluminum Fabrication encompasses a broader range of techniques. Many Aluminum Extrusion Press Manufacturers also provide equipment for additional processing steps, such as:

1. Precision cutting

2. CNC machining

3. Surface treatment

4. Assembly

5. Quality control and testing

These complementary processes allow manufacturers to offer complete solutions, from raw material to finished product, all under one roof.

The Global Impact of Aluminum Extrusion Press Manufacturers

The influence of Aluminum Extrusion Press Manufacturers extends far beyond the factory floor. Their innovations drive progress in countless industries, enabling the creation of lighter, stronger, and more efficient products. From reducing the weight of vehicles to improving the energy efficiency of buildings, the impact of aluminum extrusion technology is felt in every corner of the modern world.

Conclusion: The Future of Aluminum Extrusion

As we look to the future, it's clear that Aluminum Extrusion Press Manufacturers will continue to play a pivotal role in shaping the world around us. With ongoing advancements in materials science, automation, and sustainability, the possibilities for aluminum extrusion are virtually limitless. From smart cities to space exploration, the products of these innovative companies will be at the forefront of human progress for generations to come.

Frequently Asked Questions

1. What is the typical lifespan of an aluminum extrusion press?

Answer: With proper maintenance, a high-quality aluminum extrusion press can last 20-30 years or more. However, many companies choose to upgrade their equipment sooner to take advantage of technological advancements and improve efficiency.

2. How does the size of an extrusion press affect its capabilities?

Answer: The size of an extrusion press, typically measured in tons of force, determines the maximum size and complexity of profiles it can produce. Larger presses can handle bigger billets and create more complex shapes, but they also require more space and energy to operate.

3. What are the environmental benefits of aluminum extrusion?

Answer: Aluminum extrusion is an environmentally friendly process because aluminum is 100% recyclable without loss of quality. Additionally, extruded aluminum products are often lighter than alternatives, reducing energy consumption in transportation and use.

4. How do Aluminum Extrusion Press Manufacturers contribute to innovation in other industries?

Answer: By developing more advanced and efficient extrusion technology, these manufacturers enable other industries to create innovative products. For example, more precise extrusion processes allow for the creation of complex heat sinks in electronics, improving device performance and lifespan.

5. What factors should be considered when choosing an Aluminum Extrusion Press Manufacturer?

Answer: Key factors include the manufacturer's reputation, the range of press sizes and types offered, after-sales support and maintenance services, the level of automation and control systems provided, and the ability to customize solutions for specific industry needs.