Content Menu

● The Fundamentals of Aluminum Extrusion Mounting Brackets

● Precision Through Design

>> Key Design Features:

● Enhancing Accuracy in Assembly

● Versatility and Customization

>> Customization Options:

● Precision in Load Distribution

● Advanced Manufacturing Techniques

● Applications Across Industries

>> Aerospace Industry

>> Automotive Manufacturing

>> Robotics and Automation

>> Medical Equipment

● Advantages of Aluminum Extrusion Mounting Brackets

● Innovations in Aluminum Extrusion Mounting Brackets

● Best Practices for Maximizing Precision

● Case Studies: Precision in Action

>> Case Study 1: Aerospace Component Manufacturing

>> Case Study 2: Automotive Production Line Upgrade

● Future Trends in Precision Mounting

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What materials are commonly used for aluminum extrusion mounting brackets?

>> 2. How do aluminum extrusion mounting brackets compare to steel brackets in terms of precision?

>> 3. Can aluminum extrusion mounting brackets be used in outdoor applications?

>> 4. How do I ensure proper alignment when using aluminum extrusion mounting brackets?

>> 5. Are there any limitations to the precision achievable with aluminum extrusion mounting brackets?

● Citations:

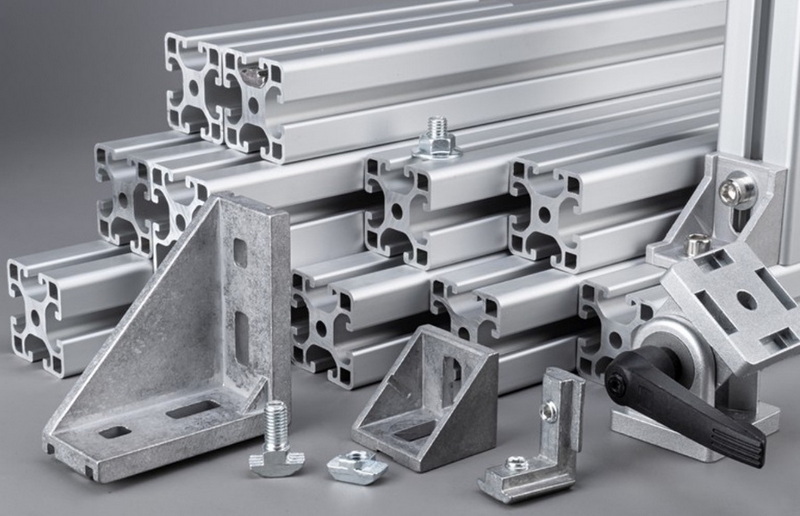

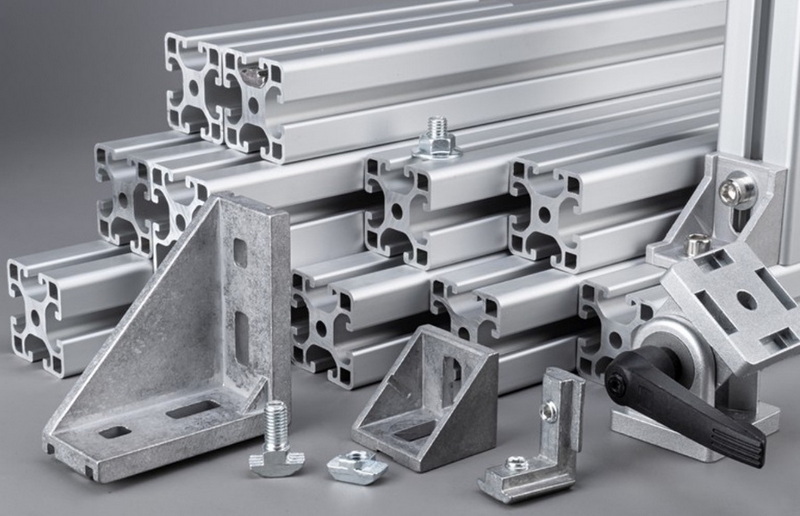

Aluminum extrusion mounting brackets play a crucial role in various industries, from manufacturing to construction, by providing precise and accurate support for components and structures. These versatile brackets offer numerous advantages that contribute to enhanced precision and accuracy in assembly and installation processes. In this comprehensive article, we will explore the various ways in which aluminum extrusion mounting brackets help achieve precision and accuracy, their applications, and their impact on different industries.

The Fundamentals of Aluminum Extrusion Mounting Brackets

Aluminum extrusion mounting brackets are specialized components designed to securely connect and support aluminum extrusion profiles. These brackets are typically made from high-quality aluminum alloys, offering a perfect balance of strength, lightweight properties, and corrosion resistance. The extrusion process allows for the creation of complex shapes and profiles, enabling manufacturers to produce brackets that fit precisely with various aluminum extrusion systems.

Precision Through Design

One of the primary ways aluminum extrusion mounting brackets contribute to precision and accuracy is through their thoughtful design. These brackets are engineered to provide a snug fit with aluminum extrusion profiles, ensuring minimal play or movement once assembled. The precise tolerances achieved during the manufacturing process result in brackets that align perfectly with the T-slots or other features of the extrusion profiles.

Key Design Features:

1. Exact dimensioning to match extrusion profiles

2. Integrated alignment features

3. Pre-drilled holes for accurate fastener placement

4. Reinforced structures for enhanced stability

Enhancing Accuracy in Assembly

Aluminum extrusion mounting brackets significantly improve the accuracy of assembly processes. Their modular nature allows for quick and precise positioning of components, reducing the likelihood of misalignment or errors during construction. This is particularly beneficial in industries where even minor deviations can have significant consequences, such as aerospace or precision manufacturing.

Versatility and Customization

The versatility of aluminum extrusion mounting brackets contributes to their ability to enhance precision across various applications. These brackets can be easily customized to meet specific project requirements, allowing for precise adjustments and fine-tuning of assemblies. This adaptability ensures that components can be positioned exactly where they need to be, maintaining accuracy throughout the entire structure.

Customization Options:

- Custom angles for unique joint configurations

- Specialized surface treatments for improved grip

- Integration of additional features like cable management

- Tailored sizes to accommodate specific load requirements

Precision in Load Distribution

Aluminum extrusion mounting brackets excel in distributing loads evenly across structures. This precise load management is crucial for maintaining the integrity and accuracy of assembled systems. By effectively transferring forces, these brackets help prevent deformation or misalignment that could compromise the precision of the overall structure.

Advanced Manufacturing Techniques

The precision of aluminum extrusion mounting brackets is further enhanced by advanced manufacturing techniques. Computer Numerical Control (CNC) machining and other high-precision manufacturing methods ensure that each bracket meets exact specifications. This level of manufacturing precision translates directly into improved accuracy when the brackets are used in assemblies.

Applications Across Industries

The precision and accuracy offered by aluminum extrusion mounting brackets make them invaluable in numerous industries. Let's explore some key applications:

Aerospace Industry

In aerospace applications, precision is paramount. Aluminum extrusion mounting brackets are used in the construction of aircraft interiors, satellite components, and ground support equipment. Their ability to provide accurate and stable connections ensures that critical systems function as intended, meeting the stringent safety and performance standards of the aerospace industry.

Automotive Manufacturing

The automotive industry relies heavily on precision components to ensure vehicle safety and performance. Aluminum extrusion mounting brackets are used in assembly lines, jigs, and fixtures, providing accurate positioning for robotic systems and ensuring consistent quality in vehicle production.

Robotics and Automation

In the field of robotics and automation, precision is essential for repeatable and accurate movements. Aluminum extrusion mounting brackets are used to construct frames and supports for robotic arms, conveyor systems, and sensor arrays, ensuring that automated processes maintain high levels of accuracy over time.

Medical Equipment

The medical industry demands utmost precision in equipment design and functionality. Aluminum extrusion mounting brackets are utilized in the construction of imaging machines, surgical equipment supports, and laboratory apparatus, where accuracy can directly impact patient care and research outcomes.

Advantages of Aluminum Extrusion Mounting Brackets

The use of aluminum extrusion mounting brackets offers several advantages that contribute to enhanced precision and accuracy:

1. Lightweight yet Strong: The low density of aluminum combined with the strength of extrusion profiles results in brackets that are easy to handle without compromising on load-bearing capacity.

2. Corrosion Resistance: Aluminum's natural resistance to corrosion ensures that brackets maintain their precision over time, even in challenging environments.

3. Thermal Stability: Aluminum's excellent thermal properties help maintain dimensional stability across a wide range of temperatures, preserving accuracy in various operating conditions.

4. Easy Modification: The soft nature of aluminum allows for easy on-site modifications, enabling fine-tuning of assemblies for maximum precision.

5. Cost-Effective: The combination of durability, low maintenance requirements, and recyclability makes aluminum extrusion mounting brackets a cost-effective choice for precision applications.

Innovations in Aluminum Extrusion Mounting Brackets

Ongoing innovations in the field of aluminum extrusion mounting brackets continue to push the boundaries of precision and accuracy. Some notable advancements include:

- Smart Brackets: Integration of sensors and IoT technology for real-time monitoring of structural integrity and alignment.

- 3D-Printed Customization: Utilization of additive manufacturing techniques to create highly specialized bracket designs for unique applications.

- Nano-Coatings: Development of advanced surface treatments to enhance grip and reduce wear, maintaining precision over extended periods.

- Composite Materials: Incorporation of carbon fiber or other high-performance materials to further improve strength-to-weight ratios and dimensional stability.

Best Practices for Maximizing Precision

To fully leverage the precision and accuracy offered by aluminum extrusion mounting brackets, consider the following best practices:

1. Proper Planning: Carefully design your assembly layout to optimize bracket placement for maximum stability and accuracy.

2. Use of Calibrated Tools: Employ precision tools and measuring devices during installation to ensure accurate alignment.

3. Regular Inspections: Conduct periodic checks to verify that brackets maintain their precise positioning over time.

4. Environmental Considerations: Account for thermal expansion and contraction in extreme environments to preserve accuracy.

5. Professional Installation: When possible, rely on experienced technicians familiar with aluminum extrusion systems for optimal results.

Case Studies: Precision in Action

Case Study 1: Aerospace Component Manufacturing

A leading aerospace manufacturer implemented aluminum extrusion mounting brackets in their satellite component assembly process. The result was a 30% reduction in alignment errors and a 25% decrease in assembly time, directly contributing to improved satellite performance and reliability.

Case Study 2: Automotive Production Line Upgrade

An automotive plant upgraded its assembly line using aluminum extrusion mounting brackets for robotic arm supports. This change led to a 15% increase in production accuracy and a 20% reduction in recalibration downtime, significantly improving overall efficiency.

Future Trends in Precision Mounting

As technology continues to advance, we can expect to see further improvements in the precision and accuracy offered by aluminum extrusion mounting brackets. Some potential future trends include:

- Integration of augmented reality for assisted assembly and alignment

- Development of self-adjusting brackets that automatically correct for minor misalignments

- Increased use of simulation and digital twin technology for optimizing bracket design and placement

- Exploration of new alloys and manufacturing techniques to push the boundaries of precision

Conclusion

Aluminum extrusion mounting brackets play a pivotal role in achieving precision and accuracy across a wide range of industries and applications. Their unique combination of strength, lightweight properties, and versatility makes them an ideal choice for projects where exact positioning and stability are crucial. As technology continues to evolve, these brackets will undoubtedly remain at the forefront of precision engineering, enabling innovations and advancements in fields ranging from aerospace to medical equipment manufacturing.

By understanding the capabilities and advantages of aluminum extrusion mounting brackets, engineers and designers can leverage these components to create more precise, efficient, and reliable systems. As we look to the future, the continued development and refinement of these brackets will undoubtedly lead to even greater levels of precision and accuracy, pushing the boundaries of what is possible in manufacturing and construction.

Frequently Asked Questions (FAQ)

1. What materials are commonly used for aluminum extrusion mounting brackets?

Aluminum extrusion mounting brackets are typically made from high-strength aluminum alloys such as 6061-T6 or 6063-T5. These alloys offer an excellent balance of strength, corrosion resistance, and machinability, making them ideal for precision applications.

2. How do aluminum extrusion mounting brackets compare to steel brackets in terms of precision?

Aluminum extrusion mounting brackets often provide superior precision compared to steel brackets due to their tighter manufacturing tolerances and resistance to warping. Additionally, their lightweight nature makes them easier to handle during installation, reducing the risk of misalignment.

3. Can aluminum extrusion mounting brackets be used in outdoor applications?

Yes, aluminum extrusion mounting brackets are well-suited for outdoor applications due to their natural corrosion resistance. Many brackets are also available with additional surface treatments or anodizing to further enhance their durability in harsh environments.

4. How do I ensure proper alignment when using aluminum extrusion mounting brackets?

To ensure proper alignment, use precision measuring tools during installation, follow manufacturer guidelines for torque specifications, and consider using alignment pins or other specialized accessories designed for your specific extrusion system.

5. Are there any limitations to the precision achievable with aluminum extrusion mounting brackets?

While aluminum extrusion mounting brackets offer high levels of precision, factors such as thermal expansion, load stress, and installation technique can affect overall accuracy. It's important to consider these factors in your design and follow best practices for installation and maintenance to achieve optimal results.

Citations:

[1] https://www.richardsonmetals.com/innovations-in-aluminum-extrusion-pioneering-precision-and-quality/

[2] https://www.tuli-shop.com/blog/aluminum-extrusion-brackets.html

[3] https://it.misumi-ec.com/files/images/products/docs/framingsupport.pdf

[4] https://www.youtube.com/watch?v=QhfbRTivxf0

[5] https://www.industrialprofile.com/aluminum-extrusion-joints-design-and-assembly-considerations/

[6] https://www.davantech.com/products-we-fabricate/aluminum-mounting-brackets-manufacturing/

[7] https://www.pailian-aluminium.com/news/zhonglian-advantages-of-aluminum-profile-sola-63237077.html

[8] https://anglelock.com/collections/components

[9] https://sinoextrud.com/importance-of-precision-in-aluminium-extrusion/