Content Menu

● Understanding Aluminum Extrusion

● The Design of Aluminum Extrusion Drawers

● Benefits of Aluminum Extrusion Drawers

>> 1. Space Optimization

>> 2. Enhanced Organization

>> 3. Customizable Layouts

>> 4. Improved Ergonomics

>> 5. Sustainability

● Practical Applications of Aluminum Extrusion Drawers

● Case Study: Aluminum Extrusion Drawers in Action

● Visualizing the Impact

● Installation Process

● Maintenance Tips

● User Testimonials

● Comparisons with Other Storage Solutions

● Additional Ergonomic Benefits

● Future Trends in Workspace Design

● Conclusion

● FAQ

>> 1. What are aluminum extrusion drawers made from?

>> 2. How do I install aluminum extrusion drawers?

>> 3. Are aluminum extrusion drawers customizable?

>> 4. Can these drawers be used outdoors?

>> 5. How do aluminum extrusion drawers improve ergonomics?

● Citations:

In today's fast-paced work environments, efficiency is paramount. One innovative solution that has gained traction across various industries is the use of aluminum extrusion drawers. These drawers not only optimize space but also enhance the overall functionality of workspaces. This article delves into how aluminum extrusion drawers contribute to workspace efficiency, exploring their design, benefits, and practical applications.

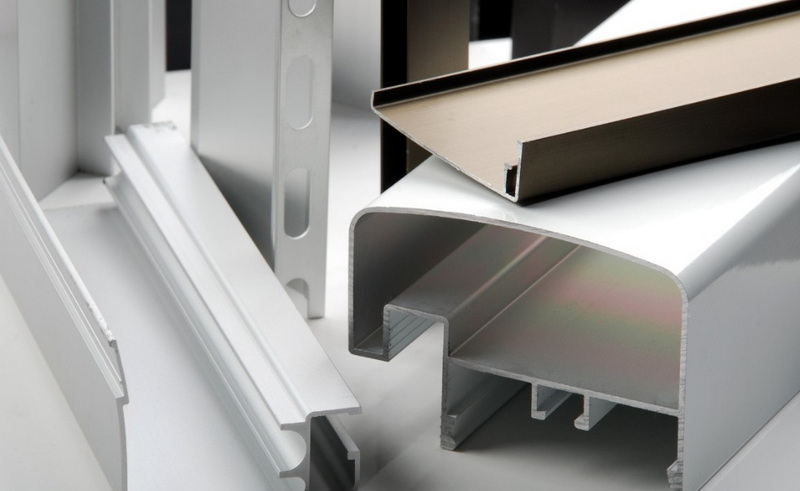

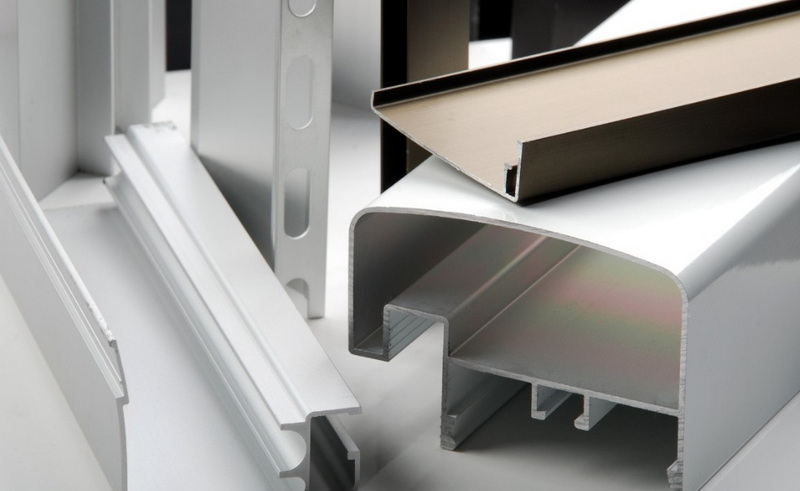

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This technique allows for the creation of complex shapes and profiles that are lightweight yet incredibly strong. The versatility of aluminum makes it an ideal material for a wide range of applications, including furniture and storage solutions.

The Design of Aluminum Extrusion Drawers

Aluminum extrusion drawers are designed with flexibility and adaptability in mind. Their modular nature allows them to be customized according to specific workspace needs. Key features include:

- Modular Construction: Drawers can be easily added or removed based on changing requirements.

- Lightweight yet Durable: The strength of aluminum ensures that these drawers can hold significant weight without compromising on mobility.

- Corrosion Resistance: Aluminum does not rust, making these drawers suitable for various environments, including humid or outdoor settings.

- Aesthetic Appeal: The sleek design of aluminum extrusion drawers adds a modern touch to any workspace, enhancing its visual appeal while maintaining functionality.

Benefits of Aluminum Extrusion Drawers

The integration of aluminum extrusion drawers into workspaces offers numerous advantages:

1. Space Optimization

One of the primary benefits of aluminum extrusion drawers is their ability to maximize available space. By utilizing vertical storage solutions, these drawers help keep work surfaces clear and organized. This is particularly beneficial in environments such as workshops or warehouses where space is often limited.

2. Enhanced Organization

Aluminum extrusion drawers can be configured to store a variety of tools and materials efficiently. By categorizing items within designated drawers, employees can quickly locate what they need, reducing time spent searching for tools or supplies. This organized approach minimizes clutter and enhances workflow efficiency.

3. Customizable Layouts

The modular nature of aluminum extrusion allows for easy reconfiguration. As workflow changes or new tools are introduced, the layout can be adjusted without significant investment or effort. This adaptability ensures that workspaces remain efficient and relevant to current needs.

4. Improved Ergonomics

Aluminum extrusion drawers can be designed to suit ergonomic standards, promoting better posture and reducing strain on workers. Adjustable heights and easy access to stored items contribute to a more comfortable working environment. Ergonomically designed drawers can help prevent injuries related to repetitive motions or awkward reaching.

5. Sustainability

Aluminum is a highly recyclable material, making aluminum extrusion drawers an environmentally friendly choice. By opting for these sustainable solutions, companies can reduce their carbon footprint while maintaining high standards of efficiency.

Practical Applications of Aluminum Extrusion Drawers

Aluminum extrusion drawers find applications in various industries:

- Manufacturing: In factories, these drawers can hold tools and components, streamlining assembly lines.

- Offices: In office environments, they serve as filing systems for documents and supplies, promoting organization.

- Workshops: Craftsmen utilize these drawers for tool storage, ensuring quick access during projects.

- Retail: Retailers implement aluminum extrusion drawers in display units to showcase products while keeping them organized.

- Laboratories: In labs, these drawers are used to store equipment and materials securely while ensuring easy access when needed.

Case Study: Aluminum Extrusion Drawers in Action

Consider a manufacturing facility that implemented aluminum extrusion drawers in its assembly line. Before the change, workers spent considerable time searching for tools scattered across the workspace. After installing modular aluminum drawers:

- Time Efficiency: Workers reported a 30% reduction in time spent searching for tools.

- Increased Productivity: With organized storage, assembly times improved significantly as workers could access necessary tools swiftly.

- Employee Satisfaction: A more organized workspace led to higher employee morale and reduced frustration levels.

This case highlights how effective storage solutions can lead to tangible improvements in productivity and worker satisfaction.

Visualizing the Impact

To fully appreciate the benefits of aluminum extrusion drawers, consider incorporating visuals such as diagrams showing drawer configurations or photos of organized workspaces utilizing these systems. Videos demonstrating the installation process or showcasing real-life applications can also enhance understanding.

Installation Process

Installing aluminum extrusion drawers is straightforward but requires careful planning to maximize their benefits:

1. Assess Workspace Needs: Determine what items will be stored and how frequently they need to be accessed.

2. Select Drawer Sizes: Choose appropriate sizes based on the items being stored—larger items may require deeper or wider drawers.

3. Mounting Hardware: Ensure you have all necessary mounting hardware ready before installation.

4. Installation Steps:

- Attach drawer slides to the chosen frame.

- Securely mount the frame to your workspace (workbench or wall).

- Insert the drawers into the slides and test for smooth operation.

5. Organize Contents: Place items into the drawers systematically for easy retrieval.

By following these steps, businesses can ensure their aluminum extrusion drawer systems are set up efficiently from the start.

Maintenance Tips

To keep aluminum extrusion drawers functioning optimally over time:

- Regular Cleaning: Dust and debris can accumulate; regular cleaning will maintain appearance and functionality.

- Check Hardware: Periodically check screws and slides for wear or loosening; tighten as necessary.

- Lubrication: Apply lubricant on slides if they become stiff over time to ensure smooth operation.

By implementing these maintenance practices, companies can prolong the lifespan of their storage solutions.

User Testimonials

Real-world testimonials from users highlight the transformative impact of aluminum extrusion drawer systems:

- *“Since we installed our new drawer system in our workshop, I've noticed a significant drop in time wasted looking for tools,”* says John Smith, a workshop manager at a local manufacturing firm. *“Our team works faster now because everything has its place.”*

- *“The modularity is fantastic,”* shares Lisa Chen from an architectural firm using these systems in their office spaces. *“We can easily adjust our setups as projects change without needing new furniture.”*

Comparisons with Other Storage Solutions

When comparing aluminum extrusion drawers with traditional wooden cabinets or plastic bins:

| Feature | Aluminum Extrusion Drawers | Wooden Cabinets | Plastic Bins |

| Durability | High | Moderate | Low |

| Customization | High | Low | Moderate |

| Weight | Lightweight | Heavy | Lightweight |

| Aesthetic Appeal | Modern | Classic | Basic |

| Corrosion Resistance | Yes | No | No |

This comparison illustrates how aluminum extrusion offers superior durability and customization options compared to traditional materials while maintaining aesthetic appeal.

Additional Ergonomic Benefits

Research indicates that ergonomically designed workspaces contribute significantly to employee health outcomes:

- A study published by the National Institute for Occupational Safety and Health (NIOSH) found that workplaces emphasizing ergonomic designs saw a 25% reduction in musculoskeletal disorders among employees over three years.

- By allowing workers easier access through adjustable heights tailored specifically for individual users' needs—aluminum extrusion drawer systems help minimize strain injuries associated with repetitive lifting or awkward reaching motions common in traditional setups.

Future Trends in Workspace Design

As workplace dynamics evolve towards more flexible arrangements post-pandemic—design trends indicate an increasing reliance on modular furniture solutions like those offered by aluminum extrusions:

- *Smart Storage Solutions*: Integration with technology such as RFID tracking systems could further enhance organization by providing real-time inventory management capabilities within these drawer systems.

- *Sustainable Materials*: As sustainability continues gaining importance across industries—future iterations may incorporate recycled materials alongside traditional alloys enhancing environmental responsibility without sacrificing performance quality.

By embracing these trends early on—companies position themselves favorably within competitive markets while enhancing operational efficiencies through innovative design approaches like those seen with modern-day aluminum extrusions!

Conclusion

Aluminum extrusion drawers represent a significant advancement in workspace efficiency. Their customizable designs allow businesses to adapt quickly to changing needs while promoting organization and ergonomics. As industries continue to evolve, integrating innovative storage solutions like aluminum extrusion drawers will be crucial in maintaining productivity and employee satisfaction.

FAQ

1. What are aluminum extrusion drawers made from?

Aluminum extrusion drawers are primarily made from extruded aluminum profiles which provide strength while being lightweight and corrosion-resistant.

2. How do I install aluminum extrusion drawers?

Installation typically involves mounting drawer slides onto pre-fabricated aluminum frames, which can be adjusted according to your workspace needs.

3. Are aluminum extrusion drawers customizable?

Yes! One of the key benefits is their modular design which allows for easy customization based on specific requirements and available space.

4. Can these drawers be used outdoors?

Absolutely! Aluminum's corrosion resistance makes these drawers suitable for both indoor and outdoor environments.

5. How do aluminum extrusion drawers improve ergonomics?

Citations:

[1] https://flowstore.com/understand-aluminium-extrusion-modern-manufacturing/

[2] https://www.assemblymag.com/articles/95577-how-to-enhance-your-aluminum-extrusion-workstation-ergonomically

[3] https://www.youtube.com/watch?v=-ruIsv6D8Bg

[4] https://orangealuminum.com/shop-by-shape/pulls-and-handles/

[5] https://www.youtube.com/watch?v=GR1VQAgntxQ

[6] https://www.yjing-extrusion.com/what-is-the-best-aluminum-extrusion-cart-for-your-workshop.html

[7] https://www.alineautomation.com/everything-you-need-to-know-about-warehouse-workstations/

[8] https://blog.okorder.com/the-benefits-of-aluminum-extrusion-for-building-profiles/