Content Menu

● Introduction to Extrusion Blow Molding

>> Process Overview

● Ensuring Quality in 1000L Automatic Extrusion Blow Molding Machines

>> 1. Machine Design and Construction

>> 2. Material Selection

>> 3. Quality Control Measures

>> 4. Training and Expertise

>> 5. Certifications and Compliance

● Advanced Technologies in Extrusion Blow Molding

>> 1. Digitalization and IoT Integration

>> 2. Sustainable Practices

>> 3. Customization and Flexibility

● Market Trends and Future Developments

● Additional Technologies and Trends

>> 1. 3D Printing in Mold Design

>> 2. Robotics in Production

>> 3. Digital Twins

>> 4. Artificial Intelligence (AI) Integration

>> 5. Supply Chain Optimization

● Case Studies: Successful Implementations

● Conclusion

● FAQs

>> 1. What is the typical cost range for a 1000L automatic extrusion blow molding machine?

>> 2. What types of plastic materials are commonly used in extrusion blow molding?

>> 3. How do manufacturers ensure sustainability in their production processes?

>> 4. What certifications are important for ensuring quality in extrusion blow molding machines?

>> 5. What training is necessary for personnel operating extrusion blow molding machines?

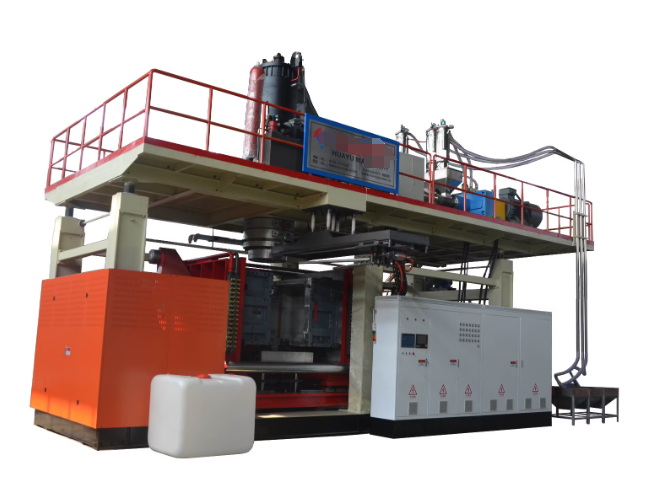

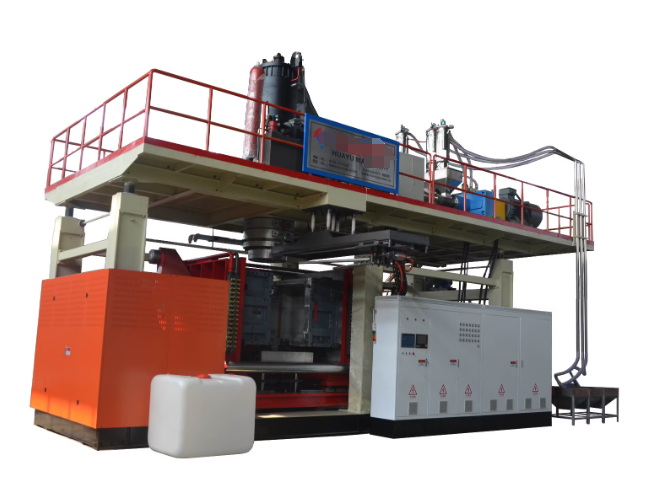

Ensuring quality in the production of 1000L automatic extrusion blow molding machines is crucial for manufacturers. These machines are used to produce large containers, such as water storage tanks and drums, which require precision and durability. In this article, we will explore the methods and technologies used by 1000L automatic extrusion blow molding machine manufacturers to ensure the quality of their products.

Introduction to Extrusion Blow Molding

Extrusion blow molding is a manufacturing process used to create hollow plastic containers. It involves melting plastic pellets, extruding them into a tube-like shape called a parison, and then inflating the parison inside a mold to form the desired shape. This process is widely used for producing bottles, jerry cans, and large storage containers.

Process Overview

1. Extrusion: Plastic pellets are melted in an extruder and formed into a parison.

2. Molding: The parison is placed inside a mold, and compressed air is used to inflate it, shaping it to the mold's contours.

3. Cooling and Trimming: The plastic cools and solidifies, and excess material is trimmed from the top and bottom.

Ensuring Quality in 1000L Automatic Extrusion Blow Molding Machines

To ensure quality, 1000L automatic extrusion blow molding machine manufacturers focus on several key areas:

1. Machine Design and Construction

- Precision Engineering: Machines are designed with precision to ensure consistent production quality. This includes using high-quality materials and components.

- Automation: Fully automated systems help minimize human error and ensure uniformity in production.

2. Material Selection

- Quality of Plastic: The choice of plastic material is critical. Manufacturers ensure that the plastic used is of high quality and suitable for the intended application.

- Recycled Materials: Some manufacturers incorporate post-consumer recycled materials to enhance sustainability while maintaining quality.

3. Quality Control Measures

- Inspection: Regular inspections are conducted at various stages of production to detect any defects or inconsistencies.

- Testing: Finished products undergo rigorous testing to ensure they meet the required standards. This includes tests for strength, durability, and leakage.

4. Training and Expertise

- Skilled Workforce: Manufacturers invest in training their personnel to ensure they have the necessary skills to operate and maintain the machines effectively.

- Continuous Improvement: Regular training programs help in adopting new technologies and improving production processes.

5. Certifications and Compliance

- ISO Certifications: Many manufacturers hold ISO certifications, such as ISO 9001, which ensure adherence to international quality standards.

- Regulatory Compliance: Compliance with local and international regulations is maintained to ensure safety and environmental responsibility.

Advanced Technologies in Extrusion Blow Molding

1. Digitalization and IoT Integration

- Real-time Monitoring: Modern machines often integrate IoT technologies, allowing for real-time monitoring of production processes. This helps in identifying and addressing issues promptly.

- Data Analytics: Data collected from sensors and monitoring systems can be analyzed to optimize production efficiency and quality.

2. Sustainable Practices

- Energy Efficiency: Manufacturers focus on developing energy-efficient machines to reduce operational costs and environmental impact.

- Recycling Initiatives: Encouraging the use of recycled materials and promoting recycling practices within the industry.

3. Customization and Flexibility

- Modular Design: Machines are designed with modular components, allowing for easier customization and upgrade.

- Versatility: Manufacturers offer machines that can produce a variety of container sizes and shapes, catering to diverse customer needs.

Market Trends and Future Developments

The market for extrusion blow molding machines is evolving rapidly, driven by technological advancements and changing consumer demands. Key trends include:

- Increased Use of Recycled Materials: There is a growing emphasis on sustainability, with manufacturers incorporating more recycled materials into their products.

- Advancements in Automation: Further automation and integration of AI in production processes are expected to enhance efficiency and quality.

Additional Technologies and Trends

1. 3D Printing in Mold Design

- Customization: 3D printing allows for the rapid creation of custom molds, enabling manufacturers to quickly adapt to changing product designs.

- Precision: It offers high precision in mold design, which can improve the quality of the final product.

2. Robotics in Production

- Efficiency: Robots can automate tasks such as handling and inspection, increasing production efficiency and reducing labor costs.

- Consistency: They ensure consistent quality by performing repetitive tasks with precision.

3. Digital Twins

- Simulation: Digital twins allow manufacturers to simulate production processes and predict potential issues before they occur.

- Optimization: This technology helps optimize production settings for better efficiency and quality.

4. Artificial Intelligence (AI) Integration

- Predictive Maintenance: AI can predict when maintenance is needed, reducing downtime and improving overall efficiency.

- Quality Prediction: AI algorithms can analyze production data to predict potential quality issues, allowing for proactive measures.

5. Supply Chain Optimization

- Logistics Management: Manufacturers use advanced logistics systems to ensure timely delivery of raw materials and finished products.

- Inventory Management: Effective inventory management helps maintain a steady supply of components and materials.

By incorporating these advanced technologies and trends, 1000L automatic extrusion blow molding machine manufacturers can further enhance the quality and efficiency of their production processes.

Case Studies: Successful Implementations

Several manufacturers have successfully implemented these strategies to improve quality and efficiency:

- Case Study 1: A leading manufacturer in Europe integrated IoT sensors to monitor production in real-time, resulting in a 20% reduction in defects.

- Case Study 2: A company in Asia adopted 3D printing for mold design, reducing production time by 30% and improving product customization.

Conclusion

Ensuring quality in 1000L automatic extrusion blow molding machines involves a combination of precise machine design, high-quality materials, rigorous quality control, skilled personnel, and adherence to international standards. By focusing on these areas and embracing technological advancements, manufacturers can produce reliable and durable large containers that meet the needs of various industries.

FAQs

1. What is the typical cost range for a 1000L automatic extrusion blow molding machine?

The cost of a 1000L automatic extrusion blow molding machine can vary significantly based on the manufacturer and specifications but generally falls within the range of $90,000 to $120,000 per set.

2. What types of plastic materials are commonly used in extrusion blow molding?

Commonly used plastic materials include HDPE (High-Density Polyethylene), PE (Polyethylene), and PP (Polypropylene), depending on the intended application and required properties.

3. How do manufacturers ensure sustainability in their production processes?

Manufacturers often incorporate post-consumer recycled materials into their production processes to enhance sustainability while maintaining product quality.

4. What certifications are important for ensuring quality in extrusion blow molding machines?

Certifications such as ISO 9001 are crucial as they ensure adherence to international quality management standards.

5. What training is necessary for personnel operating extrusion blow molding machines?

Personnel should undergo comprehensive training to understand the basics of extrusion blow molding technology, machine operation, and problem-solving techniques.