Content Menu

● Introduction

● What Is Aluminum Extrusion?

● Benefits of Using Custom Aluminum Extrusions

>> Design Flexibility and Customization Options

>> Cost-Effectiveness and Efficiency in Manufacturing

>> Lightweight Yet Strong Properties of Aluminum

● The Aluminum Extrusion Process

>> Step 1: Material Preparation

>> Step 2: Extrusion

>> Step 3: Cooling

>> Step 4: Cutting and Finishing

>> Key Equipment and Technology Used

>> Quality Control Measures in Place

● Common Applications of Aluminum Extrusions

>> Construction

>> Automotive

>> Electronics

>> Transportation

● Choosing the Right Aluminum Extrusion Profile

>> Strength

>> Weight

>> Design Requirements

● Finding Aluminum Extrusion Suppliers Near You

>> Online Research

>> Industry Directories

>> Networking

>> Requesting Quotes

>> Evaluating Supplier Capabilities

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusions in construction?

>> 2. How do I determine the right aluminum alloy for my extrusion project?

>> 3. What is the typical lead time for aluminum extrusion orders?

>> 4. Can I get custom aluminum extrusion profiles made?

>> 5. What industries commonly use aluminum extrusions?

Introduction

Aluminum extrusion is a vital manufacturing process that shapes aluminum into various profiles and components used in numerous industries. As businesses increasingly seek lightweight yet durable materials, aluminum has become a preferred choice. However, finding reliable aluminum extrusion suppliers nearby can be challenging. This article will explore the benefits of aluminum extrusion, the process involved, and how to locate trustworthy suppliers in your area.

What Is Aluminum Extrusion?

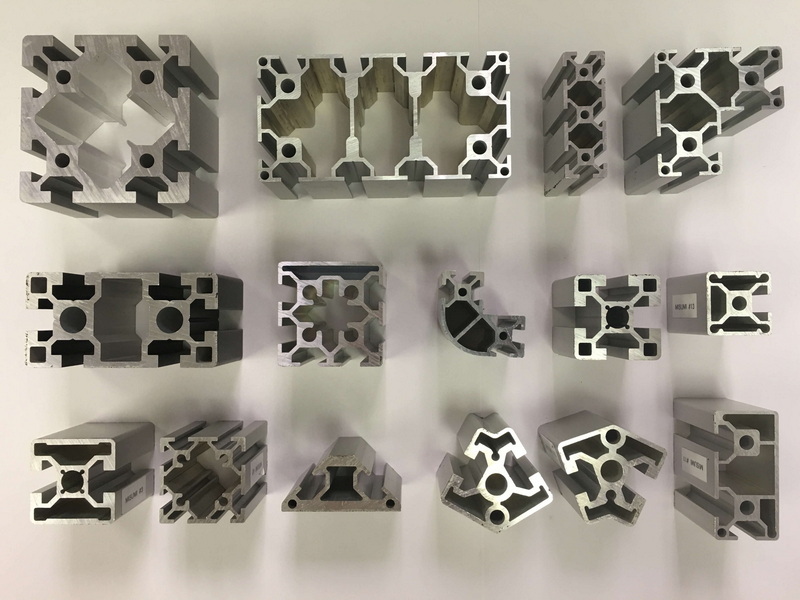

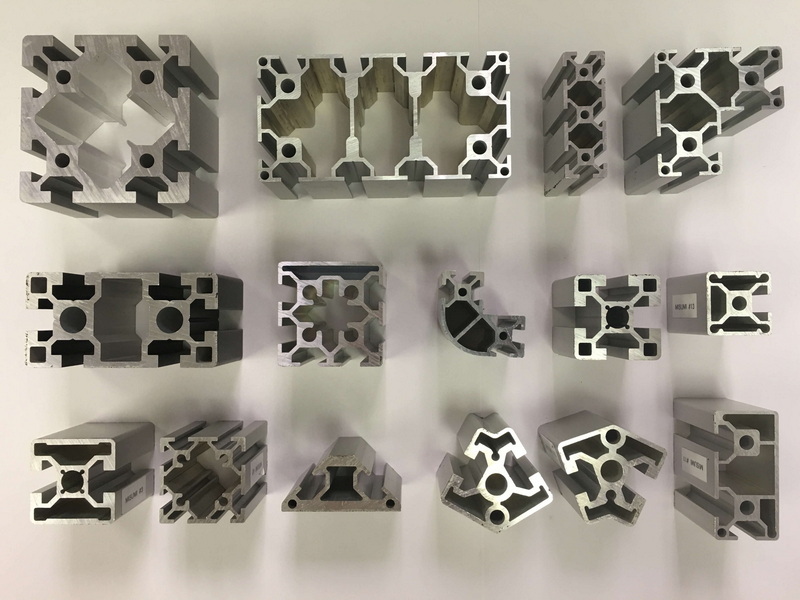

Aluminum extrusion is a manufacturing process that involves forcing aluminum alloy through a die to create a specific cross-sectional shape. This method allows for the production of complex shapes that are lightweight yet strong, making aluminum extrusions ideal for various applications, from construction to automotive parts.

The history of aluminum extrusion dates back to the early 20th century when it was first developed in Europe. Since then, advancements in technology have improved the efficiency and precision of the extrusion process, making it a staple in modern manufacturing.

Benefits of Using Custom Aluminum Extrusions

Custom aluminum extrusions offer numerous advantages that make them an attractive option for manufacturers and designers alike.

Design Flexibility and Customization Options

One of the most significant benefits of aluminum extrusion is its design flexibility. Manufacturers can create custom profiles tailored to specific project requirements. This customization allows for unique designs that can enhance the functionality and aesthetics of a product.

Cost-Effectiveness and Efficiency in Manufacturing

Aluminum extrusion is a cost-effective manufacturing method. The process allows for the production of large quantities of parts with minimal waste, reducing overall material costs. Additionally, the speed of the extrusion process means that manufacturers can meet tight deadlines without sacrificing quality.

Lightweight Yet Strong Properties of Aluminum

Aluminum is known for its lightweight properties, making it an ideal material for applications where weight is a concern. Despite its lightness, aluminum is incredibly strong and durable, providing excellent structural integrity. This combination of properties makes aluminum extrusions suitable for various industries, including aerospace, automotive, and construction.

The Aluminum Extrusion Process

Understanding the aluminum extrusion process is essential for anyone looking to utilize this manufacturing method. The process involves several key steps:

Step 1: Material Preparation

The process begins with the selection of the appropriate aluminum alloy. The chosen alloy is then heated to a specific temperature to make it malleable.

Step 2: Extrusion

Once the aluminum is prepared, it is placed in an extrusion press. A ram pushes the heated aluminum through a die, shaping it into the desired profile. This step is crucial, as the die determines the final shape of the extrusion.

Step 3: Cooling

After the aluminum has been extruded, it is cooled to solidify the shape. This cooling process can be done using air or water, depending on the specific requirements of the extrusion.

Step 4: Cutting and Finishing

Once cooled, the extruded aluminum is cut to the desired length. Additional finishing processes, such as anodizing or painting, can be applied to enhance the appearance and corrosion resistance of the aluminum.

Key Equipment and Technology Used

Modern aluminum extrusion facilities utilize advanced equipment and technology to ensure precision and efficiency. Extrusion presses, dies, and cooling systems are designed to optimize the process and produce high-quality extrusions.

Quality Control Measures in Place

Quality control is a critical aspect of the aluminum extrusion process. Manufacturers implement rigorous testing and inspection procedures to ensure that the extrusions meet industry standards and customer specifications.

Common Applications of Aluminum Extrusions

Aluminum extrusions are used in a wide range of applications across various industries. Some common uses include:

Construction

In the construction industry, aluminum extrusions are used for window frames, curtain walls, and structural components. Their lightweight nature and resistance to corrosion make them ideal for building applications.

Automotive

The automotive industry utilizes aluminum extrusions for various components, including chassis, bumpers, and heat exchangers. The lightweight properties of aluminum help improve fuel efficiency and reduce emissions.

Electronics

Aluminum extrusions are also prevalent in the electronics industry, where they are used for heat sinks, enclosures, and structural supports. The excellent thermal conductivity of aluminum makes it an ideal choice for managing heat in electronic devices.

Transportation

In transportation, aluminum extrusions are used in railings, trailers, and other structural components. Their strength-to-weight ratio is crucial for enhancing performance and safety.

Choosing the Right Aluminum Extrusion Profile

Selecting the right aluminum extrusion profile is essential for ensuring that the final product meets the desired specifications. Here are some factors to consider:

Strength

Consider the strength requirements of your application. Different aluminum alloys offer varying levels of strength, so it's essential to choose an alloy that meets your needs.

Weight

The weight of the extrusion can significantly impact the overall performance of the product. Ensure that the chosen profile is lightweight yet strong enough for its intended use.

Design Requirements

Work closely with your supplier to ensure that the extrusion profile aligns with your design requirements. Custom profiles can be created to meet specific dimensions and shapes.

Finding Aluminum Extrusion Suppliers Near You

Locating reliable aluminum extrusion suppliers nearby is crucial for ensuring timely delivery and quality products. Here are some tips for finding the right suppliers:

Online Research

Start by conducting online research to identify aluminum extrusion suppliers in your area. Use search terms like "aluminum extrusion nearby" or "aluminum extrusion suppliers near me" to find local options.

Industry Directories

Utilize industry directories and trade associations to find reputable suppliers. These resources often provide lists of certified manufacturers and suppliers in the aluminum extrusion industry.

Networking

Networking with industry professionals can also help you find reliable suppliers. Attend trade shows, conferences, and industry events to connect with potential suppliers and gather recommendations.

Requesting Quotes

Once you have identified potential suppliers, request quotes to compare pricing and services. Be sure to provide detailed specifications for your project to receive accurate quotes.

Evaluating Supplier Capabilities

Before making a decision, evaluate the capabilities of each supplier. Consider factors such as production capacity, lead times, and quality control measures. A reliable supplier should be able to meet your project requirements and deadlines.

Conclusion

Finding reliable aluminum extrusion suppliers nearby is essential for businesses looking to utilize aluminum in their projects. By understanding the benefits of aluminum extrusion, the manufacturing process, and how to choose the right suppliers, you can ensure that your projects are successful. With the right supplier, you can access high-quality aluminum extrusions tailored to your specific needs, enhancing the performance and aesthetics of your products.

Related Questions

1. What are the advantages of using aluminum extrusions in construction?

Aluminum extrusions offer lightweight, corrosion resistance, and design flexibility, making them ideal for various construction applications.

2. How do I determine the right aluminum alloy for my extrusion project?

Consider the strength, weight, and corrosion resistance requirements of your project to select the appropriate aluminum alloy.

3. What is the typical lead time for aluminum extrusion orders?

Lead times can vary based on the supplier and complexity of the order, but typical lead times range from a few weeks to several months.

4. Can I get custom aluminum extrusion profiles made?

Yes, many suppliers offer custom aluminum extrusion profiles tailored to specific project requirements.

5. What industries commonly use aluminum extrusions?

Aluminum extrusions are widely used in construction, automotive, electronics, and transportation industries due to their lightweight and durable properties.