Content Menu

● Introduction

● Understanding the Basics of Aluminum Extrusion

>> Types of Aluminum Extrusion

>> Aluminum Alloys Used in Extrusion

● The Aluminum Extrusion Process

>> Billet Preparation

>> Die Design and Preparation

● Advanced Extrusion Techniques

>> Multi-Hole Dies

>> Hollow Extrusions

● Quality Control in Aluminum Extrusion

>> Troubleshooting Common Extrusion Defects

● Post-Extrusion Processing

>> Heat Treatment

>> Surface Finishing

● Sustainability in Aluminum Extrusion

● Industry Applications

● Safety Considerations

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What are the main types of aluminum extrusion processes?

>> 2. How does heat treatment affect extruded aluminum profiles?

>> 3. What are the key factors in designing an efficient extrusion die?

>> 4. How can sustainability be improved in the aluminum extrusion process?

>> 5.What are the latest technological advancements in aluminum extrusion?

● Citations:

Introduction

Aluminum extrusion is a versatile manufacturing process that transforms aluminum alloy into complex shapes with consistent cross-sections. Learning this technique from a comprehensive aluminum extrusion manual can provide invaluable knowledge for engineers, designers, and manufacturers. This article will explore the key aspects of aluminum extrusion, highlighting the importance of a detailed manual in mastering this process.

Understanding the Basics of Aluminum Extrusion

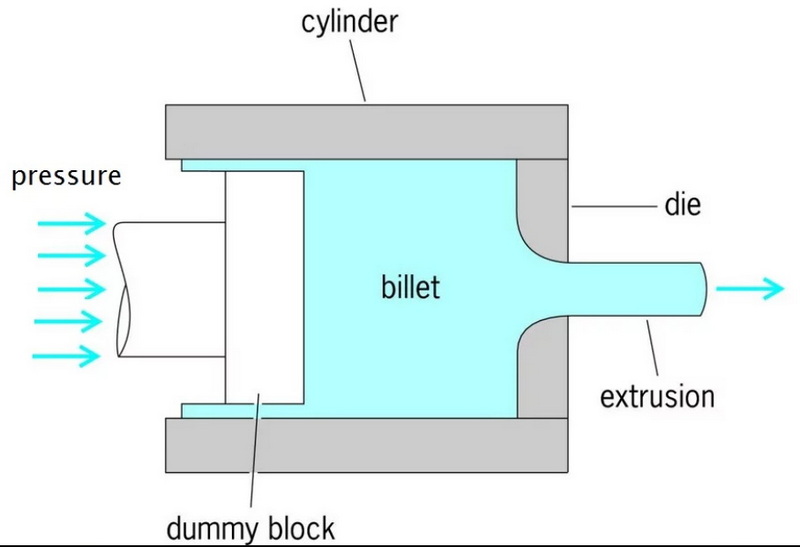

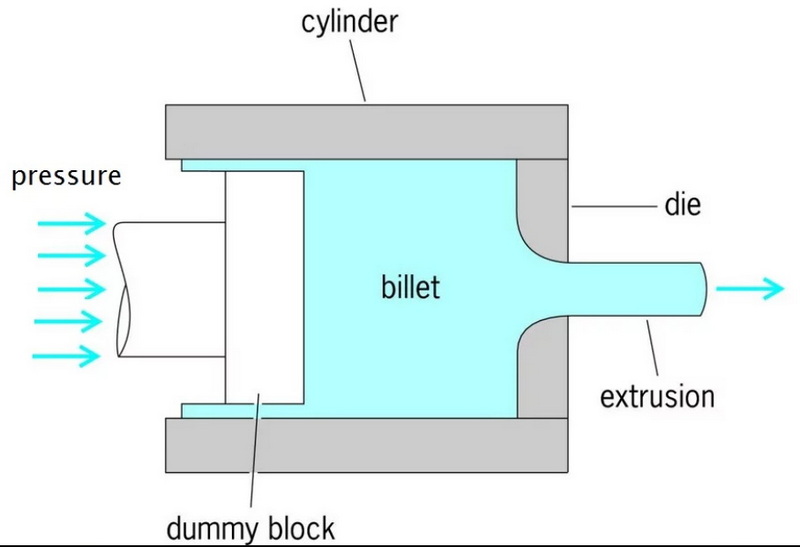

Aluminum extrusion involves forcing heated aluminum billets through a die with a specific cross-sectional profile. This process creates long, straight aluminum products with uniform cross-sections. A comprehensive aluminum extrusion manual typically covers the following fundamental aspects:

Types of Aluminum Extrusion

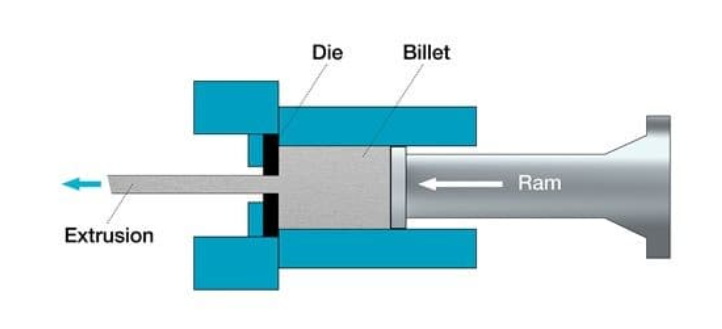

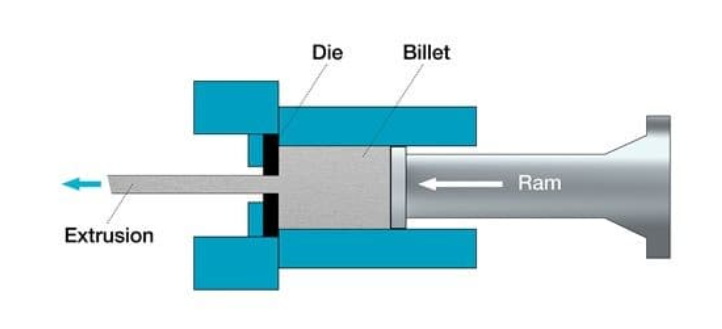

1. Direct Extrusion

2. Indirect Extrusion

3. Hydrostatic Extrusion

Aluminum Alloys Used in Extrusion

A good aluminum extrusion manual will provide detailed information on various aluminum alloys suitable for extrusion, including:

- 6xxx series (6061, 6063)

- 7xxx series (7075)

- 2xxx series (2024)

The Aluminum Extrusion Process

A comprehensive manual breaks down the extrusion process into several key steps:

1. Billet preparation

2. Die design and preparation

3. Billet heating

4. Extrusion

5. Cooling and quenching

6. Stretching

7. Heat treatment

8. Finishing

Billet Preparation

The manual should explain how to select and prepare aluminum billets for extrusion, including:

- Proper sizing

- Surface cleaning

- Preheating techniques

Die Design and Preparation

A crucial section of any aluminum extrusion manual covers die design:

- Die materials

- Profile considerations

- Die maintenance

Advanced Extrusion Techniques

As you progress through the aluminum extrusion manual, you'll encounter more advanced topics:

Multi-Hole Dies

Learn how to design and use multi-hole dies for increased productivity.

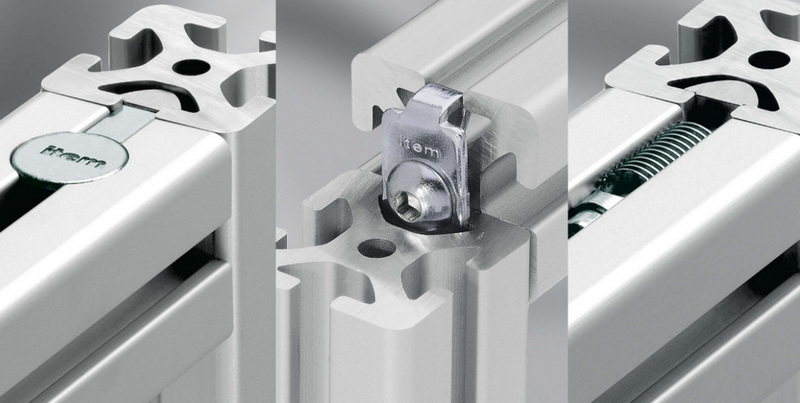

Hollow Extrusions

Understand the complexities of creating hollow profiles using specialized dies and mandrels.

Quality Control in Aluminum Extrusion

A comprehensive aluminum extrusion manual should dedicate a significant portion to quality control measures:

- Dimensional accuracy

- Surface finish

- Mechanical properties testing

Troubleshooting Common Extrusion Defects

Learn to identify and resolve issues such as:

- Surface defects

- Dimensional inaccuracies

- Structural weaknesses

Post-Extrusion Processing

The manual should cover various post-extrusion treatments:

Heat Treatment

Understand the importance of heat treatment in achieving desired mechanical properties.

Surface Finishing

Learn about anodizing, powder coating, and other surface treatments.

Sustainability in Aluminum Extrusion

A modern aluminum extrusion manual should address sustainability concerns:

- Energy-efficient extrusion techniques

- Recycling of aluminum scrap

- Reducing environmental impact

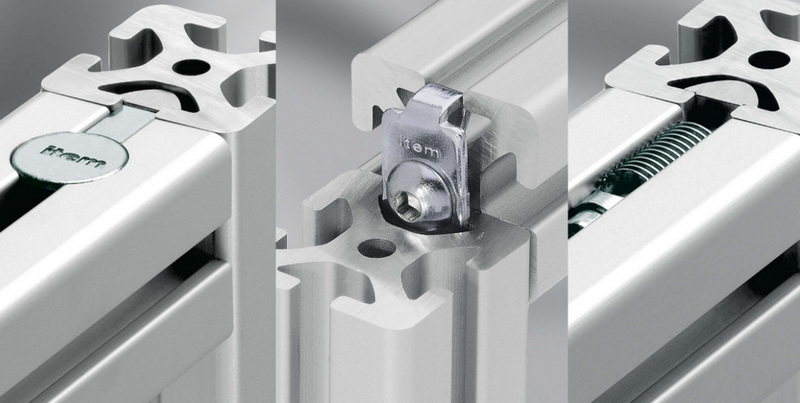

Industry Applications

Explore the diverse applications of aluminum extrusions in various industries:

- Construction

- Automotive

- Aerospace

- Consumer goods

Safety Considerations

A comprehensive aluminum extrusion manual must emphasize safety:

- Personal protective equipment

- Machine safety protocols

- Handling of hot materials

Future Trends in Aluminum Extrusion

Stay updated on emerging technologies and trends:

- 3D printing in die manufacturing

- Advanced alloy development

- Automation in extrusion processes

Conclusion

A comprehensive aluminum extrusion manual is an invaluable resource for anyone looking to master this versatile manufacturing technique. By covering everything from basic principles to advanced techniques, quality control, and industry applications, such a manual provides a solid foundation for success in aluminum extrusion. As the industry continues to evolve, staying updated with the latest information and techniques through regularly updated manuals is crucial for maintaining a competitive edge in the field of aluminum extrusion.

FAQ

1. What are the main types of aluminum extrusion processes?

The main types of aluminum extrusion processes are direct extrusion, indirect extrusion, and hydrostatic extrusion. Direct extrusion is the most common method, where the billet is pushed through a stationary die. Indirect extrusion involves a moving container and stationary ram, while hydrostatic extrusion uses a fluid medium to apply pressure to the billet.

2. How does heat treatment affect extruded aluminum profiles?

Heat treatment significantly influences the mechanical properties of extruded aluminum profiles. It can increase strength, improve ductility, and enhance corrosion resistance. Common heat treatments include solution heat treatment, quenching, and aging, which are often specified in aluminum extrusion manuals to achieve desired material characteristics.

3. What are the key factors in designing an efficient extrusion die?

Efficient extrusion die design involves considering factors such as material flow, die land length, bearing surface, and pocket design. A well-designed die, as outlined in comprehensive aluminum extrusion manuals, ensures uniform material flow, reduces extrusion pressure, and improves surface finish quality of the extruded profiles.

4. How can sustainability be improved in the aluminum extrusion process?

Sustainability in aluminum extrusion can be improved through various methods, including optimizing energy consumption during the extrusion process, implementing efficient recycling systems for aluminum scrap, and using advanced alloys that require lower extrusion temperatures. Many aluminum extrusion manuals now include sections on sustainable practices to guide manufacturers in reducing their environmental impact.

5.What are the latest technological advancements in aluminum extrusion?

Recent technological advancements in aluminum extrusion include the use of computer simulation for die design and process optimization, the development of high-strength aluminum alloys for specialized applications, and the integration of automation and robotics in extrusion lines. Advanced aluminum extrusion manuals often cover these innovations to keep industry professionals updated on the latest trends and technologies.

Citations:

[1] https://whatispiping.com/aluminum-extrusion/

[2] https://leadrp.net/blog/a-complete-guide-to-aluminum-extrusion/

[3] https://aec.org/aluminum-extrusion-manual

[4] https://www.alamy.com/stock-photo/aluminum-extrusion-manufacturing.html

[5] https://www.istockphoto.com/fr/photos/aluminum-extrusion

[6] https://www.youtube.com/watch?v=ELgtjeJyFw8

[7] https://waykenrm.com/blogs/aluminum-extrusion/

[8] https://www.atieuno.com/2023/07/17/aluminium-extrusion-process-guide/

[9] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[10] https://www.easiahome.com/aluminum-extrusion-metal-extrusion-process/

[11] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[12] https://www.youtube.com/watch?v=vHkwq_2yY9E

[13] https://aec.org/faqs

[14] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions