Content Menu

● What Is Extrusion Downstream Equipment?

>> Key Functions of Downstream Equipment

● Why Choose Goodman Extrusion Downstream Equipment?

>> Industry Leadership and Customization

>> Raising the Bar on Performance

● Components of Goodman Extrusion Downstream Equipment

>> 1. Rotary Cutters and Saws

>> 2. Pullers and Feeders

>> 3. Cooling Tanks and Calibration Tables

>> 4. Winders, Unwinders, and Coilers

>> 5. Conveyors and Haul-Offs

>> 6. Inspection and Quality Control Equipment

● How Goodman Extrusion Downstream Equipment Enhances Production

>> 1. Increased Productivity and Throughput

>> 2. Superior Accuracy and Consistency

>> 3. Customization for Unique Applications

>> 4. Reduced Downtime and Maintenance

>> 5. Improved Return on Investment (ROI)

● Application Areas: Where Goodman Equipment Excels

>> Plastics Manufacturing

>> Metalworking

>> Rubber and Specialty Products

● Customization: The Key to Optimized Production

>> Why Customization Matters

>> How Goodman Achieves Customization

● Quality Assurance and Compliance

>> Integrated Inspection and Testing

>> Traceability and Branding

● Case Study: Goodman's Impact in a Modern Production Line

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What types of products can Goodman extrusion downstream equipment handle?

>> 2. How customizable is Goodman's downstream equipment for unique production needs?

>> 3. What are the maintenance requirements for Goodman extrusion downstream equipment?

>> 4. Can Goodman's equipment be integrated with existing extrusion lines?

>> 5. How does Goodman ensure product quality and compliance with industry standards?

● Citations:

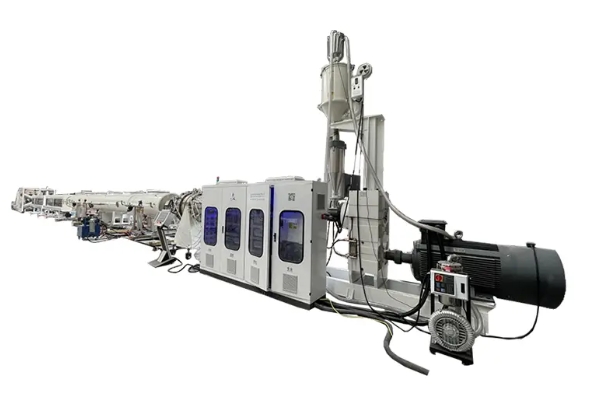

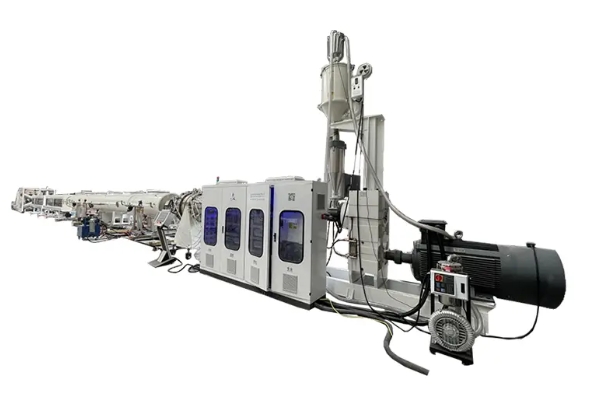

In today's manufacturing landscape, efficiency, accuracy, and customization are vital for maintaining a competitive edge. Nowhere is this more evident than in extrusion processes for plastics, metals, and rubber, where the quality and consistency of finished products depend not only on the extruder itself but also on the sophistication of downstream equipment. Goodman extrusion downstream equipment stands out as a leader in this field, offering a broad spectrum of machinery and integrated systems designed to elevate production lines to new heights of productivity and quality[1][5].

This comprehensive guide explores how Goodman extrusion downstream equipment can transform your production line, with a focus on its features, customization options, performance benefits, and application-specific solutions. We'll also address common questions about Goodman's offerings and the broader role of downstream equipment in extrusion manufacturing.

What Is Extrusion Downstream Equipment?

Extrusion downstream equipment refers to the array of machines and systems that process, finish, and inspect extruded products after they leave the extruder. These components are essential for cooling, cutting, pulling, winding, embossing, and quality control, ensuring that the final product meets precise specifications and industry standards[2][6].

Key Functions of Downstream Equipment

- Cooling: Solidifies and stabilizes the extruded product's shape and properties.

- Pulling: Maintains consistent product flow and dimensions.

- Cutting: Trims the product to exact lengths or shapes.

- Winding/Coiling: Collects extruded material for storage or transport.

- Inspection: Ensures compliance with quality standards and specifications[2][6].

Why Choose Goodman Extrusion Downstream Equipment?

Industry Leadership and Customization

Goodman extrusion downstream equipment is renowned for its wide selection, advanced technology, and exceptional customization. Goodman manufactures more models and types of downstream equipment than any other provider, allowing customers to tailor their production lines for speed, accuracy, uptime, and cost-effectiveness[1][5].

Key Advantages:

- Unmatched Selection: Goodman offers rotary cutters (servo, vacuum, electromagnetic, pneumatic, hydraulic), pullers, feeders, cooling tanks, saws, conveyors, vacuum sizing, winders, and more[1][5].

- Customization: Each machine can be customized during assembly to meet unique application requirements—without sacrificing standard pricing or lead times[1].

- Integrated Systems: Goodman's solutions are designed for seamless integration, improving overall line efficiency and reducing operational bottlenecks[1].

Raising the Bar on Performance

Goodman has a track record of innovation, exemplified by its exclusive Vac-Q-Torq vacuum clutch/brake actuated rotary cutter, which set new standards for cut length accuracy and speed. Features like real-time wear monitoring and rapid maintenance minimize downtime and enhance reliability[1][3].

Components of Goodman Extrusion Downstream Equipment

1. Rotary Cutters and Saws

Goodman's rotary cutters come in several types, each with application-specific benefits:

- Servo Cutters: Deliver high accuracy and low maintenance due to the absence of friction surfaces. Ideal for precision applications[3].

- Vacuum Clutch/Brake Cutters: Offer repeatable accuracy and are unaffected by variations in plant air or electrical supply. Best for high-speed, high-tolerance environments[1][3].

- Electromagnetic, Pneumatic, and Hydraulic Cutters: Provide solutions for various budgets and technical requirements, balancing cost, accuracy, and maintenance needs[3].

2. Pullers and Feeders

Pullers ensure consistent product movement through the downstream line, maintaining uniform dimensions and preventing deformation. Goodman's pullers are engineered for reliability and adaptability to different product sizes and speeds[5][6].

3. Cooling Tanks and Calibration Tables

Cooling tanks rapidly solidify extruded products, preserving their shape and structural integrity. Goodman offers water baths, spray cooling, and vacuum calibration tables for precise temperature control and dimensional accuracy[5][7].

4. Winders, Unwinders, and Coilers

For flexible products, Goodman supplies winders and coilers that collect extruded material efficiently, with options for tension control and roll diameter adjustment to suit various materials and production volumes[5][6].

5. Conveyors and Haul-Offs

Conveyors and haul-offs transport products smoothly through each downstream stage, ensuring steady production flow and reducing the risk of damage or misalignment[5][7].

6. Inspection and Quality Control Equipment

Integrated inspection systems measure wall thickness, diameter, strength, and other properties, ensuring products meet industry standards and customer requirements. Automated testing and feedback loops allow for real-time adjustments[2][7].

How Goodman Extrusion Downstream Equipment Enhances Production

1. Increased Productivity and Throughput

- Automated Processes: Goodman's equipment automates critical downstream tasks, reducing manual intervention, speeding up production, and minimizing errors[1][4].

- High-Speed Operation: Advanced rotary cutters and pullers enable faster line speeds without sacrificing accuracy, boosting overall output[1][3].

2. Superior Accuracy and Consistency

- Precision Cutting: Goodman's servo and vacuum rotary cutters achieve tight tolerances, ensuring each product segment meets exact specifications[1][3].

- Consistent Cooling and Pulling: Controlled cooling and synchronized pullers maintain product uniformity, reducing defects and rework[6][7].

3. Customization for Unique Applications

- Flexible Configurations: Whether producing medical tubing, automotive parts, or building materials, Goodman's customizable equipment adapts to diverse product geometries, materials, and production goals[1][5][6].

- Accessory Integration: Add-on features and accessories—such as embossers, printers, or additional inspection modules—allow further tailoring of the production line[1][5].

4. Reduced Downtime and Maintenance

- Modular Design: Many Goodman machines feature modular components for easy replacement and upgrades, minimizing downtime during maintenance or changeovers[1].

- Predictive Maintenance: Features like wear monitoring on clutch/brake systems enable scheduled maintenance, preventing unexpected failures and production stoppages[1].

5. Improved Return on Investment (ROI)

- Energy Efficiency: Modern Goodman equipment is designed for low energy consumption, reducing operational costs[1].

- Longevity and Reliability: High-quality materials and robust engineering ensure long service life, maximizing ROI over time[4][5].

Application Areas: Where Goodman Equipment Excels

Plastics Manufacturing

Goodman extrusion downstream equipment is widely used in the plastics industry for pipes, profiles, tubing, and sheets. The equipment's precision and customization capabilities are critical for maintaining tight tolerances and high throughput in plastic extrusion lines[5][6].

Metalworking

In metal extrusion, Goodman's downstream solutions handle aluminum, steel, and other metals, providing accurate cutting, embossing, and coiling for products used in construction, transportation, and aerospace[2][5].

Rubber and Specialty Products

Goodman's downstream equipment is also suitable for rubber hoses, gaskets, and specialty extrusions, with tailored solutions for unique material properties and finishing requirements[5].

Customization: The Key to Optimized Production

Why Customization Matters

Every extrusion application has unique requirements—be it product dimensions, material type, production speed, or regulatory standards. Goodman's approach allows for extensive customization, ensuring that each piece of downstream equipment fits seamlessly into your specific process[1][5][6].

How Goodman Achieves Customization

- Consultative Design: Goodman works closely with customers to understand their needs, then configures equipment accordingly[1][5].

- Modular Accessories: Standard machines can be enhanced with optional accessories for specialized tasks, such as embossing, labeling, or additional quality checks[1][5].

- Flexible Assembly: Customization during assembly allows for rapid delivery without the delays and costs typically associated with bespoke machinery[1].

Quality Assurance and Compliance

Integrated Inspection and Testing

Goodman extrusion downstream equipment often includes built-in inspection systems to monitor dimensions, wall thickness, and mechanical properties in real-time, ensuring compliance with industry standards like ISO 9000[2][7].

Traceability and Branding

Options such as printers and markers can add logos, batch numbers, or compliance codes directly onto products, supporting traceability and brand recognition[7].

Case Study: Goodman's Impact in a Modern Production Line

Consider a plastics manufacturer producing high-volume PVC piping. By integrating Goodman's servo rotary cutters, vacuum calibration tables, and automated haul-offs, the company achieved:

- 30% increase in throughput due to higher line speeds and reduced manual intervention.

- 50% reduction in scrap rates thanks to precision cutting and consistent cooling.

- Significant cost savings from lower maintenance and energy consumption.

- Enhanced product quality that consistently met or exceeded customer and regulatory requirements.

This example illustrates how Goodman extrusion downstream equipment can deliver measurable improvements across key performance indicators.

Conclusion

Goodman extrusion downstream equipment represents a benchmark for quality, innovation, and flexibility in the extrusion industry. By offering a wide selection of customizable machinery—ranging from advanced rotary cutters and pullers to cooling tanks, winders, and inspection systems—Goodman empowers manufacturers to optimize their production lines for maximum efficiency, accuracy, and profitability.

Whether you are producing high-volume commodity products or specialized, high-precision extrusions, Goodman's solutions can be tailored to your unique requirements. The result is a streamlined, reliable, and cost-effective production process that delivers consistent quality and a strong return on investment.

Frequently Asked Questions (FAQ)

1. What types of products can Goodman extrusion downstream equipment handle?

Goodman extrusion downstream equipment is engineered for a wide range of materials, including plastics, metals (such as aluminum and steel), and rubber. The equipment is suitable for producing pipes, profiles, rods, tubes, sheets, hoses, gaskets, and custom extrusions for industries like construction, automotive, aerospace, and medical[2][5][6].

2. How customizable is Goodman's downstream equipment for unique production needs?

Goodman offers extensive customization options. Machines can be configured with different drive systems, control interfaces, accessories, and modular components to fit specific product dimensions, materials, and production speeds. This ensures optimal performance for each unique application[1][5][6].

3. What are the maintenance requirements for Goodman extrusion downstream equipment?

Goodman designs its equipment for easy maintenance, with features such as modular components, field-replaceable parts, and predictive wear monitoring. Many systems allow for quick part replacement and minimal downtime, supporting efficient, continuous operation[1][3].

4. Can Goodman's equipment be integrated with existing extrusion lines?

Yes, Goodman extrusion downstream equipment is designed for seamless integration with both new and existing extrusion lines. The company provides support for installation, configuration, and training to ensure smooth implementation and optimal performance[1][5].

5. How does Goodman ensure product quality and compliance with industry standards?

Goodman's downstream equipment includes advanced inspection and testing modules that monitor key product parameters in real-time. This ensures that finished products meet or exceed industry standards (such as ISO 9000) and customer specifications. Options for product marking and traceability further support compliance and quality assurance[2][7].

Citations:

[1] http://www.gfgoodman.com/extrusion.htm

[2] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/downstream_extrusion_equipment

[3] http://www.gfgoodman.com/rubb3.htm

[4] https://www.reelpowerind.com/parts-and-service/knowledge-center/downstream-equipment-for-extrusion.html

[5] https://www.arlingtonmachinery.com/brands/pl.b.1126.0/goodman/

[6] https://jieyatwinscrew.com/blog/downstream-equipment/

[7] https://sicaindia.com/downstream-pipe-extrusion-equipment/

[8] http://www.gfgoodman.com

[9] https://www.rdnmfg.com/products-downstream-extrusion-equipment/

[10] https://www.explorium.ai/manufacturing/companies/g-f-goodman-and-son

[11] https://www.trelleborg.com/inthegroove/-/media/tss-media-repository/itg/pdfs/in_the_groove_34_en.pdf?la=en&revision=2213208e-6b67-45cf-9812-c4baf08e97f6&hash=A546BAC4DCBAA43D67BDEF6D295FE286B0576DC8

[12] https://farmasi.unimman.ac.id/wp-content/uploads/2022/07/Goodman-Gilmans-The-Pharmacological-Basis-of-Therapeutics-11th-Edition-2006.pdf

[13] https://www.thefreelibrary.com/Downstream+equipment+for+precision+extrusion.-a08892254

[14] https://recycled-parts.com/Drop-off-Centers-/Plastic-/G-f-goodman-extrusion-downstream-med-1000-servo-cutter.cgi

[15] https://www.thefreelibrary.com/Extrusion+systems.+(Product+Lines+Reviewed).-a093534836

[16] https://www.thomasnet.com/products/extrusion-takeups-82670241-1.html

[17] https://www.eastman.com/content/dam/eastman/corporate/en/literature/s/spmbs1431.pdf

[18] https://www.thefreelibrary.com/Extrusion+systems.-a0309981449

[19] https://www.ptonline.com/articles/new-player-familiar-name-in-downstream-extrusion-equipment(2)

[20] https://bbsbec.edu.in/wp-content/uploads/2019/12/Question-Bank-ME.pdf

[21] https://www.ptonline.com/articles/extrusion(1)

[22] https://www.goodmanmfg.com/resources/faq/maintenance

[23] http://repo.upertis.ac.id/1824/1/Goodman___Gilman_s-_manual_of_Pharmacology_and_Therapeutics.pdf

[24] https://download.e-bookshelf.de/download/0000/8349/70/L-G-0000834970-0003656414.pdf

[25] https://api.pageplace.de/preview/DT0400.9781569905395_A22613947/preview-9781569905395_A22613947.pdf

[26] https://vinyl-concepts.com/research/vinyl-extrusion/

[27] https://www.plasticsnews.com/article/19970728/NEWS/307289977/downstream-equipment-debuts

[28] https://www.ptonline.com/articles/a-culture-built-on-innovation-in-medical-tubing-extrusion

[29] https://patents.google.com/patent/US5051222A/en

[30] https://www.goodmanmfg.com/resources/hvac-learning-center/?param1=maintenance