Content Menu

● Introduction to Extrusion Printing Machinery

>> Key Components of Extrusion Printing Machinery

● Applications of Extrusion Printing Machinery

>> Aerospace and Automotive

>> Healthcare

>> Consumer Products

● Advancements in Extrusion Printing Machinery

>> Dual Extrusion Systems

>> Pellet Extrusion Technologies

● The Integration of Industry 4.0 Technologies

● Material Innovations in Extrusion Printing

>> Smart and Functional Materials

● High-Speed 3D Printing with Klipper Firmware

● The Role of Extrusion Printing in Sustainable Manufacturing

● Market Trends and Growth

>> Market Consolidation

● Challenges and Future Directions

● Extrusion Printing in 2025

>> AI and Automation

● Conclusion

● Frequently Asked Questions

>> 1. What is extrusion printing machinery?

>> 2. What are the benefits of dual extrusion systems?

>> 3. How does pellet extrusion compare to filament extrusion?

>> 4. What industries benefit from extrusion printing machinery?

>> 5. What are the future challenges for extrusion printing machinery?

● Citations:

Extrusion printing machinery has been at the forefront of the 3D printing revolution, transforming the way we design, prototype, and manufacture products across various industries. This technology involves forcing materials through a heated nozzle to create three-dimensional objects layer by layer, offering unparalleled flexibility and efficiency in production. In this article, we will delve into the capabilities of extrusion printing machinery, its applications, and how it is revolutionizing the field of additive manufacturing.

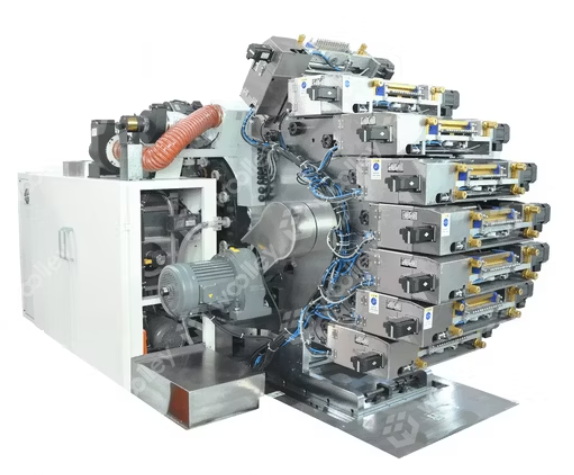

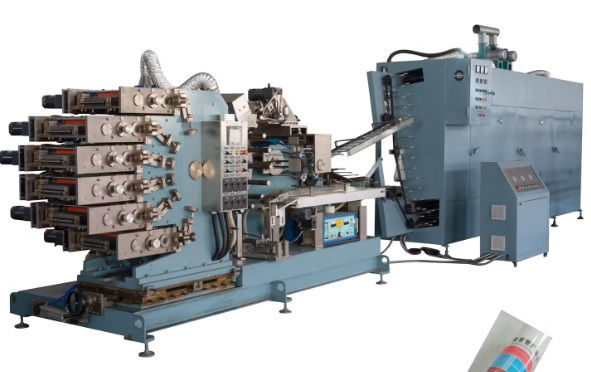

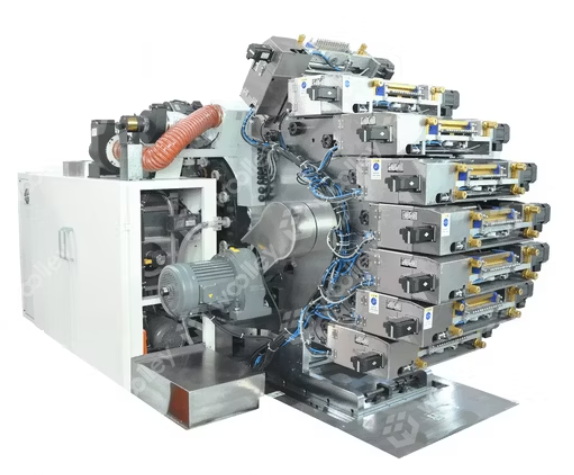

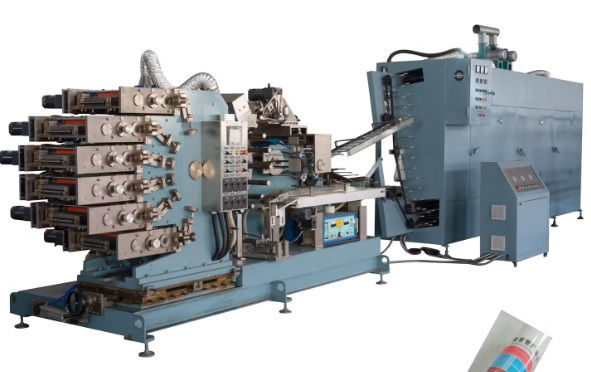

Introduction to Extrusion Printing Machinery

Extrusion printing machinery is based on the material extrusion process, which is one of the most common 3D printing techniques. It involves melting and extruding thermoplastic materials, such as ABS, PLA, and nylon, through a heated nozzle to build objects layer by layer. This method allows for the creation of complex geometries and structures that cannot be produced using traditional manufacturing methods.

Key Components of Extrusion Printing Machinery

1. Heated Nozzle: This is where the thermoplastic material is melted before being extruded onto the build platform.

2. Extruder: Responsible for feeding the filament into the heated nozzle.

3. Build Platform: The surface on which the object is built layer by layer.

4. Control System: Manages the movement of the extruder and build platform to ensure precise layer deposition.

Applications of Extrusion Printing Machinery

Extrusion printing machinery has a wide range of applications across various industries:

Aerospace and Automotive

In these sectors, extrusion printing is used to create lightweight yet durable components, such as aircraft parts and car prototypes. The ability to produce complex geometries allows for improved aerodynamics and reduced material usage. AI-driven generative design is accelerating the development of lightweight, high-performance components, particularly in aerospace, defense, and automotive sectors[1].

Healthcare

Extrusion printing is used in healthcare for creating custom prosthetics, implants, and surgical models. The precision and customization capabilities of extrusion printing machinery enable tailored medical solutions.

Consumer Products

From phone cases to furniture, extrusion printing machinery allows for rapid prototyping and production of consumer goods with complex designs and personalized features.

Advancements in Extrusion Printing Machinery

Recent advancements in extrusion printing machinery include the development of dual extrusion systems and pellet extrusion technologies.

Dual Extrusion Systems

Dual extrusion systems allow for the simultaneous use of two different materials or colors, enhancing productivity and enabling the creation of more complex parts with varied mechanical properties.

Pellet Extrusion Technologies

Pellet extrusion offers greater scalability and cost efficiency compared to traditional filament-based systems. It is particularly beneficial for large-scale industrial applications, allowing for the use of a broader range of materials, including high-performance plastics. The pellet extruder 3D printing market is experiencing substantial growth due to technological advancements leading to improved print speeds, higher resolution, and broader material compatibility[6].

The Integration of Industry 4.0 Technologies

The integration of Industry 4.0 technologies is a key driver of future growth in extrusion machinery[4]. These technologies include:

AI and Machine Learning: AI-powered systems optimize processing parameters, improving product quality while reducing waste and energy consumption[7].

Automation: Automation enhances efficiency, reduces waste, and improves product quality in the extrusion machinery market[4].

Internet of Things (IoT): Integration of 3D printing with IoT holds immense potential to unlock new possibilities and usher in a new era of innovation and efficiency[2].

Material Innovations in Extrusion Printing

Material innovations in the 3D printing sector are driving significant advances in scope, applicability, and cost, ramping up the capabilities of additive manufacturing technology[5]. R&D is focused on developing advanced polymer materials with enhanced mechanical properties, chemical resistance, and thermal stability[5]. Innovations in metal additive manufacturing materials are resulting in new metal alloys with improved strength, durability, and corrosion resistance[5].

Smart and Functional Materials

Future material innovations are going to include smart and functional materials with embedded sensors, actuators, and responsive properties typified in 4D printing[5]. This enables the fabrication of smart devices, wearable electronics, and intrinsically functional prototypes[5].

High-Speed 3D Printing with Klipper Firmware

One of the most exciting trends in the 3D printing industry is the emergence of high-speed printers with Klipper firmware[2]. Klipper is an open-source firmware that allows for faster and more precise printing, making it a game-changer for manufacturers and hobbyists alike[2]. Manufacturers have developed more efficient extruders and print heads that can deposit material at higher speeds without compromising print quality[2].

The Role of Extrusion Printing in Sustainable Manufacturing

Sustainability plays a crucial role as manufacturers focus on recycling and processing recycled materials[4]. This not only reduces environmental impact but also aligns with growing consumer demand for eco-friendly products[4]. The growing focus on sustainability necessitates the development of eco-friendly practices and materials to minimize environmental impact[2]. Digitally manufactured homes also have the potential to be more sustainable as the minimization of waste and the use of eco-friendly construction materials can greatly reduce the environmental impact of construction[5].

Market Trends and Growth

The extrusion machinery market is expected to grow significantly over the next few years, driven by increasing demand for plastic and metal[4]. The plastic extrusion machine market is projected to grow at a CAGR of 4.7% during 2025-2035, boosting the global industry to USD 12,343.2 million by 2035[7]. This growth is fueled by AI-driven automation, increasing plastic product demand, and strong investments in the construction and automotive sectors[7].

Market Consolidation

Industry consolidation is creating a more competitive and robust market, offering greater profitability for suppliers and improved services for customers[1]. This convergence of technology and sustainability positions AM as a transformative force across sectors, enabling them to achieve ambitious environmental and operational goals[1].

Challenges and Future Directions

Despite the advancements, extrusion printing machinery faces challenges such as material limitations and the need for improved reproducibility across different printer models. Future developments will focus on enhancing material properties and printer calibration to ensure consistent results.

Extrusion Printing in 2025

The 3D printing industry is entering a new phase of innovation in 2025, driven by technological advances, materials, and supply chain models[1]. In 2025, the metal Additive Manufacturing industry will signal the transition to production-scale operations[1]. The focus is on scaling additive manufacturing for high-performance applications, particularly in the defense, aerospace, medical, and automotive sectors[1].

AI and Automation

Many experts believe Artificial intelligence (AI) and automation will turbo-charge 3D printing by optimizing design, production, and post-processing workflows[1]. AI-powered monitoring systems will ensure real-time quality control, reduce failures, and enable “Born Qualified” production, where printed parts are certified in real-time[1].

Conclusion

Extrusion printing machinery has revolutionized the field of 3D printing by offering unprecedented flexibility, efficiency, and customization capabilities. As technology continues to evolve, we can expect even more innovative applications across industries. Whether it's in aerospace, healthcare, or consumer products, extrusion printing machinery is set to play a pivotal role in shaping the future of manufacturing.

Frequently Asked Questions

1. What is extrusion printing machinery?

Extrusion printing machinery uses a process where thermoplastic materials are melted and extruded through a heated nozzle to build objects layer by layer.

2. What are the benefits of dual extrusion systems?

Dual extrusion systems allow for the use of two different materials or colors simultaneously, enhancing productivity and enabling the creation of more complex parts with varied mechanical properties.

3. How does pellet extrusion compare to filament extrusion?

Pellet extrusion offers greater scalability and cost efficiency, making it suitable for large-scale industrial applications. It also provides more material options and reduces waste compared to filament extrusion.

4. What industries benefit from extrusion printing machinery?

Extrusion printing machinery benefits industries such as aerospace, automotive, healthcare, and consumer products by enabling rapid prototyping and production of complex parts.

5. What are the future challenges for extrusion printing machinery?

Future challenges include improving material properties and ensuring reproducibility across different printer models to enhance consistency and reliability.

Citations:

[1] https://3dprintingindustry.com/news/3d-printing-trends-for-2025-executive-survey-of-leading-additive-manufacturing-companies-236247/

[2] https://www.sunlu.com/en-gb/blogs/3d-printing-guide/3d-printing-technology-trends-in-2024

[3] https://www.thebusinessresearchcompany.com/report/extrusion-machinery-global-market-report

[4] https://www.yjing-extrusion.com/what-are-the-latest-trends-in-the-extrusion-machinery-market.html

[5] https://www.xometry.com/resources/3d-printing/future-of-3d-printing/

[6] https://www.datainsightsmarket.com/reports/pellet-extruder-3d-printer-49527

[7] https://www.globenewswire.com/news-release/2025/02/05/3021359/0/en/Plastic-Extrusion-Machine-Market-to-Grow-at-4-7-CAGR-During-2025-2035-Boosting-Global-Industry-to-USD-12-343-2-Million-by-2035-Future-Market-Insights-Inc.html

[8] https://flashforge.com/blogs/news/flashforge-shines-at-tct-asia-2025

[9] https://amfg.ai/2025/03/31/latest-developments-in-additive-manufacturing-march-2025/

[10] https://www.designtechproducts.com/articles/future-trends-3d-printing

[11] https://www.datainsightsmarket.com/reports/extrusion-press-machine-57480

[12] https://www.engineering.com/additive-manufacturing-progress-update-feb-2025/

[13] https://3dprintingindustry.com/news/3d-printing-trends-for-2024-industry-expert-analysis-on-what-to-watch-this-year-228030/

[14] https://inkworld.sg/printing-technology-innovations/future/%20

[15] https://www.globenewswire.com/news-release/2025/03/26/3049388/0/en/Asia-Pacific-3D-Printing-Market-Forecast-to-Reach-32-8-Billion-at-an-18-4-CAGR-Metal-3D-Printing-Gaining-Traction-in-Aerospace-Automotive-and-Defence-Industries.html

[16] https://www.wevolver.com/article/the-metal-3d-printing-technology-report-chapter-7-future-outlook-and-emerging-trends

[17] https://press.kraussmaffei.com/en/news/kraussmaffei-at-jec-2025-innovations-for-fiber-composite-technology-and-additive-manufacturing

[18] https://www.3dsystems.com/events/3d-printings-impact-transportation-2025-solutions-unlock-new-opportunities

[19] https://www.linkedin.com/pulse/future-trends-3d-printing-david-nishimoto-4zuic

[20] https://www.idtechex.com/en/research-article/the-long-term-trends-shaping-additive-manufacturing/30547