Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Key Benefits of Custom Aluminum Profiles

>> Versatility

>> Cost-Effectiveness

>> Lightweight and Strong

>> Corrosion Resistance

● Applications of Custom Aluminum Profiles

>> Construction and Architecture

>> Automotive Industry

>> Electronics and Appliances

● Choosing the Right Aluminum Extrusion Supplier

>> Quality and Certification

>> Customization Capabilities

>> Lead Times and Delivery

>> Customer Support

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using custom aluminum profiles in product design?

>> 2. How does the aluminum extrusion process work?

>> 3. In which industries are custom aluminum profiles commonly used?

>> 4. What should I consider when choosing an aluminum extrusion supplier?

>> 5. How do custom aluminum profiles contribute to sustainability?

Introduction

In the world of product design, the materials used can significantly influence the final outcome. Among these materials, aluminum stands out due to its unique properties, versatility, and aesthetic appeal. Custom aluminum profiles, particularly standard aluminum extrusion profiles, have become increasingly popular in various industries, from automotive to electronics. This article explores how custom aluminum profiles can enhance product design, focusing on their benefits, applications, and the process of selecting the right profiles for your needs.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which creates a continuous length of the desired shape. The process allows for a high degree of customization, making it possible to produce complex shapes that meet specific design requirements.

Standard aluminum extrusion profiles are pre-defined shapes that are widely used in various applications. These profiles can be easily sourced, making them a cost-effective option for designers looking to incorporate aluminum into their products. The versatility of aluminum extrusion means that it can be tailored to meet the needs of different industries, including construction, automotive, and consumer electronics.

Key Benefits of Custom Aluminum Profiles

Versatility

One of the most significant advantages of custom aluminum profiles is their versatility. Designers can create profiles that fit specific applications, whether they require structural support, aesthetic appeal, or functional features. Standard aluminum extrusion profiles can be modified to suit various needs, allowing for a wide range of applications.

For instance, in the construction industry, aluminum profiles are used for window frames, curtain walls, and roofing systems. In the automotive sector, they are utilized for lightweight structural components that enhance fuel efficiency. The ability to customize these profiles means that designers can achieve the exact specifications required for their projects.

Cost-Effectiveness

Custom aluminum profiles can also be a cost-effective solution for product design. By using standard aluminum extrusion profiles, manufacturers can reduce production costs while maintaining high-quality standards. The efficiency of the extrusion process allows for mass production, which can lead to lower prices for bulk orders.

Moreover, aluminum's lightweight nature contributes to cost savings in shipping and handling. Products designed with aluminum profiles are often easier to transport, reducing logistics costs. This cost-effectiveness makes aluminum an attractive option for businesses looking to optimize their product design without compromising quality.

Lightweight and Strong

Aluminum is known for its excellent strength-to-weight ratio, making it an ideal material for various applications. Custom aluminum profiles can provide the necessary strength while keeping the overall weight of the product low. This is particularly important in industries such as aerospace and automotive, where weight reduction can lead to improved performance and fuel efficiency.

The lightweight nature of aluminum also allows for easier handling during the manufacturing process. Designers can create intricate shapes without worrying about the structural integrity of the product. This flexibility enables innovation in product design, as designers can experiment with different shapes and configurations.

Corrosion Resistance

Another significant benefit of custom aluminum profiles is their natural resistance to corrosion. Aluminum forms a protective oxide layer when exposed to air, which helps prevent rust and degradation. This property makes aluminum profiles suitable for outdoor applications and environments where moisture is a concern.

For example, in the construction industry, aluminum profiles are often used for exterior applications such as cladding and roofing. Their corrosion resistance ensures that these components maintain their appearance and structural integrity over time. This durability translates to lower maintenance costs and longer product lifespans, making aluminum an excellent choice for long-term investments.

Applications of Custom Aluminum Profiles

Construction and Architecture

Custom aluminum profiles play a crucial role in modern construction and architecture. They are used in various applications, including window frames, doors, and structural supports. The ability to customize profiles allows architects and builders to create unique designs that meet aesthetic and functional requirements.

For instance, aluminum curtain walls are popular in commercial buildings due to their lightweight and durable nature. These walls provide excellent thermal insulation and can be designed to accommodate large glass panels, enhancing the building's overall appearance. Custom aluminum profiles can also be used to create intricate designs that add character to a structure.

Automotive Industry

In the automotive industry, custom aluminum profiles are increasingly used to reduce vehicle weight and improve fuel efficiency. Manufacturers are turning to aluminum for various components, including chassis, body panels, and structural reinforcements. The lightweight nature of aluminum allows for better performance without sacrificing safety.

Custom aluminum profiles can be designed to meet specific performance criteria, such as crashworthiness and rigidity. This customization enables automotive engineers to create vehicles that are not only lighter but also safer and more efficient. As the industry moves towards more sustainable practices, aluminum's recyclability further enhances its appeal.

Electronics and Appliances

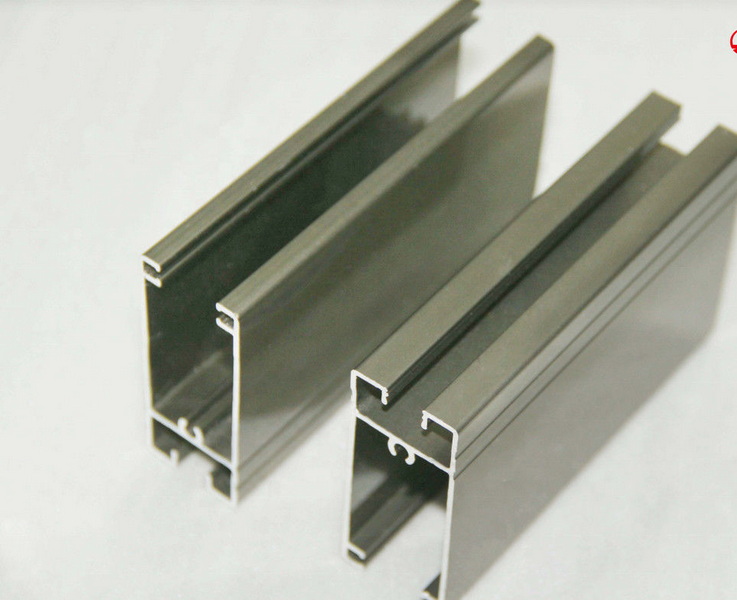

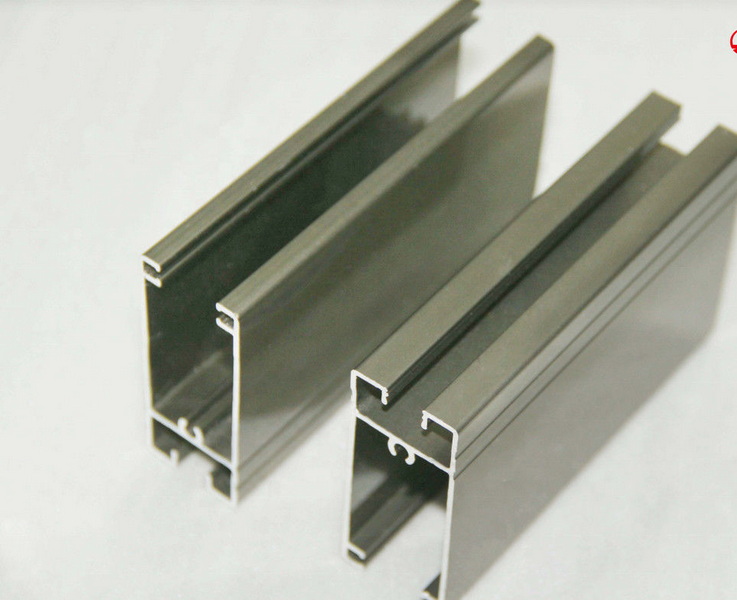

Custom aluminum profiles are also widely used in the electronics and appliances sector. They provide a sleek and modern appearance while offering the necessary structural support for various components. Aluminum profiles can be designed to house electronic components, ensuring proper ventilation and heat dissipation.

For example, custom aluminum enclosures are commonly used for computers, servers, and other electronic devices. These enclosures protect sensitive components from damage while allowing for efficient cooling. The aesthetic appeal of aluminum also enhances the overall design of consumer electronics, making them more attractive to consumers.

Choosing the Right Aluminum Extrusion Supplier

When selecting an aluminum extrusion supplier, several factors should be considered to ensure the best results for your product design.

Quality and Certification

It is essential to choose a supplier that adheres to industry standards and certifications. Look for suppliers that provide high-quality aluminum profiles with consistent dimensions and tolerances. Certifications such as ISO 9001 can indicate a commitment to quality management and customer satisfaction.

Customization Capabilities

Not all suppliers offer the same level of customization. Ensure that the supplier you choose can accommodate your specific design requirements. This includes the ability to create custom shapes, sizes, and finishes that align with your product vision.

Lead Times and Delivery

Timely delivery is crucial in product design and manufacturing. Discuss lead times with potential suppliers to ensure they can meet your project deadlines. A reliable supplier should have a proven track record of delivering products on time without compromising quality.

Customer Support

Good customer support can make a significant difference in your experience with an aluminum extrusion supplier. Look for suppliers that offer responsive communication and assistance throughout the design and manufacturing process. This support can help address any issues that may arise and ensure a smooth collaboration.

Conclusion

Custom aluminum profiles offer numerous benefits that can significantly enhance product design. Their versatility, cost-effectiveness, lightweight strength, and corrosion resistance make them an ideal choice for various applications across multiple industries. By understanding the advantages of standard aluminum extrusion profiles and selecting the right supplier, designers can create innovative products that meet the demands of today's market.

As industries continue to evolve, the role of aluminum in product design will only grow. Embracing custom aluminum profiles can lead to improved performance, aesthetic appeal, and sustainability in product development.

Frequently Asked Questions

1. What are the main advantages of using custom aluminum profiles in product design?

Custom aluminum profiles offer versatility, cost-effectiveness, lightweight strength, and corrosion resistance, making them ideal for various applications.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves forcing aluminum alloy through a die to create a desired cross-sectional profile, allowing for high customization.

3. In which industries are custom aluminum profiles commonly used?

Custom aluminum profiles are widely used in construction, automotive, electronics, and consumer appliances.

4. What should I consider when choosing an aluminum extrusion supplier?

Consider factors such as quality and certification, customization capabilities, lead times, and customer support when selecting a supplier.

5. How do custom aluminum profiles contribute to sustainability?

Aluminum is recyclable, and using lightweight materials can lead to reduced energy consumption in transportation and manufacturing, contributing to overall sustainability efforts.