Content Menu

● Introduction to Co-Rotating Twin Screw Extrusion Machinery

>> Key Features of Co-Rotating Twin Screw Extruders

● Operational Advantages for Cost Reduction

>> 1. Efficient Material Processing

>> 2. Reduced Maintenance and Downtime

>> 3. Energy Efficiency

>> 4. Versatility and Customization

>> 5. Direct Compounding and Recycling

● Practical Applications

● Conclusion

● FAQ

>> 1. What are the primary advantages of co-rotating twin screw extruders?

>> 2. How does the modular design of co-rotating twin screw extruders reduce maintenance costs?

>> 3. What role does energy efficiency play in reducing production costs with co-rotating twin screw extruders?

>> 4. How can co-rotating twin screw extruders be customized for different applications?

>> 5. What are some common applications of co-rotating twin screw extruders?

● Citations:

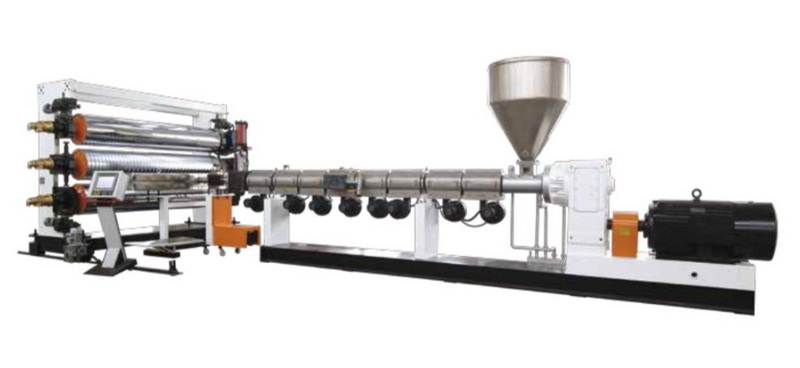

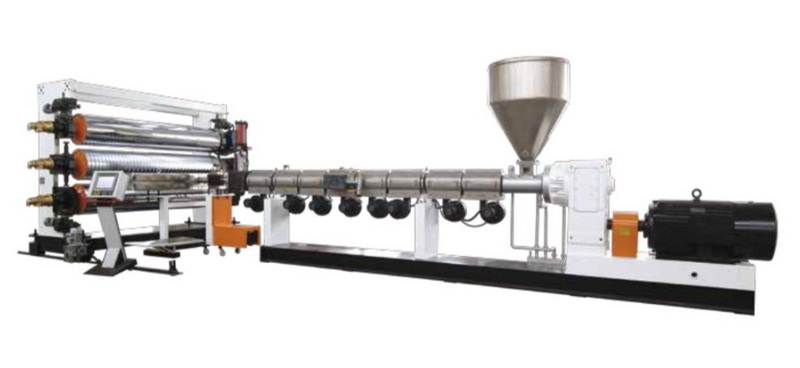

Co-rotating twin screw extrusion machinery has become a cornerstone in modern manufacturing, particularly in the plastics and polymer industries. Its ability to efficiently process a wide range of materials, from simple polymers to complex compounds, makes it an indispensable tool for achieving high-quality products while minimizing costs. This article delves into the specifics of how co-rotating twin screw extrusion machinery can reduce production costs, exploring its design, operational advantages, and practical applications.

Introduction to Co-Rotating Twin Screw Extrusion Machinery

Co-rotating twin screw extruders feature two intermeshing screws that rotate in the same direction within a barrel. This design facilitates intense mixing, kneading, and shearing actions, ensuring thorough blending of components and uniform dispersion of additives. The machinery is highly versatile, capable of processing polymers, plastics, rubber compounds, food ingredients, and pharmaceutical formulations[2][3].

Key Features of Co-Rotating Twin Screw Extruders

- High Throughput Rates: These machines are designed for large-scale production, offering high throughput rates that make them ideal for industrial applications[2].

- Intensive Mixing: The co-rotating motion of the screws provides superior mixing capabilities, ensuring consistent product quality[2].

- Precise Control: Operators can precisely control processing parameters such as temperature, pressure, screw speed, and residence time, allowing for tailored processing for specific materials and formulations[2].

- Self-Cleaning: The high shear speed in co-rotating extruders helps scrape off accumulated material, reducing residence time and preventing local degradation[1][6].

Operational Advantages for Cost Reduction

1. Efficient Material Processing

Co-rotating twin screw extruders are highly efficient in processing materials. They can handle a wide range of viscosities and materials, including polymers, fillers, and additives, without requiring extensive pre-processing. This efficiency reduces the need for additional machinery and labor, thereby lowering overall production costs.

2. Reduced Maintenance and Downtime

The modular design of these extruders allows for easy maintenance. The barrel can be quickly opened for inspection and repair, reducing downtime and labor intensity. This feature is particularly beneficial when changing product formulations or colors, as it eliminates the need for extensive cleaning and reduces waste[1][9].

3. Energy Efficiency

Modern co-rotating twin screw extruders are designed to be energy-efficient. They utilize advanced screw designs and optimized processing parameters to achieve high throughput rates while consuming less energy. This not only reduces operational costs but also aligns with sustainable manufacturing practices[3].

| Model | Screw Diameter [mm] | Maximum Speed [rpm] | Motor [Kw] | Output [Kg/h] |

| KTE-16 | 15.6 | 500 | 2.2 | 1~5 |

| KTE-20 | 21.7 | 500 | 4 | 2~15 |

4. Versatility and Customization

Co-rotating twin screw extruders can be customized with different screw elements, barrel designs, and auxiliary equipment to meet diverse production needs. This versatility ensures that the machinery can adapt to various applications, maximizing investment efficiency[3].

5. Direct Compounding and Recycling

Some co-rotating twin screw extruders allow for direct compounding and recycling, eliminating the need for pelletizing. This process reduces power consumption and investment costs by minimizing the need for re-processing materials[10].

Practical Applications

Co-rotating twin screw extruders are widely used in various industries:

- Plastics and Polymers: For compounding, masterbatch production, and engineering plastics[3][4].

- Food and Pharmaceuticals: For processing ingredients and formulations requiring precise mixing and control[7].

- Reactive Extrusion: For chemical reactions within the extruder, such as polymerization and modification[8].

Conclusion

Co-rotating twin screw extrusion machinery offers a robust solution for reducing production costs in various manufacturing sectors. Its efficiency, versatility, and ability to handle complex materials make it an indispensable tool for achieving high-quality products while minimizing operational expenses. By leveraging its advanced design and operational advantages, manufacturers can optimize their production processes, enhance product quality, and improve profitability.

FAQ

1. What are the primary advantages of co-rotating twin screw extruders?

Co-rotating twin screw extruders offer high throughput rates, intensive mixing capabilities, precise control over processing parameters, and good self-cleaning performance. These features make them ideal for large-scale production and complex material processing[2][6].

2. How does the modular design of co-rotating twin screw extruders reduce maintenance costs?

The modular design allows for easy opening of the barrel, enabling quick inspection and repair. This reduces downtime and labor intensity, especially during product changes or color shifts, by eliminating the need for extensive cleaning[1][9].

3. What role does energy efficiency play in reducing production costs with co-rotating twin screw extruders?

Energy efficiency is crucial as it reduces operational costs and aligns with sustainable manufacturing practices. Advanced screw designs and optimized processing parameters help achieve high throughput rates while consuming less energy[3].

4. How can co-rotating twin screw extruders be customized for different applications?

These extruders can be customized with different screw elements, barrel designs, and auxiliary equipment to meet specific production needs. This versatility allows the machinery to adapt to various applications, maximizing investment efficiency[3].

5. What are some common applications of co-rotating twin screw extruders?

Co-rotating twin screw extruders are commonly used in plastics and polymers for compounding and masterbatch production, in food and pharmaceuticals for precise mixing, and in reactive extrusion for chemical reactions[3][7].

Citations:

[1] https://www.kaironggroup.com/what-is-a-co-rotating-twin-screw-extruder/

[2] https://www.kaironggroup.com/co-rotating-vs-counter-rotating-twin-screw-extruders/

[3] https://www.kerkeextruder.com/ms/products/compounding/kte-series-twin-screw-extruder/

[4] https://audop.com/plastic-extruders/co-rotating-parallel-twin-screw-extruder.htm

[5] https://www.youtube.com/watch?v=jFMzrsB5VrY

[6] https://www.cowellextrusion.com/co-rotating-twin-screw-extruder-vs-counter-rotating-twin-screw-extruder/

[7] https://jieyatwinscrew.com/blog/how-does-a-twin-screw-extruder-work/

[8] https://jieyatwinscrew.com/blog/understanding-the-twin-screw-extruder-a-comprehensive-guide/

[9] https://www.zj-junyue.com/news/development-history-of-twin-screw-extruder-and-six-advantages.html

[10] https://www.industrysourcing.com/article/twin-screw-extruders-cost-control

[11] https://torontech.com/twin-screw-extruder-explained-from-basics-to-applications/

[12] https://www.keyatwinscrew.com/how-to-choose-the-twin-screw-extruder.html

[13] https://www.keyatwinscrew.com/what-are-the-benefits-of-using-twin-screw-extruders.html

[14] https://www.ptonline.com/articles/strategically-manage-pressure-to-help-ensure-quality-in-co-rotating-twin-screw-extrusion-

[15] https://www.banline.com/co-rotating-twin-screw-extruder