As a core element in the aluminum extrusion process, the performance and efficiency of the die is directly related to the quality, cost and market competitiveness of aluminum products. Therefore, for aluminum processing enterprises, want to produce high-quality aluminum products, in addition to high-end equipment, precision mold is also essential. YEJING Machinery, as a professional aluminum extrusion equipment supplier, in order to help customers create more high-end aluminum, built a strong die manufacturing system.

Extruder manufacturer cross-border precision mold

With the rapid development of construction, new energy, automotive lightweight and aerospace technology, the demand for aluminum profiles continues to rise, the industry will usher in a period of steady growth, while customers demand more and more precision, appearance and performance of the product, precision molds, as a key tool to improve product quality, the market demand is increasingly strong. YEJING machinery keen insight into the market trend, 34 years of aluminum extruder manufacturing experience into the mold design and manufacturing, began the mold manufacturing road.

In the face of the high standard requirements of the photovoltaic and new energy automobile industries for molds and the rapidly changing market, YEJING Machinery has been able to occupy a leading position in just a few years because of its precise control of three core elements: steel selection, heat treatment technology and processing technology.

YEJING insists on the principle of “selecting the best among the best” in the procurement of raw materials, and cooperates closely with the world's top steel suppliers, such as ASSAB and Baowu Special Steel, to ensure that the molds maintain stable performance and accurate dimensions in long-time, high-intensity use. Secondly, YEJING Machinery combines the self-developed vacuum quenching technology, through the fine control of temperature and time, effectively improve the hardness and toughness of the mold, reduce the risk of deformation and cracking in the heat treatment process, so that the mold in the complex and changing working conditions can still show excellent stability and durability. In terms of processing technology, YEJING Machinery actively introduces advanced equipments and technologies such as porous graphite whole electrode, mirror spark machine, slow walking wire and multi-axis machining center, which not only greatly improves the processing precision and surface quality of the mold, but also significantly shortens the production cycle and reduces the production cost, making YEJING Machinery able to respond to the market demand more quickly and accurately.

“Can't you have it both ways? YEJING has something to say about that!

Nowadays, YEJING mold products are developing in the direction of large-scale, precision, complexity, economy and speed, and the annual output of molds has exceeded 15,000 sets of mark. Can achieve such results is not by chance, but from the industry fine machinery in the technical innovation and equipment upgrading in the relentless pursuit of excellence is the inevitable result. YEJING Machinery has an independent mold R & D team, over the years focused on the research and development and production of molds, through technological innovation to improve the production efficiency and quality of molds, accurate docking market diversification needs, in the product delivery time is significantly shortened at the same time, but also significantly improve the speed of extrusion and the surface quality of the profile.

In order to ensure the accuracy and efficiency of mold manufacturing, the production workshop of YEJING Machinery is equipped with a variety of high-quality, precision mold processing and testing equipment, such as CNC lathes, CNC machining centers, CNC slow-feeding wire cutting, vacuum quenching furnace. At the same time, through the continuous optimization of the processing process and technological innovation, YEJING Machinery continues to make breakthroughs in the field of cemented carbide extrusion and one out of multiple holes mold research and development, further consolidating its leading position in the industry.

Linking Customers and Factories with Numbers and Striving for Excellence in Intelligent Manufacturing

Intelligent manufacturing as a new generation of information technology and advanced manufacturing technology in-depth fusion of the new production mode, has become the core driving force of the new round of industrial revolution, YEJING Machinery also follow the pace of the times, and actively promote the intelligent upgrading of production management.

YEJING Machinery has independently researched and developed ERP (Enterprise Resource Planning), MES (Manufacturing Execution System) and PLM (Product Life Cycle Management) systems, which are like the enterprise's “intelligent brain” and can realize intelligent management and optimization in various aspects. Various types of production equipment in the workshop can be seamlessly docked, the company's management can be visualized on the big screen in the cloud to see the working status of each machine, production efficiency, energy consumption and material consumption and other key indicators. At the same time, the digital development of its mold is to achieve the whole process of traceability, customers can easily understand the processing progress of the mold and various parameters through the cell phone.

In addition, YEJING Machinery has also fully implemented the system of scanning code to record the work into the warehouse, and digital management throughout the entire production process. From raw materials to finished products, each link realizes instant data collection and automatic entry. We make full use of automated equipment such as AGV carriers to accurately and precisely complete the automatic handling and transfer of workpieces, and realize the automatic operation of workpieces in each process in the workshop. This intelligent logistics system not only significantly improves production efficiency, but also effectively reduces errors and delays caused by human factors, ensuring a smooth and efficient production process.

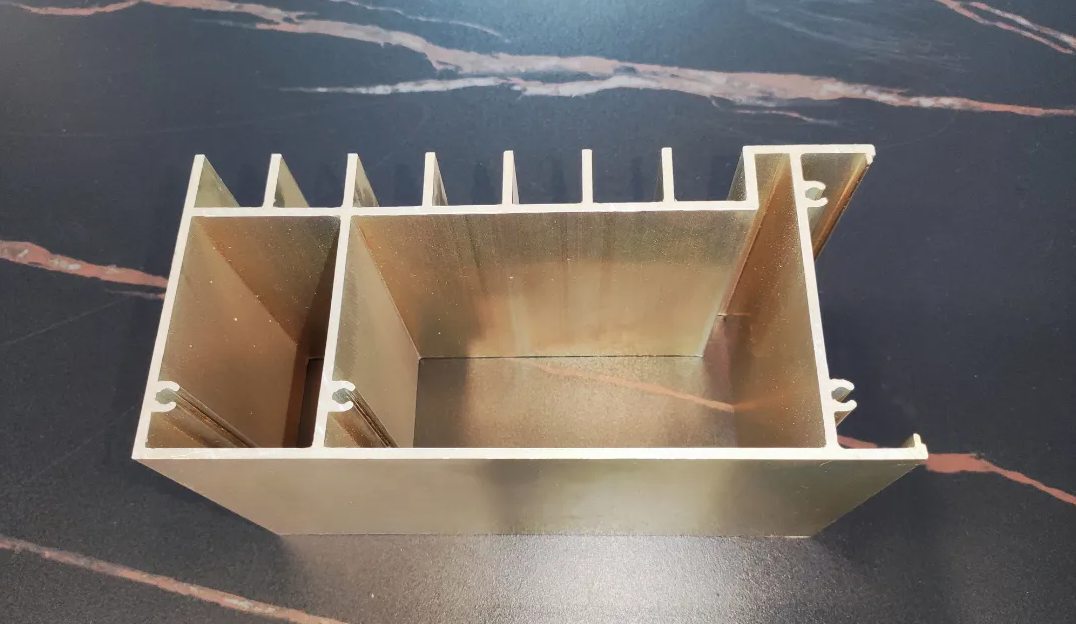

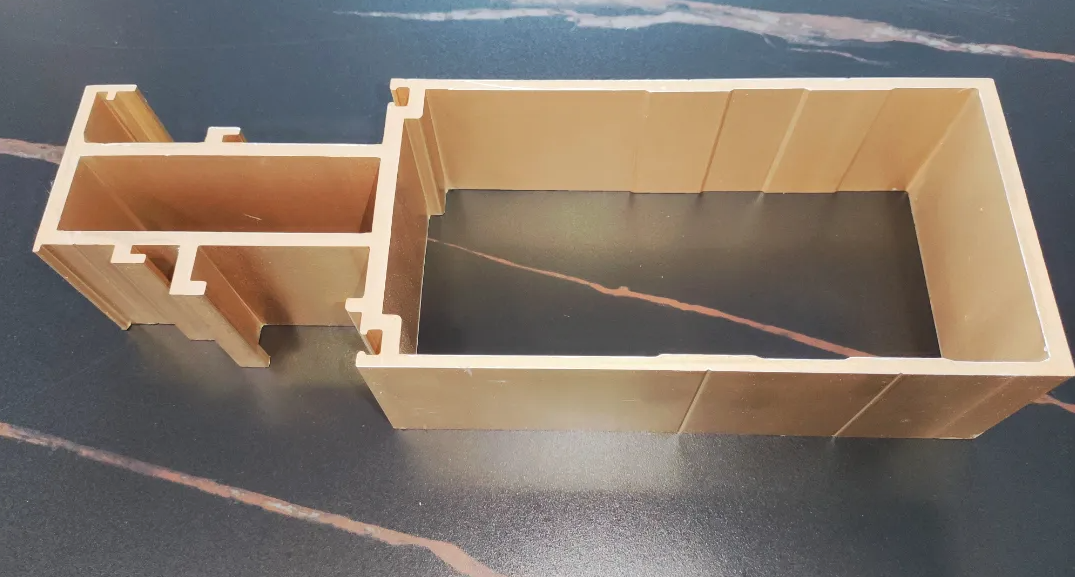

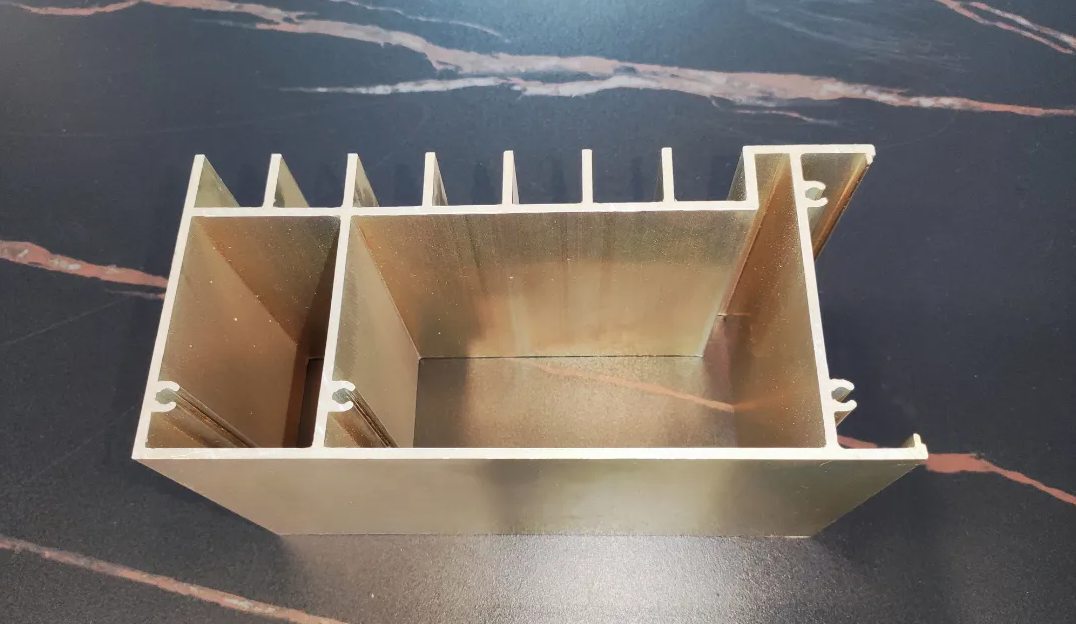

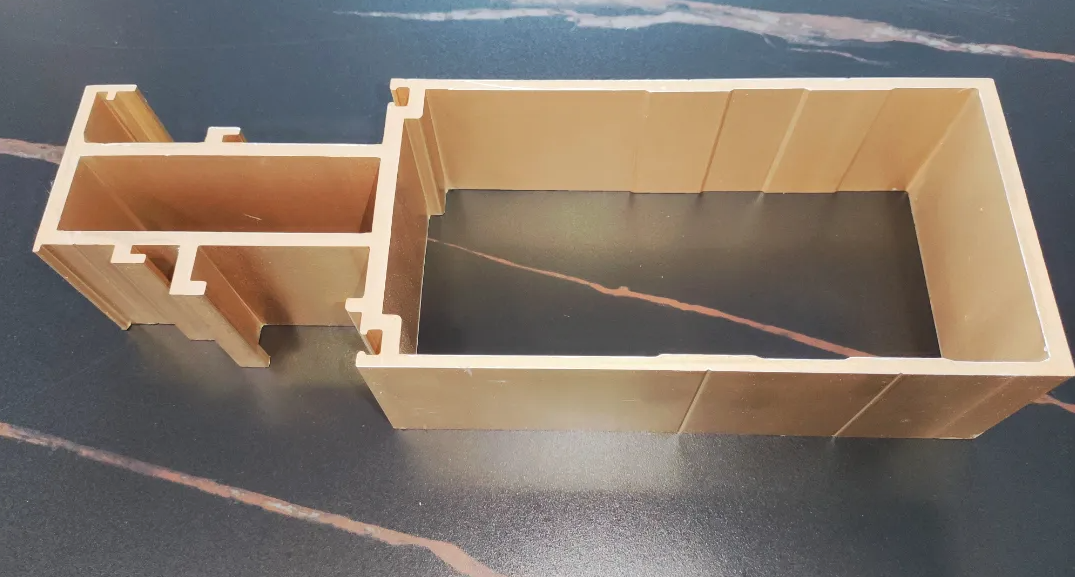

Industrial profiles extruded with YEJING molds

From efficiently shortening the mold manufacturing cycle to significantly improving product quality, YEJING Machinery has taken the core concept of “more speed, better savings” in mold manufacturing, and has continued to make breakthroughs to create high-quality aluminum extrusion molds that have won wide recognition in the market. Looking to the future, just as the spirit of “dedication and refinement” of YEJING Machinery, we will keep pace with the times, constantly explore new technologies and processes, and make fine molds and equipment!

Hot Tags: aluminum extrusion machine, aluminum extrusion press machine, aluminum extrusion bending machine, aluminum extrusion cnc machine, aluminum extrusion cutting machine, aluminum extrusion machine for sale, aluminum extrusion machine guarding, aluminum extrusion machining, aluminum extrusion machining center, aluminum extrusion milling machine, China, manufacturing company, manufacturers, suppliers, factory, price, Pricelist, quotation