Content Menu

● The Aluminum Extrusion Industry: An Overview

● Top Aluminum Extrusion Jobs in 2024

>> 1. Aluminum Extrusion Press Operator

>> 2. Extrusion Die Designer

>> 3. Quality Control Inspector

>> 4. Extrusion Process Engineer

>> 5. Aluminum Extrusion Sales Representative

● The Future of Aluminum Extrusion Jobs

>> Emerging Trends in Aluminum Extrusion

● Skills for Success in Aluminum Extrusion Jobs

● Education and Training for Aluminum Extrusion Careers

● The Impact of Technology on Aluminum Extrusion Jobs

● Challenges and Opportunities in Aluminum Extrusion Careers

● Conclusion

● Frequently Asked Questions

>> 1. What qualifications do I need to start a career in aluminum extrusion?

>> 2. How does the aluminum extrusion industry contribute to sustainability?

>> 3. What are the career growth opportunities in aluminum extrusion?

>> 4. How is technology changing aluminum extrusion jobs?

>> 5. What are the biggest challenges facing the aluminum extrusion industry in 2024?

● Citations:

In the ever-evolving landscape of manufacturing and industry, aluminum extrusion jobs continue to play a crucial role in 2024. As the demand for lightweight, durable, and versatile materials grows across various sectors, the aluminum extrusion industry offers a wide array of career opportunities for skilled professionals. This article will explore the best aluminum extrusion jobs available in 2024, providing insights into the industry's current trends, job roles, and the skills required to succeed in this dynamic field.

The Aluminum Extrusion Industry: An Overview

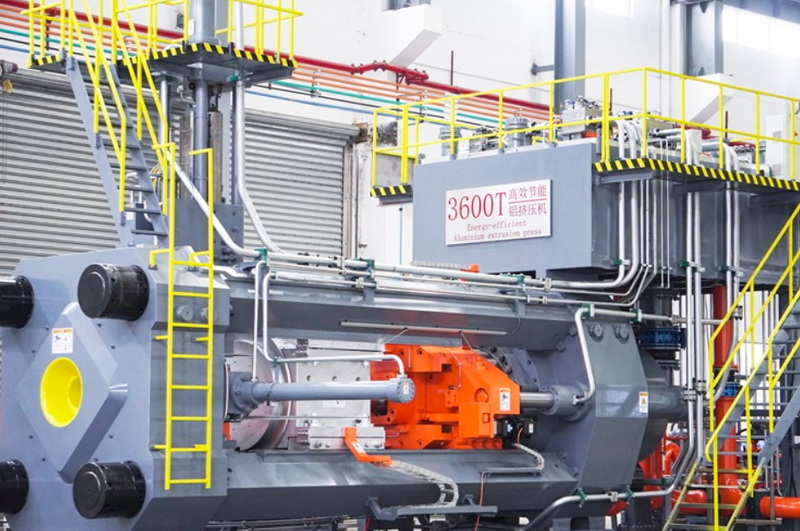

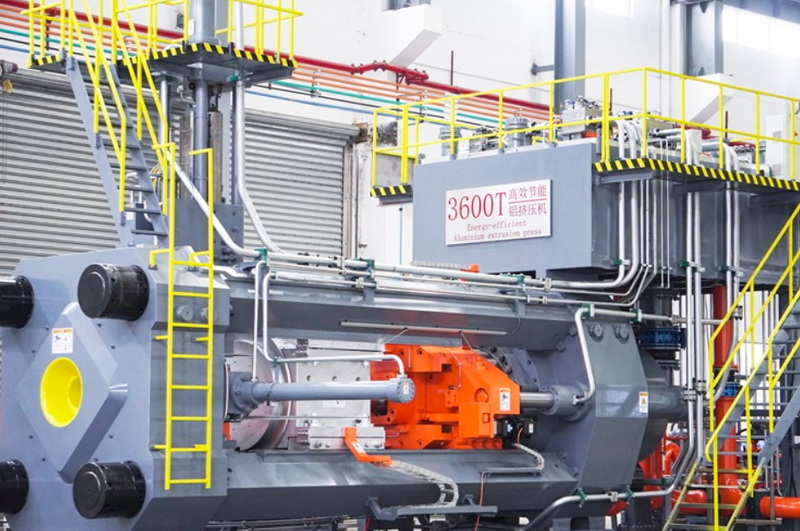

Aluminum extrusion is a process used to create objects of a fixed cross-sectional profile by forcing aluminum material through a die of the desired shape. This technique is widely used in industries such as construction, automotive, aerospace, and consumer goods manufacturing. The versatility and efficiency of aluminum extrusion have led to its increased adoption, creating a robust job market for those with the right skills and expertise.

Top Aluminum Extrusion Jobs in 2024

1. Aluminum Extrusion Press Operator

Aluminum extrusion press operators are at the heart of the production process. They are responsible for operating and monitoring the extrusion presses that shape aluminum into various profiles. This role requires a combination of technical knowledge and hands-on skills.

Key Responsibilities:

- Setting up and operating extrusion presses

- Monitoring the extrusion process for quality and efficiency

- Adjusting machine parameters as needed

- Ensuring safety protocols are followed

Required Skills:

- Understanding of aluminum extrusion processes

- Ability to read and interpret technical drawings

- Attention to detail and quality control

- Knowledge of safety procedures

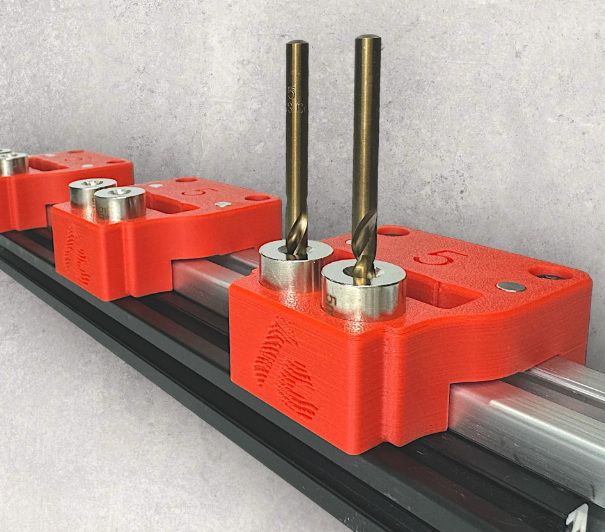

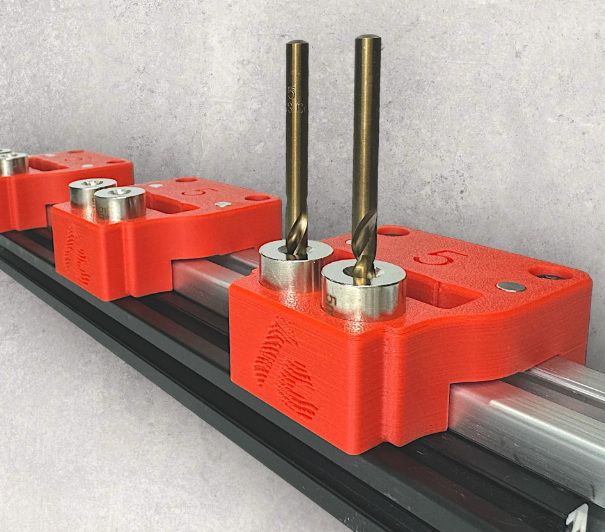

2. Extrusion Die Designer

Extrusion die designers play a crucial role in creating the tools that shape aluminum into specific profiles. This job requires a blend of creativity, technical expertise, and problem-solving skills.

Key Responsibilities:

- Designing extrusion dies based on client specifications

- Using CAD software to create detailed die designs

- Collaborating with production teams to optimize die performance

- Troubleshooting and refining die designs

Required Skills:

- Proficiency in CAD software

- Strong understanding of metallurgy and material properties

- Analytical and problem-solving abilities

- Attention to detail and precision

3. Quality Control Inspector

Quality control inspectors ensure that aluminum extrusion products meet the required specifications and standards. This role is critical in maintaining the reputation and reliability of the company's output.

Key Responsibilities:

- Inspecting extruded products for defects and inconsistencies

- Conducting measurements and tests to verify product quality

- Documenting inspection results and maintaining quality records

- Collaborating with production teams to address quality issues

Required Skills:

- Knowledge of quality control procedures and standards

- Familiarity with measurement tools and techniques

- Attention to detail and strong observational skills

- Ability to interpret technical specifications and drawings

4. Extrusion Process Engineer

Extrusion process engineers are responsible for optimizing the production process, improving efficiency, and developing new extrusion techniques. This role requires a deep understanding of both engineering principles and practical manufacturing processes.

Key Responsibilities:

- Analyzing and improving extrusion processes

- Developing new extrusion techniques and methodologies

- Troubleshooting production issues and implementing solutions

- Collaborating with other departments to enhance overall efficiency

Required Skills:

- Degree in Engineering (Mechanical, Materials, or related field)

- Strong analytical and problem-solving abilities

- Knowledge of lean manufacturing principles

- Excellent communication and teamwork skills

5. Aluminum Extrusion Sales Representative

Sales representatives in the aluminum extrusion industry play a vital role in connecting manufacturers with clients. This position requires a blend of technical knowledge and strong interpersonal skills.

Key Responsibilities:

- Identifying and pursuing new sales opportunities

- Providing technical advice to clients on extrusion capabilities

- Negotiating contracts and managing client relationships

- Collaborating with internal teams to meet client needs

Required Skills:

- Strong understanding of aluminum extrusion processes and applications

- Excellent communication and negotiation skills

- Ability to build and maintain client relationships

- Sales experience, preferably in a technical field

The Future of Aluminum Extrusion Jobs

As industries continue to seek lightweight and sustainable materials, the demand for aluminum extrusion professionals is expected to grow. Advancements in technology and increasing environmental concerns are shaping the future of aluminum extrusion jobs.

Emerging Trends in Aluminum Extrusion

1. Automation and Robotics: The integration of automated systems and robotics in the extrusion process is creating new job opportunities for those with skills in programming and robotics.

2. Sustainable Practices: As sustainability becomes a priority, jobs focused on developing eco-friendly extrusion processes and recycling technologies are on the rise.

3. Advanced Materials: The development of new aluminum alloys and composite materials is opening up opportunities for materials scientists and researchers in the extrusion field.

4. Digital Manufacturing: The adoption of Industry 4.0 technologies is creating demand for professionals who can manage and interpret data from smart manufacturing systems.

Skills for Success in Aluminum Extrusion Jobs

To thrive in the aluminum extrusion industry, professionals should focus on developing a combination of technical and soft skills:

1. Technical Knowledge: Understanding of metallurgy, material properties, and extrusion processes is fundamental.

2. Digital Literacy: Proficiency in CAD software, data analysis tools, and manufacturing management systems is increasingly important.

3. Problem-Solving: The ability to troubleshoot issues and develop innovative solutions is highly valued.

4. Adaptability: As technology evolves, the willingness to learn and adapt to new processes and tools is crucial.

5. Communication: Strong verbal and written communication skills are essential for collaboration and client interactions.

6. Safety Awareness: A thorough understanding of safety protocols and commitment to maintaining a safe work environment is non-negotiable.

Education and Training for Aluminum Extrusion Careers

Many aluminum extrusion jobs require specific education and training. Here are some common pathways:

- Vocational Training: For roles like press operators, vocational programs in manufacturing or metalworking can provide essential skills.

- Engineering Degrees: Positions such as process engineers or die designers often require bachelor's degrees in mechanical, materials, or industrial engineering.

- Apprenticeships: Many companies offer apprenticeship programs that combine on-the-job training with classroom instruction.

- Certifications: Industry-specific certifications, such as those offered by the Aluminum Extruders Council, can enhance career prospects.

The Impact of Technology on Aluminum Extrusion Jobs

Technology is reshaping the aluminum extrusion industry, influencing job roles and creating new opportunities:

1. 3D Printing: The integration of 3D printing in die design and prototyping is creating new roles for additive manufacturing specialists.

2. Artificial Intelligence: AI is being used to optimize extrusion processes, creating demand for data scientists and AI specialists in the industry.

3. Virtual Reality: VR technologies are being employed in training and design visualization, opening up new roles for VR specialists.

4. Internet of Things (IoT): The implementation of IoT in extrusion plants is creating jobs for professionals who can manage and interpret data from connected devices.

Challenges and Opportunities in Aluminum Extrusion Careers

While the aluminum extrusion industry offers many exciting career opportunities, it also comes with its own set of challenges:

Challenges:

- Keeping up with rapidly evolving technology

- Meeting increasing demands for sustainability and efficiency

- Adapting to global market fluctuations

- Addressing skills gaps in the workforce

Opportunities:

- Innovation in sustainable manufacturing processes

- Development of new applications for extruded aluminum products

- Expansion into emerging markets

- Career growth through continuous learning and skill development

Conclusion

The aluminum extrusion industry continues to offer a diverse range of career opportunities in 2024. From hands-on roles like press operators to technical positions such as process engineers and die designers, there are paths for various skill sets and interests. As the industry evolves with technological advancements and sustainability initiatives, professionals who combine technical expertise with adaptability and innovation will find themselves well-positioned for success.

Whether you're just starting your career or looking to transition into the aluminum extrusion field, staying informed about industry trends, continuously updating your skills, and embracing new technologies will be key to thriving in this dynamic sector. The best aluminum extrusion jobs in 2024 are those that not only offer stability and growth but also contribute to shaping the future of manufacturing and sustainable material use.

Frequently Asked Questions

1. What qualifications do I need to start a career in aluminum extrusion?

The qualifications needed for a career in aluminum extrusion vary depending on the specific role. Entry-level positions like press operators may require a high school diploma or vocational training, while engineering roles typically require a bachelor's degree in a relevant field such as mechanical or materials engineering. Many companies also offer apprenticeship programs that provide on-the-job training.

2. How does the aluminum extrusion industry contribute to sustainability?

The aluminum extrusion industry contributes to sustainability in several ways. Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly material. The industry is also focusing on energy-efficient extrusion processes and developing lightweight aluminum products that contribute to fuel efficiency in transportation applications. Many companies are investing in closed-loop recycling systems to minimize waste.

3. What are the career growth opportunities in aluminum extrusion?

Career growth opportunities in aluminum extrusion are diverse. Entry-level workers can progress to supervisory roles or specialize in areas like quality control or maintenance. Engineers can advance to senior positions or move into management roles. There are also opportunities to specialize in areas like research and development, process optimization, or sustainable manufacturing practices. Continuous learning and staying updated with industry trends are key to career advancement.

4. How is technology changing aluminum extrusion jobs?

Technology is significantly impacting aluminum extrusion jobs. Automation and robotics are changing the nature of production roles, requiring workers to develop skills in operating and maintaining advanced machinery. Digital technologies like CAD/CAM systems are essential for design and engineering positions. The integration of data analytics and AI is creating new roles focused on process optimization and predictive maintenance. Professionals who can adapt to these technological changes will be in high demand.

5. What are the biggest challenges facing the aluminum extrusion industry in 2024?

Some of the biggest challenges facing the aluminum extrusion industry in 2024 include managing raw material costs, meeting increasing demands for sustainability, adapting to rapidly evolving technologies, and addressing skills gaps in the workforce. Global market fluctuations and trade policies also pose challenges. However, these challenges also present opportunities for innovation and growth for those who can develop effective solutions.

Citations:

[1] https://www.indeed.com/q-aluminum-extrusion-jobs.html

[2] https://ca.indeed.com/q-aluminum-extrusion-jobs.html

[3] https://www.factmr.com/report/aluminum-extrusion-market

[4] https://www.youtube.com/watch?v=iiGlq7408ME

[5] https://www.youtube.com/watch?v=WZaP_-0jV5E

[6] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[7] https://www.altecextrusions.com/faqs/

[8] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[9] https://jooble.org/jobs-aluminum-extrusion

[10] https://www.ziprecruiter.com/t/Most-Popular-Types-Of-Aluminum-Extrusion-Jobs

[11] https://starext.com/frequently-asked-questions-about-aluminum-extrusions