Content Menu

● 1. Die Material and Construction

● 2. Design Complexity

● 3. Tooling and Maintenance Costs

● 4. Production Volume

● 5. Current Aluminum Prices

● 6. Labor Costs

● 7. Surface Finishing Options

● 8. Geopolitical Factors

● 9. Technological Advancements

● 10. Market Competition

● Conclusion

● FAQ

>> 1. What is an aluminum extrusion die?

>> 2. How does die complexity affect its cost?

>> 3. Why do raw aluminum prices fluctuate?

>> 4. What role does labor play in aluminum extrusion die pricing?

>> 5. How do surface finishes impact overall extrusion costs?

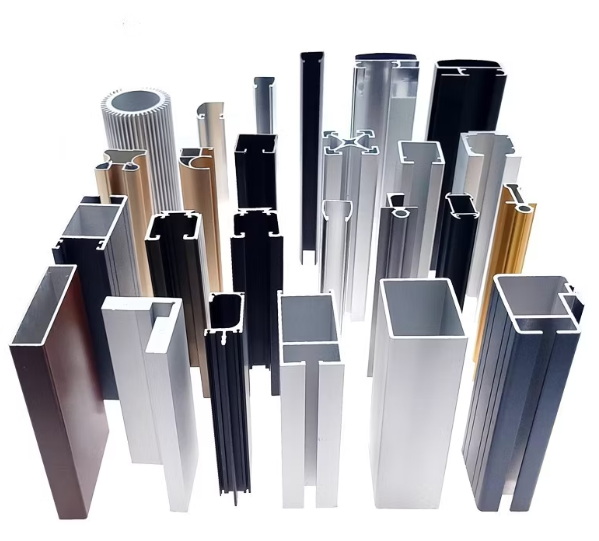

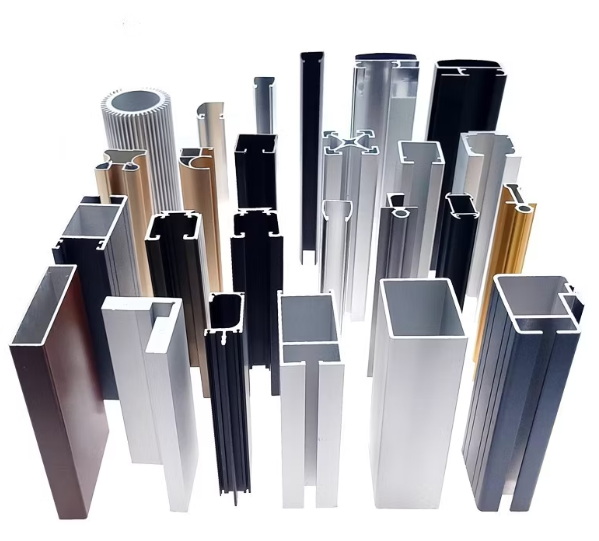

Aluminum extrusion is a widely used manufacturing process that allows for the creation of complex shapes and profiles from aluminum alloys. The cost of aluminum extrusion dies plays a crucial role in determining the overall expenses associated with this process. Understanding the factors that influence the price of these dies can help manufacturers and consumers make informed decisions. This article explores the various elements that affect aluminum extrusion die costs, providing insights into how each factor contributes to the final pricing.

1. Die Material and Construction

The material used to manufacture aluminum extrusion dies significantly affects their cost. High-quality materials, such as H13 steel or carbide, are commonly used due to their durability and ability to withstand high pressures during the extrusion process.

- Material Quality: Higher-grade materials generally result in longer-lasting dies, which can reduce costs in the long run by minimizing the need for replacements. For instance, H13 steel is known for its excellent heat resistance and toughness, making it a preferred choice for high-volume production.

- Die Complexity: More complex die designs, which may involve intricate shapes or multiple cavities, require more advanced machining techniques and additional material, leading to higher costs. The intricacy of the design can also affect the cooling channels within the die, impacting both performance and cost.

2. Design Complexity

The complexity of the die design is another key factor influencing its price.

- Shape and Profile: Simple shapes are less expensive to produce than intricate profiles that require detailed engineering and precise machining. For example, a standard rectangular profile can be produced at a lower cost compared to a custom-shaped profile designed for specific applications.

- Tolerance Requirements: Stricter tolerances necessitate more precise manufacturing processes, which can increase labor and material costs. Manufacturers often need to invest in advanced machinery capable of achieving these tolerances, further driving up costs.

- Simulation and Prototyping: Before finalizing a die design, manufacturers may use computer-aided design (CAD) software to simulate the extrusion process. This step helps identify potential issues but adds to initial costs due to software licensing and skilled labor requirements.

3. Tooling and Maintenance Costs

In addition to the die itself, various tooling components are necessary for the extrusion process.

- Support Tools: Items such as bolster plates and stack rings are essential for die operation and can add to the overall cost. These components ensure proper alignment and support during extrusion, which is critical for maintaining quality.

- Maintenance Needs: Regular maintenance is required to ensure optimal performance of the dies. This includes reconditioning or replacing worn-out components, which can add to long-term expenses. Manufacturers must budget for maintenance schedules and potential downtime during repairs.

- Reconditioning Services: Some manufacturers offer reconditioning services for worn dies, allowing them to be reused rather than replaced entirely. While this can save money in the short term, it requires an investment in skilled labor and equipment capable of restoring dies to their original specifications.

4. Production Volume

The volume of production significantly impacts die costs.

- Economies of Scale: Larger production runs can reduce the per-unit cost of dies since fixed costs are spread over more units. Conversely, low-volume orders often lead to higher per-unit costs due to setup and tooling expenses. Manufacturers often evaluate their production forecasts to determine whether it makes sense to invest in custom dies or use standard options.

- Prototype Costs: Prototyping often incurs higher costs because of the additional labor and resources needed for small runs or custom designs. However, investing in prototypes can lead to better outcomes in large-scale production by identifying potential design flaws early on.

5. Current Aluminum Prices

The fluctuating prices of aluminum itself directly influence die costs.

- Market Volatility: Aluminum is a commodity traded on global markets, with prices influenced by supply-demand dynamics, geopolitical events, and economic conditions. Recent trends have seen prices range from $1,500 to $3,500 per metric ton. Manufacturers must stay informed about market trends to adjust their pricing strategies accordingly.

- Raw Material Costs: The cost of aluminum ingots impacts not only the price of finished extrusions but also the cost structure associated with producing dies. When raw material prices rise, manufacturers may need to adjust their pricing models or seek alternative suppliers.

6. Labor Costs

Labor is a significant factor in determining die costs.

- Skilled Labor Requirements: The design and manufacturing of high-quality dies require skilled labor, which can be costly depending on regional wage standards. Training programs may be necessary to ensure workers have the skills needed for precision machining.

- Production Efficiency: Efficient production processes can help mitigate labor costs. Automation and advanced manufacturing technologies may reduce reliance on manual labor but require initial investments in equipment and training.

- Outsourcing vs In-House Production: Companies must decide whether to produce dies in-house or outsource this function. Outsourcing may reduce labor costs but could introduce delays or quality issues if not managed properly.

7. Surface Finishing Options

Surface finishing treatments can enhance the durability and aesthetic appeal of extrusions but also contribute to overall costs.

- Finishing Techniques: Processes such as anodizing or powder coating add additional steps in production, impacting both time and material costs. These treatments not only improve corrosion resistance but also allow for color customization that meets client specifications.

- Customization Needs: Custom finishes tailored to specific applications can further increase expenses due to their unique requirements. Manufacturers must balance customer demands with cost-effectiveness when offering surface finishing options.

8. Geopolitical Factors

Geopolitical events can have a profound impact on aluminum prices and consequently on die costs.

- Tariffs and Trade Policies: Tariffs imposed on aluminum imports can lead to increased raw material prices for manufacturers, which may be passed down to consumers through higher die costs. Companies must navigate these policies carefully when sourcing materials globally.

- Global Supply Chain Issues: Events such as natural disasters or political instability in key aluminum-producing regions can disrupt supply chains, affecting availability and pricing. Diversifying suppliers or investing in local sourcing strategies may help mitigate these risks.

9. Technological Advancements

Advancements in technology also play a crucial role in shaping die manufacturing processes.

- Computer Numerical Control (CNC) Machining: The adoption of CNC technology has revolutionized die manufacturing by increasing precision and reducing lead times. However, investing in CNC machinery requires significant upfront capital that can affect overall pricing strategies.

- Additive Manufacturing (3D Printing): Emerging technologies such as 3D printing are beginning to influence die production by allowing for rapid prototyping and reduced waste during manufacturing processes. While still relatively new in this field, these technologies hold promise for lowering future die costs through increased efficiency.

10. Market Competition

The competitive landscape within the aluminum extrusion industry influences pricing strategies as well.

- Supplier Competition: A competitive market encourages suppliers to offer better pricing structures or value-added services such as faster delivery times or enhanced customer support.

- Consumer Expectations: As customers become more informed about their options, they may demand higher quality at lower prices, pushing manufacturers to innovate while keeping costs manageable.

Conclusion

The cost of aluminum extrusion dies is influenced by a multitude of factors ranging from material quality and design complexity to labor expenses and geopolitical conditions. Understanding these variables enables manufacturers to make strategic decisions regarding production processes and budgeting for custom aluminum extrusions. By considering these factors carefully, businesses can optimize their operations while managing costs effectively.

FAQ

1. What is an aluminum extrusion die?

An aluminum extrusion die is a specialized tool used in the extrusion process that shapes molten aluminum into desired profiles by forcing it through an opening in the die.

2. How does die complexity affect its cost?

More complex dies require advanced machining techniques and materials, leading to higher production costs compared to simpler designs.

3. Why do raw aluminum prices fluctuate?

Raw aluminum prices fluctuate due to market demand, geopolitical events, supply chain disruptions, and economic conditions affecting production levels globally.

4. What role does labor play in aluminum extrusion die pricing?

Labor costs are significant due to the need for skilled workers in designing and manufacturing dies; higher wages or inefficient processes can increase overall expenses.

5. How do surface finishes impact overall extrusion costs?

Surface finishes enhance durability and aesthetics but add additional processing steps that increase both time and material costs during production.