Content Menu

● Introduction to the Ender 3 and Metal Extruders

>> Aluminum Filament Printing

● Upgrading to an Ender 3 Metal Extruder

>> Tools Needed

>> Installation Steps

● Printing with Aluminum Filament

>> Retraction Settings for Aluminum Filaments

>> Temperature Settings

● Additional Modifications for Enhanced Performance

>> All-Metal Hotend

>> Enclosure

>> Upgraded Cooling System

● Common Issues and Troubleshooting

>> Filament Grinding

>> Inconsistent Extrusion

>> Warping

● Conclusion

● FAQs

>> 1. Can the Ender 3 Metal Extruder Handle Aluminum Filament?

>> 2. What Are the Benefits of Upgrading to a Metal Extruder on the Ender 3?

>> 3. How Do I Install an Aluminum Extruder on My Ender 3?

>> 4. Are There Any Special Considerations for Printing with Aluminum-Infused Filaments?

>> 5. Will Upgrading to a Metal Extruder Void My Warranty?

● Citations:

The Creality Ender 3 is a popular and versatile 3D printer known for its affordability and ease of modification. One common upgrade for the Ender 3 is replacing the stock plastic extruder with a metal extruder, which can significantly improve print quality and reliability. However, when it comes to printing with aluminum filament, there are specific considerations and limitations to be aware of.

Introduction to the Ender 3 and Metal Extruders

The Ender 3 features a Bowden-style extrusion system, where filament is fed from a remote stepper motor through a PTFE tube to the hotend. The stock plastic extruder, while functional, has limitations such as durability issues, inconsistent filament feeding, and heat sensitivity.

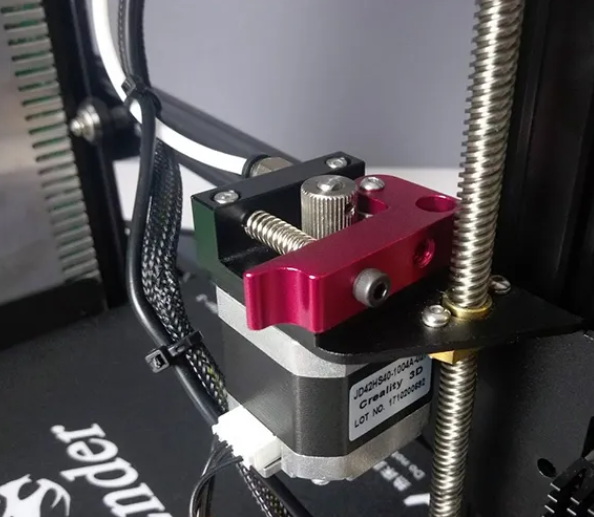

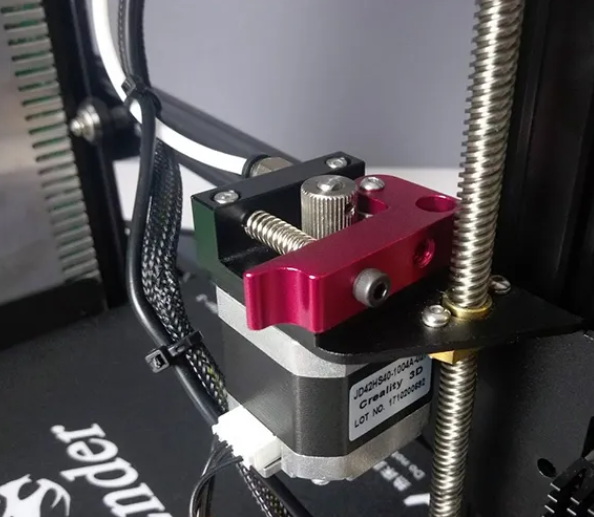

Upgrading to a metal extruder, typically made of aluminum, offers several benefits:

- Increased Durability: Aluminum is more resistant to wear and tear than plastic, ensuring long-term reliability.

- Improved Consistency: The rigid metal construction provides more consistent filament feeding, leading to better print quality.

- Better Heat Dissipation: Aluminum conducts heat more efficiently, reducing the risk of heat-related issues.

Aluminum Filament Printing

Aluminum filament, often used for its metallic appearance, is not actual metal but rather a composite material infused with metal particles. Printing with such filaments requires specific considerations:

- Temperature Requirements: Aluminum-infused filaments typically do not require higher temperatures than standard PLA or PETG, but they can be more abrasive.

- Extruder Compatibility: A metal extruder can handle aluminum-infused filaments more effectively than a plastic one due to its durability and consistent feeding.

Upgrading to an Ender 3 Metal Extruder

Upgrading the Ender 3 with a metal extruder is a relatively straightforward process that requires basic technical skills. Here's a step-by-step guide:

Tools Needed

- Allen wrenches (1.5mm, 2mm, and 2.5mm)

- Screwdriver

- Pliers (optional)

- New aluminum extruder kit

Installation Steps

1. Prepare Your Printer: Turn off and unplug your Ender 3. Allow the hotend to cool completely.

2. Unload Filament: Remove any filament from the extruder by heating up the hotend and pulling it out gently.

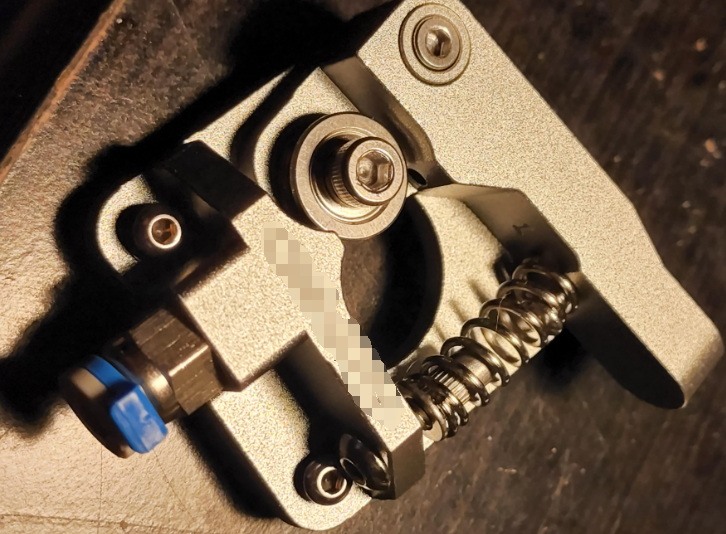

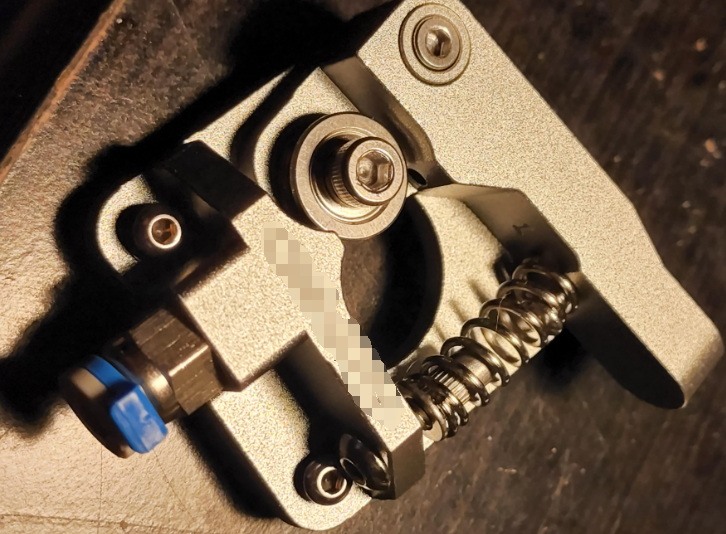

3. Disassemble the Stock Extruder:

- Unscrew the coupling holding the Bowden tube in place.

- Disconnect the stepper motor from the extruder body.

- Detach the lever arm from the old extruder assembly.

4. Install the Aluminum Extruder:

- Attach the new aluminum base plate to the stepper motor.

- Install the new gear onto the motor shaft, ensuring proper alignment.

- Assemble the lever arm and idler pulley.

5. Reconnect Components:

- Reattach the Bowden tube to its new coupling.

- Reconnect any electrical connectors.

6. Calibrate E-Steps: After installation, recalibrate your extruder steps per millimeter (E-steps) for accurate extrusion.

7. Test Print: Run a test print to ensure everything is functioning correctly.

Printing with Aluminum Filament

When printing with aluminum-infused filaments, consider the following tips:

- Abrasion: These filaments can be more abrasive than standard PLA or PETG, so ensure your extruder is well-maintained.

- Temperature: Typically, the same temperatures used for PLA or PETG are suitable, but monitor your prints for any signs of overheating.

- Retraction Settings: Adjust retraction settings to minimize stringing and oozing, which can be more pronounced with metal-infused filaments.

Retraction Settings for Aluminum Filaments

Retraction settings are crucial when printing with aluminum-infused filaments to prevent oozing and stringing. Here are some general guidelines:

- Retraction Distance: A distance of around 5 mm is typically effective, but you may need to adjust this based on the specific filament and print conditions.

- Retraction Speed: A speed between 30 mm/s and 50 mm/s is recommended to prevent oozing without causing filament grinding.

Temperature Settings

For most aluminum-infused filaments, the temperature settings are similar to those for PLA or PETG:

- Hotend Temperature: Typically between 190°C and 245°C, depending on the specific filament.

- Bed Temperature: Around 60°C to 80°C for optimal adhesion.

Additional Modifications for Enhanced Performance

All-Metal Hotend

While not necessary for aluminum-infused filaments, an all-metal hotend can be beneficial for printing materials that require higher temperatures. However, it may compromise smooth extrusion and retraction due to the lack of a PTFE liner.

Enclosure

An enclosure can help maintain a stable temperature environment, which is beneficial for printing with materials that are sensitive to temperature fluctuations. However, it's not typically required for aluminum-infused filaments.

Upgraded Cooling System

Improving the cooling system can enhance print quality by reducing warping and improving layer adhesion. This is particularly useful for larger prints.

Common Issues and Troubleshooting

Filament Grinding

- Cause: Incorrect retraction settings or misaligned extruder gears.

- Solution: Adjust retraction distance and speed, ensure proper gear alignment.

Inconsistent Extrusion

- Cause: Incorrect E-step calibration or clogged nozzle.

- Solution: Recalibrate E-steps, clean the nozzle.

Warping

- Cause: Insufficient bed adhesion or uneven temperature.

- Solution: Use adhesion aids like glue or tape, ensure a stable temperature environment.

Conclusion

Upgrading the Ender 3 with a metal extruder is a worthwhile investment for improving print quality and reliability, especially when printing with aluminum-infused filaments. While the Ender 3 metal extruder can handle such filaments effectively, it's essential to consider factors like abrasion and retraction settings for optimal results.

FAQs

1. Can the Ender 3 Metal Extruder Handle Aluminum Filament?

Yes, the Ender 3 metal extruder can handle aluminum-infused filaments effectively due to its durability and consistent filament feeding. However, ensure proper maintenance and adjust settings as needed for optimal results.

2. What Are the Benefits of Upgrading to a Metal Extruder on the Ender 3?

Upgrading to a metal extruder offers increased durability, improved consistency in filament feeding, better heat dissipation, and a longer lifespan compared to plastic extruders.

3. How Do I Install an Aluminum Extruder on My Ender 3?

Installation involves disassembling the stock extruder, attaching the new aluminum base plate and gear, reassembling components, and recalibrating E-steps. Refer to the step-by-step guide provided earlier.

4. Are There Any Special Considerations for Printing with Aluminum-Infused Filaments?

Yes, aluminum-infused filaments can be more abrasive and may require adjustments in retraction settings to minimize stringing and oozing. Monitor temperatures to avoid overheating.

5. Will Upgrading to a Metal Extruder Void My Warranty?

Modifying your printer may affect its warranty. It's best to check with the seller or manufacturer about their specific warranty policies regarding upgrades.

Citations:

[1] https://www.youtube.com/watch?v=UtemZqFJ5rY

[2] https://www.wevolver.com/article/ender-3-v2-max-speed

[3] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[4] https://www.youtube.com/watch?v=zJRxRVN3p3Y

[5] https://www.youtube.com/watch?v=uMHtzwEHfUc

[6] https://3dprinting.stackexchange.com/questions/14239/additional-mods-for-printing-metal-filled-filament-with-ender-3-v2

[7] https://www.aliexpress.com/item/1005006067667720.html

[8] https://www.youtube.com/watch?v=BUFC9YDIiLg

[9] https://www.youtube.com/watch?v=aKDym_qGLEw

[10] https://www.reddit.com/r/ender3/comments/cc4gcs/metal_printing_with_the_ender_3/

[11] https://www.youtube.com/watch?v=GHunYt9Yh6o

[12] https://all3dp.com/1/3d-printing-metal-with-metal-filament/

[13] https://www.reddit.com/r/ender3v2/comments/193nzb0/i_upgraded_to_the_all_metal_extruder_and_now_the/

[14] https://www.youtube.com/watch?v=sYwtE9A6F2A

[15] https://www.youtube.com/watch?v=rzNmFK2zIWo

[16] https://www.youtube.com/watch?v=ZBKeQWzqTPs

[17] https://letsprint3d.net/how-to-upgrade-the-extruder-ender-3/

[18] https://www.youtube.com/watch?v=Z5JmfNRNmtU

[19] https://www.youtube.com/watch?v=EGXQgN6PBmE