Content Menu

● Introduction to the Anycubic All Metal MK8 Extruder

>> Features of the Anycubic All Metal MK8 Extruder

● Handling Flexible Filaments

>> Benefits for Flexible Filament Printing

>> Anycubic i3 Mega and Flexible Filaments

● Tips for Printing with Flexible Filaments

>> Adjust Print Settings

>> Use the Right Bed Surface

>> Avoid Over-Extrusion

>> Experiment with Infill Settings

>> Extruder Tension

● Additional Tips for Printing with Flexible Filaments

>> Retraction Settings

>> Filament Path Optimization

>> Bed Adhesion

● Upgrading for Better Performance

>> Modified Designs for Flexibles

>> Direct Drive vs. Bowden Extruders

>> Benefits of All-Metal Extruders

>>> Durability

>>> Consistency

>>> Aesthetics and Reliability

● Advanced Modifications for Enhanced Performance

>> Hotend Upgrades

>> Cooling Systems

>> Firmware Adjustments

● Troubleshooting Common Issues

>> Filament Jamming

>> Inconsistent Extrusion

>> Warping and Curling

● Future Developments in Extruder Technology

>> Enhanced Drive Gears

>> Smart Extruders

>> Modular Designs

● Advanced Printing Techniques

>> Multi-Material Printing

>> Post-Processing Techniques

● Conclusion

● FAQ

>> 1. Can the Anycubic All Metal MK8 Extruder handle flexible filaments?

>> 2. What types of flexible filaments can it handle?

>> 3. Is the Anycubic All Metal MK8 Extruder compatible with the Anycubic i3 Mega?

>> 4. How does the Anycubic All Metal MK8 Extruder improve printing with flexible filaments?

>> 5. Do I need to change the stepper motor when installing the Anycubic All Metal MK8 Extruder?

The Anycubic All Metal MK8 Extruder is a popular upgrade for various 3D printers, including models from Creality and potentially Anycubic. This extruder is designed to enhance the printing experience by providing a more stable and durable setup compared to the stock plastic extruders. One of the key questions users have is whether this extruder can handle flexible filaments effectively. In this article, we will explore the capabilities of the Anycubic All Metal MK8 Extruder, focusing on its compatibility with flexible filaments like TPU and TPE.

Introduction to the Anycubic All Metal MK8 Extruder

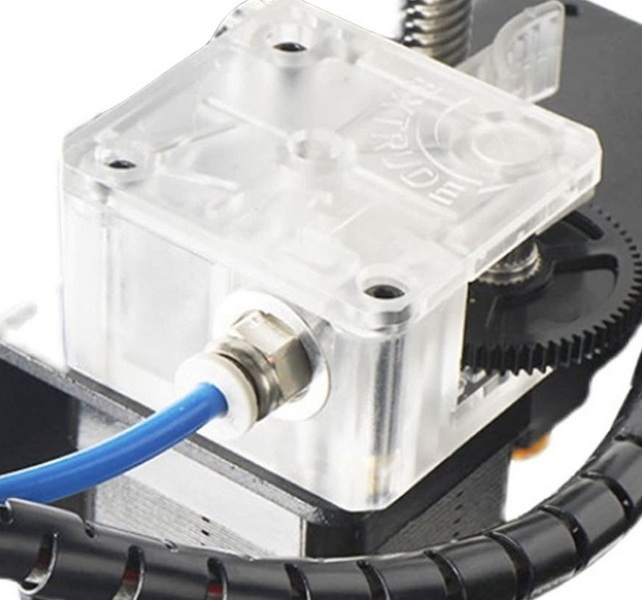

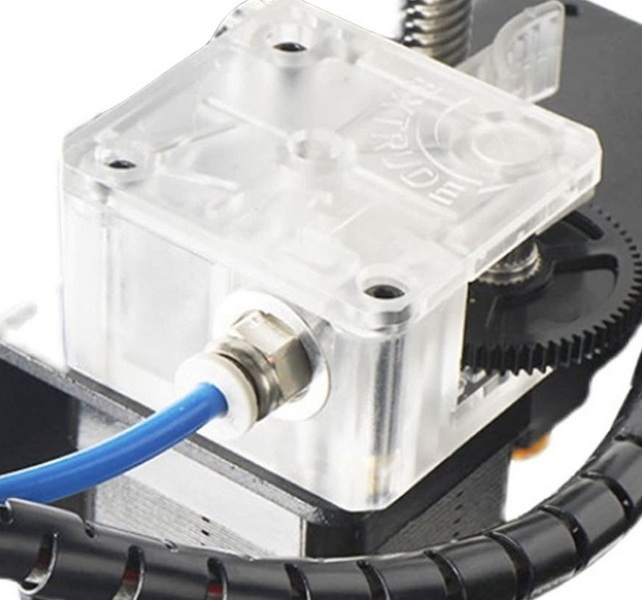

The Anycubic All Metal MK8 Extruder is typically made from high-quality aluminum, offering a robust and reliable solution for feeding filaments into the hotend of a 3D printer. It is designed to be compatible with 1.75mm filaments and is often used in Bowden-style extruder setups. This extruder is praised for its ability to handle various types of filaments, including PLA, ABS, and potentially flexible materials.

Features of the Anycubic All Metal MK8 Extruder

- Material: Constructed from high-quality aluminum, ensuring durability and stability.

- Compatibility: Designed for 1.75mm filaments, making it versatile for different printing needs.

- Easy Installation: Typically comes with instructions and is relatively straightforward to install, replacing the stock plastic extruder.

- Filament Handling: Equipped with a robust drive gear system that can grip the filament firmly, reducing the risk of slipping or grinding.

Handling Flexible Filaments

Flexible filaments, such as TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer), present unique challenges in 3D printing. They are more prone to bending and twisting, which can cause issues with the extruder's ability to feed them consistently. The Anycubic All Metal MK8 Extruder, with its robust design and high-quality drive gears, is well-suited to handle these flexible materials.

Benefits for Flexible Filament Printing

1. Stability and Consistency: The all-metal construction ensures that the extruder maintains its shape and function under varying temperatures and pressures, providing a consistent feed rate for flexible filaments.

2. Grip and Traction: The extruder's drive gears are designed to grip the filament firmly, reducing the likelihood of slippage or jamming, which is particularly beneficial when working with flexible materials.

3. Reduced Wear and Tear: By minimizing the risk of filament grinding or slipping, the extruder helps extend the lifespan of both the extruder itself and the printer's other components.

Anycubic i3 Mega and Flexible Filaments

For printers like the Anycubic i3 Mega, handling flexible filaments requires careful consideration of the extruder setup. While the i3 Mega can be modified to print flexible materials, it often requires additional modifications to ensure smooth filament flow.

Tips for Printing with Flexible Filaments

Printing with flexible filaments can be challenging, but with the right techniques and settings, it can be highly rewarding. Here are some tips to improve your experience:

Adjust Print Settings

- Printing Speed: Flexible filaments generally require slower printing speeds to prevent buckling and curling. A speed of around 20mm/s is often recommended.

- Extrusion Temperature: Ensure that the extruder temperature is high enough to properly melt the filament. Gradually raise the temperature by 5°C if necessary, up to a maximum of around 255°C.

- Nozzle Size: Using a slightly larger nozzle (e.g., 0.6mm or 0.8mm) can improve the flow of flexible filaments and reduce clogging issues.

Use the Right Bed Surface

Flexible filaments tend to stick well to the build plate, so a smooth and clean surface is essential. A PEI-coated bed works well for these materials.

Avoid Over-Extrusion

Over-extrusion can cause flexible filaments to buckle and curl. Ensure that the filament is being extruded at the correct rate to prevent this issue.

Experiment with Infill Settings

For flexible filaments, it's best to use a lower infill density and a simple infill pattern to achieve better print quality.

Extruder Tension

When printing with flexible filaments, it's crucial to adjust the extruder tension. Lower tension can help prevent filament buckling by limiting the maximum force applied to the filament.

Additional Tips for Printing with Flexible Filaments

Retraction Settings

Flexible filaments are sensitive to quick movements like retractions. Initially, it's advisable to disable retraction to focus on finding the optimal speed and extrusion rates. Once confident in these settings, a small amount of retraction with a slower retraction speed can be added to prevent oozing.

Filament Path Optimization

Ensure that the filament path is as straight and smooth as possible. Avoid sharp turns or kinks in the Bowden tube, and use a PTFE liner in the hotend to reduce thermal expansion issues.

Bed Adhesion

For flexible filaments, a smooth and clean bed surface is crucial. Consider using adhesives specifically designed for flexible materials to enhance bed adhesion.

Upgrading for Better Performance

Upgrading your printer with an all-metal extruder like the MK8 can significantly enhance its performance with flexible filaments. Here are some considerations:

Modified Designs for Flexibles

Some modified MK8 extruders are specifically designed to support flexible filaments, offering features like improved Bowden tube fittings and adjustable outfeed tubes.

Direct Drive vs. Bowden Extruders

While the Anycubic All Metal MK8 Extruder is typically used in Bowden setups, direct drive extruders are often preferred for flexible filaments due to their shorter filament path and reduced risk of clogs.

Benefits of All-Metal Extruders

Durability

All-metal extruders are more durable than their plastic counterparts, reducing the risk of cracking or breaking under stress. This is particularly important when handling flexible filaments, which can exert more force on the extruder due to their elasticity.

Consistency

The consistent grip and feed rate provided by an all-metal extruder help maintain print quality over time, reducing issues like under-extrusion or over-extrusion that can occur with flexible filaments.

Aesthetics and Reliability

Upgrading to an all-metal extruder not only improves performance but also enhances the appearance of the printer, giving it a more professional look. The reliability of these extruders ensures that they can handle a variety of filaments without compromising on quality.

Advanced Modifications for Enhanced Performance

Hotend Upgrades

Upgrading the hotend to a model with a longer melt zone can improve the flow of flexible filaments, reducing the risk of clogs and improving overall print quality.

Cooling Systems

Implementing a more efficient cooling system can help maintain a stable temperature environment, which is crucial for printing with flexible materials. This can include upgrading the fan or adding additional cooling components.

Firmware Adjustments

Adjusting the printer's firmware to optimize retraction settings and extrusion rates can further enhance performance with flexible filaments. This may involve tweaking parameters such as retraction speed and distance.

Troubleshooting Common Issues

Filament Jamming

If filament jamming occurs, check for blockages in the hotend or Bowden tube. Ensure that the filament path is clear and that the extruder tension is properly adjusted.

Inconsistent Extrusion

Inconsistent extrusion can be due to incorrect temperature settings or insufficient extruder grip. Adjust the extruder temperature and tension as needed to achieve consistent flow.

Warping and Curling

To prevent warping and curling, ensure that the print bed is level and that adhesion is optimal. Using a brim or raft can also help secure the print to the bed.

Future Developments in Extruder Technology

Enhanced Drive Gears

Future extruders may feature advanced drive gears with improved grip and traction, specifically designed to handle flexible filaments more efficiently.

Smart Extruders

The development of smart extruders with integrated sensors could provide real-time feedback on filament flow and temperature, allowing for more precise control over the printing process.

Modular Designs

Modular extruder designs could offer users the flexibility to easily swap between different types of extruders or upgrade components without replacing the entire extruder.

Advanced Printing Techniques

Multi-Material Printing

For printers capable of multi-material printing, combining flexible filaments with rigid materials can create complex and functional prints. This requires precise control over extruder temperatures and retraction settings.

Post-Processing Techniques

Flexible prints can be further enhanced through post-processing techniques such as sanding, painting, or applying coatings to improve durability and appearance.

Conclusion

The Anycubic All Metal MK8 Extruder is well-suited for handling flexible filaments due to its robust design and high-quality components. While it may not be specifically branded as "Anycubic," the MK8 extruder design is widely compatible with various 3D printer models, including those from Anycubic. By upgrading to an all-metal extruder, users can enhance their printer's performance with flexible materials like TPU and TPE.

FAQ

1. Can the Anycubic All Metal MK8 Extruder handle flexible filaments?

Yes, the Anycubic All Metal MK8 Extruder is capable of handling flexible filaments due to its robust design and high-quality drive gears.

2. What types of flexible filaments can it handle?

It can handle various types of flexible filaments, including TPU and TPE, provided they are within the hardness range suitable for the extruder's design.

3. Is the Anycubic All Metal MK8 Extruder compatible with the Anycubic i3 Mega?

While not specifically designed for the i3 Mega, the MK8 extruder can be adapted for use with modifications to ensure compatibility.

4. How does the Anycubic All Metal MK8 Extruder improve printing with flexible filaments?

It improves printing by providing a consistent feed rate, reducing slippage, and minimizing wear on the printer's components.

5. Do I need to change the stepper motor when installing the Anycubic All Metal MK8 Extruder?

Typically, no stepper motor change is required, as the extruder is designed to be compatible with existing hardware.