Content Menu

● Understanding 3030 Aluminum Extrusions

>> Benefits of 3030 Aluminum Extrusions

● Customization Options for 3030 Aluminum Extrusions

>> Length Customization

>> Profile Modifications

>> Surface Treatments

>> Machining Services

>> Accessory Integration

● Practical Applications of Customized 3030 Aluminum Extrusions

>> Industrial Automation

>> Robotics

>> Workstations and Furniture

>> DIY Projects

>> Architectural Applications

● The Customization Process

>> Initial Consultation

>> Design and Prototyping

>> Production

>> Delivery and Assembly

● Conclusion

● Frequently Asked Questions

>> 1. What is the standard length of 3030 aluminum extrusions?

>> 2. Can I order 3030 aluminum extrusions in different colors?

>> 3. Are there any limitations to customizing 3030 aluminum extrusions?

>> 4. How do I determine the right dimensions for my project?

>> 5. Can I use 3030 aluminum extrusions for outdoor applications?

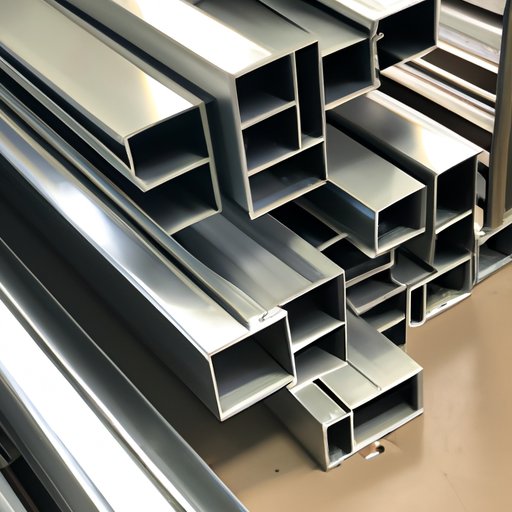

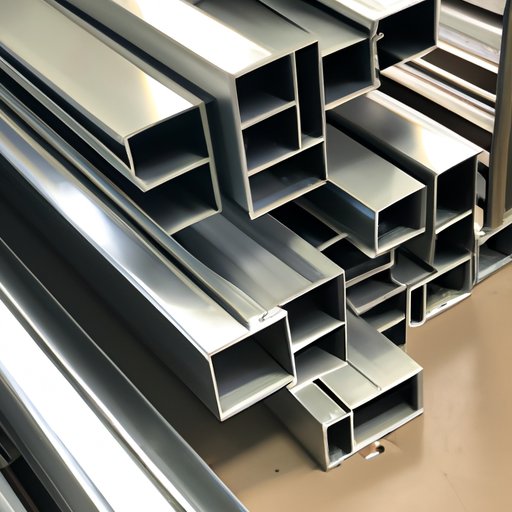

Aluminum extrusions are a popular choice in various industries due to their versatility, strength, and lightweight properties. Among the many types of aluminum extrusions available, the 3030 aluminum extrusion is particularly favored for its balanced dimensions and structural integrity. This article will explore the customization options available for 3030 aluminum extrusions, the benefits of customization, and practical applications in different fields.

Understanding 3030 Aluminum Extrusions

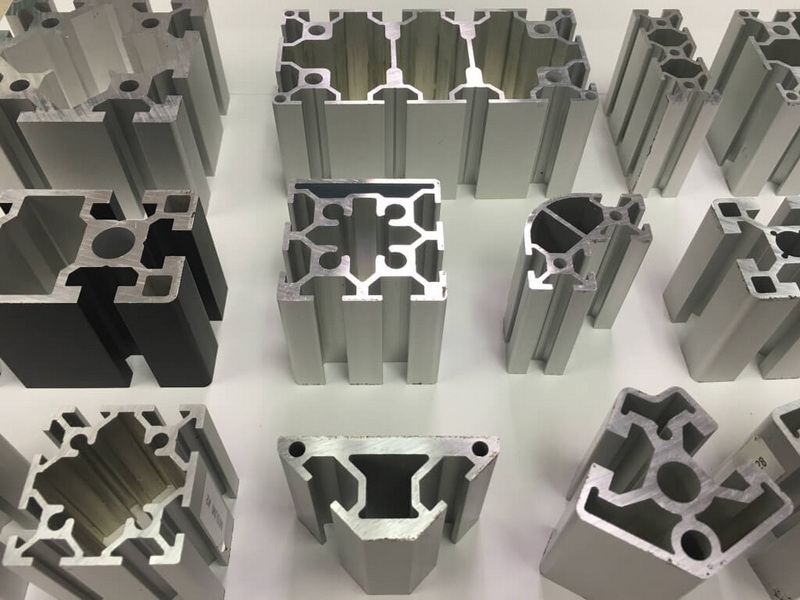

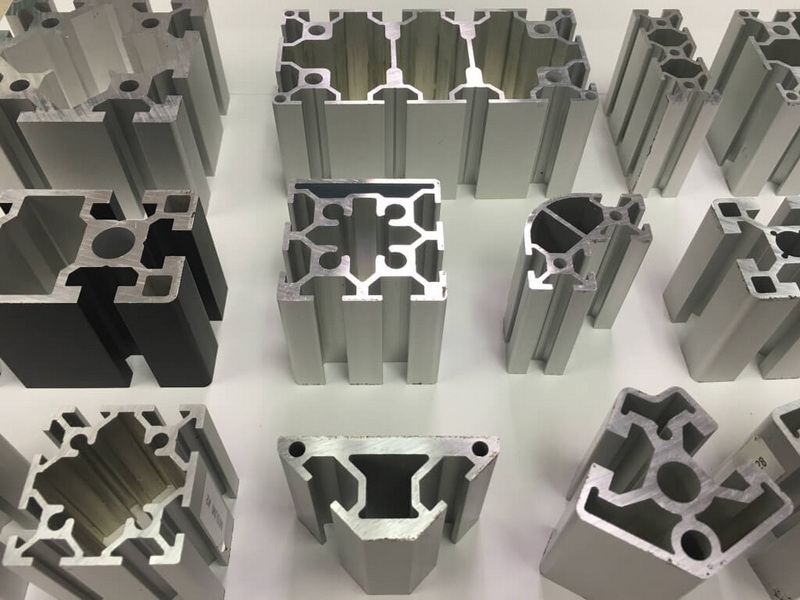

The term "3030" refers to the dimensions of the aluminum extrusion profile, which measures 30mm by 30mm. This square profile is part of the 30 series of T-slot aluminum extrusions, which are characterized by their T-shaped slots that allow for easy assembly and integration with various components. The 3030 profile is commonly used in building frames, machine guards, workstations, and other structural applications.

Benefits of 3030 Aluminum Extrusions

1. Lightweight and Strong: Aluminum is known for its high strength-to-weight ratio, making 3030 extrusions ideal for applications where weight is a concern without compromising strength.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion, making it suitable for both indoor and outdoor applications.

3. Ease of Assembly: The T-slot design allows for quick and easy assembly using standard fasteners, reducing the need for specialized tools or skills.

4. Versatility: 3030 extrusions can be used in a wide range of applications, from industrial machinery to DIY projects, making them a versatile choice for engineers and hobbyists alike.

5. Customization Options: One of the most significant advantages of 3030 aluminum extrusions is the ability to customize their dimensions and features to meet specific project requirements.

Customization Options for 3030 Aluminum Extrusions

Length Customization

One of the most straightforward customization options is the length of the extrusion. While standard lengths are typically available (often around 6 meters), manufacturers can cut the extrusions to specific lengths based on project needs. This flexibility allows users to minimize waste and ensure that they have the right size for their application.

Profile Modifications

In addition to length, the profile of the extrusion can be modified. This includes altering the wall thickness, adding or removing slots, and changing the shape of the profile. Custom profiles can be designed to accommodate specific loads or to fit unique assembly requirements.

Surface Treatments

Aluminum extrusions can undergo various surface treatments to enhance their appearance and performance. Common treatments include anodizing, powder coating, and painting. Anodizing not only improves corrosion resistance but also allows for color customization, making it an excellent choice for aesthetic applications.

Machining Services

For more complex projects, machining services can be employed to add features such as holes, grooves, or custom shapes to the extrusions. This allows for precise fitting and integration with other components, enhancing the overall functionality of the assembly.

Accessory Integration

3030 aluminum extrusions are compatible with a wide range of accessories, including brackets, connectors, and fasteners. Customizing the dimensions of the extrusion can also involve selecting specific accessories that fit the modified profile, ensuring a seamless assembly process.

Practical Applications of Customized 3030 Aluminum Extrusions

Industrial Automation

In industrial settings, customized 3030 aluminum extrusions are often used to create machine frames, conveyor systems, and safety guards. The ability to tailor the dimensions and features of the extrusions allows engineers to design systems that meet specific operational requirements. For instance, a conveyor system may require specific lengths and slot placements to accommodate various components, ensuring smooth operation and efficiency.

Robotics

The robotics industry frequently utilizes 3030 aluminum extrusions for building lightweight and robust frames. Custom lengths and profiles can be designed to accommodate various robotic components, ensuring optimal performance and stability. The modular nature of the T-slot design allows for easy adjustments and upgrades as technology evolves.

Workstations and Furniture

In office and workshop environments, customized 3030 extrusions can be used to create ergonomic workstations, shelving units, and display racks. The flexibility in design allows for the incorporation of features such as adjustable heights and modular configurations. This adaptability is particularly beneficial in dynamic work environments where needs may change frequently.

DIY Projects

Hobbyists and DIY enthusiasts appreciate the versatility of 3030 aluminum extrusions for building custom projects. Whether constructing a home automation system or a unique piece of furniture, the ability to customize dimensions and features makes it an ideal choice for creative applications. The ease of assembly and the availability of accessories further enhance the DIY experience, allowing for innovative designs.

Architectural Applications

In architecture, 3030 aluminum extrusions can be used for structural framing, facades, and decorative elements. Customization allows architects to achieve specific aesthetic and functional goals, enhancing the overall design of a building. The lightweight nature of aluminum also contributes to energy efficiency in construction, as it reduces the overall load on structures.

The Customization Process

Initial Consultation

The customization process typically begins with an initial consultation between the client and the manufacturer. During this phase, the specific requirements of the project are discussed, including dimensions, load capacities, and any special features needed. This step is crucial for ensuring that the final product meets the client's expectations.

Design and Prototyping

Once the requirements are established, the manufacturer will create a design for the customized extrusion. This may involve computer-aided design (CAD) software to visualize the final product. Prototyping may also be conducted to test the design's functionality and make any necessary adjustments before full-scale production.

Production

After finalizing the design, the production phase begins. This involves cutting the extrusions to the specified lengths, applying any surface treatments, and performing machining operations as needed. Quality control measures are implemented throughout the production process to ensure that the extrusions meet the required specifications.

Delivery and Assembly

Once the customized 3030 aluminum extrusions are produced, they are delivered to the client. Depending on the complexity of the project, assembly services may also be offered. This ensures that the extrusions are correctly integrated into the overall system, maximizing their effectiveness and functionality.

Conclusion

The ability to customize the dimensions of 3030 aluminum extrusions opens up a world of possibilities for engineers, designers, and hobbyists. From adjusting lengths to modifying profiles and integrating accessories, the customization options available ensure that these extrusions can meet the specific needs of any project. With their lightweight, strong, and corrosion-resistant properties, 3030 aluminum extrusions are an excellent choice for a wide range of applications.

Frequently Asked Questions

1. What is the standard length of 3030 aluminum extrusions?

The standard length is typically around 6 meters, but they can be cut to custom lengths as needed.

2. Can I order 3030 aluminum extrusions in different colors?

Yes, through anodizing or powder coating, you can customize the color of the extrusions.

3. Are there any limitations to customizing 3030 aluminum extrusions?

While many modifications are possible, the complexity of the design and the manufacturing capabilities may impose some limitations.

4. How do I determine the right dimensions for my project?

Consider the load requirements, space constraints, and the intended use of the extrusion to determine the appropriate dimensions.

5. Can I use 3030 aluminum extrusions for outdoor applications?

Yes, aluminum is naturally corrosion-resistant, making it suitable for outdoor use, especially with additional surface treatments.