Content Menu

● Understanding the MK8 Aluminum Extruder

● Common Causes of Jamming in 3D Printers

● How the MK8 Aluminum Extruder Addresses Jamming

>> 1. Enhanced Filament Grip

>> 2. Improved Heat Management

>> 3. Adjustable Tension Settings

● User Experiences with MK8 Aluminum Extruders

● Comparing MK8 Aluminum Extruders with Other Extruders

● Installation Process for MK8 Aluminum Extruders

● Maintaining Your MK8 Aluminum Extruder

● Conclusion

● FAQ

>> 1. What are the main advantages of using an MK8 aluminum extruder?

>> 2. Can I use flexible filaments with an MK8 aluminum extruder?

>> 3. How do I adjust the tension on my MK8 aluminum extruder?

>> 4. Is it easy to install an MK8 aluminum extruder?

>> 5. Will upgrading my extruder guarantee no more jams?

● Citations:

3D printing has revolutionized the manufacturing landscape, enabling hobbyists and professionals alike to create intricate designs with relative ease. However, one of the most common issues faced by 3D printer users is filament jamming, particularly in extruders. The MK8 aluminum extruder has gained popularity as a potential solution to this problem. This article will explore whether an MK8 aluminum extruder can effectively reduce jamming issues, examining its design, functionality, and user experiences.

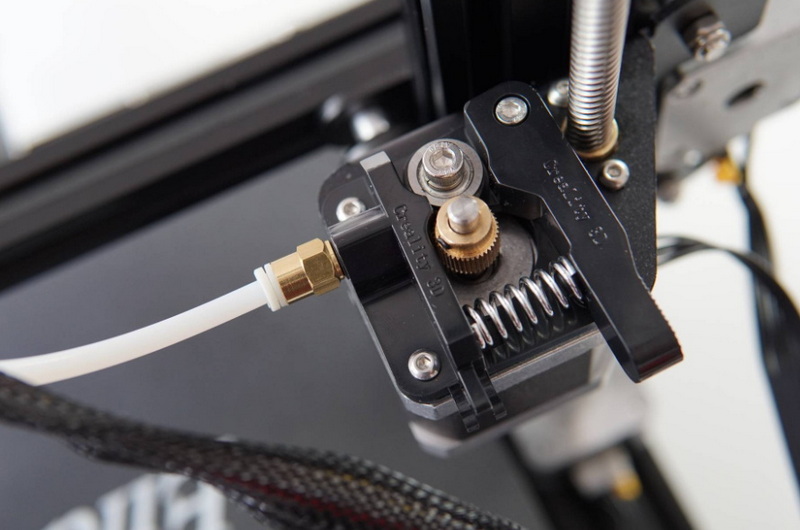

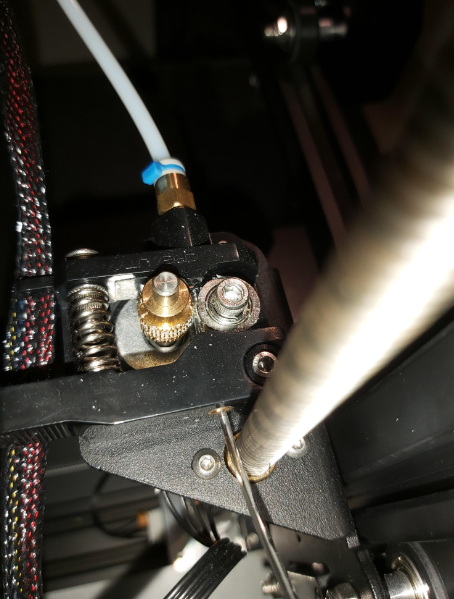

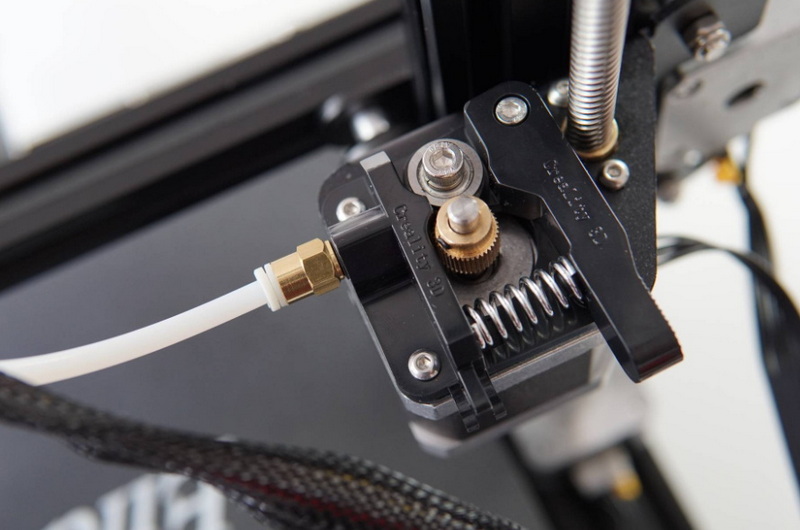

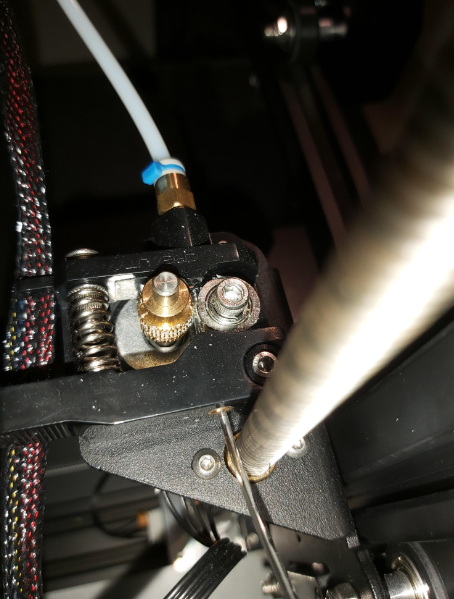

Understanding the MK8 Aluminum Extruder

The MK8 aluminum extruder is an upgrade from traditional plastic extruders. It is designed to provide better performance and reliability in feeding filament through the hot end. The key features of the MK8 aluminum extruder include:

- Durability: Made from aluminum, this extruder is less prone to wear and tear compared to plastic counterparts.

- Improved Filament Grip: The design often includes a more robust gear mechanism that enhances grip on the filament, reducing slippage.

- Better Heat Management: Aluminum dissipates heat more efficiently, which is crucial for maintaining optimal temperatures during printing.

Common Causes of Jamming in 3D Printers

Before delving into the benefits of the MK8 aluminum extruder, it's essential to understand the common causes of jamming:

- Filament Quality: Poor-quality filament can lead to inconsistencies in diameter and material properties, causing jams.

- Temperature Issues: Incorrect temperature settings can cause filament to soften too much or not enough, leading to blockages.

- Extruder Tension: Improper tension on the extruder gears can either crush the filament or fail to grip it properly.

- Nozzle Clogs: Accumulation of burnt material or debris in the nozzle can restrict filament flow.

How the MK8 Aluminum Extruder Addresses Jamming

The MK8 aluminum extruder addresses several of these issues effectively:

1. Enhanced Filament Grip

The MK8's design often features a dual-drive gear system that provides a stronger grip on the filament. This minimizes slippage and ensures that the filament is pushed consistently through the hot end. Users have reported fewer instances of under-extrusion and jamming when using this type of extruder compared to traditional plastic models.

2. Improved Heat Management

The aluminum construction allows for better heat dissipation. This is crucial because overheating can lead to filament degradation and subsequent jams. By maintaining a more stable temperature within the hot end, the MK8 helps ensure that filament flows smoothly without softening prematurely.

3. Adjustable Tension Settings

Many MK8 aluminum extruders come with adjustable tension settings. This feature allows users to fine-tune how tightly the gears grip the filament. Proper tension is vital; too much pressure can crush filaments like PLA, while too little can lead to slippage. Users have found that adjusting this tension has significantly reduced jamming incidents.

User Experiences with MK8 Aluminum Extruders

User feedback plays a critical role in assessing the effectiveness of any 3D printing component. Many users who have upgraded to an MK8 aluminum extruder report positive changes in their printing experience:

- Reduced Jams: A significant number of users have noted a decrease in jamming issues after switching from plastic to aluminum extruders.

- Better Print Quality: With improved filament feeding, users have experienced higher print quality with fewer defects such as layer separation or inconsistent extrusion.

- Compatibility with Various Filaments: Users have successfully printed with a wider range of materials (including flexible filaments) without experiencing jams, thanks to the enhanced design of the MK8.

Comparing MK8 Aluminum Extruders with Other Extruders

To understand the advantages of an MK8 aluminum extruder better, it's useful to compare it with other types of extruders commonly used in 3D printing:

| Feature | MK8 Aluminum Extruder | Plastic Extruder | Direct Drive Extruder |

| Durability | High | Low | Medium |

| Filament Grip | Excellent | Fair | Excellent |

| Heat Dissipation | Good | Poor | Good |

| Adjustable Tension | Yes | No | Yes |

| Compatibility with Flexible Filaments | High | Low | High |

As shown in this comparison table, the MK8 aluminum extruder excels in durability and grip while offering adjustable tension settings that are crucial for preventing jams.

Installation Process for MK8 Aluminum Extruders

Installing an MK8 aluminum extruder can be straightforward if you follow these steps:

1. Gather Tools: You will need basic tools like a screwdriver and possibly pliers for installation.

2. Remove Old Extruder: Carefully unbolt your existing plastic extruder from your 3D printer frame.

3. Install New Extruder: Align the new MK8 aluminum extruder where the old one was mounted and secure it using screws provided in your kit.

4. Connect Filament Guide Tube: If your kit includes a filament guide tube (like Capricorn tubing), ensure it is connected properly for optimal performance.

5. Calibrate Your Printer: After installation, calibrate your printer settings according to your new setup for best results.

Maintaining Your MK8 Aluminum Extruder

To ensure your MK8 aluminum extruder continues to perform well over time, consider these maintenance tips:

- Regularly check for any signs of wear on gears or other components.

- Clean any debris from around the nozzle area to prevent clogs.

- Periodically recalibrate tension settings based on your current filament type.

- Monitor temperature settings closely during prints; adjust as necessary based on material being used.

Conclusion

In conclusion, upgrading to an MK8 aluminum extruder can significantly reduce jamming issues associated with 3D printing. Its durable construction, enhanced grip on filament, improved heat management, and adjustable tension settings collectively contribute to a smoother printing experience. For those struggling with frequent jams using traditional plastic extruders, investing in an MK8 aluminum extruder could be a worthwhile solution.

FAQ

1. What are the main advantages of using an MK8 aluminum extruder?

The main advantages include improved durability, better filament grip, enhanced heat management, and adjustable tension settings which collectively reduce jamming issues.

2. Can I use flexible filaments with an MK8 aluminum extruder?

Yes, many users report success when printing flexible filaments with an MK8 aluminum extruder due to its improved design that reduces binding.

3. How do I adjust the tension on my MK8 aluminum extruder?

Most MK8 aluminum extruders come with a tension adjustment screw. Turning this screw clockwise increases tension while counterclockwise decreases it.

4. Is it easy to install an MK8 aluminum extruder?

Yes, installation is generally straightforward and can be completed by following online tutorials or videos specific to your printer model.

5. Will upgrading my extruder guarantee no more jams?

While upgrading to an MK8 aluminum extruder significantly reduces jamming issues, other factors such as filament quality and temperature settings also play important roles in successful printing.

Citations:

[1] https://novo3d.in/mk8-extruder/

[2] https://www.cnckitchen.com/blog/how-to-set-extruder-tension

[3] https://www.creality.store/products/all-metal-extruder-aluminum-mk8-extruder-with-capricorn-tubing

[4] https://www.kywoo3d.com/blogs/3d-printer-news/3d-printer-extruder-system-basic-introduction

[5] https://www.aliexpress.com/i/32948241656.html

[6] https://timeto3d.com/products/mk8-extruder-aluminum-alloy-block-bowden-extruder-frame-1-75mm-filament-right-hand

[7] https://groups.google.com/g/makerbot/c/yWk6ezD9dm4

[8] https://www.youtube.com/watch?v=Npuocf_f0jk

[9] https://www.olelectronics.in/product/aluminum-3d-printer-block/

[10] https://www.aliexpress.com/item/1005006067667720.html

[11] https://www.reddit.com/r/ender5plus/comments/n02dbn/reason_to_upgrade_to_an_all_metal_mk8_extruder/

[12] https://reprap.org/forum/read.php

[13] https://www.reddit.com/r/ender3/comments/9oybbg/need_your_expert_opinion_on_mk8_extruder/

[14] https://www.cnckitchen.com/blog/which-is-the-strongest-3d-printing-extruder

[15] https://makerbase3d.com/product/upgraded-dual-gear-mk8-aluminum-extruder/

[16] https://blog.goldsupplier.com/metal-extruder/

[17] https://www.youtube.com/watch?v=fzWj6adWc-Y

[18] https://www.microcenter.com/product/625572/creality-all-metal-mk8-extruder-feeder-drive-aluminum?bvroute=Review%2F243024893&bvstate=pg%3A2%2Fct%3Ar&showfullsite=true&storeid=105

[19] https://3dprinting.stackexchange.com/questions/5434/which-is-the-difference-between-mk6-and-mk8-and-even-mk10

[20] https://3d-drucker-filament.de/en/MK8-Aluminium-Extruder-Feeder-Upgrade-CR-10-CR-10S.html