Content Menu

● Understanding Aluminum Extrusion

● Where to Buy Aluminum Extruders Locally

● Popular Local Suppliers of Aluminum Extrusions

● The Aluminum Extrusion Process

● Advantages of Aluminum Extrusion in Infrastructure

● Factors to Consider When Choosing an Aluminum Extruder

● Applications in Various Industries

● Finding "Aluminum Extruder for Sale Near Me"

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What are the advantages of buying aluminum extrusion locally?

>> 2. How do I determine the right aluminum alloy for my extrusion needs?

>> 3. Can I get custom aluminum extrusions made locally?

>> 4. What should I look for in a local aluminum extrusion supplier?

>> 5. Are there any environmental considerations when buying aluminum extrusion?

● Citations:

Aluminum extruders are essential in various industries, including construction, automotive, and electronics. If you're looking for local stores selling aluminum extruders near you, this comprehensive guide will help you navigate the options available, understand the aluminum extrusion process, and make informed decisions.

Understanding Aluminum Extrusion

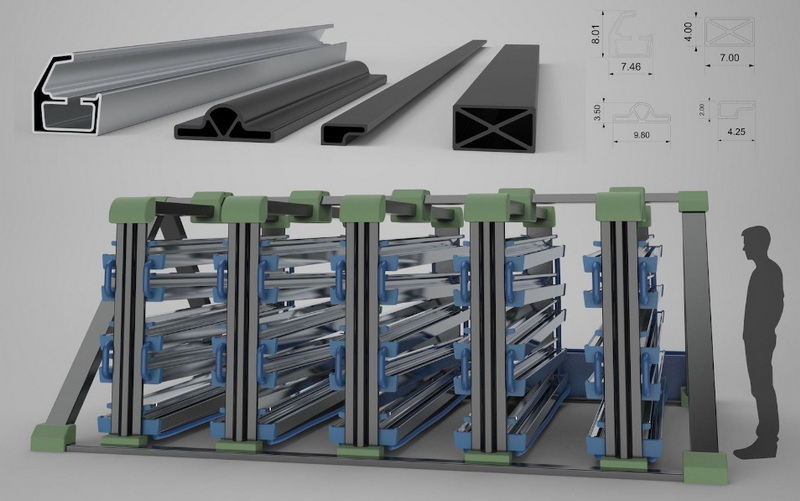

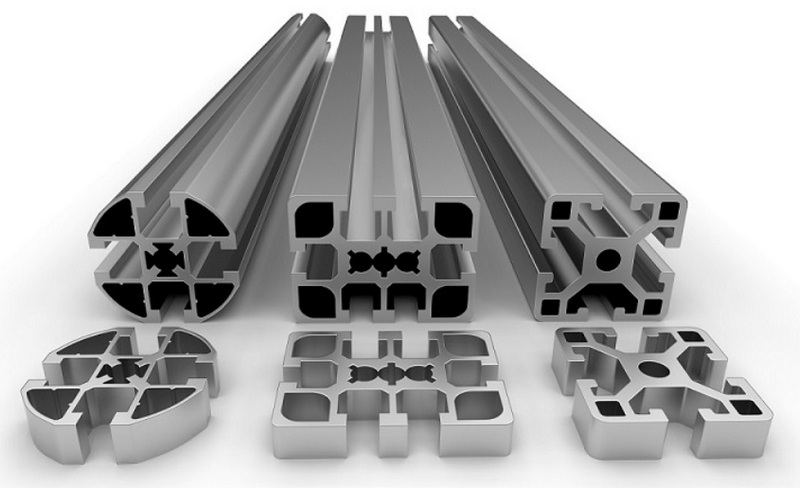

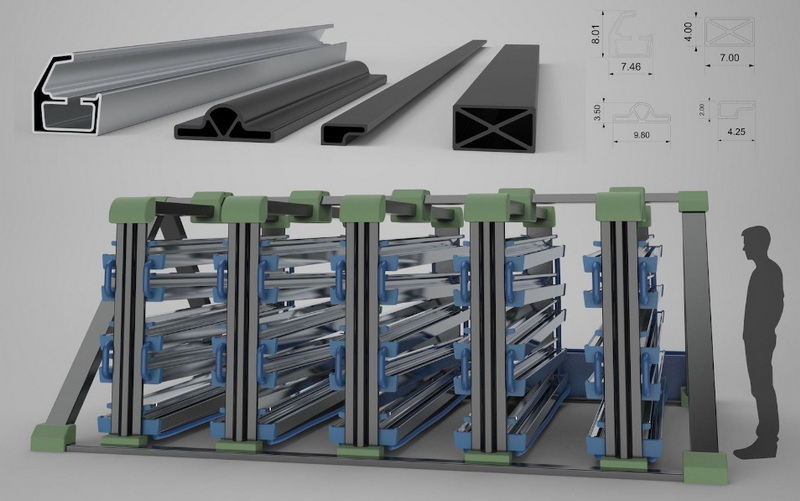

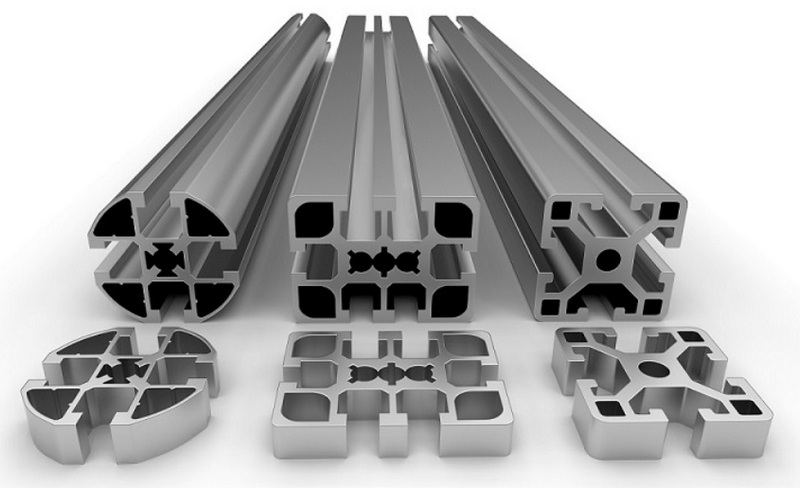

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create long shapes with a consistent cross-section. This method allows for the production of complex profiles that are lightweight yet strong, making aluminum extrusions highly versatile.

Applications of Aluminum Extrusion:

- Construction: Used for window frames, door frames, and curtain walls.

- Transportation: Essential for automotive parts and railway car components.

- Electronics: Commonly found in heat sinks and LED light housings.

- Furniture: Used in chair legs and table frames.

- Industrial Machinery: Integral to conveyor systems and workbenches.

- Renewable Energy: Utilized in solar panel frames and wind turbine components.

Where to Buy Aluminum Extruders Locally

Finding local suppliers for aluminum extruders can be straightforward if you know where to look. Here are some effective strategies:

1. Local Hardware Stores:

Many hardware stores and home improvement centers carry a selection of extruded aluminum profiles. Stores like Home Depot or Lowe's often have basic options available.

2. Metal Fabrication Shops:

Local metal fabrication shops can be excellent sources for both standard and custom aluminum extrusions. They often have the equipment to cut, drill, and weld aluminum profiles according to your specifications.

3. Industrial Distributors:

Industrial aluminum distributors typically offer a wide range of stock extruded profiles. They can provide quick delivery options and bulk purchasing discounts.

4. Online Directories:

Websites like ThomasNet or Yellow Pages can help locate nearby aluminum extrusion suppliers. Simply enter your location along with keywords like "aluminum extruder for sale near me."

5. Trade Shows:

Attending industry trade shows can provide opportunities to meet local suppliers and see their products firsthand. This is also a great way to network with professionals in the industry.

6. Aluminum Extruders Council:

The Aluminum Extruders Council has a directory of member companies across North America, which can help you find reputable suppliers nearby.

Popular Local Suppliers of Aluminum Extrusions

Here are some notable suppliers that may have locations near you:

- Orange Aluminum: Specializes in custom aluminum extrusion profiles and offers a wide range of products suitable for various applications.

- Pennex: A leader in the aluminum industry providing casting, extrusion, fabrication, and assembly services tailored to customer needs.

- BRT Extrusions: Centrally located in Ohio, they offer high-quality extruded shapes with excellent customer service.

The Aluminum Extrusion Process

To understand what goes into creating an aluminum extruder, it's essential to grasp the extrusion process itself:

1. Preparation of the Die: The die is designed based on the desired profile shape.

2. Heating the Billet: The aluminum billet is heated to about 900°F (482°C) to soften it while maintaining its solid form.

3. Extrusion: The heated billet is placed into an extrusion press where it is forced through the die under high pressure.

4. Cooling: After exiting the die, the extruded profile is cooled either naturally or through quenching methods.

5. Aging Process: The extrusions undergo aging (natural or artificial) to enhance their strength and durability.

6. Finishing Touches: Post-extrusion processes may include cutting, anodizing, or painting as per customer specifications.

Advantages of Aluminum Extrusion in Infrastructure

Aluminum extrusion offers numerous advantages for infrastructure projects, making it a sustainable and cost-effective choice[2].

Cost-Effectiveness:

Aluminum extrusions reduce costs and are easy to fabricate[2]. Using aluminum extrusion is becoming more widespread as communities, states, and the federal government seek affordable solutions that are also long-lasting and safe[2].

Ease of Assembly:

Aluminum extrusions are easy to assemble[2]. The light weight of aluminum also reduces shipping and transportation costs and makes it easier for construction crews to use[2].

Sustainability:

Aluminum extrusions have little to no impact on the environment[2].

Versatility and Applications:

Aluminum extrusions are used in multiple ways for infrastructure projects, including pedestrian bridges, bridge decking, parking shelters and railings[2]. Aluminum is already used for light poles, road signs and emergency boxes[2].

Properties of Aluminum:

- Strength: The typical aluminum alloy has a tensile strength of 70-700 MPa[2]. The typical tensile strength of alloys that are used in extrusion at aluminum fabrication shows is between 150-300 MPa[2]. Aluminum's strength increases at low temperatures, unlike steel which becomes brittle[2].

- Weight: Aluminum has about a third the density of regular steel, which makes it very light[2].

- Malleability: Aluminum alloys are easier to extrude than other types of metal[2]. It is also easily customized further using common machining methods, including cutting and punching, or bending and drilling[2].

- Conductivity: Aluminum is an excellent conductor of both electricity and heat and can replace copper conductors[2].

- Corrosion Resistance: Aluminum reacts with oxygen in the air to form a thin layer of aluminum oxide, which protects against corrosion such as rust[2]. This layer is self-repairing, and additional finishing such as anodizing can increase the thickness of the oxide layer[2].

- Other Properties: Aluminum is non-magnetic and non-toxic[2]. It is the third most common element on the planet, after oxygen and silicon[2]. Aluminum is easy to join through fusion welding, bonding, and taping, but custom extrusion designs yield even better results[2].

Market Growth:

The aluminum extrusion market size is estimated to grow by USD 41208.8 million from 2025 to 2029 at a CAGR of 9.4%[1].

Industries that Use Aluminum Extrusion

- Transportation[2]

- Automotive[2]

- Marine[2]

- Aerospace[2]

- Construction[2]

- Lighting Fixtures[2]

Factors to Consider When Choosing an Aluminum Extruder

When choosing an aluminum extruder, consider the following:

1. Experience and Expertise:

Look for a company with years of experience and a proven track record in the aluminum extrusion industry.

2. Quality Control:

Ensure the extruder has rigorous quality control processes to meet industry standards and customer specifications.

3. Customization Capabilities:

Check if the extruder can provide custom solutions tailored to your specific needs, including complex shapes and unique alloy requirements.

4. Lead Times:

Inquire about their lead times to ensure they align with your project timeline.

5. Pricing:

Compare pricing among different suppliers, but don't sacrifice quality for cost savings.

6. Customer Service:

Choose an extruder that offers excellent customer service and support throughout the entire process, from design to delivery.

7. Finishing Options:

Consider the available finishing options, such as anodizing, powder coating, or painting, to enhance the appearance and durability of the extrusions.

Applications in Various Industries

Aluminum extrusions are used across a wide range of industries due to their versatility, strength, and lightweight properties:

1. Automotive Industry:

In the automotive sector, aluminum extrusions are used for bumpers, chassis components, and heat sinks. Their lightweight nature contributes to improved fuel efficiency.

2. Construction Industry:

The construction industry relies on aluminum extrusions for window and door frames, curtain walls, and roofing systems. Their corrosion resistance ensures longevity and structural integrity.

3. Electronics Industry:

Aluminum extrusions are essential in the electronics industry for heat sinks, enclosures, and structural components. Their thermal conductivity helps dissipate heat effectively.

4. Aerospace Industry:

In aerospace, aluminum extrusions are used for aircraft structures, interior components, and seating systems. The high strength-to-weight ratio is critical for aircraft performance.

5. Renewable Energy Sector:

Aluminum extrusions play a vital role in the renewable energy sector, particularly in solar panel frames and wind turbine components. Their durability and corrosion resistance make them ideal for outdoor applications.

6. Consumer Goods:

From furniture frames to sporting goods, aluminum extrusions are used in a variety of consumer products. Their aesthetic appeal and lightweight properties make them attractive to manufacturers.

Finding "Aluminum Extruder for Sale Near Me"

When searching for "aluminum extruder for sale near me," it is crucial to refine your search to ensure you find the most suitable supplier. Consider these strategies:

1. Use Specific Keywords:

Incorporate specific keywords such as "custom aluminum extrusion," "aluminum profile," or "aluminum shapes" to narrow down your search results.

2. Utilize Online Mapping Tools:

Use online mapping tools like Google Maps or Bing Maps to locate nearby suppliers. Enter "aluminum extrusion supplier" or "metal fabrication near me" to find local businesses.

3. Check Online Marketplaces:

Explore online marketplaces like Alibaba or IndustryNet to find suppliers offering aluminum extrusions. These platforms often provide detailed product listings and supplier information.

4. Network with Industry Professionals:

Attend industry events, join online forums, and connect with professionals in your field to gather recommendations and referrals for local suppliers.

5. Request Quotes:

Once you have identified potential suppliers, request quotes for your specific requirements. This will help you compare pricing and assess their capabilities.

Future Trends in Aluminum Extrusion

The aluminum extrusion market is continuously evolving, with several key trends shaping its future:

1. Increasing Demand for Lightweight Materials:

The automotive and aerospace industries are driving demand for lightweight materials like aluminum to improve fuel efficiency and reduce emissions.

2. Growing Use of High-Strength Alloys:

Manufacturers are increasingly using high-strength aluminum alloys to create stronger and more durable extrusions for structural applications.

3. Adoption of Advanced Manufacturing Techniques:

Advanced manufacturing techniques such as 3D printing and additive manufacturing are being integrated into the aluminum extrusion process to create complex geometries and customized profiles.

4. Emphasis on Sustainability:

Sustainability is becoming a major focus, with companies implementing eco-friendly practices such as recycling scrap aluminum and using energy-efficient processes.

5. Expansion in Emerging Markets:

Emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in the construction and automotive sectors, driving demand for aluminum extrusions.

Conclusion

Finding local stores selling aluminum extruders near you is achievable by utilizing various resources such as hardware stores, metal fabrication shops, industrial distributors, online directories, trade shows, and industry associations. Understanding the extrusion process, its advantages, and the factors to consider when choosing a supplier can also help you appreciate the quality and versatility of aluminum products available for your projects. The growing aluminum extrusion market and trends towards sustainability and advanced manufacturing techniques promise a bright future for this essential material across numerous industries.

FAQ

1. What are the advantages of buying aluminum extrusion locally?

Buying locally often means faster delivery times, reduced shipping costs, and easier communication with suppliers regarding customizations or specific needs.

2. How do I determine the right aluminum alloy for my extrusion needs?

The right alloy depends on your application requirements such as strength, corrosion resistance, and thermal conductivity. Common alloys include 6061 for structural applications and 6063 for architectural applications.

3. Can I get custom aluminum extrusions made locally?

Yes! Many local metal fabrication shops offer custom extrusion services tailored to your specifications.

4. What should I look for in a local aluminum extrusion supplier?

Consider factors such as product quality, range of services offered (like finishing), turnaround times, customer reviews, and their ability to meet your specific needs.

5. Are there any environmental considerations when buying aluminum extrusion?

Yes! Look for suppliers that prioritize sustainability practices such as recycling scrap aluminum and using energy-efficient processes in their manufacturing operations.

Citations:

[1] https://www.technavio.com/report/aluminum-extrusion-market-industry-analysis

[2] http://scaluminum.com/2017/03/advantages-of-using-aluminum-extrusion-for-infrastructure/

[3] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[4] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[5] https://aec.org/features-benefits

[6] https://mmgextrusions.com/capabilities/custom-aluminum-extrusions/

[7] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[8] https://waykenrm.com/blogs/aluminum-extrusion/

[9] https://www.xometry.com/capabilities/metal-extrusion-services/custom-aluminum-extrusions/

[10] http://starext.com/news/aluminum-extrusion-trends-and-how-to-stay-ahead

[11] https://hitopindustrial.com/aluminum-extrusion-process/

[12] https://aec.org/aluminum-extrusion-process

[13] https://shop.machinemfg.com/understanding-aluminum-extrusions-importance-in-construction/

[14] https://tri-stateal.com/products/custom-extrusions/

[15] https://www.researchandmarkets.com/reports/5685568/2025-aluminium-extrusion-market-outlook-report

[16] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[17] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[18] https://profiledecor.com/benefits-of-aluminum-extrusion/

[19] https://www.minalex.com/custom-aluminum-extrusions/

[20] https://www.precedenceresearch.com/aluminum-extrusion-market