Content Menu

● The Evolution of Aluminum Extrusion Technology

>> Traditional Extrusion vs. Modern Techniques

● Key Reasons for Upgrading Aluminum Extruders

>> 1. Enhanced Precision and Quality Control

>> 2. Increased Production Efficiency

>> 3. Versatility in Design and Production

>> 4. Integration of Smart Technologies

>> 5. Environmental Sustainability

● Industries Benefiting from Upgraded Aluminum Extruders

>> Automotive Sector

>> Aerospace Industry

>> Construction and Architecture

>> Electronics and Consumer Goods

● Technological Advancements in Aluminum Extrusion

>> Nano-Coating Technologies

>> Artificial Intelligence in Process Control

>> Hybrid Extrusion Techniques

● The Economic Impact of Upgrading to Advanced Extruders

>> Reduced Operating Costs

>> Increased Market Competitiveness

>> Improved Return on Investment

● Challenges in Upgrading Aluminum Extruders

>> Initial Investment Costs

>> Training and Skill Development

>> Integration with Existing Systems

● Future Trends in Aluminum Extrusion Technology

>> 3D Printing Integration

>> Sustainable Extrusion Practices

>> Advanced Alloy Development

● Conclusion

● FAQ

>> 1. What are the main advantages of upgrading to a modern aluminum extruder?

>> 2. How does an upgraded aluminum extruder contribute to sustainability?

>> 3. What industries benefit most from advanced aluminum extrusion technology?

>> 4. How does artificial intelligence enhance the aluminum extrusion process?

>> 5. What are the challenges in upgrading to an advanced aluminum extruder?

● Citations:

In the ever-evolving landscape of manufacturing and materials engineering, the aluminum extrusion process has undergone significant advancements. These upgrades have revolutionized the industry, offering improved efficiency, precision, and versatility. This article delves into the reasons behind the push for upgraded aluminum extruders and explores the benefits they bring to various sectors.

The Evolution of Aluminum Extrusion Technology

Aluminum extrusion has been a cornerstone of manufacturing for decades, but recent technological leaps have propelled this process into a new era. The basic principle remains the same: forcing aluminum through a die to create specific shapes. However, the methods and machinery used have become increasingly sophisticated.

Traditional Extrusion vs. Modern Techniques

Traditional extrusion methods, while effective, had limitations in terms of speed, precision, and the complexity of shapes that could be produced. Modern extruders have overcome many of these constraints, offering a range of improvements that justify the upgrade.

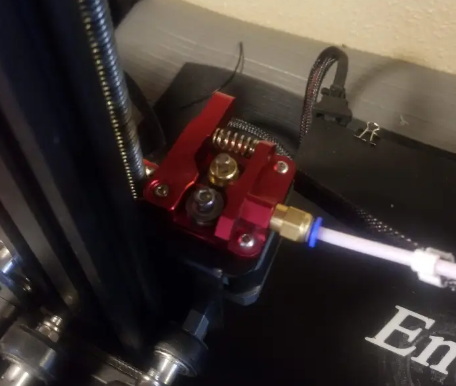

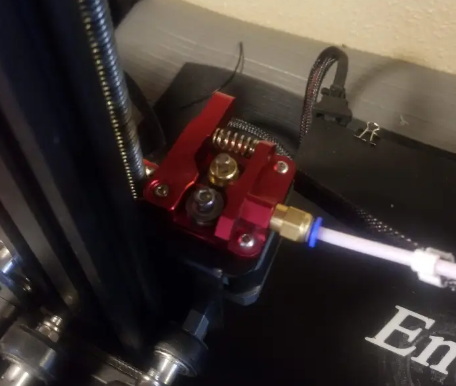

This video provides an up-close look at the aluminum extrusion process, showcasing the precision and efficiency of modern techniques.

Key Reasons for Upgrading Aluminum Extruders

1. Enhanced Precision and Quality Control

Upgraded aluminum extruders incorporate advanced control systems and sensors that allow for unprecedented precision in the extrusion process. This level of control results in:

- Tighter tolerances

- Improved surface finish

- Consistent quality across production runs

2. Increased Production Efficiency

Modern extruders are designed with efficiency in mind. They offer:

- Higher extrusion speeds

- Reduced setup times

- Improved energy efficiency

These factors contribute to increased output and reduced production costs, making upgraded extruders a valuable investment for manufacturers.

3. Versatility in Design and Production

Upgraded extruders can handle a wider range of alloys and produce more complex shapes than their predecessors. This versatility opens up new possibilities for designers and engineers, allowing for:

- Creation of intricate profiles

- Production of larger extrusions

- Ability to work with high-strength alloys

4. Integration of Smart Technologies

The incorporation of Industry 4.0 technologies has been a game-changer for aluminum extrusion. Upgraded extruders often feature:

- IoT connectivity for real-time monitoring

- AI-driven process optimization

- Predictive maintenance capabilities

These smart features contribute to reduced downtime, improved quality control, and more efficient resource utilization.

This video introduces ShAPE 2, a next-generation metal extrusion technology that exemplifies the integration of smart technologies in the extrusion process.

5. Environmental Sustainability

Upgraded aluminum extruders are often designed with sustainability in mind. They offer:

- Reduced energy consumption

- Improved material utilization

- Ability to process recycled aluminum more efficiently

These features align with growing environmental concerns and regulations, making upgraded extruders a more sustainable choice for manufacturers.

Industries Benefiting from Upgraded Aluminum Extruders

The advantages of upgraded aluminum extruders extend across various industries:

Automotive Sector

In the automotive industry, lightweight yet strong components are crucial for improving fuel efficiency and vehicle performance. Upgraded extruders allow for:

- Production of complex structural parts

- Creation of lightweight body panels

- Manufacturing of efficient heat exchangers

Aerospace Industry

The aerospace sector demands materials with exceptional strength-to-weight ratios. Advanced aluminum extruders enable:

- Production of aircraft frame components

- Manufacturing of wing spars and ribs

- Creation of lightweight interior fittings

Construction and Architecture

In construction, aluminum extrusions are used for everything from window frames to structural elements. Upgraded extruders offer:

- Ability to create larger structural profiles

- Improved thermal break designs for energy efficiency

- Enhanced surface finishes for aesthetic appeal

Electronics and Consumer Goods

The electronics industry benefits from the precision and versatility of modern extruders, allowing for:

- Production of heat sinks with complex fin designs

- Manufacturing of sleek and durable device casings

- Creation of custom components for specialized electronics

Technological Advancements in Aluminum Extrusion

Nano-Coating Technologies

One of the most exciting developments in aluminum extrusion is the application of nano-coating technologies. These ultra-thin coatings provide:

- Enhanced corrosion resistance

- Improved wear resistance

- Unique surface properties for specialized applications

Artificial Intelligence in Process Control

AI-driven process control is revolutionizing the extrusion industry. It offers:

- Real-time optimization of extrusion parameters

- Predictive quality control

- Adaptive process adjustments based on material variations

Hybrid Extrusion Techniques

Combining traditional extrusion methods with advanced processes has led to hybrid techniques that offer:

- Improved material properties

- Enhanced formability of extruded profiles

- Ability to create multi-material extrusions

This video provides an in-depth look at the aluminum extrusion process, showcasing some of the advanced techniques used in modern extrusion.

The Economic Impact of Upgrading to Advanced Extruders

Investing in upgraded aluminum extruders can have significant economic benefits:

Reduced Operating Costs

Advanced extruders often lead to:

- Lower energy consumption

- Reduced material waste

- Decreased maintenance requirements

Increased Market Competitiveness

The ability to produce higher quality and more complex extrusions allows manufacturers to:

- Enter new markets

- Meet more stringent customer requirements

- Differentiate their products from competitors

Improved Return on Investment

While the initial cost of upgrading can be substantial, the long-term benefits often include:

- Higher production output

- Reduced labor costs through automation

- Increased product value and pricing potential

Challenges in Upgrading Aluminum Extruders

Despite the numerous benefits, upgrading to advanced aluminum extruders is not without challenges:

Initial Investment Costs

The cost of new extrusion equipment can be significant, requiring careful financial planning and justification.

Training and Skill Development

Operating advanced extruders often requires specialized skills, necessitating investment in employee training and development.

Integration with Existing Systems

Incorporating new extrusion technology into existing production lines can be complex, requiring careful planning and potential downtime.

Future Trends in Aluminum Extrusion Technology

Looking ahead, several trends are shaping the future of aluminum extrusion:

3D Printing Integration

The combination of extrusion technology with 3D printing is opening up new possibilities for customization and complex geometries.

Sustainable Extrusion Practices

Increasing focus on sustainability is driving the development of more eco-friendly extrusion processes and recycling techniques.

Advanced Alloy Development

Ongoing research into new aluminum alloys promises to expand the capabilities of extrusion technology even further.

Conclusion

The upgrade to advanced aluminum extruders represents a significant leap forward in manufacturing technology. These improvements offer enhanced precision, efficiency, and versatility, enabling manufacturers to meet the growing demands of various industries. While challenges exist in terms of investment and integration, the long-term benefits of upgrading are clear. As technology continues to evolve, we can expect even more innovative developments in aluminum extrusion, further cementing its place as a crucial process in modern manufacturing.

FAQ

1. What are the main advantages of upgrading to a modern aluminum extruder?

The main advantages include improved precision and quality control, increased production efficiency, greater versatility in design and production, integration of smart technologies, and enhanced environmental sustainability. These benefits lead to better products, reduced costs, and increased competitiveness in the market.

2. How does an upgraded aluminum extruder contribute to sustainability?

Upgraded extruders contribute to sustainability through reduced energy consumption, improved material utilization, and the ability to process recycled aluminum more efficiently. They also often incorporate technologies that minimize waste and optimize resource use, aligning with environmental regulations and corporate sustainability goals.

3. What industries benefit most from advanced aluminum extrusion technology?

While many industries benefit, the automotive, aerospace, construction, and electronics sectors see significant advantages. These industries leverage the improved capabilities of advanced extruders to create lighter, stronger, and more complex components, leading to innovations in their respective fields.

4. How does artificial intelligence enhance the aluminum extrusion process?

AI enhances aluminum extrusion by enabling real-time optimization of extrusion parameters, predictive quality control, and adaptive process adjustments. This leads to improved product quality, reduced waste, and increased efficiency in the extrusion process.

5. What are the challenges in upgrading to an advanced aluminum extruder?

The main challenges include the high initial investment costs, the need for specialized training and skill development for operators, and the complexity of integrating new technology with existing production systems. However, these challenges are often outweighed by the long-term benefits of upgrading.

Citations:

[1] https://www.alexandriaindustries.com/content-library/demand-innovation/aluminum-extrusion-increases-options-optimize-supply-chain/

[2] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[3] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[4] https://www.alamy.com/stock-photo/aluminum-extrusion.html

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://www.youtube.com/watch?v=Abg78_GQNR8

[7] https://www.lightmetalage.com/news/industry-news/extrusion/upgrading-extrusion-press-hydraulics-and-controls-to-the-connected-future/

[8] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[9] https://www.istockphoto.com/de/bot-wall?returnUrl=%2Fde%2Fphotos%2Faluminum-extrusion

[10] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[11] https://taberextrusions.com/extruding-process-video/