Content Menu

● Introduction to MK8 Aluminum Extruders

>> Benefits of MK8 Aluminum Extruders

>> Filament Compatibility

● Installing an MK8 Aluminum Extruder Assembly

● Troubleshooting Common Issues

>> Advanced Troubleshooting Techniques

● Compatibility with Popular Printers

>> Upgrading on a Creality Ender 3 or CR-10

● Conclusion

● FAQs

>> 1. What types of filaments can I use with an MK8 aluminum extruder assembly?

>> 2. Is it difficult to install an MK8 aluminum extruder assembly?

>> 3. Will upgrading my extruder void my printer's warranty?

>> 4. How does an aluminum extruder improve print quality?

>> 5. Can I use an MK8 aluminum extruder assembly on any 3D printer?

● Citations:

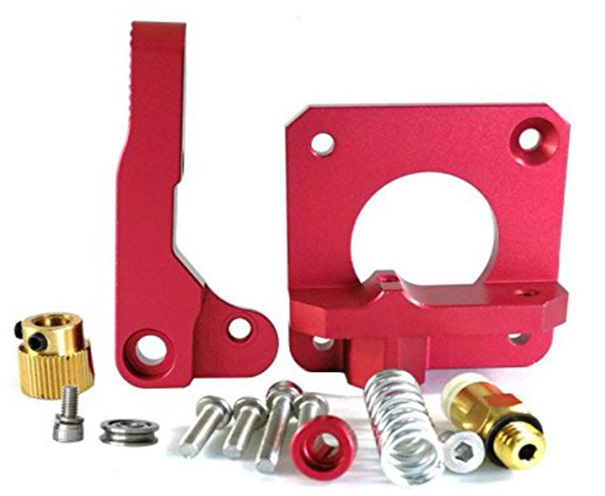

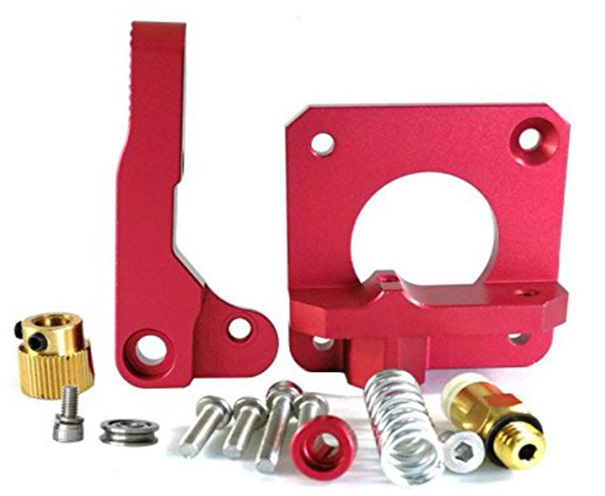

Upgrading your 3D printer with an MK8 aluminum extruder assembly can significantly enhance your printing experience. This article will delve into the benefits, installation process, and troubleshooting tips for the MK8 aluminum extruder, providing a comprehensive guide for both beginners and experienced users.

Introduction to MK8 Aluminum Extruders

The MK8 aluminum extruder assembly is a popular upgrade for many 3D printers, offering improved durability, better filament control, and enhanced temperature resistance compared to stock plastic extruders. These features make it an essential component for achieving high-quality prints, especially when working with a variety of filaments.

Benefits of MK8 Aluminum Extruders

1. Durability: Aluminum extruders are more robust and can withstand mechanical stress without cracking or warping, ensuring consistent performance over time[1][4].

2. Improved Filament Control: The aggressive grip on the filament minimizes slippage, leading to smoother feeding and more accurate prints. This is particularly beneficial for flexible filaments like TPU, which can be challenging to handle with stock extruders[4][5].

3. Higher Temperature Resistance: Aluminum can handle higher temperatures than plastic, making it suitable for printing with ABS, nylon, and other high-performance materials[1][4].

4. Precision Printing: Consistent filament flow and stable temperature control contribute to better layer adhesion, reduced stringing, and overall improved print quality[1][5].

5. Ease of Installation: Most MK8 aluminum extruder assemblies come as DIY kits that are easy to install, requiring minimal technical expertise[1][4].

Filament Compatibility

The MK8 aluminum extruder assembly supports a wide range of filaments, including PLA, ABS, PETG, TPU (flexible), and specialty filaments that require higher temperatures[1][5].

Installing an MK8 Aluminum Extruder Assembly

Installing an MK8 aluminum extruder assembly is relatively straightforward and can be done in a few steps:

1. Remove the Stock Extruder: Begin by unbolting the existing plastic extruder from your 3D printer. Keep any screws or components that may be reused[1][4].

2. Install the Aluminum Extruder: Align the new MK8 aluminum extruder assembly with the mounting holes on your printer. Secure it using the screws provided in your kit[1][4].

3. Connect Filament Path: Ensure that the filament guide tube is properly connected to the hot end. This may involve adjusting or replacing the Bowden tube if necessary[1][5].

4. Calibrate Your Printer: After installation, it's crucial to calibrate your printer settings to accommodate any changes in extrusion parameters due to the new extruder[4].

5. Test Printing: Finally, run a test print to ensure everything is functioning correctly and make any necessary adjustments[1][5].

Troubleshooting Common Issues

While the MK8 aluminum extruder assembly is reliable, some issues may arise. Here are common problems and their solutions:

- Under-Extrusion: Check if the extruder temperature is correct and if the filament is properly seated in the extruder. Adjust the extrusion multiplier in your slicer software if necessary[3].

- Over-Extrusion: Adjust the extrusion multiplier in your slicer software to reduce the amount of filament being extruded[3].

- Jams: Ensure the extruder is at the correct temperature and that the filament is not damaged. Use a wire cutter to cut the filament at a 45-degree angle and straighten the end to prevent jams[3].

Advanced Troubleshooting Techniques

For more complex issues, such as filament not entering the throat of the extruder, consider the following steps:

1. Adjust Vref on the Stepper Driver: Ensure the stepper driver's Vref is set correctly. A higher Vref can provide more torque but be cautious not to overheat the stepper motor[3].

2. Cooling and Heat Management: Ensure adequate cooling via the heatsink and fan to prevent heat from creeping up the extruder throat and causing filament expansion[3].

3. Filament Preparation: Cut the filament at a 45-degree angle and straighten the end to facilitate smooth entry into the extruder[3].

Compatibility with Popular Printers

The MK8 aluminum extruder assembly is compatible with many popular 3D printers, such as the Ender 3 and CR-10 series. However, it's essential to check compatibility with your specific printer model before purchasing[4].

Upgrading on a Creality Ender 3 or CR-10

For Creality printers like the Ender 3 or CR-10, the installation process involves a few additional steps:

1. Unload Filament: Ensure no filament is loaded in the extruder before starting the upgrade[2].

2. Unscrew Coupling: Remove the coupling holding the tube to access the extruder mechanism[2].

3. Install New Extruder Gear: Attach the new extruder gear, ensuring proper alignment with the motor shaft[2].

4. Secure Metal Housing: Use countersunk screws to secure the metal extruder housing, ensuring the motor cable is correctly oriented[2].

5. Assemble Lever Arm: Attach the lever arm with the idler pulley, using a spring to maintain tension[2].

Conclusion

Upgrading to an MK8 aluminum extruder assembly is a worthwhile investment for anyone seeking improved print quality, reliability, and durability. While there are initial costs and potential compatibility issues to consider, the long-term benefits far outweigh these drawbacks. Whether you're a hobbyist or a professional, this upgrade can elevate your 3D printing experience.

FAQs

1. What types of filaments can I use with an MK8 aluminum extruder assembly?

You can use a wide range of filaments, including PLA, ABS, PETG, TPU (flexible), and specialty filaments that require higher temperatures[1][5].

2. Is it difficult to install an MK8 aluminum extruder assembly?

No, most MK8 aluminum extruder assemblies come as DIY kits that are easy to install, requiring minimal technical expertise[1][4].

3. Will upgrading my extruder void my printer's warranty?

This depends on the manufacturer's policies. It's best to check with your printer's manufacturer before making any upgrades.

4. How does an aluminum extruder improve print quality?

Aluminum extruders provide better filament control, higher temperature resistance, and consistent filament flow, leading to improved layer adhesion and reduced stringing[1][4].

5. Can I use an MK8 aluminum extruder assembly on any 3D printer?

While the MK8 aluminum extruder assembly is compatible with many popular 3D printers, such as the Ender 3 and CR-10 series, it's crucial to ensure compatibility before purchasing[4].

Citations:

[1] https://www.yjing-extrusion.com/why-should-you-choose-an-mk8-extruder-aluminum-over-stock-extruders.html

[2] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[3] https://forum.v1e.com/t/mk8-extruder-issues/5113

[4] https://www.yjing-extrusion.com/is-an-aluminum-mk8-extruder-upgrade-worth-it.html

[5] https://www.yjing-extrusion.com/how-does-the-creality-mk8-aluminum-extruder-improve-filament-flow.html

[6] https://www.reddit.com/r/ender5plus/comments/n02dbn/reason_to_upgrade_to_an_all_metal_mk8_extruder/

[7] https://electropeak.com/mk8-extruder-aluminum-block-kit-for-3d-printers

[8] https://gr33nonline.wordpress.com/2019/05/15/assembly-of-an-mk8/

[9] https://www.reddit.com/r/ender3v2/comments/o90cgl/design_flaw_in_mk8_aluminum_metal_extruder/

[10] https://www.reddit.com/r/3Dprinting/comments/ml3btp/purpose_of_a_full_metal_extruder_on_am_ender_3_v2/

[11] https://www.youtube.com/watch?v=AAe7k_X7kQg

[12] https://forum.v1e.com/t/problem-with-mk8-extruder/6793

[13] https://makers-hut.com/product/mk8-extruder-upgrade-kit-aluminium-block-reprap-makerbot-3d-printer-2/

[14] https://www.youtube.com/watch?v=6q2xWd40U8g

[15] https://www.youtube.com/watch?v=k4zALRcICmk

[16] https://www.aliexpress.com/i/32951483648.html

[17] http://wiki.fysetc.com/Mk8%20Grey%20Extruder/

[18] https://www.youtube.com/watch?v=TPyTiZ6-_jM

[19] https://www.youtube.com/watch?v=UtemZqFJ5rY

[20] https://images-na.ssl-images-amazon.com/images/I/91LRfSP8lYL.pdf