Content Menu

● Introduction to the CR-10 and Extruder Upgrades

>> CR-10 Aluminum Extruder Benefits

● How to Upgrade Your CR-10 with an Aluminum Extruder

>> Tools Required:

>> Steps to Upgrade:

>> Tips for Successful Upgrade:

● Common Issues Solved by the Aluminum Extruder

>> Under-Extrusion

>> Wear and Tear

>> Thermal Issues

● Advanced Features of Aluminum Extruders

>> Adjustable Pressure

>> DualDrive Systems

>> Innovative Designs

● Choosing the Right Aluminum Extruder

● Real-World Applications and Benefits

● Troubleshooting Common Issues with Aluminum Extruders

● Conclusion

● FAQ

>> 1. What are the primary benefits of using a CR-10 aluminum extruder?

>> 2. Is the CR-10 aluminum extruder compatible with all types of filaments?

>> 3. How difficult is it to install the CR-10 aluminum extruder?

>> 4. Can the CR-10 aluminum extruder improve print speed?

>> 5. Are there any specific maintenance requirements for the CR-10 aluminum extruder?

● Citations:

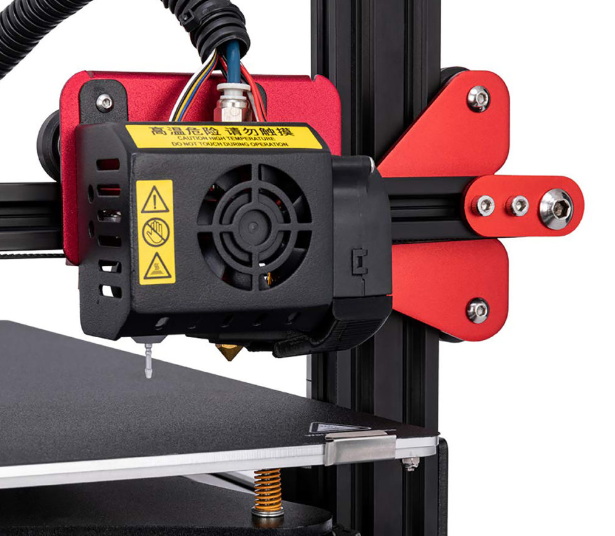

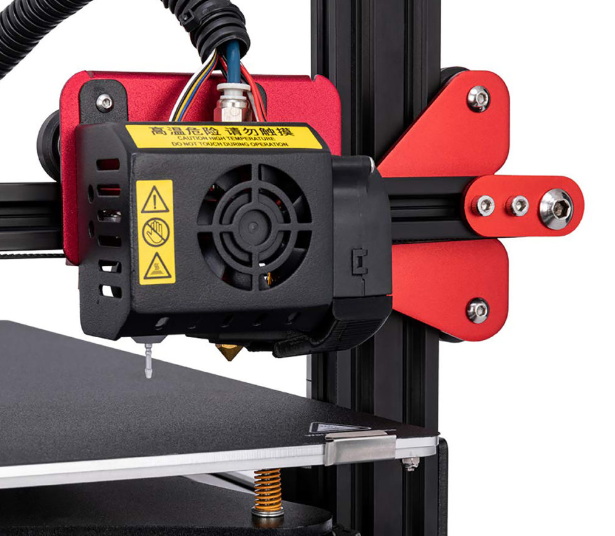

Upgrading your Creality CR-10 3D printer with an aluminum extruder can significantly enhance your printing experience. The CR-10 series, known for its reliability and versatility, benefits from this upgrade in several key areas, including durability, filament handling, and overall print quality. In this article, we will explore the advantages of using a CR-10 aluminum extruder and guide you through the process of upgrading your printer.

Introduction to the CR-10 and Extruder Upgrades

The Creality CR-10 is a popular choice among hobbyists and professionals alike due to its large build volume and affordability. However, like many budget-friendly printers, it comes with a plastic extruder that may not be optimal for all types of filaments or printing conditions. The plastic extruder can lead to issues such as under-extrusion, especially with flexible filaments like TPU, and may wear out over time, affecting print consistency.

CR-10 Aluminum Extruder Benefits

1. Durability: Aluminum extruders are more durable than their plastic counterparts, providing better resistance to wear and tear. This means they can handle higher temperatures and pressures without degrading, ensuring consistent performance over time.

2. Improved Filament Handling: The CR-10 aluminum extruder offers better grip and control over the filament, reducing slippage and under-extrusion issues. This is particularly beneficial for printing with flexible or abrasive materials.

3. Enhanced Thermal Performance: Aluminum is a good conductor of heat, which can help in maintaining a stable temperature around the extruder, improving the melting and extrusion process.

4. Easy Installation: Most aluminum extruder upgrades for the CR-10 are designed to be easy to install, requiring minimal technical expertise.

How to Upgrade Your CR-10 with an Aluminum Extruder

Upgrading your CR-10 with an aluminum extruder is relatively straightforward. Here's a simplified guide:

Tools Required:

- Allen wrenches (1.5, 2, 2.5, and 3 mm)

- The aluminum extruder kit

Steps to Upgrade:

1. Unload Filament: Ensure no filament is loaded in the extruder.

2. Disconnect Power: Turn off the printer and unplug it.

3. Remove Old Extruder: Unscrew the coupling holding the tube in place and remove the screws attaching the lever arm.

4. Install New Extruder: Attach the new extruder gear and housing, ensuring proper alignment and secure fastening.

5. Reassemble and Test: Reattach all components and test the extruder for proper function.

Tips for Successful Upgrade:

- Ensure all screws are securely tightened but not over-tightened.

- Adjust the tension on the extruder gear as needed for optimal filament grip.

- Test the extruder with a simple print job to ensure everything is working correctly.

Common Issues Solved by the Aluminum Extruder

Under-Extrusion

Under-extrusion is a common problem with plastic extruders, especially when printing with flexible filaments. The CR-10 aluminum extruder helps mitigate this issue by providing a more consistent and reliable grip on the filament.

Wear and Tear

Plastic extruders can wear out quickly, leading to inconsistent prints. The durability of aluminum extruders reduces the need for frequent replacements.

Thermal Issues

Aluminum's thermal conductivity helps maintain a stable temperature around the extruder, reducing thermal-related issues during printing.

Advanced Features of Aluminum Extruders

Adjustable Pressure

Many aluminum extruder kits, such as the Creality Metal Extruder Upgrade Kit, feature adjustable pressure settings. This allows users to fine-tune the extruder's grip on the filament, ensuring optimal performance with different types of filaments[1].

DualDrive Systems

Some advanced extruder upgrades, like the Bondtech Mini Geared (BMG) extruder, incorporate DualDrive systems. These systems ensure that the extruder maintains a consistent grip on the filament, preventing slipping and grinding, which can be particularly beneficial for printing with flexible filaments[5].

Innovative Designs

Aluminum extruders often feature innovative designs that improve mechanical stability and reduce gear play. For example, using a collet instead of a pneumatic push-fit can minimize breakage between the joint and the Bowden tube[1].

Choosing the Right Aluminum Extruder

When selecting an aluminum extruder for your CR-10, consider the following factors:

- Compatibility: Ensure the extruder is compatible with your printer model and filament diameter (usually 1.75 mm for CR-10 series)[1][2].

- Material Quality: Look for high-quality aluminum alloys that provide durability and thermal stability.

- Ease of Installation: Opt for kits with easy installation processes to minimize downtime.

- Adjustability: Consider extruders with adjustable pressure settings for better filament control.

Real-World Applications and Benefits

Upgrading to an aluminum extruder can significantly enhance your printing experience across various applications:

- Prototyping: Improved filament handling and durability ensure consistent results, even with complex prototypes.

- Model Making: Enhanced thermal performance and reduced under-extrusion issues result in smoother, more detailed models.

- Educational Settings: The reliability and ease of use of aluminum extruders make them ideal for educational environments where printers are frequently used.

Troubleshooting Common Issues with Aluminum Extruders

While aluminum extruders are generally reliable, some issues may arise:

- Slipping Filament: Check the extruder gear teeth for wear or shallow design. Consider replacing the gear if necessary[3].

- Incorrect Tension: Adjust the tension on the extruder to ensure proper grip without damaging the filament.

- Thermal Issues: Verify that the extruder is properly cooled and that the temperature settings are correct.

Conclusion

Upgrading your Creality CR-10 with an aluminum extruder can significantly enhance your printing experience by improving durability, filament handling, and overall print quality. Whether you're dealing with under-extrusion issues or looking to improve your printer's performance with flexible filaments, the CR-10 aluminum extruder is a worthwhile investment.

FAQ

1. What are the primary benefits of using a CR-10 aluminum extruder?

The primary benefits include improved durability, better filament handling, and enhanced thermal performance, which lead to more consistent and reliable prints.

2. Is the CR-10 aluminum extruder compatible with all types of filaments?

Yes, the aluminum extruder is compatible with a wide range of filaments, including PLA, PETG, ABS, and flexible materials like TPU. It provides better grip and control, reducing issues with under-extrusion.

3. How difficult is it to install the CR-10 aluminum extruder?

The installation process is relatively easy and requires minimal technical expertise. Most kits come with clear instructions and are designed for a straightforward swap with the original plastic extruder.

4. Can the CR-10 aluminum extruder improve print speed?

While the aluminum extruder itself does not directly increase print speed, it can help maintain consistent extrusion rates, especially with flexible filaments, allowing for smoother and more reliable printing at higher speeds.

5. Are there any specific maintenance requirements for the CR-10 aluminum extruder?

Regular maintenance involves ensuring the extruder gear is clean and properly aligned. Unlike plastic extruders, aluminum ones are less prone to wear but should still be checked periodically for optimal performance.

Citations:

[1] https://www.3djake.com/creality-3d-printers-spare-parts/metal-extruder-upgrade-kit

[2] https://de.sainsmart.com/products/aluminum-mk8-extruder-for-cr-10-series-3d-printers

[3] https://www.3djake.com/reviews/creality-3d-printers-spare-parts/metal-extruder-upgrade-kit

[4] https://www.youtube.com/watch?v=fT91Oj2RUDk

[5] https://www.dold-mechatronik.de/Extruder-Upgrade-Kit-for-Creality-CR-10-With-Mount-for-CR-10

[6] https://3dpblog.com/direct-extruder-creality-cr-10/

[7] https://www.makerhacks.com/creality-cr-10-3-dprinter-review/

[8] https://www.bastelgarage.ch/creality-aluminum-extruder-upgrade-kit-gray

[9] https://makersteve.com/2018/11/07/ultimate-build-guide-for-creality-cr-10s-cr-10-step-by-step-a-makersteve-special-report/

[10] https://makershop.co/creality-cr-10-troubleshooting/

[11] https://www.youtube.com/watch?v=U36YkBClQx8

[12] https://www.reddit.com/r/CR10/comments/p9j8xx/problems_with_my_extruder_is_it_worn_out_cr10_v2/

[13] https://3d-drucker-filament.de/en/MK8-Aluminium-Extruder-Feeder-Upgrade-CR-10-CR-10S.html

[14] https://www.youtube.com/watch?v=OfAJsjgttCs

[15] https://forum.creality.com/t/cr-10s-extruder-trouble/9680

[16] https://www.reddit.com/r/CR10/comments/reqqew/broken_extruderwhat_to_upgrade_too/

[17] https://yarkspirifantasyart.com/cr10-smart-review-how-good-is-it/

[18] https://www.ifixit.com/Guide/CR-10+V2++Linear+Rail+Kit+Hotend+Installation/152339

[19] https://www.youtube.com/watch?v=cAPN7_vF_Ss

[20] https://www.youtube.com/watch?v=h7-wWXDN6z8