Content Menu

● Introduction to Extrusion Machinery

● Benefits of Choosing an Experienced Manufacturer

>> Track Record and Reliability

>> Quality of Components

>> Service and Support

>> Advanced Technology and Sustainability

● Choosing the Right Extrusion Machinery

● Custom Extrusion Solutions

● Innovations in Extrusion Technology

>> Role of Artificial Intelligence

>> Automation and Robotics

>> Sustainability and Environmental Impact

>> Integration with 3D Printing

>> Industry 4.0 Technologies

● Challenges in Extrusion Processes

● Overcoming Challenges

● Conclusion

● FAQs

>> 1. What are the key factors to consider when choosing an extrusion machinery manufacturer?

>> 2. How does the quality of components affect the performance of extrusion machinery?

>> 3. What role does service and support play in the operation of extrusion machinery?

>> 4. How can advanced technology enhance the sustainability of extrusion processes?

>> 5. What are some common challenges faced in the extrusion process?

● Citations:

In the realm of manufacturing, the choice of machinery can significantly impact production efficiency, product quality, and overall business success. When it comes to extrusion processes, selecting an experienced extrusion machinery manufacturer is crucial for ensuring that your operations run smoothly and effectively. This article will delve into the reasons why choosing an experienced manufacturer is essential, highlighting key factors such as reliability, quality of components, service and support, and the benefits of advanced technology.

Introduction to Extrusion Machinery

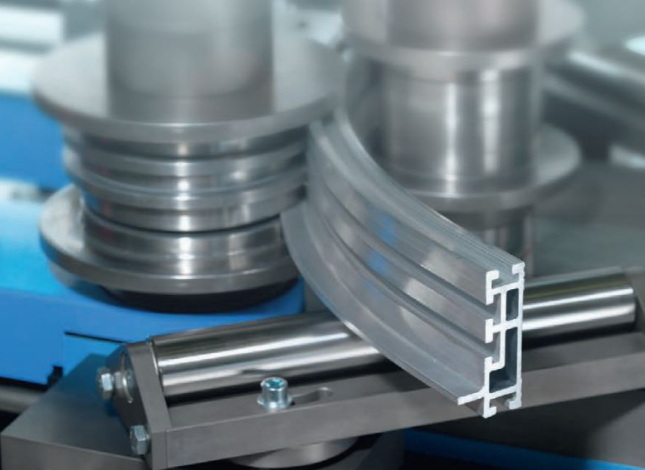

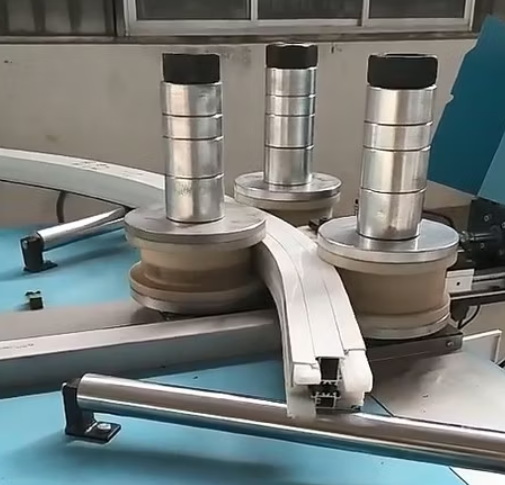

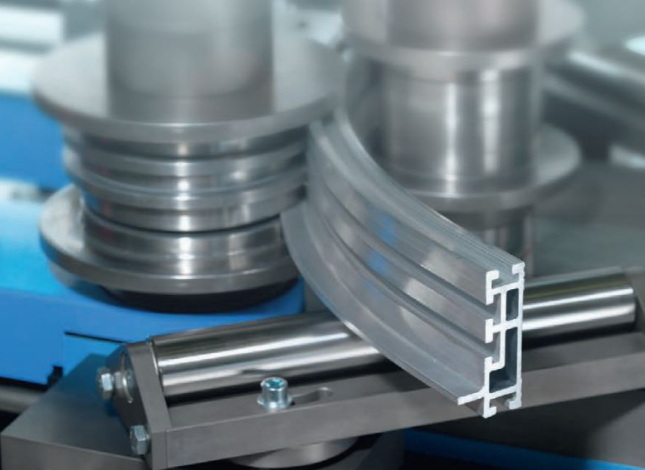

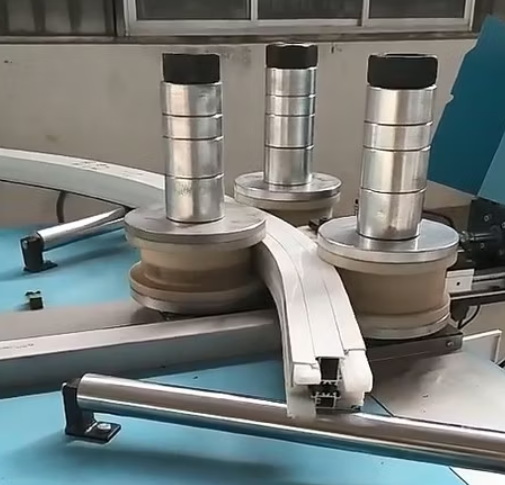

Extrusion machinery is used across various industries, including plastics, metals, and food processing. It involves forcing raw materials through a die to create a desired shape. The complexity of this process requires machinery that is both reliable and efficient.

Benefits of Choosing an Experienced Manufacturer

Track Record and Reliability

An experienced extrusion machinery manufacturer offers a proven track record of success. This is crucial because it demonstrates the manufacturer's ability to deliver high-quality machinery and provide ongoing support throughout the product's lifecycle. Companies like DRTS, with over 35 years of experience and installations in more than 30 countries, exemplify this reliability.

Quality of Components

High-quality components are essential for ensuring that the machinery operates efficiently and requires minimal maintenance. Manufacturers that use globally recognized brands like Siemens and ABB provide assurance that spare parts can be easily sourced and integrated.

| Component | Brands Used |

| Gearbox | Zambello |

| Motors | ABB/Siemens |

| HMI/PLC | B&R/Siemens/Omron |

Service and Support

Effective service and support are vital for minimizing downtime and ensuring that production runs smoothly. Experienced manufacturers offer comprehensive support, including equipment selection, installation, training, and maintenance.

Advanced Technology and Sustainability

Modern extrusion machinery manufacturers often integrate advanced technology to enhance efficiency and sustainability. This includes optimizing resource use and minimizing waste, which not only reduces operational costs but also aligns with environmental responsibilities.

Choosing the Right Extrusion Machinery

When selecting an extrusion machinery manufacturer, several factors should be considered:

- Material Type: Different materials require specific extruder designs.

- Product Specifications: The desired properties of the final product influence the choice of extruder and die design.

- Production Volume: The required production capacity determines the size and type of extruder needed.

- Energy Efficiency: Choosing an energy-efficient extruder reduces operational costs and environmental impact.

Custom Extrusion Solutions

Specific industries have unique requirements for their extrusion processes that cannot be met with standard equipment. In these situations, custom extrusion solutions become crucial. A manufacturer that offers customization can design and build equipment specifically tailored to your industry's needs, considering factors like material properties, output rates, and end-product specifications. For instance, initiatives such as automotive or aerospace may need precise temperature control and specialized dies. In contrast, the food industry may require extruders that comply with strict hygiene standards. Thus, selecting a manufacturer capable of providing custom solutions can significantly enhance your industry-specific production processes, delivering improved efficiency, quality, and reliability.

Innovations in Extrusion Technology

Recent advancements in extrusion technology have revolutionized the industry, enhancing efficiency, precision, and product quality. These innovations are driven by the integration of cutting-edge technologies such as Artificial Intelligence (AI) and advanced sensor systems, which have their roots in the increasing demand for smarter and more efficient manufacturing processes.

Role of Artificial Intelligence

AI plays a pivotal role in optimizing extrusion processes. AI algorithms analyze vast amounts of data generated during extrusion, identifying patterns and predicting outcomes that are not easily discernible by human operators. This enables real-time adjustments to parameters like temperature, pressure, and screw speed, ensuring optimal performance and reducing material waste.

Automation and Robotics

Automation and robotics handle tasks such as material transport and positioning with high precision, reducing errors and improving safety. Robotics also enable the handling of complex tasks that were previously challenging or impossible for manual labor.

Sustainability and Environmental Impact

There is a growing emphasis on sustainable materials and practices in extrusion. Bioplastics and recycled materials are increasingly used to reduce environmental impact. This shift towards sustainability not only aligns with environmental regulations but also appeals to consumers who prioritize eco-friendly products.

Integration with 3D Printing

The integration of extrusion with 3D printing technologies offers new possibilities for complex geometries and customized products. This combination allows manufacturers to produce parts with intricate designs that cannot be achieved through traditional extrusion methods alone.

Industry 4.0 Technologies

The adoption of Industry 4.0 technologies, such as data analytics and digital twinning, enhances efficiency and predictive maintenance in extrusion processes. Digital twins allow for virtual testing and optimization of production lines before actual implementation, reducing downtime and improving overall performance.

Challenges in Extrusion Processes

Despite the advancements, extrusion processes face several challenges:

- Material Selection: Choosing the right material for the application is crucial. Different materials have varying properties, such as flexibility, strength, thermal resistance, and chemical compatibility.

- Dimensional Accuracy: Maintaining precise dimensions is essential. Factors such as temperature fluctuations, uneven cooling, and die wear can impact the precision of the extruded profiles.

- Material Degradation: Overheating can cause material degradation or color changes.

- Extruder Screw Wear: Regular maintenance is necessary to prevent wear or deformation of extruder screws.

Overcoming Challenges

To overcome these challenges, manufacturers should focus on:

- Regular Maintenance: Regular cleaning of filters, calibration, and checks of screws.

- Advanced Monitoring Systems: Using laser measurement tools for real-time feedback.

- Collaboration with Experts: Working closely with material experts and suppliers to ensure the chosen material meets all functional and environmental requirements.

Conclusion

Choosing an experienced extrusion machinery manufacturer is pivotal for ensuring the success of your manufacturing operations. Their expertise in providing reliable machinery, high-quality components, comprehensive support, and advanced technology can significantly enhance production efficiency and product quality. As the manufacturing landscape continues to evolve, partnering with a seasoned manufacturer will be crucial for staying competitive and meeting the demands of a rapidly changing market.

FAQs

1. What are the key factors to consider when choosing an extrusion machinery manufacturer?

When selecting an extrusion machinery manufacturer, consider their track record, quality of components, service and support, and ability to integrate advanced technology.

2. How does the quality of components affect the performance of extrusion machinery?

High-quality components ensure that the machinery operates efficiently, requires less maintenance, and allows for easy sourcing of spare parts if needed.

3. What role does service and support play in the operation of extrusion machinery?

Effective service and support are crucial for minimizing downtime, ensuring smooth production, and providing comprehensive assistance from equipment selection to maintenance.

4. How can advanced technology enhance the sustainability of extrusion processes?

Advanced technology helps optimize resource use, minimize waste, and reduce energy consumption, aligning with environmental responsibilities and reducing operational costs.

5. What are some common challenges faced in the extrusion process?

Common challenges include material incompatibility, die wear, heat management, achieving product consistency, and environmental impact, all of which require careful process optimization and equipment selection.

Citations:

[1] https://jieyatwinscrew.com/blog/exploring-the-world-of-extrusion-machines-understanding-the-basics-and-benefits/

[2] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-automatic-extrusion-machines.html

[3] https://deltaplastik.com/blog/challenges-and-solutions-in-plastic-extrusion-process

[4] https://www.liveline.tech/case-studies

[5] https://www.plasticsmachinerymanufacturing.com/extrusion/article/21161172/oems-forecast-high-tech-future-for-extrusion

[6] https://www.pearltechinc.com/2025/02/13/extrusion-equipment-blown-film-efficiency/

[7] https://www.wevolver.com/article/extruding-plastic

[8] https://www.inplexllc.com/blog/overcoming-common-challenges-in-plastic-extrusion-projects/

[9] https://www.cm-pet.com/msg/case-study.html

[10] https://www.yjing-extrusion.com/what-are-the-latest-trends-in-the-extrusion-machinery-market.html

[11] https://www.rssinc.com/blog/understanding-the-role-of-an-extrusion-operator/

[12] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[13] https://www.boyuextruder.com/blog/plastic-extrusion-problems-and-how-to-solve.html

[14] https://www.ekogruppo.com/case-studies-eko-gruppo-second-hand-machine

[15] https://www.transamshop.co.uk/blogs/news/future-plastic-extrusion-trends-2024

[16] https://www.fangliextru.com/news-show-1069125.html

[17] https://www.aetextruder.com

[18] https://www.bausano.com/en/press-and-news/common-problems-in-the-plastic-extrusion-process

[19] https://ptfe-machinery.com/success-case/

[20] https://www.marketreportanalytics.com/reports/plastic-compounding-and-extrusion-machines-21908