Content Menu

● Introduction to Plastic Extrusion

>> Types of Plastic Extrusion Machines

● Advantages of Wholesale Plastic Extrusion Machinery

>> Cost-Effectiveness

>> High Production Volume

>> Flexibility and Versatility

>> Consistent Quality

>> Environmental Benefits

● Challenges in Plastic Extrusion

● Wholesale Plastic Extrusion Machinery Market

>> Suppliers and Manufacturers

● Conclusion

● FAQ

>> 1. What are the key advantages of wholesale plastic extrusion machinery?

>> 2. How does wholesale plastic extrusion machinery contribute to cost-effectiveness?

>> 3. What types of plastic extrusion machines are available for wholesale purchase?

>> 4. How does plastic extrusion impact the environment?

>> 5. What are the common challenges faced in the plastic extrusion process?

● Citations:

Plastic extrusion is a widely used manufacturing process that involves converting raw plastic materials into various shapes and forms. This process is favored for its efficiency, versatility, and cost-effectiveness. Wholesale plastic extrusion machinery plays a crucial role in this industry, offering businesses a way to produce high-quality plastic products at a lower cost. In this article, we will explore why wholesale plastic extrusion machinery is a cost-effective choice for manufacturers.

Introduction to Plastic Extrusion

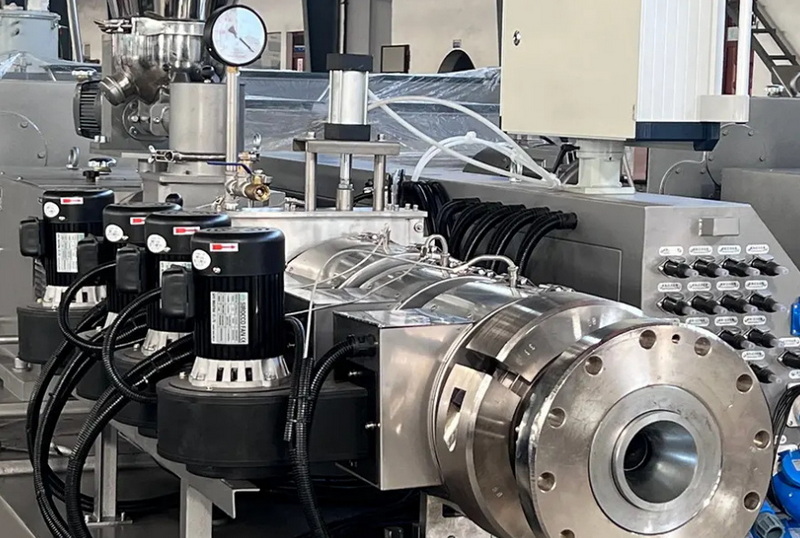

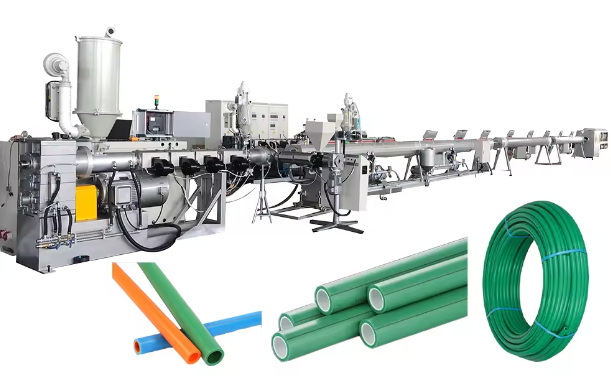

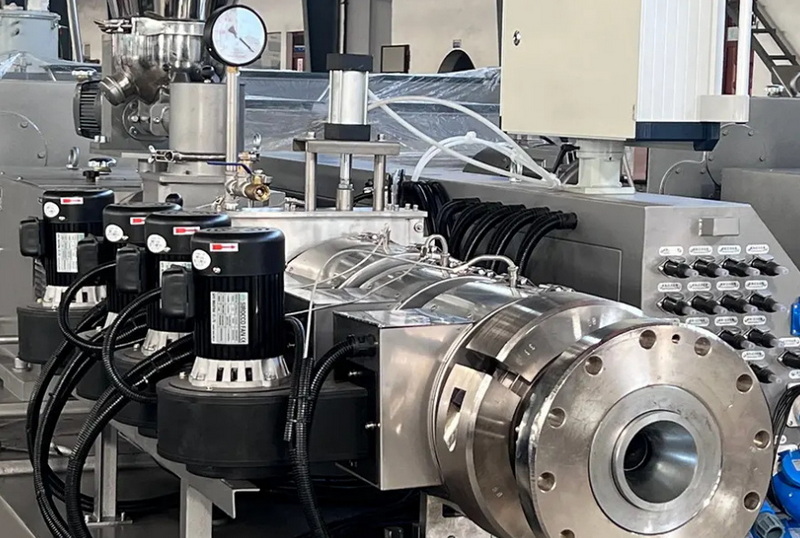

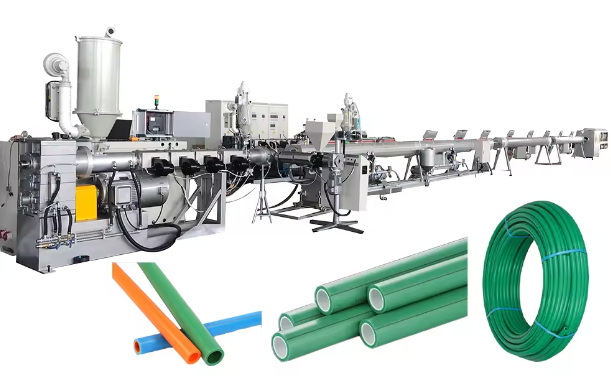

Plastic extrusion is a continuous process where plastic materials are melted and formed into a desired shape using a die. This process is used to produce a wide range of products, including pipes, tubes, profiles, and sheets. The machinery involved in plastic extrusion includes single-screw extruders, twin-screw extruders, and multilayer extruders, each designed for specific applications.

Types of Plastic Extrusion Machines

1. Single-Screw Extruders: These are the most common type of extruder, suitable for processing thermoplastics like polyethylene and polypropylene. They are cost-effective and easy to maintain.

2. Twin-Screw Extruders: These machines offer better mixing capabilities and are used for more complex formulations. They are ideal for producing filled plastics and masterbatches.

3. Multilayer Extruders: These are used to produce products with multiple layers of different plastics, often used in packaging films.

Advantages of Wholesale Plastic Extrusion Machinery

Cost-Effectiveness

Wholesale plastic extrusion machinery is cost-effective for several reasons:

- Lower Initial Investment: Purchasing machinery in bulk can reduce the cost per unit compared to buying individual machines.

- Efficient Production: Plastic extrusion allows for continuous production with minimal waste, reducing material costs.

- Low Labor Costs: The process is highly automated, requiring less labor compared to other manufacturing methods.

High Production Volume

Plastic extrusion machinery can operate continuously, producing large volumes of products quickly. This high output rate reduces the risk of inventory shortages and ensures consistent supply to meet demand.

Flexibility and Versatility

Plastic extrusion offers the flexibility to produce a wide range of products with varying shapes, sizes, and properties. This versatility allows manufacturers to cater to different market needs and adapt to changing consumer preferences.

Consistent Quality

The extrusion process ensures consistent product quality, with precise dimensions and uniform properties. This consistency is crucial for meeting industry standards and customer expectations.

Environmental Benefits

Plastic extrusion can utilize recycled materials, reducing waste and conserving resources. The process also allows for the reuse of excess material, minimizing environmental impact.

Challenges in Plastic Extrusion

Despite its advantages, plastic extrusion faces several challenges:

- Die Swell: The expansion of plastic upon exiting the die can affect product dimensions, requiring adjustments in production settings.

- Temperature Control: Maintaining consistent temperatures is crucial to prevent material degradation and ensure product quality.

- Equipment Maintenance: Frequent maintenance is necessary to prevent breakdowns and ensure optimal performance.

Wholesale Plastic Extrusion Machinery Market

The market for wholesale plastic extrusion machinery is growing due to increasing demand for plastic products across various industries. Manufacturers are looking for cost-effective solutions that can meet high production volumes without compromising quality.

Suppliers and Manufacturers

Several suppliers offer wholesale plastic extrusion machinery, including companies in China, which is known for its competitive pricing and wide range of products.

Conclusion

Wholesale plastic extrusion machinery is a cost-effective choice for manufacturers due to its efficiency, versatility, and ability to produce high-quality products at a lower cost. By understanding the advantages and challenges of plastic extrusion, businesses can make informed decisions about investing in this technology.

FAQ

1. What are the key advantages of wholesale plastic extrusion machinery?

Wholesale plastic extrusion machinery offers several advantages, including cost-effectiveness, high production volume, flexibility in product design, consistent quality, and environmental benefits.

2. How does wholesale plastic extrusion machinery contribute to cost-effectiveness?

Wholesale plastic extrusion machinery is cost-effective due to lower initial investment costs, efficient production processes, and reduced labor costs. Additionally, it allows for the reuse of excess material, minimizing waste and conserving resources.

3. What types of plastic extrusion machines are available for wholesale purchase?

The main types of plastic extrusion machines available for wholesale include single-screw extruders, twin-screw extruders, and multilayer extruders. Each type is suited for different applications and materials.

4. How does plastic extrusion impact the environment?

Plastic extrusion can have a positive environmental impact by utilizing recycled materials and minimizing waste. However, it also involves energy consumption and potential material degradation if not managed properly.

5. What are the common challenges faced in the plastic extrusion process?

Common challenges include die swell, temperature control issues, and the need for frequent equipment maintenance. These challenges can affect product quality and production efficiency if not addressed properly.

Citations:

[1] https://polymer-process.com/what-does-the-average-plastic-extrusion-line-cost/

[2] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[3] https://ir.boyuextruder.com/extruder/5-advantages-plastic-extrusion.html

[4] https://www.alibaba.com/showroom/photo-frame-extrusion-machine.html

[5] https://www.youtube.com/watch?v=hQSo_uvAIFA

[6] https://www.cnchaoxu.com/news-center/what-are-the-different-types-of-plastic-extrusion-machines

[7] https://plasticextrusiontech.net/benefits-of-plastic-extrusion/

[8] https://www.made-in-china.com/products-search/hot-china-products/Wholesale_Plastic_Extrusion_Machinery.html

[9] https://www.youtube.com/watch?v=zNGuuSKE1pY

[10] https://www.kellerplastics.com/plastic-tube-extrusion-machines/

[11] https://www.clarkrandp.com/exploring-the-benefits-of-plastic-extrusion/

[12] https://www.alliedmarketresearch.com/plastic-extrusion-machine-market

[13] https://www.youtube.com/watch?v=oYgtuEQjEEA

[14] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[15] https://paulmurphyplastics.com/industry-news-blog/plastic-extrusion-advantages-and-disadvantages-of-plastic-extrusion/

[16] https://www.sourcifychina.com/plastic-extrusion-machine-guide-in-depth/

[17] https://www.rayda.co.uk/blog/advantages-and-disadvantages-of-plastic-extrusion/

[18] https://weiermachine.en.made-in-china.com/product/kdHAjDfKfCYi/China-Cost-Effective-Plastic-PVC-UPVC-CPVC-Conduit-Pipe-Extrusion-Machine-with-Low-Material-Cost.html

[19] https://www.kellerplastics.com/plastic-extrusions/benefits-of-extrusion/

[20] https://www.globenewswire.com/news-release/2024/05/16/2883237/0/en/Global-Plastic-Extrusion-Machines-Market-Expected-to-Reach-11-002-1-Million-by-2032-Allied-Market-Research.html

[21] https://www.databridgemarketresearch.com/reports/global-extrusion-machinery-market

[22] https://plasticextrusiontech.net/what-are-the-benefits-of-using-plastic-extrusions-over-other-materials/

[23] https://www.sourcifychina.com/top-plastic-extrusion-machine-supplier-compare/

[24] https://www.euroextrusions.com/plastic-extrusion-advantages-benefits/

[25] https://www.grandviewresearch.com/industry-analysis/extrusion-machinery-market-repor