Content Menu

● Understanding Aluminum Extrusion

● Factors Contributing to Toronto's Success in Aluminum Extrusion

>> 1. Strategic Location

>> 2. Strong Manufacturing Base

>> 3. Skilled Workforce

>> 4. Innovation and Technology

>> 5. Sustainability Focus

● Key Players in Toronto's Aluminum Extrusion Market

● Applications of Aluminum Extrusions

● Challenges Facing the Industry

● Future Prospects

● Conclusion

● FAQs

>> 1. What are the advantages of using aluminum extrusions?

>> 2. How does Toronto compare with other cities regarding aluminum extrusion services?

>> 3. What industries primarily use aluminum extrusions?

>> 4. How do companies ensure quality in their aluminum extrusions?

>> 5. What trends are shaping the future of aluminum extrusion services?

● Citations:

Toronto, the largest city in Canada, has emerged as a leading hub for aluminum extrusion services. This development is attributed to several factors, including a robust manufacturing infrastructure, a skilled workforce, and a growing demand for aluminum products across various industries. This article explores the reasons behind Toronto's prominence in the aluminum extrusion sector, highlighting its advantages, key players, and future prospects.

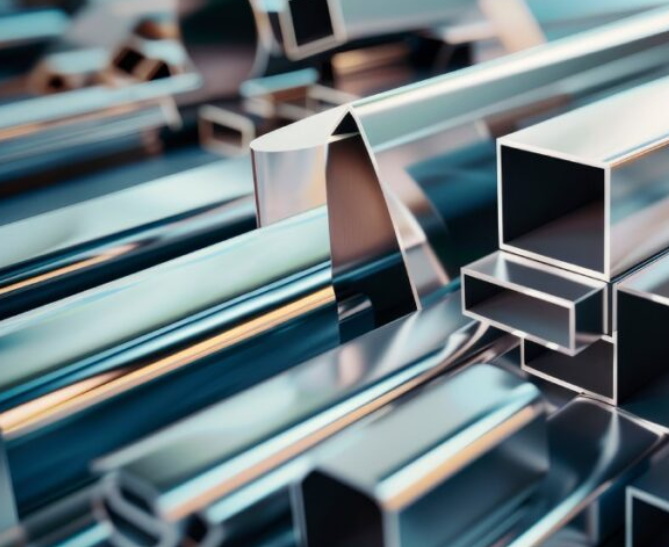

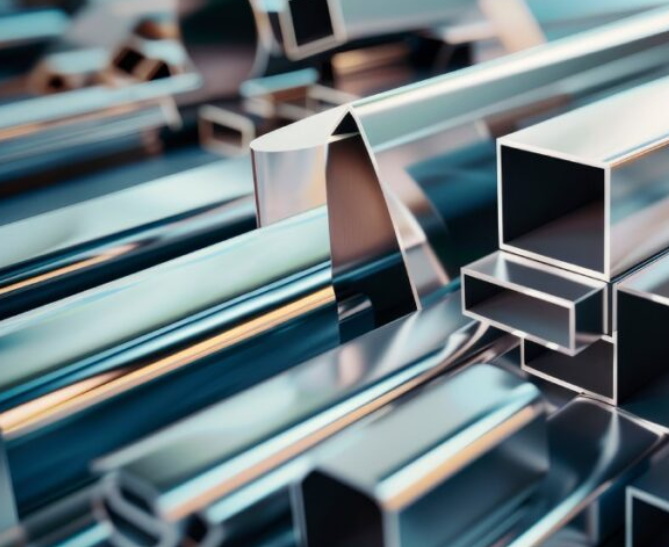

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create objects with a specific cross-sectional profile. This technique is widely used due to aluminum's lightweight nature, corrosion resistance, and versatility. The process allows for the creation of complex shapes that can be used in various applications, including construction, automotive, aerospace, and consumer goods.

Factors Contributing to Toronto's Success in Aluminum Extrusion

1. Strategic Location

Toronto's geographical location provides easy access to major markets in North America. The city is well-connected through an extensive transportation network that includes highways, railroads, and proximity to ports. This connectivity facilitates efficient distribution of aluminum products to customers across Canada and the United States.

2. Strong Manufacturing Base

Toronto boasts a diverse manufacturing base that supports the aluminum extrusion industry. The presence of advanced manufacturing facilities equipped with state-of-the-art technology enhances production capabilities. Companies like Signature Aluminum Canada and Extrudex Aluminum have established operations in the region, providing high-quality extruded products tailored to meet client specifications.

3. Skilled Workforce

The availability of a skilled workforce is crucial for the success of any manufacturing sector. Toronto benefits from a pool of talented engineers and technicians who specialize in aluminum processing and fabrication. Educational institutions in the area offer programs focused on metallurgy and materials science, ensuring that companies have access to knowledgeable employees.

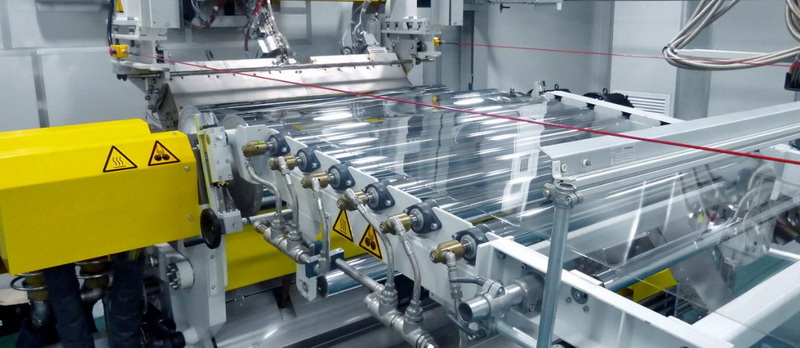

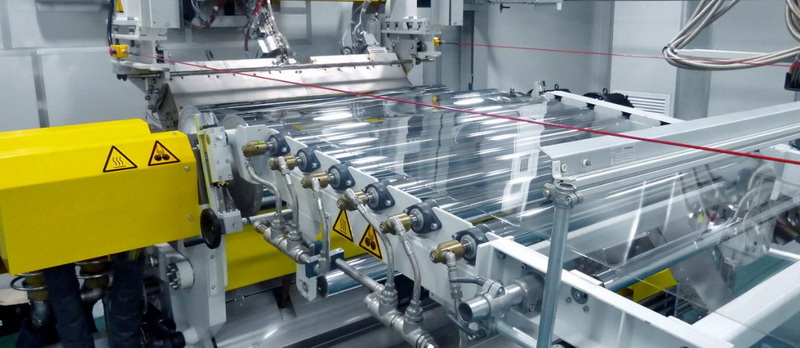

4. Innovation and Technology

Innovation plays a significant role in the aluminum extrusion industry. Toronto-based companies invest heavily in research and development to improve their processes and product offerings. The integration of advanced technologies such as automation and computer-aided design (CAD) enhances efficiency and precision in production.

Recent advancements include:

- Nano-coating Technologies: These improve durability by providing an extra layer of protection against corrosion and abrasion.

- AI-Powered Precision Control Solutions: AI algorithms analyze real-time data from extrusion machinery for immediate adjustments, enhancing product quality.

- Hybrid Extrusion Techniques: These methods blend conventional approaches with new technologies to produce stronger profiles suitable for demanding applications.

- Smart Extrusion Lines: Integrated with IoT technology, these enable comprehensive monitoring that enhances productivity and reduces downtime[2].

5. Sustainability Focus

With increasing emphasis on sustainability, many manufacturers are adopting eco-friendly practices in their operations. Aluminum is inherently recyclable, making it an attractive choice for environmentally conscious companies. Toronto's manufacturers are at the forefront of this trend, utilizing recycled aluminum in their extrusion processes.

Key Players in Toronto's Aluminum Extrusion Market

Several companies have established themselves as leaders in the aluminum extrusion sector within Toronto:

- Signature Aluminum Canada: Known for its extensive range of aluminum alloys and custom fabrication services.

- Extrudex Aluminum: Specializes in contract manufacturing and offers a wide variety of extruded products tailored for different industries.

- Can Art Aluminum Extrusion: Focuses on producing components for the electric vehicle market, reflecting the growing demand for lightweight materials in automotive applications.

These companies not only contribute to local employment but also enhance Toronto's reputation as a center for high-quality aluminum extrusion services.

Applications of Aluminum Extrusions

Aluminum extrusions find applications across various sectors:

- Construction: Used in window frames, structural components, and architectural features due to their strength and aesthetic appeal.

- Automotive: Lightweight extrusions help improve fuel efficiency while maintaining structural integrity in vehicles.

- Aerospace: The aerospace industry relies on aluminum extrusions for components that require high strength-to-weight ratios.

- Consumer Goods: Many everyday products utilize aluminum extrusions for their durability and lightweight properties.

The increasing applications in automobile manufacturing are particularly noteworthy; the push towards fuel-efficient vehicles drives sales of aluminum extrusion solutions significantly[1].

Challenges Facing the Industry

Despite its strengths, the aluminum extrusion industry in Toronto faces several challenges:

- Global Competition: Manufacturers must compete with overseas suppliers who may offer lower prices due to lower labor costs.

- Supply Chain Disruptions: Fluctuations in raw material availability can impact production schedules and costs.

- Technological Advancements: Keeping up with rapid technological changes requires continuous investment in new equipment and training.

Moreover, rising raw material costs pose significant challenges as manufacturers navigate fluctuating prices influenced by global economic conditions[8].

Future Prospects

The future of aluminum extrusion services in Toronto looks promising due to several factors:

- Growth of Electric Vehicles (EVs): The increasing demand for EVs presents significant opportunities for aluminum extruders as manufacturers seek lightweight materials to enhance vehicle performance.

- Infrastructure Development: Ongoing investments in infrastructure projects will drive demand for durable aluminum components. For instance, Canada's government invested over USD 33 billion into infrastructure programs recently[1].

- Sustainability Initiatives: As industries shift towards sustainable practices, the demand for recycled aluminum will likely increase, benefiting local manufacturers who are already adopting eco-friendly methods.

Conclusion

Toronto has established itself as a leading hub for aluminum extrusion services due to its strategic location, strong manufacturing base, skilled workforce, focus on innovation, and commitment to sustainability. As industries continue to evolve and demand lightweight materials grows, Toronto's position is likely to strengthen further. The city's manufacturers are well-equipped to meet these challenges and seize new opportunities in the global market.

FAQs

1. What are the advantages of using aluminum extrusions?

Aluminum extrusions offer several benefits including lightweight properties, corrosion resistance, design flexibility, cost-effectiveness over time due to low maintenance needs, and recyclability.

2. How does Toronto compare with other cities regarding aluminum extrusion services?

Toronto stands out due to its strategic location near major markets, a robust manufacturing infrastructure, access to skilled labor, and innovative practices among local companies.

3. What industries primarily use aluminum extrusions?

Aluminum extrusions are widely used in construction, automotive manufacturing, aerospace applications, consumer goods production, and renewable energy sectors.

4. How do companies ensure quality in their aluminum extrusions?

Manufacturers adhere to strict quality standards such as ISO certifications and implement rigorous inspection processes throughout production to ensure compliance with specifications.

5. What trends are shaping the future of aluminum extrusion services?

Key trends include increased demand from the electric vehicle market, advancements in recycling technologies, sustainability initiatives across industries, and ongoing innovations in manufacturing processes.

Citations:

[1] https://www.researchnester.com/reports/aluminum-extrusion-market/7191

[2] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[3] https://jmaluminium.com/the-evolution-of-aluminium-extrusion-industry-challenges-and-future-outlook/

[4] https://www.precedenceresearch.com/north-america-aluminum-extrusion-market

[5] https://www.grandviewresearch.com/industry-analysis/north-america-soft-alloy-aluminum-extrusion-market-report

[6] https://profileprecisionextrusions.com/aluminum-extrusion-demand-challenges-in-2022/

[7] https://www.globenewswire.com/news-release/2024/11/21/2985360/0/en/North-America-Aluminum-Extrusion-Market-Size-to-Surpass-USD-18-56-Bn-by-2033.html

[8] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[9] https://www.canart.com/blog/t-slot-aluminum-extrusions-the-new-found-solution-to-modular-design-in-canada/

[10] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[11] https://straitsresearch.com/report/north-america-aluminum-extrusion-market

[12] https://gloriaaluminium.com/blog/aluminium-extrusion-demand-challenges-in-2023/

[13] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[14] https://www.metalsminingreview.com/cxoinsight/exploring-emerging-trends-and-technologies-in-aluminum-extrusions-nwid-1012.html

[15] https://www.harboraluminum.com/en/news/automotive-aluminum-extrusions-challenges-and-opportunities

[16] https://www.thomasnet.com/suppliers/ontario/all-cities/aluminum-extrusions-26890400

[17] https://www.technavio.com/report/aluminum-extrusion-market-industry-analysis

[18] https://jmaluminium.com/aluminium-industry-challenges/

[19] https://www.alliedmarketresearch.com/aluminum-extrusion-market-A09001

[20] https://www.6wresearch.com/industry-report/canada-aluminum-extrusion-market