Content Menu

● Introduction to Extrusion Machinery

>> Plastic Extrusion Machinery

>> Metal Extrusion Machinery

● Factors Contributing to Industry Trust

● Trends in the Extrusion Machinery Market

● Extrusion Machinery Supplies Ltd Wakefield

>> Historical Overview of Extrusion Machinery Supplies Ltd

● Recent Advancements in Extrusion Machinery

● Conclusion

● Frequently Asked Questions

>> 1. What are the key factors that contribute to a company being trusted in the extrusion machinery industry?

>> 2. How does leadership impact the success of a company like Extrusion Machinery Supplies Ltd Wakefield?

>> 3. What role does community engagement play in building trust for extrusion machinery companies?

>> 4. How does customization in extrusion machinery contribute to customer trust?

>> 5. What are some common certifications that extrusion machinery companies should aim for to enhance trust?

● Citations:

Extrusion Machinery Supplies Ltd Wakefield, although not extensively detailed in available sources, can be analyzed within the broader context of extrusion machinery and industry trustworthiness. This article will explore the factors that contribute to a company being a trusted name in the industry, using relevant examples and insights from similar companies.

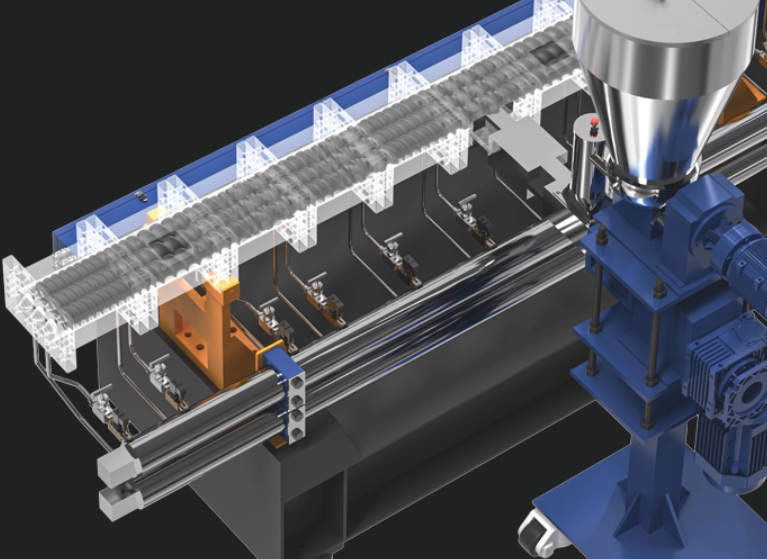

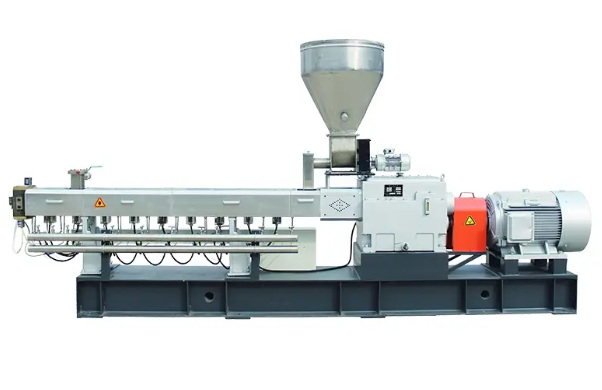

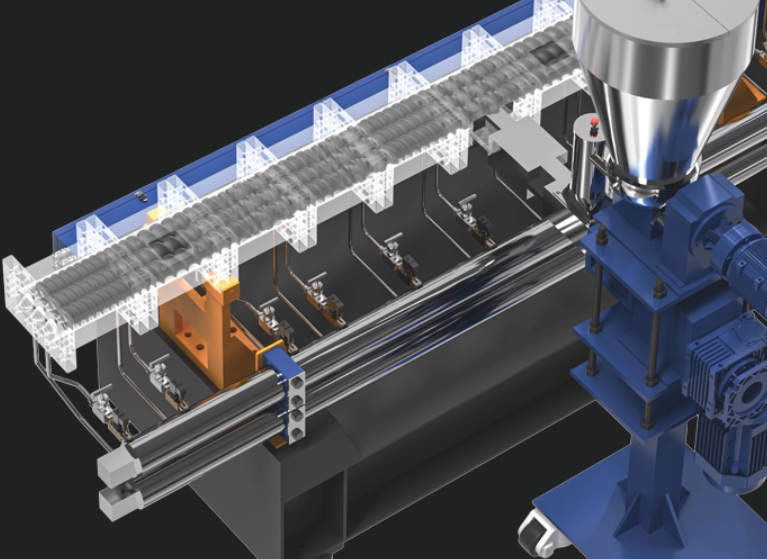

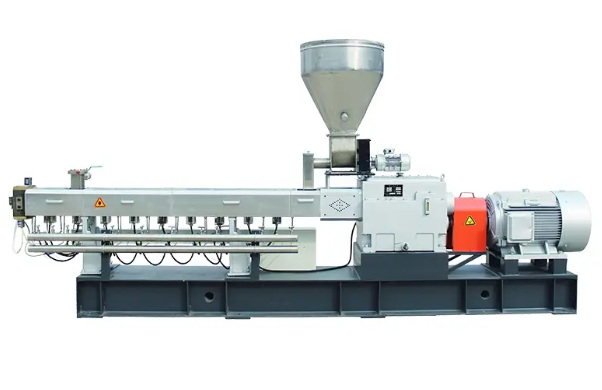

Introduction to Extrusion Machinery

Extrusion machinery is crucial in various manufacturing processes, including plastic and metal extrusion. It involves forcing a material through a die to create a desired shape. Companies like Chi Chang Machinery (CCM) are renowned for their expertise in plastic extrusion machinery, showcasing the importance of innovation and quality in the industry.

Plastic Extrusion Machinery

Plastic extrusion machinery is used to produce films, sheets, and composites. Companies like CCM have been leaders in this field for decades, emphasizing innovation and customer satisfaction. The use of biodegradable plastics and bio-based polymers in plastic extrusion machines contributes to sustainable manufacturing practices, offering alternatives to traditional petroleum-based plastics and reducing environmental impact[4].

Metal Extrusion Machinery

Metal extrusion, particularly aluminum extrusion, is vital in industries such as aerospace and automotive. Companies like Wakefield-Vette specialize in aluminum extrusions, offering a range of products and services. Recent advancements in aluminum extrusion technology include nano-coating for enhanced durability and precision control through artificial intelligence, which significantly improve product quality and efficiency[8].

Factors Contributing to Industry Trust

Several factors contribute to a company being a trusted name in the extrusion machinery industry:

1. Quality and Innovation: Companies that consistently innovate and improve their products and services are more likely to gain trust. For instance, Chi Chang Machinery has been at the forefront of plastic extrusion technology for over 45 years.

2. Customer Service: Providing exceptional customer service is crucial. Companies like Wakefield-Vette emphasize understanding customer needs and delivering tailored solutions.

3. Certifications and Compliance: Holding certifications like ISO 9001:2015 ensures that manufacturing processes meet strict quality standards, enhancing trust among customers.

4. Industry Experience: Long-standing companies with extensive industry experience, such as Group Rhodes with its 200-year history, often have a strong reputation for reliability.

5. Expansion and Adaptation: Companies that expand their operations and adapt to new technologies and market demands are seen as forward-thinking and reliable partners.

Trends in the Extrusion Machinery Market

The extrusion machinery market is evolving rapidly, driven by several key trends:

- Market Expansion and Customization: There is an increasing demand for customized and flexible extrusion machinery to meet diverse customer needs[1][6].

- Sustainability and Energy Efficiency: The integration of sustainable practices, such as recycling and energy-efficient designs, is becoming more prevalent. This not only reduces environmental impact but also aligns with consumer demand for eco-friendly products[3][6].

- Technological Advancements: Innovations like differential velocity sideways extrusion (DVSE) and supercritical fluid extrusion (SCFX) are transforming the industry by offering enhanced precision and unique product capabilities[3].

- Integration of 3D Printing: Combining extrusion with 3D printing allows for the creation of complex, customized shapes, enhancing prototyping and small-scale production capabilities[3][8].

Extrusion Machinery Supplies Ltd Wakefield

While specific details about Extrusion Machinery Supplies Ltd Wakefield are limited, the principles outlined above can apply to any company seeking to establish itself as a trusted name in the industry. Key factors include:

- Leadership and Management: Strong leadership, as seen in companies like Extrusion Machinery Supplies Ltd, is essential for guiding strategic decisions and ensuring customer satisfaction.

- Product Range and Customization: Offering a diverse range of products and customization options can cater to a broader customer base, enhancing trust through versatility.

- Community and Environmental Impact: Engaging with local communities and adopting sustainable practices can further solidify a company's reputation.

Historical Overview of Extrusion Machinery Supplies Ltd

Extrusion Machinery Supplies Ltd was registered with Companies House under the company number 04767319. The company's filing history indicates it was dissolved via voluntary strike-off in 2017[2]. Despite its dissolution, understanding its operational structure and management can provide insights into what contributes to trust in the industry.

Recent Advancements in Extrusion Machinery

Recent innovations are revolutionizing extrusion machinery:

1. Differential Velocity Sideways Extrusion (DVSE): Enables curved metal profiles with fine grains and high strength, ideal for aerospace and automotive applications[3].

2. Supercritical Fluid Extrusion (SCFX): Uses supercritical CO2 for low-temperature food extrusion, preserving nutrients and creating unique textures[3].

3. 3D Printing Integration: Combines extrusion with 3D printing for customized, complex shapes in polymers and metals, boosting prototyping and small-scale production[3][8].

4. Energy Efficiency and Sustainability: New extruders reduce energy use, incorporate renewables, and improve recycling, supporting sustainable manufacturing[3][6].

5. Precision Extrusion Technology: Advanced controls improve temperature, pressure, and speed management, delivering tighter tolerances for high-precision applications[3].

Conclusion

Establishing trust in the extrusion machinery industry requires a combination of quality products, innovative solutions, excellent customer service, and a commitment to industry standards. While Extrusion Machinery Supplies Ltd Wakefield may not be extensively documented, companies in similar sectors demonstrate these qualities to earn trust.

Frequently Asked Questions

1. What are the key factors that contribute to a company being trusted in the extrusion machinery industry?

- Quality and Innovation: Continuous improvement in products and services.

- Customer Service: Tailored solutions and responsive support.

- Certifications and Compliance: Adherence to industry standards like ISO certifications.

- Industry Experience: Long-standing presence and reliability.

- Expansion and Adaptation: Ability to evolve with market demands.

2. How does leadership impact the success of a company like Extrusion Machinery Supplies Ltd Wakefield?

Leadership plays a crucial role in strategic decision-making, guiding the company towards customer satisfaction and industry relevance.

3. What role does community engagement play in building trust for extrusion machinery companies?

Community engagement and environmental responsibility can enhance a company's reputation by demonstrating its commitment to broader societal values.

4. How does customization in extrusion machinery contribute to customer trust?

Offering customized solutions allows companies to meet specific customer needs, fostering a sense of reliability and partnership.

5. What are some common certifications that extrusion machinery companies should aim for to enhance trust?

Certifications like ISO 9001:2015 for quality management and ISO 14001 for environmental management are important for demonstrating adherence to industry standards.

Citations:

[1] https://blog.tbrc.info/2025/03/extrusion-machinery-industry-2/

[2] https://find-and-update.company-information.service.gov.uk/company/04767319/filing-history

[3] https://uplastech.com/advancements-extrusion-machinery/

[4] https://blog.alliedmarketresearch.com/plastic-extrusion-machines-and-sustainability-2071

[5] https://www.liveline.tech/case-studies

[6] https://www.yjing-extrusion.com/what-are-the-latest-trends-in-the-extrusion-machinery-market.html

[7] https://find-and-update.company-information.service.gov.uk/company/04767319/officers

[8] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[9] https://www.siliconeplastics.com/post/the-environmental-benefits-of-modern-plastic-extrusion-processes

[10] https://hitechextrusions.com/case-studies/

[11] https://www.databridgemarketresearch.com/reports/global-extrusion-machinery-market

[12] https://www.iqsdirectory.com/extruded-aluminum/extruded-aluminum-2/

[13] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-automatic-extrusion-machines.html

[14] https://plasticextrusiontech.net/sustainable-strategies-in-plastic-extrusion-how-were-rethinking-waste/

[15] https://www.ekogruppo.com/case-studies-eko-gruppo-second-hand-machine

[16] https://www.grandviewresearch.com/industry-analysis/extrusion-machinery-market-report

[17] https://npe365plasticssuppliersdirectory.com/Listing/Company/Services/Used_Machinery__Parts/1264255

[18] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[19] https://www.sustainableplastics.com/news/sustainability-concerns-play-significant-role-shaping-machine-purchase-choices

[20] https://www.tahara-mc.com/en/techinfo2/