Content Menu

● Understanding Aluminum Extrusion

>> The Manufacturing Process

● Benefits of Aluminum Extrusion for LED Strip Lighting

● Enhancing Performance with Accessories

● Applications of Aluminum Extrusion for LED Strip Lights

● Choosing the Right Aluminum Extrusion Profile

● Cost-Effectiveness

● Environmental Considerations

● Future Trends in Aluminum Extrusion for Lighting

● Conclusion

● FAQs

>> 1. What is aluminum extrusion?

>> 2. How does aluminum extrusion improve LED performance?

>> 3. Can I use aluminum extrusions outdoors?

>> 4. Are there different types of aluminum profiles available?

>> 5. How do I install LED strips in an aluminum extrusion?

● Citations:

LED strip lighting has revolutionized the way we illuminate spaces, offering flexibility, energy efficiency, and a modern aesthetic. However, to maximize the performance and longevity of LED strips, the use of aluminum extrusion has become increasingly popular. This article explores the numerous advantages of aluminum extrusion for LED strip lights, detailing its benefits, applications, and why it stands out as the best choice for lighting solutions.

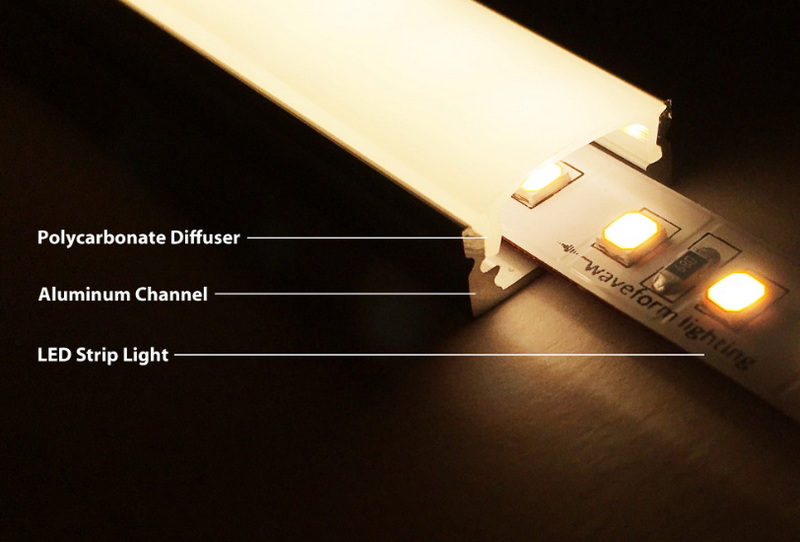

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that shapes aluminum into a desired cross-sectional profile. This technique allows for the creation of complex shapes that can be used in various applications, including housing for LED strip lights. The process involves forcing heated aluminum through a die to produce long lengths of material with consistent cross-sections.

The Manufacturing Process

The aluminum extrusion process begins with heating aluminum billets to a malleable state. Once heated, these billets are placed in an extrusion press where they are forced through a die. The die determines the final shape of the aluminum profile. After exiting the die, the extruded aluminum is cooled and cut to length. This method allows for high precision and repeatability, making it ideal for producing components used in LED lighting.

Benefits of Aluminum Extrusion for LED Strip Lighting

1. Effective Heat Dissipation

One of the primary advantages of using aluminum extrusion for LED strip lights is its excellent thermal conductivity. LEDs generate heat during operation, which can reduce their lifespan and performance if not managed properly. Aluminum extrusions effectively dissipate this heat, ensuring that the LEDs operate at optimal temperatures. This thermal management helps maintain consistent brightness and extends the lifespan of the lighting system.

2. Durability and Protection

Aluminum is known for its strength and corrosion resistance. By encasing LED strips in aluminum extrusions, they are protected from physical damage, dust, moisture, and other environmental factors. This durability makes aluminum extrusions ideal for both indoor and outdoor applications.

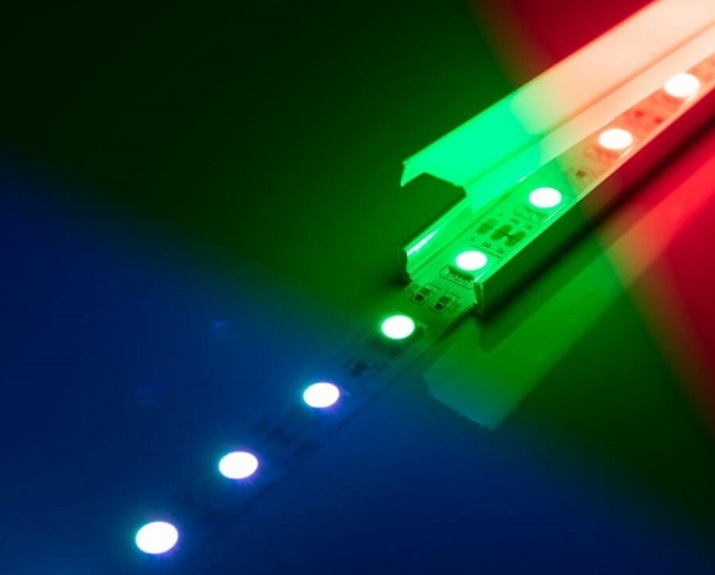

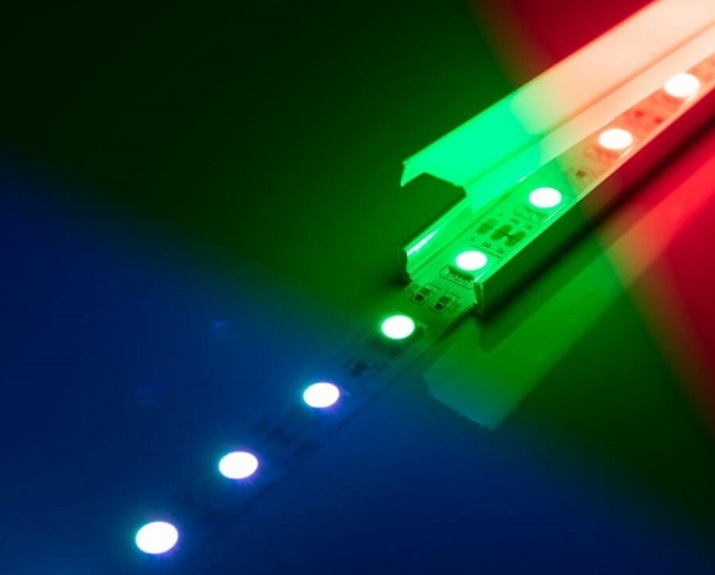

3. Aesthetic Appeal

Aluminum extrusions provide a sleek and modern look that enhances the overall design of lighting installations. They can be finished in various ways—such as anodizing or powder coating—to match different interior styles and preferences. This versatility allows designers to create visually appealing lighting solutions without compromising functionality.

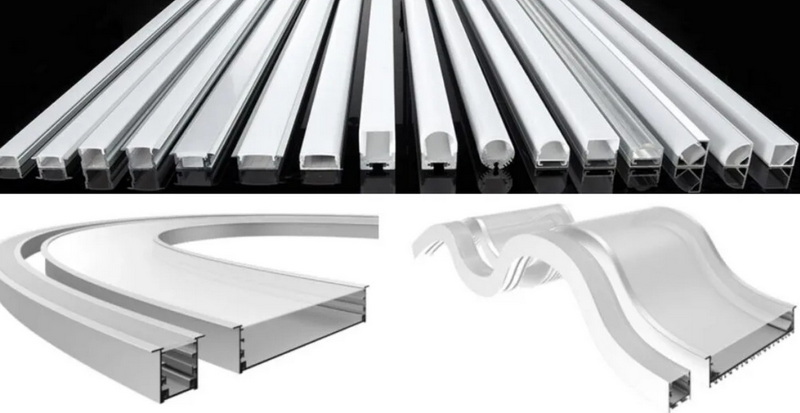

4. Versatile Design Options

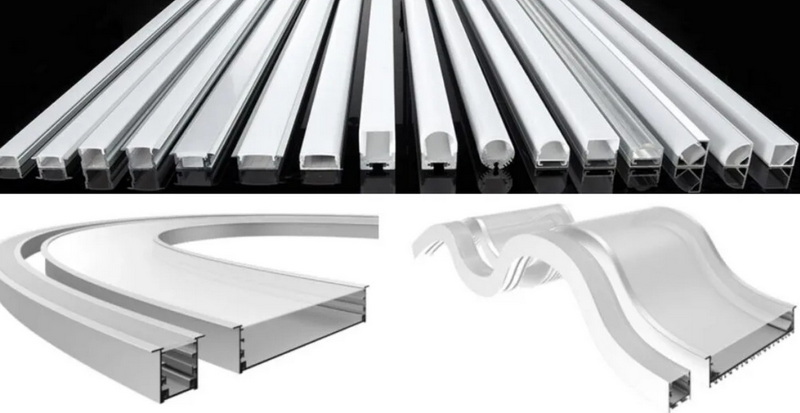

The extrusion process allows manufacturers to create a wide range of profiles tailored to specific lighting needs. Whether it's recessed, surface-mounted, or corner installations, there are aluminum profiles available to suit any design requirement. This flexibility enables creative lighting solutions that can adapt to various architectural styles.

5. Ease of Installation

Installing LED strips within aluminum extrusions is straightforward and often requires minimal tools. Many profiles come with clip mounting systems or integrated channels that simplify the installation process. This ease of use saves time and reduces labor costs during installation.

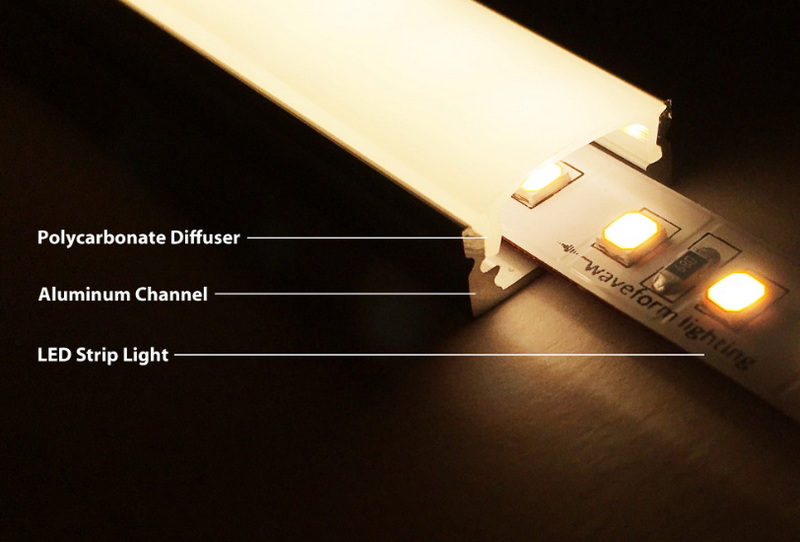

Enhancing Performance with Accessories

To further improve the performance of LED strip lights housed in aluminum extrusions, several accessories can be utilized:

- Diffusers: These are transparent covers that help to soften and distribute light evenly across surfaces. They reduce glare while maintaining brightness.

- End Caps: End caps protect exposed ends of LED strips from dust and moisture while providing a finished look to installations.

- Mounting Clips: These clips secure the aluminum profile in place during installation, ensuring stability and alignment.

Applications of Aluminum Extrusion for LED Strip Lights

Aluminum extrusions are used in diverse settings due to their adaptability and functionality:

- Architectural Lighting: Used to highlight building facades or structural elements.

- Retail Displays: Enhances product visibility and creates attractive showcases.

- Residential Lighting: Provides ambient or task lighting in kitchens, living rooms, and bedrooms.

- Commercial Spaces: Ideal for offices, hotels, and restaurants where ambiance is crucial.

- Entertainment Venues: Creates dynamic lighting effects in theaters and event spaces.

- Outdoor Lighting: Protects LED strips from environmental elements while providing illumination.

Choosing the Right Aluminum Extrusion Profile

When selecting an aluminum extrusion profile for LED strip lights, several factors should be considered:

- Size Compatibility: Ensure that the profile can accommodate the width and height of your LED strips.

- Design Intent: Choose a profile that aligns with your aesthetic goals—whether you prefer a low-profile look or something more pronounced.

- Installation Type: Determine whether you need surface-mounted or recessed profiles based on your installation environment.

Cost-Effectiveness

Investing in aluminum extrusion for LED strip lighting may seem more expensive upfront compared to other materials; however, it proves cost-effective over time due to its durability and efficiency:

- Long Lifespan: The combination of effective heat dissipation and protection from environmental factors significantly extends the life expectancy of both the aluminum housing and the LED strips themselves.

- Reduced Maintenance Costs: With enhanced durability comes lower maintenance needs; fewer replacements mean savings in both time and money.

Environmental Considerations

Aluminum is a highly recyclable material, making it an environmentally friendly choice for LED strip lighting applications. When considering sustainability:

- Recyclability: At the end of its life cycle, aluminum can be recycled without losing quality or properties.

- Energy Efficiency: LEDs consume significantly less energy than traditional lighting solutions; pairing them with efficient aluminum extrusions further reduces overall energy consumption.

Future Trends in Aluminum Extrusion for Lighting

As technology advances, so too does the potential for innovation within aluminum extrusion applications for LED strip lights:

- Smart Lighting Integration: With the rise of smart home technology, integrating sensors within aluminum profiles could allow for automated lighting solutions based on occupancy or ambient light levels.

- Customizable Designs: Advances in 3D printing technology could lead to more customized designs tailored specifically to individual projects or architectural requirements.

Conclusion

In conclusion, aluminum extrusion is undoubtedly the best option for LED strip lighting due to its superior heat dissipation capabilities, durability, aesthetic flexibility, versatile design options, ease of installation, cost-effectiveness, and environmental benefits. As LED technology continues to evolve, integrating aluminum extrusions into lighting designs will enhance performance while providing stylish solutions suitable for any setting.

FAQs

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where heated aluminum is forced through a die to create long sections with specific cross-sectional shapes used in various applications.

2. How does aluminum extrusion improve LED performance?

Aluminum extrusion enhances LED performance by dissipating heat effectively, which helps maintain optimal operating temperatures and prolongs the lifespan of the LEDs.

3. Can I use aluminum extrusions outdoors?

Yes, aluminum extrusions are durable and corrosion-resistant, making them suitable for outdoor applications where they can protect LED strips from environmental factors.

4. Are there different types of aluminum profiles available?

Yes, there are various types of aluminum profiles available for different applications including recessed mounts, surface mounts, corner mounts, and flexible options to accommodate various design needs.

5. How do I install LED strips in an aluminum extrusion?

Installing LED strips in an aluminum extrusion typically involves cutting the profile to size, inserting the LED strip into the channel, securing it with clips if necessary, and then closing it with a cover.

Citations:

[1] https://www.profall.com/en/aluminum-extrusion-for-led-strip-lights

[2] https://kimsen.vn/5-reasons-why-aluminium-extrusion-profilesare-perfect-for-led-lighting-ne123.html

[3] https://www.youtube.com/watch?v=-jpsxQ2oAsw

[4] https://www.glowbackledstore.com/sample-of-aluminum-extrusion-u-or-led-strip-alumusample/

[5] https://marcled.com/blog/2024/02/07/4-benefits-of-using-led-extrusion-channels/

[6] https://www.youtube.com/watch?v=ywfaZWoKY4s

[7] https://www.boscolighting.com.au/aluminium-extrusions

[8] https://hitlights.com/blogs/premium-led-strip-lighting/upgrade-your-led-strip-light-installation-5-benefits-of-aluminum-channels-hitlights

[9] https://www.youtube.com/watch?v=azas4X4Mp4A

[10] https://thelightingoutlet.com.au/collections/led-profiles