Content Menu

● The Evolution of Plastic Pipe Extrusion Technology

● Key Benefits of Advanced Plastic Pipe Extrusion Machinery

>> Enhanced Efficiency and Productivity

>> Unparalleled Quality Control

>> Cost-Effectiveness in the Long Run

>> Versatility and Adaptability

>> Energy Efficiency

● Technological Innovations in Plastic Pipe Extrusion

>> Multi-Layer Pipe Extrusion

>> Servo Motor Control

>> Advanced Die Technologies

● The Impact on Various Industries

>> Construction Sector

>> Automotive Industry

>> Packaging Industry

● Choosing the Right Plastic Pipe Extrusion Machinery

>> Production Capacity

>> Technological Features

>> Customization Options

>> Brand Reputation and Support

● The Best Plastic Pipe Extrusion Machinery Price: A Comprehensive Guide

>> Price Ranges for Different Types of Extrusion Machinery

>> Factors Influencing the Best Plastic Pipe Extrusion Machinery Price

>> Finding the Best Value for Your Investment

● Future Trends in Plastic Pipe Extrusion Technology

>> Sustainability and Recycling

>> Industry 4.0 Integration

>> Advanced Materials Processing

● Case Studies: Success Stories in Plastic Pipe Extrusion

>> Company A: Boosting Productivity with Advanced Extrusion Technology

>> Company B: Customization Capabilities Leading to New Markets

● Conclusion

● FAQ

>> 1. What is the average lifespan of a plastic pipe extrusion machine?

>> 2. How does the best plastic pipe extrusion machinery price compare to traditional manufacturing methods?

>> 3. Can advanced plastic pipe extrusion machinery handle recycled materials?

>> 4. What kind of training is required to operate advanced plastic pipe extrusion machinery?

>> 5. How does energy efficiency factor into the best plastic pipe extrusion machinery price?

● Citations:

In today's rapidly evolving manufacturing landscape, the plastic pipe industry stands at the forefront of innovation and efficiency. As demand for high-quality, durable, and cost-effective piping solutions continues to surge across various sectors, from construction to agriculture, the role of advanced plastic pipe extrusion machinery has become increasingly pivotal. This article delves into the compelling reasons why investing in cutting-edge plastic pipe extrusion technology is not just a smart business move, but a necessity for companies aiming to stay competitive in the global market.

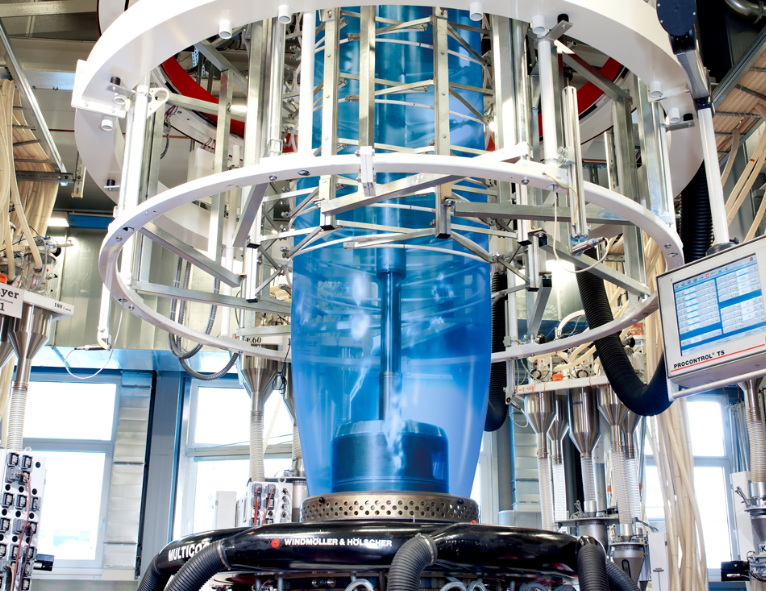

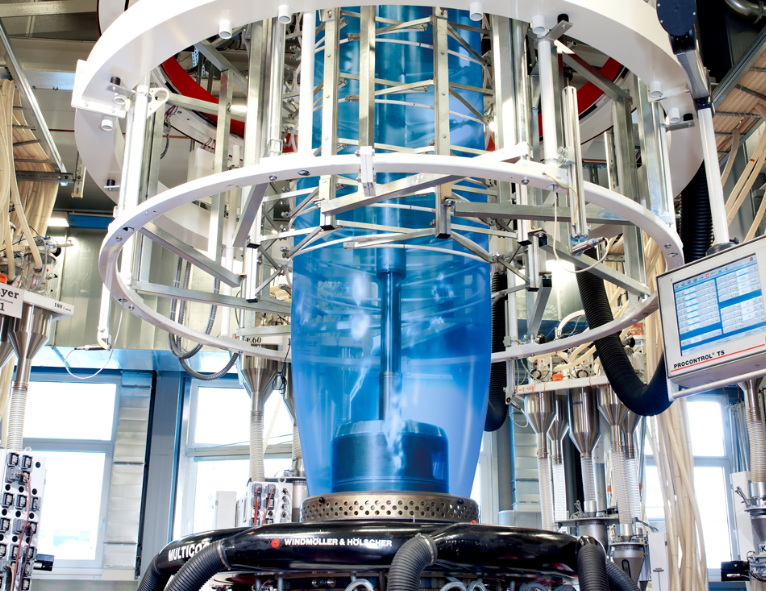

The Evolution of Plastic Pipe Extrusion Technology

The journey of plastic pipe extrusion has been marked by continuous technological advancements. From rudimentary processes to today's sophisticated, computer-controlled systems, the evolution has been nothing short of remarkable. Modern plastic pipe extrusion machinery represents the pinnacle of this progress, offering unprecedented levels of precision, efficiency, and versatility.

Key Benefits of Advanced Plastic Pipe Extrusion Machinery

Enhanced Efficiency and Productivity

One of the primary advantages of investing in state-of-the-art plastic pipe extrusion machinery is the significant boost in efficiency and productivity. These advanced systems are capable of producing a higher volume of pipes in less time, meeting escalating market demand with ease[1]. The automation of key manufacturing processes eliminates inefficiencies inherent in manual labor, resulting in accelerated production cycles.

Unparalleled Quality Control

Modern extrusion machines offer precise control over critical parameters such as temperature, pressure, and speed. This meticulous control ensures unwavering standards of product quality, which is paramount for meeting industry specifications and satisfying customer requirements[1]. Consistency in quality fosters trust and loyalty in the brand, a crucial factor in today's competitive market.

Cost-Effectiveness in the Long Run

While the initial investment in advanced plastic pipe extrusion machinery may seem substantial, it yields significant long-term cost savings. Reduced labor costs, diminished scrap rates, and increased production output collectively contribute to improved profitability over time[1]. This makes advanced extrusion machinery a prudent investment for forward-thinking manufacturers.

Versatility and Adaptability

One of the standout features of modern plastic pipe extrusion machinery is its remarkable versatility. These systems can accommodate a diverse array of pipe sizes, shapes, and specifications[1]. This flexibility allows manufacturers to swiftly respond to shifting market dynamics and customer preferences, maintaining a competitive edge in a dynamic industry landscape.

Energy Efficiency

In an era where sustainability is paramount, the energy efficiency of manufacturing processes is crucial. Advanced plastic pipe extrusion machines are designed with energy conservation in mind, reducing operational costs while maintaining high output levels[2]. This not only contributes to cost savings but also aligns with global efforts towards more sustainable manufacturing practices.

Technological Innovations in Plastic Pipe Extrusion

Multi-Layer Pipe Extrusion

One of the most exciting developments in plastic pipe extrusion technology is multi-layer extrusion. This innovation allows manufacturers to create pipes with different layers of materials, each offering unique properties such as heat resistance or chemical durability[2]. This technology opens up new possibilities for creating pipes tailored to specific environmental conditions or industrial applications.

Servo Motor Control

The integration of servo motors in extrusion machinery has revolutionized the level of precision achievable in the production process. Servo motors provide exact control over the extrusion process, allowing for better consistency and higher output rates[2]. This level of control is particularly crucial when producing pipes that require strict adherence to dimensional tolerances.

Advanced Die Technologies

Innovations in die design have significantly expanded the range of pipe profiles that can be produced. New die technologies offer manufacturers the ability to create customized products, meeting the unique needs of various industries[2]. This flexibility in production capabilities can be a significant competitive advantage in markets that demand specialized piping solutions.

The Impact on Various Industries

Construction Sector

The construction industry has been one of the primary beneficiaries of advancements in plastic pipe extrusion technology. Modern extruded pipes offer superior durability, corrosion resistance, and ease of installation, making them ideal for plumbing, electrical, and structural applications in modern construction projects[5].

Automotive Industry

In the automotive sector, plastic extrusion plays a crucial role in manufacturing components such as weather stripping, interior trim, and wiring ducts. The lightweight nature of extruded plastic products contributes to fuel efficiency and overall vehicle performance, aligning with the industry's push toward more sustainable transportation solutions[5].

Packaging Industry

The packaging industry has also seen significant benefits from advancements in plastic extrusion technology. Extruded films and sheets are widely used for packaging food, pharmaceuticals, and consumer goods, providing essential barrier properties that protect products from moisture, oxygen, and contaminants[5].

Choosing the Right Plastic Pipe Extrusion Machinery

Selecting the appropriate plastic pipe extrusion machinery is crucial for maximizing the benefits of this technology. Several factors should be considered when making this important decision:

Production Capacity

The daily output capacity of a machine is one of the key determinants of its price and suitability for your operations. High-capacity plastic extrusion machines tend to be positioned at the higher end of the pricing spectrum but offer significant advantages in terms of productivity[4].

Technological Features

Features such as automated control systems, PLC touchscreen panels, and energy-efficient motors can significantly enhance the performance and efficiency of extrusion machinery. While these features may increase the initial cost, they offer substantial long-term benefits in terms of operational efficiency and product quality[4].

Customization Options

Many plastic extrusion machines can be customized to meet specific client needs. Consider machines that offer flexibility in terms of size, additional modules, and production capacity to ensure they can meet your unique requirements[4].

Brand Reputation and Support

Choosing a high-quality plastic extrusion machine from a trusted manufacturer can pay off in the long run. Consider factors such as the brand's reputation, after-sales support, and availability of spare parts when making your decision[4].

The Best Plastic Pipe Extrusion Machinery Price: A Comprehensive Guide

When it comes to finding the best plastic pipe extrusion machinery price, it's essential to consider the balance between cost and value. While it might be tempting to opt for the lowest-priced option, investing in quality machinery often proves more economical in the long run.

Price Ranges for Different Types of Extrusion Machinery

As of 2024, plastic pipe extrusion machines typically range from $30,000 to $150,000[4]. Machines designed for smaller diameter pipes are generally more affordable, while those capable of producing larger diameter pipes tend to be at the higher end of the price spectrum.

It's important to note that these prices can vary based on factors such as production capacity, technological features, and customization options. Here's a breakdown of price ranges for different types of extrusion machinery:

- Plastic Pipe Extrusion Machines: $30,000 - $150,000

- Profile Extrusion Machines: $25,000 - $100,000

- Granule Extrusion Machines: $40,000 - $120,000

- Filament Extrusion Machines: $20,000 - $90,000

- Sheet Extrusion Machines: $50,000 - $200,000[4]

Factors Influencing the Best Plastic Pipe Extrusion Machinery Price

Several factors can influence the price of plastic pipe extrusion machinery:

1. Production Capacity: Machines with higher output capabilities generally command higher prices.

2. Technological Features: Advanced features like automated control systems and energy-efficient designs can increase the initial cost but offer long-term savings.

3. Customization: Tailored solutions to meet specific production needs may come at a premium.

4. Brand and Manufacturer: Renowned global brands typically have higher price tags but often offer superior quality and reliability.

5. After-Sales Support: Comprehensive service packages and readily available spare parts can add value to the overall package.

Finding the Best Value for Your Investment

To find the best plastic pipe extrusion machinery price that offers optimal value for your investment, consider the following steps:

1. Assess Your Needs: Clearly define your production requirements, including output capacity, pipe specifications, and any special features you need.

2. Research Multiple Suppliers: Don't limit yourself to a single supplier. Explore options from various manufacturers to compare features and prices.

3. Consider Total Cost of Ownership: Look beyond the initial price tag. Factor in operational costs, energy efficiency, and potential maintenance expenses over the machine's lifetime.

4. Evaluate ROI: Calculate the potential return on investment based on increased productivity, reduced waste, and improved quality.

5. Request Demonstrations: Where possible, ask for demonstrations or trials of the machinery to ensure it meets your expectations.

Future Trends in Plastic Pipe Extrusion Technology

As we look to the future, several trends are shaping the landscape of plastic pipe extrusion technology:

Sustainability and Recycling

With increasing focus on environmental sustainability, future extrusion machinery is likely to incorporate more features that support the use of recycled materials and reduce waste. This trend aligns with the growing demand for eco-friendly manufacturing processes and products.

Industry 4.0 Integration

The integration of Industry 4.0 technologies, such as IoT sensors, AI-driven predictive maintenance, and cloud-based monitoring systems, is set to revolutionize plastic pipe extrusion. These advancements will enable real-time optimization of production processes, further enhancing efficiency and quality control.

Advanced Materials Processing

As new plastic formulations and composite materials emerge, extrusion machinery will need to evolve to handle these advanced materials effectively. This may lead to the development of more versatile and adaptable extrusion systems.

Case Studies: Success Stories in Plastic Pipe Extrusion

Company A: Boosting Productivity with Advanced Extrusion Technology

Company A, a medium-sized plastic pipe manufacturer, invested in a state-of-the-art plastic pipe extrusion line. Within the first year of implementation, they reported:

- 30% increase in production output

- 15% reduction in material waste

- 20% improvement in energy efficiency

These improvements led to a significant boost in profitability and allowed the company to expand its market share.

Company B: Customization Capabilities Leading to New Markets

By investing in a highly flexible extrusion system with advanced die technologies, Company B was able to produce specialized pipe profiles for niche industries. This capability opened up new market opportunities, resulting in:

- 40% increase in product range

- 25% growth in annual revenue

- Expansion into two new industry sectors

These case studies highlight the tangible benefits that investing in advanced plastic pipe extrusion machinery can bring to businesses of various sizes.

Conclusion

Investing in advanced plastic pipe extrusion machinery is not just a matter of keeping up with technological trends; it's a strategic decision that can significantly impact a company's competitiveness, efficiency, and bottom line. The benefits of enhanced productivity, superior quality control, cost-effectiveness, and versatility make it a compelling choice for manufacturers looking to thrive in the dynamic plastic pipe industry.

As we've explored, the best plastic pipe extrusion machinery price is not necessarily the lowest upfront cost, but rather the option that offers the best value over time. By carefully considering factors such as production needs, technological features, and long-term ROI, manufacturers can make informed decisions that position them for success in an increasingly competitive global market.

The future of plastic pipe extrusion is bright, with ongoing innovations promising even greater efficiencies and capabilities. For businesses in the plastic pipe industry, the question is not whether to invest in advanced extrusion technology, but how to strategically implement these advancements to maximize their competitive advantage.

FAQ

1. What is the average lifespan of a plastic pipe extrusion machine?

The average lifespan of a well-maintained plastic pipe extrusion machine typically ranges from 15 to 20 years. However, with proper care and regular upgrades, some machines can remain operational for even longer periods. It's important to note that while the basic structure may last for decades, certain components may require replacement or upgrading more frequently to keep up with technological advancements and maintain optimal performance.

2. How does the best plastic pipe extrusion machinery price compare to traditional manufacturing methods?

While the initial best plastic pipe extrusion machinery price may be higher compared to traditional manufacturing methods, the long-term cost-effectiveness is significantly better. Advanced extrusion machinery offers higher production rates, reduced labor costs, improved energy efficiency, and less material waste. These factors contribute to a lower cost per unit of production over time, making it a more economical choice in the long run despite the higher upfront investment.

3. Can advanced plastic pipe extrusion machinery handle recycled materials?

Yes, many modern plastic pipe extrusion machines are designed to process recycled materials effectively. Advanced systems often include features such as enhanced filtration systems and specialized screw designs that can handle the variability in recycled plastic feedstock. This capability not only supports sustainability efforts but can also lead to cost savings on raw materials. However, it's important to choose machinery specifically designed for this purpose to ensure optimal performance and product quality when using recycled materials.

4. What kind of training is required to operate advanced plastic pipe extrusion machinery?

Operating advanced plastic pipe extrusion machinery typically requires specialized training. This training usually covers:

- Basic principles of plastic extrusion

- Machine setup and operation

- Quality control procedures

- Troubleshooting common issues

- Safety protocols

Many machinery manufacturers offer comprehensive training programs as part of their after-sales service. Additionally, ongoing training may be necessary as new features or upgrades are introduced. Investing in thorough operator training is crucial for maximizing the efficiency and lifespan of the machinery.

5. How does energy efficiency factor into the best plastic pipe extrusion machinery price?

Energy efficiency is a crucial factor to consider when evaluating the best plastic pipe extrusion machinery price. While more energy-efficient models may have a higher initial cost, they can lead to significant savings over time through reduced energy consumption. Modern extrusion machines often incorporate features like:

- High-efficiency motors

- Advanced heating and cooling systems

- Optimized screw designs for better melting efficiency

Citations:

[1] https://jydjx.com/optimizing-production-with-pvc-pipe-extrusion-machine-lines/

[2] https://www.adremac.com/pipe-extruders-comprehensive-guide-to-technology-applications-and-innovations-in-plastic-pipe-manufacturing/

[3] https://jwellmachinery.en.made-in-china.com/product/nBuJIMplsbYH/China-Plastic-Pipe-Extrusion-Machine-Machines.html

[4] https://deltaplastik.com/blog/plastic-extrusion-machine-prices-2024-choosing-the-right-machine-for-your-needs

[5] https://abhiplastics.com/revolutionizing-the-plastic-industry-how-plastic-extrusion-machinery-is-changing-the-game/

[6] https://deltaplastik.com/blog/plastic-production-machinery-the-future-of-industrial-investment

[7] https://www.caisumachinery.com/plastic-pipe-extrusion-machine-a-comprehensive-guide/

[8] https://www.alliedmarketresearch.com/plastic-extrusion-machine-market

[9] https://www.fangliextru.com/news-show-1069233.html

[10] https://www.adremac.com/complete-guide-to-pipe-extrusion-machinery-equipment-and-advanced-cutting-solutions/

[11] https://jieyatwinscrew.com/blog/pvc-pipe-extruder-machine/

[12] https://www.youtube.com/watch?v=ec6lmle4_es

[13] https://www.shutterstock.com/search/plastic-extrusion-line

[14] https://www.alibaba.com/showroom/pvc-pipe-extrusion-machine.html

[15] https://qsplasticmachine.en.made-in-china.com/product-group/foFTiLzdnPWq/PE-Pipe-Extrusion-Line-1.html

[16] https://dir.indiamart.com/impcat/pvc-extruder.html

[17] https://www.alibaba.com/product-detail/120mm-plastic-PE-pipe-extruder-machine_1600967657307.html

[18] https://www.made-in-china.com/products-search/hot-china-products/Plastic_Extruder_Price.html

[19] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[20] https://www.accextrusion.com/news/how-to-invest-in-plastic-board-extrusion-lines/

[21] https://ir.boyuextruder.com/extruder/5-advantages-plastic-extrusion.html

[22] https://www.accextrusion.com/news/the-importance-of-pvc-profile-extrusion-machines/

[23] https://www.kellerplastics.com/plastic-extrusions/benefits-of-extrusion/

[24] https://www.youtube.com/watch?v=Kv9wpOf5iVg

[25] https://www.jwellextrusions.com/function-introduction-of-pvc-pipe-extrusion-line.html

[26] https://www.bausano.com/en

[27] https://www.youtube.com/watch?v=AHBQIhwINUQ

[28] https://plastic-extrusionmachines.com/the-basic-principles-of-pipes-extrusion/

[29] https://plasticextrusiontech.net/portfolio-gallery/

[30] https://www.youtube.com/watch?v=WCznCpciRKw

[31] https://plastic-extrusionmachines.com/plastic-extrusion-machine-cost/

[32] https://faygoplast.en.alibaba.com/productgrouplist-212194291/Plastic_Pipe_Extrusion_Line.html?spm=a2700.icbuShop.prup15aafb.10.5f34487dTv5cO7

[33] https://dir.indiamart.com/impcat/pvc-pipe-extrusion-machine.html

[34] https://www.made-in-china.com/products-search/hot-china-products/Plastic_Pipe_Extrusion_Line_Price.html