Content Menu

● Introduction to Unique Machinery

>> Key Features of Unique Machinery

● Advantages of Unique Extrusion Machinery

>> Cost-Effectiveness

>> Efficient Production of Linear Shapes

>> Material Versatility

>> Speed and Efficiency in Production

>> Simplicity in Design and Operation

● Modern Extrusion Machinery: Efficiency and Precision

>> High-Precision Temperature Control

>> Programmable Logic Controllers (PLCs)

>> Integration of Emerging Technologies

>> Customization and Flexibility

● Innovations in Extrusion Manufacturing

>> Smart Extrusion Technology

>> Biodegradable Materials and Eco-Friendly Practices

>> Automated Quality Control

>> Integration of Artificial Intelligence

>> Synergy Between 3D Printing and Extrusion

● Future of Extrusion Machinery

>> Enhanced Automation

>> Eco-Friendly Technologies

>> Customization and Flexibility

>> Integration with Digital Twins

● Conclusion

● Frequently Asked Questions

>> 1. What types of extrusion machines does Unique Machinery offer?

>> 2. How does Unique Machinery ensure the quality of its products?

>> 3. What are the advantages of choosing extrusion over injection molding?

>> 4. How does Unique Machinery support customization in extrusion?

>> 5. What is Unique Machinery's vision for the future?

● Citations:

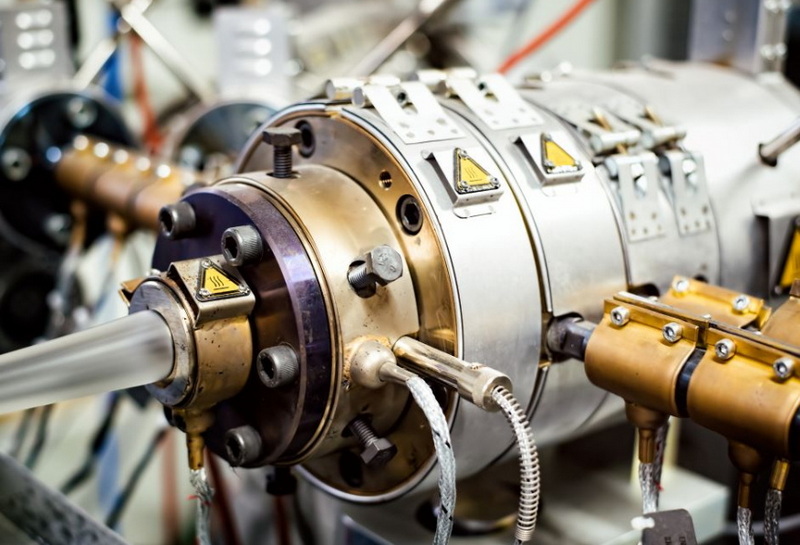

In the realm of plastic processing, extrusion is a pivotal technique used to create a wide array of products, from pipes and tubes to profiles and sheets. Among the numerous manufacturers offering extrusion machinery, Unique Machinery stands out due to its commitment to quality, innovation, and customer satisfaction. This article delves into the reasons why Unique Machinery is the go-to choice for businesses seeking reliable and efficient extrusion solutions.

Introduction to Unique Machinery

Unique Machinery is a renowned manufacturer, trader, exporter, and supplier of a qualitative assortment of extrusion machines, industrial extruders, and related equipment. Founded in 2016 in Ahmedabad, India, the company has established itself as a leader in the national market, with a strong focus on delivering high-quality products at competitive prices.

Key Features of Unique Machinery

- State-of-the-art Infrastructure: Equipped with a well-functional infrastructural unit, Unique Machinery ensures the production of high-quality machines and pipes.

- Experienced Leadership: Managed by partners Mr. Jignesh Patel and Mr. Sagar Kanojiya, the company benefits from their expertise and vision.

- Diverse Product Range: Offers a wide range of products, including PVC pipe extrusion lines, HDPE pipe extruder lines, and twin screw extruders.

Advantages of Unique Extrusion Machinery

Cost-Effectiveness

One of the significant advantages of Unique Machinery's extrusion equipment is its cost-effectiveness. Unlike injection molding, which requires complex molds, extrusion machines have lower tooling costs, making them more budget-friendly for projects with financial constraints.

Efficient Production of Linear Shapes

Unique Machinery's extrusion machines excel in producing continuous linear profiles, such as tubes and pipes. This capability is particularly beneficial for manufacturing long sections of a product in a single, unbroken sequence, which is challenging to achieve with injection molding.

Material Versatility

The extrusion process offered by Unique Machinery is compatible with a wide range of plastic materials, including thermoplastics like polyethylene and polypropylene. This flexibility allows manufacturers to choose the most suitable plastic resin for each specific project.

Speed and Efficiency in Production

Compared to injection molding, Unique Machinery's extrusion equipment can be faster, especially for manufacturing long, continuous shapes. The continuous nature of the extrusion process lends itself to higher production rates, making it ideal for large-scale manufacturing.

Simplicity in Design and Operation

Extrusion molds, known as dies, are typically simpler to design and manufacture than the complex molds used in injection molding. This simplicity translates into a shorter setup time and easier operability, beneficial for manufacturers looking to streamline their production processes.

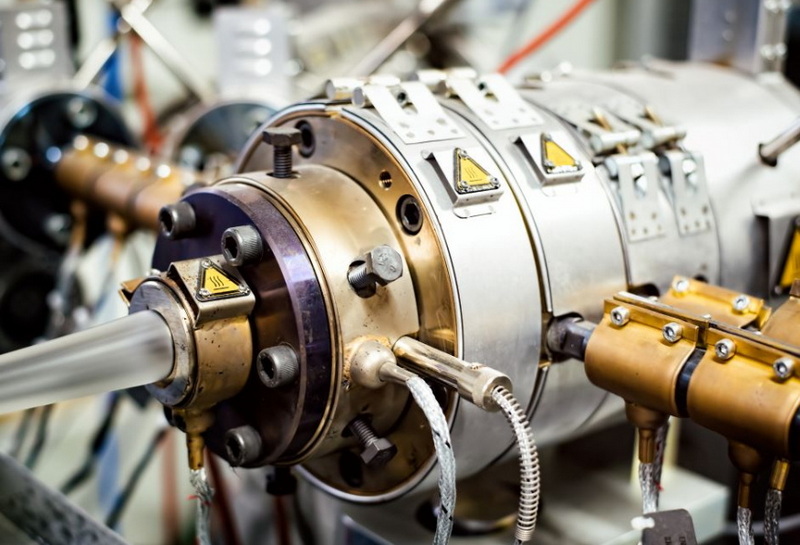

Modern Extrusion Machinery: Efficiency and Precision

Modern extrusion machinery, such as those offered by Unique Machinery, has revolutionized the efficiency and precision of processing plastic materials. These machines are equipped with advanced control systems that maintain a consistent output rate, ensuring swift production without compromising on the quality of the end products.

High-Precision Temperature Control

Modern extrusion machines feature high-precision temperature control systems that manage the heat during the extrusion process, thereby preserving the plastic's material properties and achieving a superior finish.

Programmable Logic Controllers (PLCs)

These machines are equipped with PLCs that offer operational precision. The PLCs provide real-time monitoring and control of the extrusion process parameters, facilitating adjustments as needed to maintain the desired product dimensions and quality consistently.

Integration of Emerging Technologies

The extrusion industry is witnessing a significant transformation driven by emerging technologies such as IoT, AI, and advanced materials. These technologies enhance the precision, efficiency, and overall performance of extrusion processes. For instance, IoT facilitates remote monitoring and control of extrusion lines, providing real-time data analytics to optimize operations and predict maintenance issues. AI algorithms can identify patterns and predict outcomes, leading to more precise control over quality and process efficiency.

Customization and Flexibility

Modern extrusion machinery also boasts enhanced capabilities in custom plastic extrusion. This advancement has opened up new possibilities for manufacturing bespoke plastic profiles tailored to specific industrial needs. The integration of technologies like 3D printing allows for rapid prototyping and testing, reducing lead times and enabling customization at a fraction of traditional costs.

Innovations in Extrusion Manufacturing

In recent years, the extrusion manufacturing landscape has seen numerous innovations that are transforming the industry. Some of these key advancements include:

Smart Extrusion Technology

Smart extrusion technology, powered by IoT, enables real-time monitoring and control of extrusion processes. This integration allows for quick adjustments to optimize production efficiency and includes predictive analytics to forecast potential downtimes or maintenance needs.

Biodegradable Materials and Eco-Friendly Practices

There is a growing shift towards biodegradable materials and eco-friendly practices in extrusion manufacturing. This includes sourcing eco-friendly raw materials and implementing energy-efficient machinery to minimize environmental impact.

Automated Quality Control

Automated quality control systems employ advanced sensing tools and machine learning algorithms to monitor quality in real time. This technology ensures higher quality products by detecting defects or inconsistencies during production, allowing for immediate corrections.

Integration of Artificial Intelligence

AI plays a crucial role in extrusion manufacturing by analyzing vast amounts of data generated during the process. This enables manufacturers to make data-driven decisions, optimize processes, and predict potential failures before they occur.

Synergy Between 3D Printing and Extrusion

The synergy between 3D printing and extrusion manufacturing is becoming increasingly prominent. 3D printing complements traditional extrusion processes by allowing rapid iterations and testing phases, accelerating product development cycles and enabling smaller batch sizes without incurring hefty costs.

Future of Extrusion Machinery

Looking toward the future, next-generation extrusion equipment will focus on several key innovations:

Enhanced Automation

Further automation of extrusion lines, combined with intelligent systems capable of self-optimization, will significantly improve efficiency and product consistency.

Eco-Friendly Technologies

Innovations aimed at reducing energy consumption and minimizing waste production will be vital in aligning with global sustainability goals.

Customization and Flexibility

Equipment designed for greater versatility will enable manufacturers to easily switch between different materials and product specifications, accommodating a more comprehensive range of applications.

Integration with Digital Twins

Digital twins, or virtual replicas of physical systems, will enhance predictive maintenance, process optimization, and the development of new products by allowing simulations and adjustments in a virtual environment.

Conclusion

In conclusion, Unique Machinery offers a comprehensive range of extrusion solutions that cater to diverse industrial needs. With its focus on quality, innovation, and customer satisfaction, Unique Machinery is the ideal partner for businesses seeking reliable and efficient extrusion machinery.

Frequently Asked Questions

1. What types of extrusion machines does Unique Machinery offer?

Unique Machinery offers a variety of extrusion machines, including PVC pipe extrusion lines, HDPE pipe extruder lines, twin screw extruders, and more. These machines are designed to meet different industrial requirements, ensuring versatility and adaptability.

2. How does Unique Machinery ensure the quality of its products?

Unique Machinery ensures the quality of its products by using the finest raw materials and continuously improving its manufacturing processes to meet international quality standards. The company's commitment to quality is reflected in its state-of-the-art infrastructure and adroit team of professionals.

3. What are the advantages of choosing extrusion over injection molding?

Extrusion offers several advantages over injection molding, including lower tooling costs, efficient production of linear shapes, material versatility, speed, and simplicity in design and operation. These factors make extrusion a preferred choice for many manufacturing applications.

4. How does Unique Machinery support customization in extrusion?

Unique Machinery supports customization by offering modern extrusion machinery capable of producing bespoke plastic profiles. This capability allows manufacturers to tailor products to specific industrial needs, enhancing flexibility and innovation in production.

5. What is Unique Machinery's vision for the future?

Unique Machinery aims to continue enriching lifestyles with innovative products while maintaining its position as a leader in the machinery industry. The company focuses on providing high-quality, industry-specific solutions that contribute to the country's economy and meet the evolving needs of its customers.

Citations:

[1] https://jieyatwinscrew.com/blog/unlocking-the-potential-of-extrusion-machines/

[2] https://www.aluecor.com/post/extrusion-manufacturing-innovations

[3] https://jieyatwinscrew.com/blog/exploring-the-world-of-extrusion-machines-understanding-the-basics-and-benefits/

[4] http://uniqueextrusionmachinery.com

[5] https://www.adremac.com/understanding-extruder-machines-key-technologies-applications-and-why-they-matter/

[6] https://www.uniquemachinery.co.in/industrial-extrusion-machines.html

[7] https://www.wevolver.com/article/extruding-plastic

[8] https://www.uniquemachinery.co.in/industrial-extruder-machines.html

[9] https://www.uniquemachinery.co.in

[10] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[11] https://uniqueextrusionmachinery.com/screw-barrel.php

[12] https://www.uniquemachinery.co.in/extruders-extrusion-machines.html

[13] https://www.petfoodprocessing.net/articles/17125-recent-advancements-edging-extrusion-tech-toward-excellence

[14] https://www.indiamart.com/proddetail/jockey-extruder-machine-21087616512.html

[15] https://uniqueextrusionmachinery.com/about.php

[16] https://www.extrusion-world.com/en/detail-view/einzigartiger-extruder-mas-110-vor-einfuehrung/

[17] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/extrusion_machines

[18] https://press.kraussmaffei.com/en/news/kraussmaffei-bundles-all-extrusion-technologies-under-a-single-roof-2

[19] https://abhiplastics.com/revolutionizing-the-plastic-industry-how-plastic-extrusion-machinery-is-changing-the-game/

[20] https://polarismep.org/results/machine-manufacturer-innovation-case-study/