Content Menu

● Introduction to Aluminum Extrusion

>> Benefits of Aluminum Extrusion

● Why Choose Mitsumi Aluminum Extruder?

>> Superior Quality Control

>> Customization and Design Support

>> Environmental Responsibility

● Applications of Mitsumi Aluminum Extrusions

● Manufacturing Process Overview

● Designing with Mitsumi Aluminum Extrusions

>> Example: Using Misumi Aluminum Extrusions in Design

● Advantages of Aluminum Extrusions

● Sustainability of Aluminum Extrusions

>> Industry-Wide Sustainability Initiatives

● Conclusion

● Frequently Asked Questions

>> 1. What is the largest size of aluminum extrusion that Mitsumi can produce?

>> 2. How does Mitsumi ensure environmental sustainability in its manufacturing processes?

>> 3. What customization options are available for Mitsumi aluminum extrusions?

>> 4. What are the primary industries that use Mitsumi aluminum extrusions?

>> 5. How does Mitsumi maintain quality control in its extrusions?

● Citations:

In the realm of manufacturing, selecting the right materials and processes is crucial for achieving high-quality products efficiently. Among various options, aluminum extrusion stands out due to its versatility, cost-effectiveness, and environmental sustainability. Mitsumi aluminum extruders are particularly renowned for their superior quality and reliability. This article explores the benefits of choosing Mitsumi aluminum extruders for your manufacturing needs, highlighting their advantages in terms of quality control, design flexibility, and environmental responsibility.

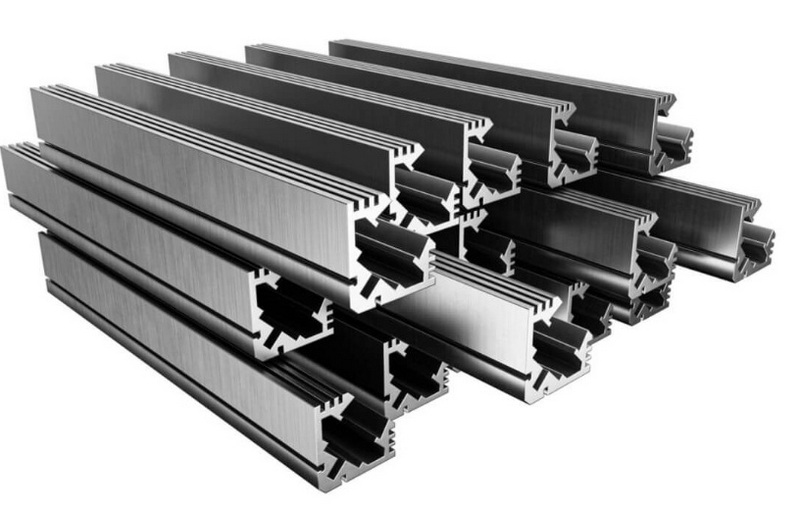

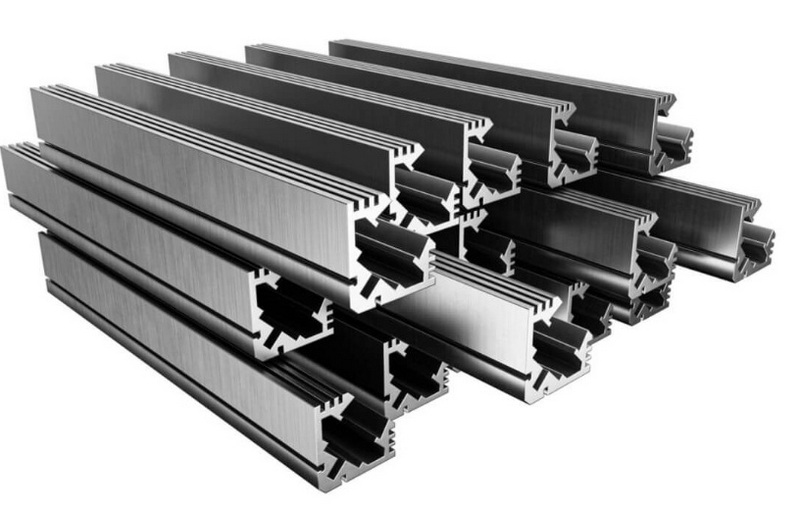

Introduction to Aluminum Extrusion

Aluminum extrusion is a process where aluminum alloy is forced through a die to create profiles with specific cross-sectional shapes. This technique allows for the production of complex shapes with high precision and minimal material waste, making it ideal for various industries such as construction, automotive, and aerospace.

Benefits of Aluminum Extrusion

1. Design Flexibility: Aluminum extrusion enables the creation of complex profiles, including hollow and semi-hollow shapes, allowing for innovative designs tailored to specific applications.

2. Lightweight Yet Strong: Aluminum offers an excellent strength-to-weight ratio, making it perfect for industries where both strength and reduced weight are crucial.

3. Recyclable and Sustainable: Aluminum is highly recyclable without losing its material properties, making it an environmentally friendly choice.

4. Economical for Large-Scale Production: Extrusion offers significant cost savings, especially for large-scale production runs, due to high repeatability and low material waste.

Why Choose Mitsumi Aluminum Extruder?

Mitsumi aluminum extruders are preferred by many manufacturers due to their commitment to quality, customization, and environmental responsibility.

Superior Quality Control

Mitsumi ensures that all extrusions meet high standards of quality, with precise dimensions and surface finishes. This is crucial for applications where consistency and reliability are paramount. The quality control process involves rigorous testing and inspection to ensure that every extrusion meets the required specifications.

Customization and Design Support

Mitsumi offers custom design and engineering services, allowing clients to create profiles tailored to their specific needs. This includes assistance with CAD/CAM design and alloy selection to optimize product performance. By working closely with clients, Mitsumi helps ensure that the final product meets all functional, aesthetic, and manufacturability objectives.

Environmental Responsibility

By using aluminum, which is highly recyclable, Mitsumi supports sustainable manufacturing practices. Additionally, local production reduces transportation costs and carbon emissions associated with international shipping. This commitment to sustainability aligns with global efforts to reduce environmental impact while maintaining high production standards.

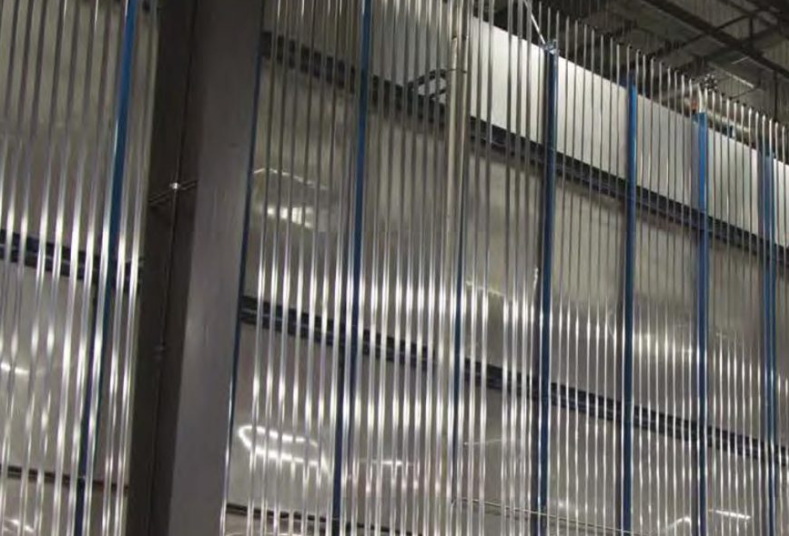

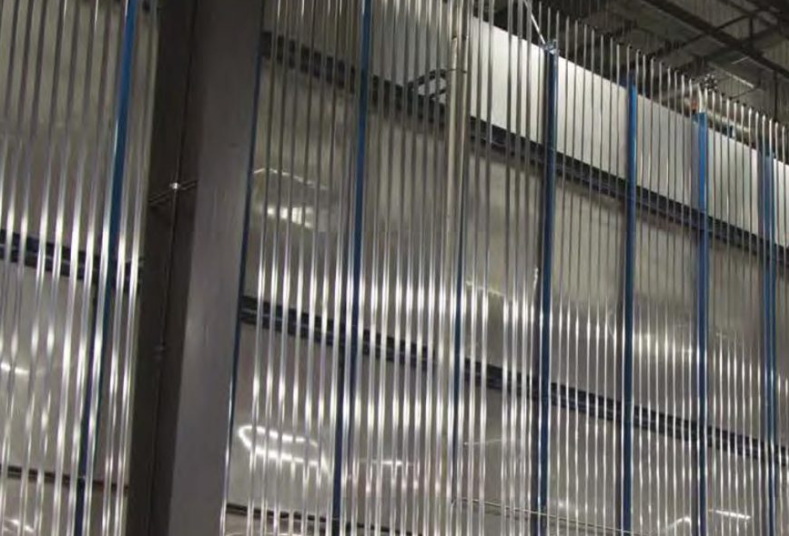

Applications of Mitsumi Aluminum Extrusions

Mitsumi aluminum extrusions are versatile and can be applied across various industries:

- Construction: Used for structural components, window frames, and decorative elements due to their strength and corrosion resistance.

- Automotive: Ideal for vehicle parts where weight reduction and strength are critical, such as engine components and body frames.

- Aerospace: Utilized in aircraft structures due to its high strength-to-weight ratio and resistance to corrosion.

Manufacturing Process Overview

The aluminum extrusion process involves several key steps:

1. Die Preparation: The extrusion die is preheated to ensure smooth metal flow.

2. Billet Heating: The aluminum billet is heated to make it malleable.

3. Extrusion: The billet is forced through the die under high pressure.

4. Quenching: The extruded profile is cooled to achieve desired metallurgical properties.

Designing with Mitsumi Aluminum Extrusions

Designing with Mitsumi aluminum extrusions offers numerous benefits, including:

- Design Flexibility: Complex shapes can be easily created to meet specific design requirements.

- Cost-Effectiveness: Reduces the need for secondary machining operations, saving time and costs.

Example: Using Misumi Aluminum Extrusions in Design

Aluminum extrusions are widely used in various applications due to their versatility. For instance, in the construction industry, they are used for building frames and window frames, while in electronics, they serve as heat sinks due to their good thermal conductivity.

Advantages of Aluminum Extrusions

In addition to the benefits of Mitsumi aluminum extruders, aluminum extrusions themselves offer several advantages:

- Modularity: Standardized dimensions allow for easy integration with connectors and accessories, enabling quick and flexible assembly. This modularity is particularly beneficial in applications where rapid setup and teardown are necessary[1].

- Strength-to-Weight Ratio: Aluminum extrusions are lightweight yet maintain high strength, making them ideal for applications like aerospace and automotive where load carrying is critical[1].

- Corrosion Resistance: Aluminum naturally forms a protective oxide coating, providing resistance to corrosion. This is vital for applications in harsh environments and can be further enhanced by anodizing or other finishing processes[1].

- Thermal Conductivity: Exhibiting good thermal conductivity, aluminum profiles are suitable for applications requiring heat dissipation, such as electronic enclosures[1].

- Customization: Aluminum extrusions offer design freedom, allowing for complex shapes tailored to specific needs. This ability to design a profile to meet specific functional, aesthetic, and manufacturability objectives makes aluminum extrusions a preferred element in many product solutions[1].

- Increased Strength: Products made by aluminum extrusion typically have increased strength and therefore wear resistance. This is because the material is formed under pressure to produce a homogeneous structure with no cavities, chips, or pores[5].

- Low Material Loss: The aluminum extrusion process ensures minimal material wastage, making it an efficient production method[1].

- Non-Sparking: Because aluminum is non-sparking, aluminum extrusions are well suited for applications involving explosive materials or taking place in highly flammable environments[1].

- Electrical Conductivity: Pound-for-pound, aluminum is twice as conductive as copper, making extruded aluminum a cost-effective alternative for electrical connectors and bus bar distribution components[1].

- Non-Combustible and Non-Toxic: Aluminum does not burn and even at extremely high temperatures does not produce toxic fumes[1].

- Cost-Effectiveness: Aluminum extrusion is generally a competitive and economical production option, especially when dealing with very complex cross-sections. Tooling for aluminum extrusion is relatively inexpensive with generally short lead times, facilitating rapid prototype development, testing, and product launch[1].

- Design Flexibility: Complex shapes can be realized in one-piece extruded aluminum sections without having to rely on mechanical joining[1].

- Sustainability: Aluminum's inherent “green” features of recyclability and sustainability, coupled with its other unique attributes, make aluminum a versatile material for many applications[1].

- Efficiency: Aluminum extrusions have continuously demonstrated superior performance, reliability, and efficiency for a variety of markets–from consumer durables to transportation and from electronics to building and construction[1].

Sustainability of Aluminum Extrusions

Aluminum extrusion plays a significant role in promoting sustainable manufacturing practices. By utilizing aluminum, which is highly recyclable, the process reduces material usage and enhances energy efficiency. This makes aluminum extrusions ideal for industries aiming to reduce their environmental footprint, such as automotive, renewable energy, and construction[4].

Industry-Wide Sustainability Initiatives

The aluminum extrusion industry actively promotes sustainability through initiatives like energy-efficient production practices and the widespread use of recycled materials. Organizations such as the Aluminum Extruders Council (AEC) lead these efforts, ensuring sustainability extends beyond individual manufacturers and sets industry standards for sustainable development[4].

Conclusion

Choosing Mitsumi aluminum extruders for your manufacturing needs offers a range of benefits, from superior quality control and customization options to environmental sustainability. With their commitment to delivering high-quality products and supporting innovative designs, Mitsumi stands out as a reliable partner for industries seeking efficient and sustainable manufacturing solutions.

Frequently Asked Questions

1. What is the largest size of aluminum extrusion that Mitsumi can produce?

Mitsumi can produce aluminum extrusions up to a certain size depending on the press capacity and billet size. For specific dimensions, it's best to consult directly with Mitsumi's manufacturing team.

2. How does Mitsumi ensure environmental sustainability in its manufacturing processes?

Mitsumi supports environmental sustainability by using aluminum, which is highly recyclable, and by reducing carbon emissions through local production and efficient supply chains.

3. What customization options are available for Mitsumi aluminum extrusions?

Mitsumi offers custom design and engineering services, including CAD/CAM design assistance and alloy selection to meet specific project requirements.

4. What are the primary industries that use Mitsumi aluminum extrusions?

Mitsumi aluminum extrusions are used in various industries such as construction, automotive, aerospace, and electronics due to their versatility and performance.

5. How does Mitsumi maintain quality control in its extrusions?

Mitsumi ensures quality control through rigorous testing and inspection processes, ensuring that all extrusions meet precise dimensional and surface finish standards.

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-advantages-of-using-a-720mm-20-series-aluminum-extruder.html

[2] https://spool3d.ca/2020-aluminum-extrusion-misumi-clone/

[3] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[4] https://taberextrusions.com/not-just-a-new-years-resolution-aluminum-extrusion-sustainability/

[5] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[6] https://hackaday.com/2018/05/08/how-to-build-anything-out-of-aluminum-extrusion-and-3d-printed-brackets/

[7] https://www.nicerapid.com/project/the-impact-of-aluminum-extrusion-process-on-the-environment/

[8] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[9] https://sdkemet.en.made-in-china.com/product/qwXtfymofPVS/China-Misumi-Aluminum-Extrusion-for-Window-and-Door.html

[10] https://profileprecisionextrusions.com/aluminum-extrusion-manufacturing-process/

[11] https://www.businesswire.com/news/home/20110117005753/en/MISUMI-Launches-New-Line-of-Aluminum-Extrusion-Sliding-Doors-Expands-Lines-of-Safety-Fences-and-Panel-Doors

[12] https://aec.org/sustainability

[13] https://www.linkedin.com/pulse/everything-you-need-know-frames-aluminum-extrusion-design-software-gpj5c

[14] https://www.businesswire.com/news/home/20120214006275/en/MISUMI%E2%80%99s-Aluminum-Extrusions-in-a-Wide-Range-of-Profiles-Offer-Practical-Affordable-Choices-for-Many-Industrial-Applications

[15] https://www.youtube.com/watch?v=ELgtjeJyFw8

[16] https://uk.misumi-ec.com/vona2/mech/M1500000000/M1501000000/M1501010000/

[17] https://www.minebeamitsumi.com/english/csr/environmental/management/

[18] https://www.reddit.com/r/voroncorexy/comments/4fxznz/aluminum_extrusion_compatibility/

[19] https://www.youtube.com/watch?v=3pch9hC0czQ

[20] https://www.rapiddirect.com/blog/aluminum-extrusion-process/