Content Menu

● Introduction

● Understanding Oval Aluminum Profiles

>> Characteristics of Oval Aluminum Profiles

● Benefits of Using Lightweight Aluminum Extrusions

>> Lightweight Yet Strong

>> Aesthetic Appeal

>> Corrosion Resistance

● Applications of Oval Aluminum Extrusions

>> Construction

>> Transportation

>> Consumer Products

● The Aluminum Extrusion Process

>> Importance of Die Design

● Choosing the Right Aluminum Extrusion Manufacturer

>> Key Factors to Consider

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using lightweight aluminum tubing?

>> 2. How does the aluminum extrusion process work?

>> 3. What applications benefit from oval aluminum profiles?

>> 4. How can I choose the right aluminum extrusion manufacturer?

>> 5. Are there any maintenance requirements for aluminum tubing?

Introduction

In the world of construction and manufacturing, the choice of materials can significantly impact the overall success of a project. Among the various materials available, aluminum has emerged as a popular choice due to its unique properties. Lightweight aluminum tubing, particularly in the form of oval aluminum extrusion, offers a range of benefits that make it an ideal option for various applications. This article explores the advantages of using lightweight aluminum tubing, its applications, and why it should be considered for your next project.

Understanding Oval Aluminum Profiles

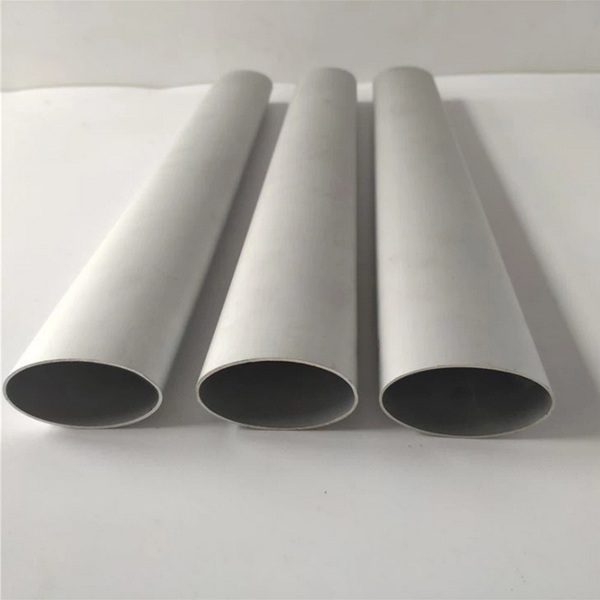

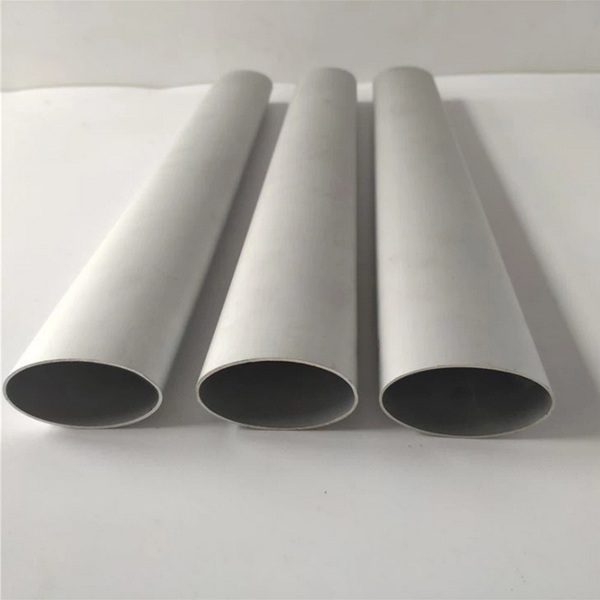

Aluminum extrusion is a process that shapes aluminum alloy into a desired cross-sectional profile. Oval aluminum profiles are a specific type of extrusion that features an elongated, rounded shape. This design not only provides aesthetic appeal but also enhances the structural integrity of the material. The versatility of oval aluminum profiles allows them to be used in a wide range of applications, from architectural elements to automotive components.

Characteristics of Oval Aluminum Profiles

Oval aluminum profiles are characterized by their smooth, rounded edges and lightweight nature. These profiles can be produced in various sizes and thicknesses, making them suitable for different applications. The unique shape of oval aluminum tubing allows for better airflow and fluid dynamics, which is particularly beneficial in industries such as automotive and aerospace.

Benefits of Using Lightweight Aluminum Extrusions

Lightweight Yet Strong

One of the most significant advantages of lightweight aluminum tubing is its strength-to-weight ratio. Aluminum is known for being lightweight, which makes it easier to handle and transport. Despite its low weight, aluminum maintains high tensile strength, making it suitable for structural applications. This characteristic is particularly important in construction, where reducing the weight of materials can lead to lower transportation costs and easier installation.

Aesthetic Appeal

The aesthetic appeal of oval aluminum extrusions cannot be overlooked. The smooth, rounded design of these profiles adds a modern touch to any project. Whether used in architectural designs, furniture, or decorative elements, oval aluminum tubing can enhance the overall look of a product. The ability to anodize aluminum also allows for a variety of finishes, further increasing its visual appeal.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent corrosion. This property is especially beneficial in outdoor applications where materials are exposed to the elements. Anodized finishes can further enhance this corrosion resistance, making lightweight aluminum tubing a durable choice for projects that require longevity and minimal maintenance.

Applications of Oval Aluminum Extrusions

Construction

In the construction industry, lightweight aluminum tubing is often used for framing, supports, and architectural elements. The strength and lightweight nature of oval aluminum profiles make them ideal for creating structures that require both stability and aesthetic appeal. For example, architects may choose oval aluminum extrusions for railings, window frames, and decorative facades.

Transportation

The transportation industry also benefits from the use of lightweight aluminum tubing. In automotive and aerospace applications, reducing weight is crucial for improving fuel efficiency and performance. Oval aluminum profiles can be used in various components, such as chassis, body panels, and structural supports, contributing to lighter and more efficient vehicles.

Consumer Products

Lightweight aluminum tubing is not limited to industrial applications; it is also widely used in consumer products. From furniture to lighting fixtures, oval aluminum extrusions provide a modern and stylish look. The versatility of aluminum allows designers to create innovative products that are both functional and visually appealing.

The Aluminum Extrusion Process

The aluminum extrusion process involves several steps to transform raw aluminum into the desired profile. First, aluminum billets are heated to a specific temperature, making them malleable. The heated aluminum is then forced through a die, which shapes it into the desired cross-section. Once extruded, the aluminum profiles are cooled and cut to length.

Importance of Die Design

The design of the die is crucial in achieving the desired shape and quality of the aluminum extrusion. For oval aluminum profiles, the die must be carefully engineered to ensure uniformity and precision. A well-designed die can significantly reduce production costs and improve the overall quality of the finished product.

Choosing the Right Aluminum Extrusion Manufacturer

When selecting an aluminum extrusion manufacturer, several factors should be considered. Quality is paramount; look for manufacturers that adhere to strict quality control standards. Customization options are also essential, as different projects may require unique profiles and finishes. Additionally, consider the manufacturer's experience and reputation in the industry.

Key Factors to Consider

1. Quality Control: Ensure the manufacturer has a robust quality control process in place to guarantee the consistency and reliability of their products.

2. Customization Options: Look for manufacturers that offer a range of customization options, including different sizes, shapes, and finishes.

3. Experience: Choose a manufacturer with a proven track record in the industry, as their experience can lead to better product quality and service.

4. Customer Service: Good customer service is essential for addressing any concerns or questions during the manufacturing process.

5. Delivery Times: Consider the manufacturer's ability to meet deadlines, as timely delivery is crucial for project success.

Conclusion

Lightweight aluminum tubing, particularly in the form of oval aluminum extrusion, offers numerous benefits that make it an excellent choice for various applications. Its strength, aesthetic appeal, and corrosion resistance make it suitable for construction, transportation, and consumer products. By understanding the advantages of lightweight aluminum tubing and choosing the right manufacturer, you can ensure the success of your next project.

Frequently Asked Questions

1. What are the main advantages of using lightweight aluminum tubing?

Lightweight aluminum tubing offers a high strength-to-weight ratio, aesthetic appeal, and excellent corrosion resistance, making it suitable for various applications.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating aluminum billets, forcing them through a die to create the desired shape, and then cooling and cutting the extruded profiles to length.

3. What applications benefit from oval aluminum profiles?

Oval aluminum profiles are used in construction, transportation, and consumer products, providing structural support and aesthetic appeal.

4. How can I choose the right aluminum extrusion manufacturer?

Consider factors such as quality control, customization options, experience, customer service, and delivery times when selecting a manufacturer.

5. Are there any maintenance requirements for aluminum tubing?

Aluminum tubing is generally low maintenance due to its corrosion resistance. However, regular cleaning and inspection can help maintain its appearance and performance over time.