Content Menu

● What is Composite Extrusion Equipment?

>> Key Features of Composite Extrusion Equipment

● Advantages of Using Composite Extrusion Equipment

>> 1. Versatility

>> 2. Efficiency

>> 3. Sustainability

>> 4. Cost-Effectiveness

>> 5. Customization

● Applications of Composite Extrusion Equipment

● How Does Composite Extrusion Work?

● Technological Advancements in Composite Extrusion Equipment

● Why Invest in High-Quality Composite Extrusion Equipment?

>> 1. Long-Term Durability

>> 2. Compliance with Standards

>> 3. Scalability

● Conclusion

● FAQs

>> 1. What industries benefit most from composite extrusion equipment?

>> 2. How does composite extrusion support sustainability?

>> 3. What factors should I consider when choosing composite extrusion equipment?

>> 4. What are the maintenance requirements for composite extrusion machines?

>> 5. Can composite extrusion equipment handle complex product designs?

● Citations:

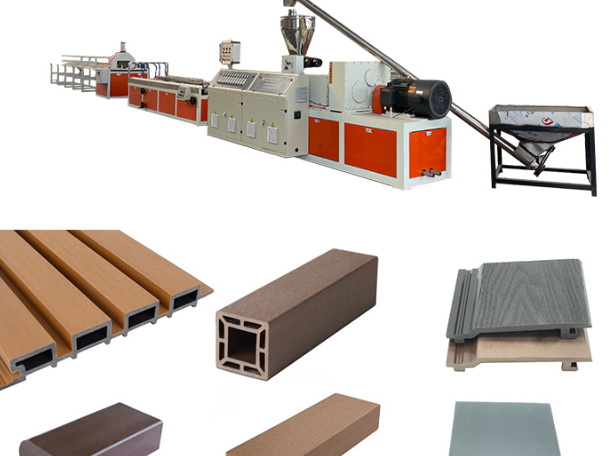

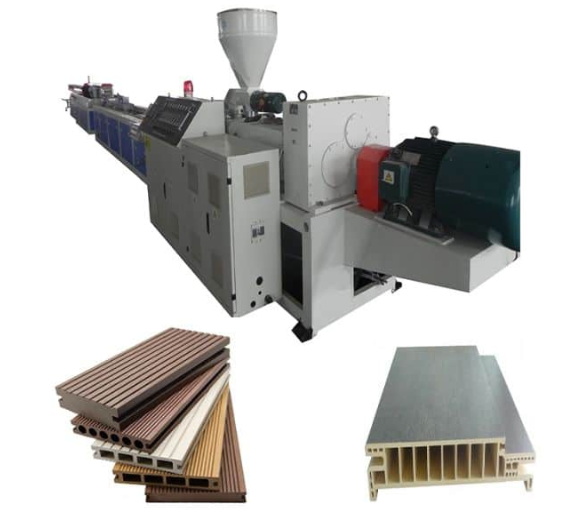

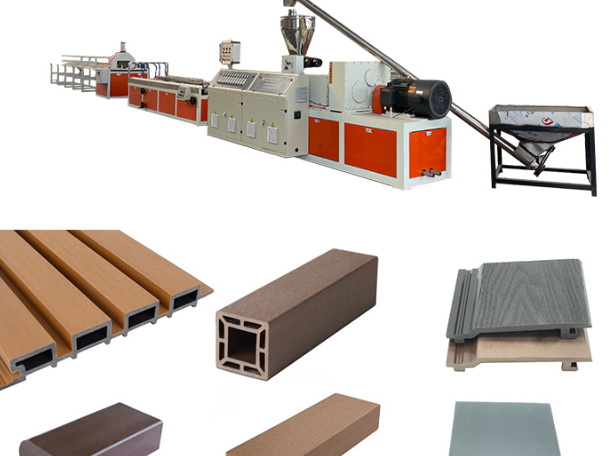

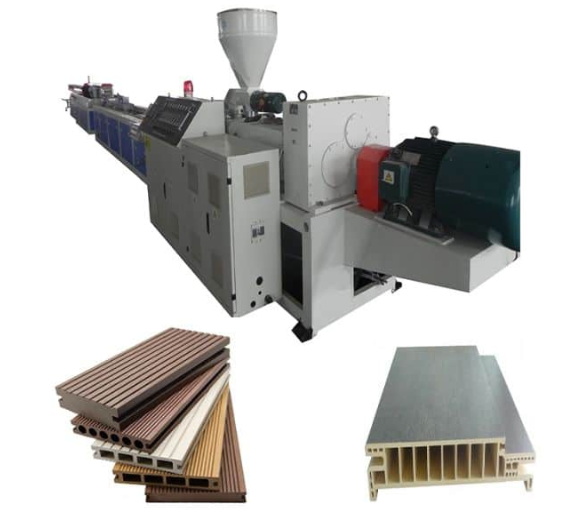

Composite extrusion equipment has revolutionized manufacturing processes across industries, offering unmatched precision, efficiency, and versatility. Whether you're producing plastic pipes, wood-plastic composites (WPC), or multi-layered films, composite extrusion equipment provides the tools to meet modern production demands. This article delves into the reasons why composite extrusion equipment is a must-have for your production line.

What is Composite Extrusion Equipment?

Composite extrusion equipment refers to machinery designed to combine multiple materials—such as plastics, wood fibers, or metals—into a single product through the extrusion process. This process involves heating raw materials until they melt and forcing them through a die to create products with specific cross-sectional shapes.

Key Features of Composite Extrusion Equipment

- Multi-Material Compatibility: Capable of processing various materials like PVC, PE, PP, ABS, and wood fibers.

- High Precision: Ensures consistent dimensions and quality.

- Customizable Outputs: Allows for intricate designs and multi-layered structures.

- Energy Efficiency: Advanced systems reduce energy consumption while maintaining high output.

Advantages of Using Composite Extrusion Equipment

1. Versatility

Composite extrusion machines can handle a wide range of materials and applications. For instance:

- Plastic pipes

- Wood-plastic decking

- Multi-layered films

This versatility enables manufacturers to diversify their product offerings and adapt to market demands[1][2].

2. Efficiency

The continuous nature of extrusion minimizes downtime and maximizes production rates. Modern composite extrusion equipment is highly automated, reducing labor costs while ensuring consistent quality[1][3].

3. Sustainability

By incorporating recycled materials like wood flour or thermoplastics, composite extrusion reduces waste and promotes eco-friendly manufacturing practices[2][9].

4. Cost-Effectiveness

The efficient use of raw materials and minimal waste generation make this equipment a cost-effective choice for large-scale production[9][10].

5. Customization

Composite extrusion allows for the creation of complex profiles, multi-layered products, and tailored designs to meet specific industry needs[2][13].

Applications of Composite Extrusion Equipment

Composite extrusion equipment is used in various industries due to its adaptability:

1. Construction: Producing PVC pipes, WPC decking, and window frames.

2. Packaging: Manufacturing multi-layered films for food and industrial packaging.

3. Automotive: Creating lightweight yet durable components.

4. Consumer Goods: Producing items like furniture components and household plastics.

How Does Composite Extrusion Work?

The composite extrusion process involves several key steps:

1. Material Feeding: Raw materials are fed into the hopper.

2. Melting & Mixing: The materials are heated and mixed in the barrel using screws.

3. Shaping: The molten material is forced through a die to achieve the desired shape.

4. Cooling: The extruded product is cooled using water baths or air systems.

5. Cutting & Finishing: The product is cut to length and finished as required[6][13].

*Illustration 1: Diagram of the Composite Extrusion Process*

Technological Advancements in Composite Extrusion Equipment

Recent innovations have enhanced the performance of composite extrusion machines:

- Intelligent Control Systems: Real-time monitoring ensures consistent quality[2].

- Energy-Efficient Designs: Reduced power consumption without compromising output[8].

- Advanced Screw Designs: Improved mixing and material dispersion for better product properties[13].

Why Invest in High-Quality Composite Extrusion Equipment?

1. Long-Term Durability

High-quality machines are built to last, reducing maintenance costs over time.

2. Compliance with Standards

Top-tier equipment meets stringent safety and environmental regulations, ensuring smooth operations[8].

3. Scalability

As your business grows, composite extrusion equipment can adapt to increased production demands.

Conclusion

Investing in composite extrusion equipment is a strategic move for manufacturers aiming to enhance efficiency, reduce costs, and meet diverse market needs. With advancements in technology and growing demand for sustainable solutions, this equipment remains a cornerstone of modern production lines.

FAQs

1. What industries benefit most from composite extrusion equipment?

Composite extrusion equipment is widely used in construction (e.g., PVC pipes), packaging (e.g., multi-layer films), automotive (e.g., lightweight parts), and consumer goods industries.

2. How does composite extrusion support sustainability?

By enabling the use of recycled materials like wood flour or thermoplastics, composite extrusion reduces waste and promotes eco-friendly manufacturing practices.

3. What factors should I consider when choosing composite extrusion equipment?

Key factors include material compatibility, production volume requirements, energy efficiency, customization options, and compliance with industry standards.

4. What are the maintenance requirements for composite extrusion machines?

Regular cleaning of screws and dies, lubrication of moving parts, and periodic inspections are essential for optimal performance.

5. Can composite extrusion equipment handle complex product designs?

Yes, advanced machines can produce intricate profiles and multi-layered products tailored to specific applications.

Citations:

[1] https://www.caisumachinery.com/benefits-of-using-a-pipe-extrusion-machine-in-manufacturing/

[2] https://jieyatwinscrew.com/blog/guide-to-wpc-extruder/

[3] https://jieyatwinscrew.com/blog/exploring-the-world-of-extrusion-machines-understanding-the-basics-and-benefits/

[4] https://www.alamy.com/stock-photo/extrusion-machine.html

[5] https://www.youtube.com/watch?v=RPwh2znn5zU

[6] https://www.youtube.com/watch?v=NSCX6K1eecI

[7] https://www.sanfoundry.com/mechanical-metallurgy-questions-answers-extrusion-equipments/

[8] https://www.pearltechinc.com/2025/02/13/extrusion-equipment-blown-film-efficiency/

[9] https://plasticextrusiontech.net/benefits-of-plastic-extrusion/

[10] https://www.boyuextruder.com/Blog/5-advantages-plastic-extrusion.html

[11] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/extrusion_machines

[12] https://www.macocorporation.com/blog/extruder-machine/

[13] https://engitech.in/extrusion-machines-and-extruders-guide/

[14] https://theplasticmachine.com/advantages-of-using-a-profile-extrusion-machine-for-wood-plastic-composite/

[15] https://jydjx.com/benefits-of-working-with-a-professional-plastic-pipe-extrusion-line-supplier/

[16] https://www.cowellextrusion.com/key-points-when-choosing-a-plastic-extruder-machine/

[17] https://www.euroextrusions.com/plastic-extrusion-advantages-benefits/

[18] https://www.hao-yu.com.tw/wpc-production-line-machine/profile-extrusion

[19] https://paulmurphyplastics.com/industry-news-blog/3-tips-you-should-consider-when-choosing-a-plastic-extrusion-machine/

[20] https://reschcor.com/wood-composite-extrusion/

[21] https://www.jinhupm.com/products/plastic-profiles-production-line/wood-plastic-composite-production-line/

[22] https://www.caisumachinery.com/wpc-extrusion-machine-key-features-and-benefits/

[23] https://www.rayda.co.uk/blog/advantages-and-disadvantages-of-plastic-extrusion/

[24] https://www.sharcpm.com/solution/wood-plastic-composite-wpc-production-line/

[25] https://www.sciencedirect.com/science/article/pii/S0263822324006184

[26] https://www.istockphoto.com/photos/extrusion

[27] https://www.shutterstock.com/video/search/extrusion

[28] https://stock.adobe.com/search?k=plastic+extrusion+machine

[29] https://www.youtube.com/watch?v=qvPlvn3Ar7s

[30] https://www.shutterstock.com/search/extrusion-machine