Content Menu

● Introduction to Battenfeld

>> Battenfeld's Product Range

● Features of Battenfeld Machines

>> Energy Efficiency

>> Modular Design

>> Advanced Technology

>> Multi-Component Molding

● Applications of Battenfeld Machines

● Benefits of Choosing Battenfeld

>> High Precision and Quality

>> Energy Efficiency and Cost Savings

>> Comprehensive Support

>> Customization and Flexibility

>> Integration with Automation Solutions

● Market Trends and Future Developments

● Case Studies and Success Stories

● Conclusion

● FAQs

>> 1. What types of injection molding machines does Battenfeld offer?

>> 2. How does Battenfeld's modular design benefit production?

>> 3. What is Wittmann 4.0, and how does it enhance Battenfeld machines?

>> 4. What are the advantages of using Battenfeld's servo-hydraulic machines?

>> 5. How does Battenfeld support its customers?

● Citations:

Battenfeld, a renowned name in the plastics processing industry, offers a comprehensive range of extrusion and injection molding machines that cater to diverse manufacturing needs. Founded in 1876 in Vienna, Austria, Battenfeld has evolved significantly over the years, especially after merging with Wittmann in 1993, enhancing its capabilities in automation and robotics for the plastics sector. This article delves into the reasons why Battenfeld extrusion injection molding machines are preferred by industries worldwide, highlighting their features, applications, and benefits.

Introduction to Battenfeld

Battenfeld's history dates back to 1876, and since then, it has become a leading manufacturer of high-quality machinery for injection molding, extrusion, and blow molding. The company's merger with Wittmann further expanded its product line to include advanced automation solutions, making it a one-stop-shop for the plastics industry.

Battenfeld's Product Range

Battenfeld offers a wide range of machines suitable for various applications:

- Injection Molding Machines: These include hydraulic, electric, hybrid, and multi-component machines designed for precision and energy efficiency. For instance, the HM series provides a wide range of clamping forces and shot sizes, while the Microsystem series is ideal for high-precision molding of small parts.

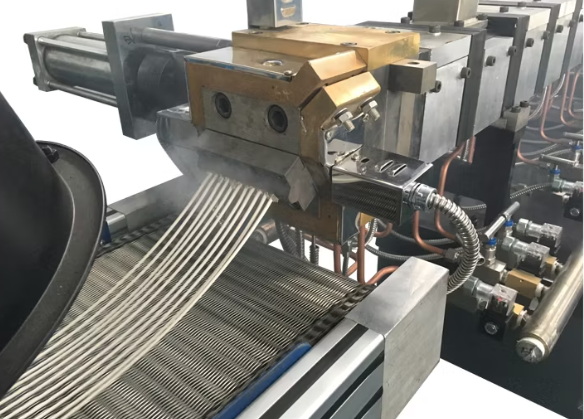

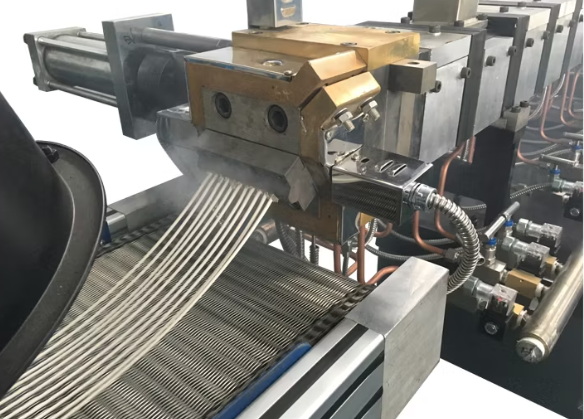

- Extrusion Machines: Battenfeld-Cincinnati, a subsidiary, specializes in extruders for large-diameter PVC pipes and profiles, offering high-output solutions with efficient resource utilization.

- Blow Molding Machines: These machines are used for producing hollow plastic products through extrusion or injection blow molding processes.

Features of Battenfeld Machines

Energy Efficiency

Battenfeld machines, especially the servo-hydraulic models like SmartPower and MacroPower, are designed to achieve energy efficiency comparable to electric machines while maintaining flexibility and precision. This is particularly important in today's manufacturing environment, where reducing energy consumption is crucial for both cost savings and environmental sustainability.

Modular Design

The modular design of Battenfeld machines allows for easy integration with peripheral equipment, reducing floor space and enhancing production efficiency. This is particularly evident in Wittmann Battenfeld's SmartPower series, which features a compact, 3-platen design that minimizes the footprint while maximizing output.

Advanced Technology

Battenfeld machines incorporate advanced technologies such as Wittmann 4.0, which enables seamless communication between the molding machine and peripheral devices, streamlining production processes and reducing errors. This technology integrates all equipment into a single network, allowing for automated setup changes and real-time monitoring, thereby improving productivity and quality.

Multi-Component Molding

Battenfeld offers multi-component injection molding machines that allow for the production of parts with multiple colors or materials, enhancing product design flexibility. This capability is particularly valuable in industries where complex parts are required, such as automotive and electronics.

Applications of Battenfeld Machines

Battenfeld machines are versatile and cater to various industries:

- Automotive: Used for producing large and complex parts such as dashboards and bumpers. The precision and quality provided by Battenfeld machines ensure that these parts meet the stringent standards of the automotive industry.

- Medical: Ideal for precision molding of medical devices and pharmaceutical packaging. The cleanliness and precision of Battenfeld machines are crucial in this sector, where product quality directly impacts safety and efficacy.

- Electronics: Suitable for producing small, intricate components like connectors and switches. The high precision of Battenfeld machines ensures that these components meet the exacting standards required in electronic devices.

Benefits of Choosing Battenfeld

High Precision and Quality

Battenfeld machines are designed to deliver high precision and quality in the final products, making them suitable for demanding applications. This precision is achieved through advanced control systems and robust machine design.

Energy Efficiency and Cost Savings

The energy-efficient design of Battenfeld machines helps reduce operational costs and environmental impact. This is particularly important for companies looking to minimize their carbon footprint while maintaining profitability.

Comprehensive Support

Wittmann Battenfeld offers comprehensive support, including training, consulting, and spare parts availability, ensuring continuous production without downtime. This support system is crucial for maintaining high productivity levels and reducing maintenance costs.

Customization and Flexibility

Battenfeld machines can be customized to meet specific production needs, offering flexibility in terms of mold size, material handling, and automation integration. This flexibility allows manufacturers to adapt quickly to changing market demands or new product lines.

Integration with Automation Solutions

Battenfeld machines can be seamlessly integrated with Wittmann automation solutions, such as robots and conveyor systems, enhancing production efficiency and reducing labor costs. This integration enables manufacturers to automate entire production lines, from molding to packaging.

Market Trends and Future Developments

The plastics industry is constantly evolving, with trends shifting towards sustainability, digitalization, and customization. Battenfeld is well-positioned to meet these challenges by continuously innovating its product line to incorporate more sustainable materials, advanced automation, and digital technologies. For instance, the integration of Industry 4.0 technologies allows for real-time monitoring and predictive maintenance, further enhancing machine efficiency and reliability.

Case Studies and Success Stories

Battenfeld machines have been successfully implemented in various manufacturing settings worldwide. For example, a leading automotive parts supplier used Battenfeld's multi-component molding machines to produce complex dashboard components with multiple colors and materials, achieving significant cost savings and quality improvements. Similarly, a medical device manufacturer utilized Battenfeld's precision injection molding machines to produce high-quality syringe components, meeting stringent regulatory standards.

Conclusion

Battenfeld extrusion injection molding machines are preferred due to their high precision, energy efficiency, and versatility. With a wide range of applications across industries, these machines offer a reliable solution for manufacturing complex plastic parts. The integration of advanced technologies like Wittmann 4.0 further enhances their appeal by streamlining production processes. As the plastics industry continues to evolve, Battenfeld's commitment to innovation and customer support positions it as a leader in the market.

FAQs

1. What types of injection molding machines does Battenfeld offer?

Battenfeld offers a variety of injection molding machines, including hydraulic, electric, hybrid, and multi-component models. These machines cater to different applications, from small precision parts to large-scale industrial components.

2. How does Battenfeld's modular design benefit production?

The modular design of Battenfeld machines allows for easy integration with peripheral equipment, reducing floor space and enhancing production efficiency by enabling seamless communication and operation between different components.

3. What is Wittmann 4.0, and how does it enhance Battenfeld machines?

Wittmann 4.0 is an advanced technology that enables communication between the molding machine and peripheral devices, streamlining production processes, reducing errors, and improving efficiency. It integrates all equipment into a single network, allowing for automated setup changes and real-time monitoring.

4. What are the advantages of using Battenfeld's servo-hydraulic machines?

Battenfeld's servo-hydraulic machines, such as the SmartPower series, offer flexibility and energy efficiency comparable to electric machines. They are suitable for a wide range of applications and provide high precision and reliability.

5. How does Battenfeld support its customers?

Battenfeld, through Wittmann Battenfeld, provides comprehensive customer support, including training, consulting services, and long-term availability of original spare parts. This ensures that customers can maintain continuous production with minimal downtime.

Citations:

[1] https://www.exapro.com/battenfeld-tm-45002800-p90116053/

[2] https://hub.exapro.com/battenfeld-a-popular-injection-solution-in-the-used-machinery-trade

[3] https://www.advancedplasticsmachinery.com/injection-molding-machines

[4] https://www.wittmann-group.com/en

[5] https://www.youtube.com/watch?v=0s_W18nuSNo

[6] https://www.plasticsmachinerymanufacturing.com/injection-molding/article/21228980/wittmann-battenfeld-upgrades-nitrogen-injection-system

[7] http://www.battenfeld.pl/dane/prospekty_new_02/HM-MK_gb.pdf

[8] https://www.leshanmachines.com/blogs/battenfeld-blow-molding-machines

[9] https://www.log-machine.com/injection-molding-machine-manufacturer/

[10] https://www.plasticsmachinerymanufacturing.com/extrusion/article/13000251/battenfeld-cincinnati-extruder-designed-for-large-diameter-pvc-pipe

[11] https://hub.exapro.com/battenfeld-injection-moulding-machines

[12] https://prototool.com/injection-molding-machine/

[13] https://www.sciencedirect.com/topics/materials-science/injection-molding

[14] https://maszyneria.com/en/product/battenfeld-tm-1300-injection-moulding-machine/

[15] https://plastiwin.com/brands/used-battenfeld-extruders/

[16] https://www.battenfeld-cincinnati.com/company/about-us

[17] https://www.wittmann-group.com/en/injection-molding

[18] https://www.battenfeld-cincinnati.com

[19] https://www.wittmann-group.com/en

[20] https://www.alibaba.com/product-detail/battenfeld-injection-molding-machine-1600969979998.html

[21] https://www.arlingtonmachinery.com/brands/pl.b.1033.0/battenfeld/

[22] https://www.chinaplasonline.com/eMarketplace/exhibitorinfo/eng?compid=1006934

[23] https://www.plasticstoday.com/injection-molding/wittmann-battenfeld-to-feature-six-operating-injection-molding-machine-workcells

[24] https://www.degruyter.com/document/doi/10.3139/217.950002/pdf

[25] https://www.ptonline.com/articles/new-owners-for-battenfeld-cincinnati-

[26] https://www.youtube.com/watch?v=Gw-w9S0Mt0c

[27] https://www.alibaba.com/injection-molding-machine-battenfeld-suppliers.html

[28] https://www.youtube.com/watch?v=iQ1taJq5bO0

[29] https://www.camargoindustrial.com/brand/?c=Battenfeld_27A

[30] https://www.youtube.com/watch?v=zNsSFFdlm6w