Content Menu

● The Aluminum Extrusion Process: A Closer Look

● Advantages of Aluminum Extrusion

● Why Choose a Local Aluminum Extruder?

● Iowa Aluminum, Inc.: A Blue Grass Success Story

● Industries Served by Aluminum Extruders in Blue Grass, Iowa

● Customization Capabilities

● Quality and Standards

● Environmental Benefits

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What types of aluminum extrusions does Iowa Aluminum specialize in?

>> 2. What industries does Iowa Aluminum serve?

>> 3. What are the advantages of choosing a local aluminum extruder like Iowa Aluminum?

>> 4. What quality standards does Iowa Aluminum adhere to?

>> 5. What services does Iowa Aluminum offer in addition to extrusion?

● Citations:

Blue Grass, Iowa, might not be the first place that comes to mind when you think of advanced manufacturing, but this small city is home to Iowa Aluminum, Inc., a company specializing in custom aluminum extrusion and fabrication[1][6]. Choosing an "aluminum extruder blue grass iowa", like Iowa Aluminum, offers distinct advantages, combining personalized service with high-quality products. This article explores the benefits of selecting a local aluminum extruder in Blue Grass, Iowa, and why it might be the best choice for your next project.

The Aluminum Extrusion Process: A Closer Look

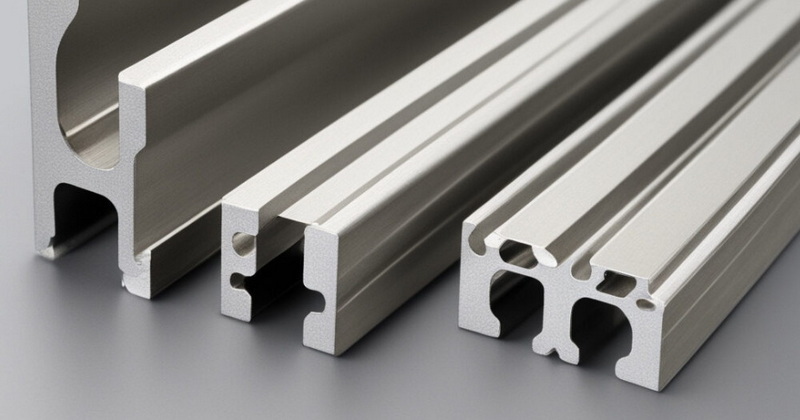

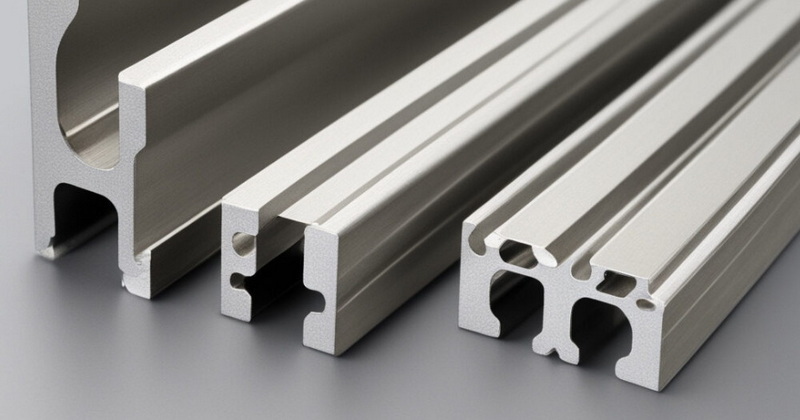

Before diving into the specifics of why Blue Grass, Iowa, is a good choice for aluminum extrusion, it's essential to understand the extrusion process itself. Aluminum extrusion is a method where aluminum alloy is forced through a die with a specific cross-sectional profile[3]. Think of it like squeezing toothpaste out of a tube; the aluminum emerges in the shape of the die opening[3].

Here's a step-by-step breakdown of the aluminum extrusion process[3]:

1. Die Preparation: The extrusion die is preheated to between 450-500 degrees Celsius to maximize its life and ensure even metal flow[3].

2. Billet Preheating: An aluminum billet is preheated in an oven to between 400-500 degrees Celsius, making it malleable enough for extrusion but not molten[3].

3. Billet Transfer: The billet is transferred to the extrusion press, with a lubricant applied to prevent sticking[3].

4. Ram Pressure: A ram pushes the billet material into the container of the extrusion press, expanding to fill the walls[3].

5. Extrusion: The aluminum material is pressed against the die and emerges through the opening in the shape of the desired profile[3].

6. Cooling and Quenching: Extrusions are guided along a runout table and quenched, uniformly cooled by water or fans[3].

7. Shearing: Once the extrusion reaches full table length, it is sheared by a hot saw[3].

8. Cooling to Room Temperature: Extrusions are transferred to a cooling table until they reach room temperature[3].

9. Stretching: Profiles are stretched to correct any twisting and ensure they meet specifications[3].

10. Cutting to Length: Finally, extrusions are sawed to pre-specified lengths[3].

Advantages of Aluminum Extrusion

Aluminum extrusion offers several key benefits that make it a preferred choice for various applications[4]:

- Strength: Aluminum extrusions can be developed with varying levels of strength, concentrating it where needed through internal reinforcement and varying wall thicknesses[4].

- Lightweight: Aluminum combines low weight and high strength, ideal for applications where minimizing weight and supporting heavy loads are crucial[4].

- Corrosion Resistance: Aluminum is naturally corrosion-resistant due to oxidation, preventing rust. This can be enhanced further through anodization or other finishing processes[4].

- Thermal Conductivity: Aluminum conducts heat and cold efficiently, making it suitable for heat dissipation and heat exchangers[4].

- Electrical Conductivity: Aluminum is a cost-effective electrical conductor, with twice the conductivity of copper pound for pound[4].

- Non-Sparking: Aluminum is non-sparking, making it safe for use in flammable environments[4].

- Non-Toxic and Non-Combustible: Aluminum does not emit toxic fumes or burn, even at high temperatures[4].

- Non-Magnetic: Aluminum does not develop a magnetic charge, suitable for high-voltage and electronic applications[4].

- Seamless Construction: Aluminum extrusions offer seamless construction, enhancing structural integrity[4].

Why Choose a Local Aluminum Extruder?

Selecting a local *aluminum extruder blue grass iowa*, such as Iowa Aluminum, offers numerous advantages over larger, national suppliers:

- Customization and Flexibility: Local extruders specialize in customization, offering tailored solutions to meet specific project requirements[1]. Iowa Aluminum, for example, focuses on custom aluminum fabrication for various sectors, including automotive, commercial, sporting goods, and industrial[2].

- Personalized Service: Local companies provide personalized attention and support, building long-term relationships with their clients[1]. This customer-centric approach ensures a seamless experience and complete satisfaction[1].

- Faster Turnaround Times: With proximity comes faster turnaround times. Local extruders can offer rapid prototyping and short lead times, helping bring ideas to life quickly[1].

- Cost-Effectiveness: While larger companies might offer economies of scale, local extruders can provide competitive pricing by reducing shipping costs and offering more flexible order sizes[5].

- Quality Control: Local *aluminum extruders blue grass iowa* maintain rigorous quality control measures throughout the manufacturing process, ensuring consistency, precision, and durability[1]. Iowa Aluminum, for instance, is committed to meeting or exceeding industry standards and certifications[1].

- Support for the Local Economy: Choosing a local *aluminum extruder blue grass iowa* supports the local economy, fostering job creation and community development[10].

Iowa Aluminum, Inc.: A Blue Grass Success Story

Iowa Aluminum, Inc., founded in 2001 by Mike Lawrence Jr., exemplifies the benefits of a local *aluminum extruder blue grass iowa*[10]. The company started with a single 6-inch diameter extrusion press and a handful of employees[10]. Over the years, Iowa Aluminum has expanded to meet increasing demand, now operating two state-of-the-art presses/extrusion lines[10].

Iowa Aluminum specializes in custom aluminum extrusion and fabrication, focusing on shapes that many other companies avoid, such as small orders and light wall shapes[6]. Their capabilities include solids, hollows, semi-hollows, and heat sinks, serving industries like industrial, construction, automotive, and electronics[10].

The company's fabrication department offers precision cutting, punching, forming, mitering, drilling, tapping, CNC machining, and more[10]. They also provide special packaging to ensure products arrive in excellent condition and offer outside processing services such as painting and anodizing[10].

Industries Served by Aluminum Extruders in Blue Grass, Iowa

Aluminum extruders in Blue Grass, Iowa, serve a diverse range of industries[2][7]:

- Automotive: Providing components for vehicles, including bar stock, trim, and door/window panels[2].

- Construction: Offering products for doors, windows, store fronts, and building frames[2].

- Commercial: Supplying components for office furniture, partitions, and drafting equipment[2].

- Sporting Goods: Manufacturing products like basketball backboards[2].

- Industrial: Creating parts for electrical systems, file cabinet handles, and machine components[2].

- Marine: Providing extrusions for marine applications[2].

- Trucking: Manufacturing components for trailers and trucks[2].

Customization Capabilities

Customization is a core strength of *aluminum extruders blue grass iowa*[1]. These companies work closely with customers to provide tailored solutions, offering assistance with product design, material selection, and custom extrusion development[1]. Whether it's a unique profile shape, specific alloy requirements, or specialized finishing, local extruders can meet the most demanding needs[1][6].

Iowa Aluminum, for example, offers custom aluminum fabrication using 6000 series aluminum and provides various fabrication methods, including countersinking, cutting, drilling, punching, slotting, tapping, and tumbling[2]. They also offer anodizing, painting, and powder coating as secondary services[2].

Quality and Standards

Quality is paramount for *aluminum extruders blue grass iowa*[1]. These companies adhere to a wide range of industry standards to ensure the highest quality products[2]. Iowa Aluminum extrudes to Aluminum Association and ASTM Standards and is in the process of becoming International Automotive Task Force (IATF) certified[2][6]. Their Quality Management System complies with ISO9001 requirements and certain requirements of QS 9000 and TS16949[6].

Environmental Benefits

Choosing aluminum extrusions also offers environmental benefits[5][9]. Aluminum is an economically and environmentally friendly material[5]. It is highly recyclable, and the extrusion process itself is energy-efficient compared to other metal forming methods[9]. Additionally, aluminum extrusions can contribute to energy savings in applications such as thermal management and lightweighting of vehicles[4][5].

Conclusion

Selecting an *aluminum extruder blue grass iowa*, like Iowa Aluminum, provides a blend of customization, personalized service, and high-quality products. Local extruders offer faster turnaround times, cost-effectiveness, and support for the local economy. With a commitment to meeting industry standards and providing tailored solutions, *aluminum extruders blue grass iowa* are well-positioned to meet the diverse needs of various industries. For your next project, consider the advantages of choosing a local *aluminum extruder blue grass iowa* for a seamless and satisfactory experience.

Frequently Asked Questions (FAQ)

1. What types of aluminum extrusions does Iowa Aluminum specialize in?

Iowa Aluminum specializes in custom aluminum extrusion and fabrication, focusing on shapes that many other companies avoid, such as small orders and light wall shapes. Their capabilities include solids, hollows, semi-hollows, and heat sinks, serving industries like industrial, construction, automotive, and electronics[6][10].

2. What industries does Iowa Aluminum serve?

Iowa Aluminum serves a diverse range of industries, including automotive, construction, commercial, sporting goods, industrial, marine, and trucking[2][7].

3. What are the advantages of choosing a local aluminum extruder like Iowa Aluminum?

Choosing a local *aluminum extruder blue grass iowa* offers several advantages, including customization, personalized service, faster turnaround times, cost-effectiveness, and support for the local economy[1][5].

4. What quality standards does Iowa Aluminum adhere to?

Iowa Aluminum extrudes to Aluminum Association and ASTM Standards and is in the process of becoming International Automotive Task Force (IATF) certified. Their Quality Management System complies with ISO9001 requirements and certain requirements of QS 9000 and TS16949[2][6].

5. What services does Iowa Aluminum offer in addition to extrusion?

In addition to extrusion, Iowa Aluminum offers custom aluminum fabrication using 6000 series aluminum and provides various fabrication methods, including countersinking, cutting, drilling, punching, slotting, tapping, and tumbling. They also offer anodizing, painting, and powder coating as secondary services[2].

Citations:

[1] https://aluminum-extrusions.net/iowa-aluminum-inc/

[2] https://iowaaluminum.com/services/

[3] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[4] https://www.howardprecision.com/benefits-of-aluminum-extrusions/

[5] https://www.howardprecision.com/the-advantages-of-aluminum-extruded-products/

[6] https://iowaaluminum.com

[7] https://www.hydro.com/profiles/aluminum-extrusions-manufacturer-in-iowa

[8] https://www.youtube.com/watch?v=iiGlq7408ME

[9] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[10] https://iowaaluminum.com/about2/

[11] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[12] https://www.youtube.com/watch?v=DqILlMsNYLw

[13] https://www.youtube.com/watch?v=PbwCXCIG_S0

[14] https://www.dnb.com/business-directory/company-profiles.kauffman_patterns_inc.c90a0b0064e2b241e19f56b4929b2cf7.html

[15] https://www.ziprecruiter.com/Jobs/Manufacturing/-in-Blue-Grass,IA

[16] https://www.priesenterprises.com

[17] https://www.indeed.com/q-mills-l-colona,-il-jobs.html

[18] https://facilities.nmsu.edu/documents/22115L-OEM-EOC-Building-SPECS.pdf

[19] https://www.linkedin.com/in/rich-england-hunter-porter-02994627

[20] https://www.a2gov.org/media/gnhjo3qr/itb_4424_addendum4.pdf

[21] https://www.yelp.com/biz/rich-metals-blue-grass

[22] https://www.iowarealty.com/realestate/details/30302010/213-e-meuse-street-blue-grass-ia-52726

[23] https://www.rvtrader.com/Iowa-Intech-Toy-Hauler/rvs-for-sale?type=Toy+Hauler%7C139350904&make=Intech%7C765335022&state=Iowa%7CIA&dealerid=2894268

[24] https://www.iqsdirectory.com/aluminum-extruders/iowa/

[25] https://www.facebook.com/groups/420194656204845/posts/1138987994325504/

[26] https://www.bgsod.com

[27] https://www.indeed.com/q-cost-l-bowling-green,-ky-jobs.html

[28] https://www.tiktok.com/@engineerplace/video/7323989736954105121

[29] https://www.outhousesanitation.com/gallery

[30] https://www.shutterstock.com/video/search/aluminum-extrusion

[31] https://stock.adobe.com/search?k=%22aluminium+extrusion%22

[32] https://www.shutterstock.com/video/search/aluminium-extrusions

[33] https://www.istockphoto.com/photos/aluminum-extrusion

[34] https://www.bossplow.com

[35] https://www.sunbeltrentals.com

[36] https://iowaaluminum.com/about2/

[37] https://spectraaluminum.com/frequently-asked-questions-about-aluminum-extrusion/

[38] https://aec.org/faqs

[39] https://www.uniqueextrusions.com/aluminum-extrusion-faq/

[40] https://pmc.ncbi.nlm.nih.gov/articles/PMC10944486/

[41] https://www.reddit.com/r/Workbenches/comments/xn5ehd/aluminum_extrusion_questions/

[42] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[43] https://www.iqsdirectory.com/aluminum-trim/iowa/

[44] https://www.searshomeservices.com

[45] https://www.fonnovaluminium.com/faqs

[46] https://www.designnews.com/metals/your-aluminum-extrusion-questions-answered

[47] https://zjaluminum-cnc.com/faqs-on-aluminum-extrusion-and-fabrication/

[48] https://aec.org/features-benefits

[49] https://aluminum-extrusions.net/iowa-aluminum-inc/

[50] https://www.pennex.com/press/the-many-benefits-of-using-aluminum-extrusions

[51] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[52] https://www.hydro.com/profiles/aluminum-extrusions-manufacturer-in-iowa

[53] https://www.epa.gov/eg/aluminum-forming-effluent-guidelines

[54] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[55] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[56] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[57] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions

[58] https://www.altecextrusions.com/faqs/