Content Menu

● Understanding Aluminum Extrusion

>> The Aluminum Extrusion Process

● Advantages of Choosing Aluminum Extrusion in Illinois

>> 1. Customization and Versatility

>> 2. Cost-Effectiveness

>> 3. Strength-to-Weight Ratio

>> 4. Corrosion Resistance

>> 5. Eco-Friendly Option

● Why Illinois Stands Out for Aluminum Extrusion Services

● Applications of Aluminum Extrusion

● Innovations in Aluminum Extrusion Technology

● Conclusion

● FAQ

>> 1. What industries benefit from aluminum extrusion services?

>> 2. How does aluminum compare with other metals?

>> 3. What are the common finishes available for extruded aluminum?

>> 4. Is there a minimum order quantity for custom extrusions?

>> 5. How long does the aluminum extrusion process take?

● Citations:

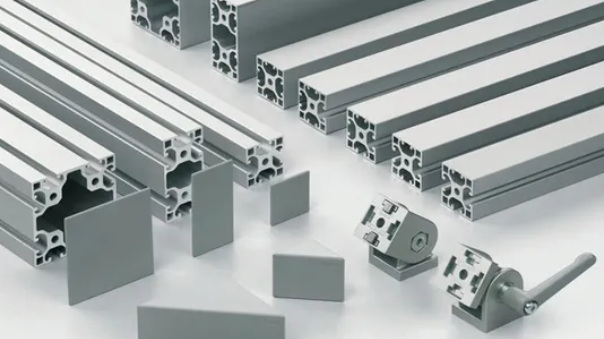

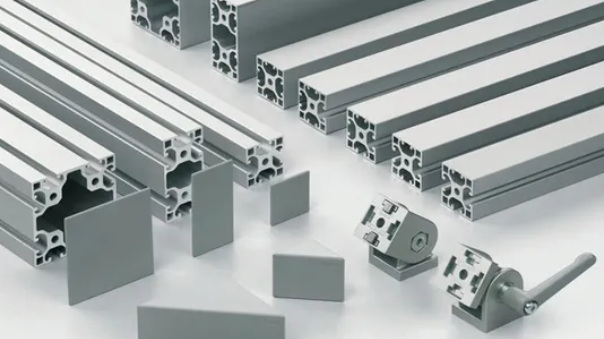

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into desired cross-sectional profiles by forcing it through a die. This technique has gained immense popularity across various industries due to its versatility, strength, and lightweight properties. In Illinois, aluminum extrusion services stand out for several reasons, making them a preferred choice over other methods. This article will explore the advantages of aluminum extrusion in Illinois, the process involved, and why it is an excellent option for businesses looking to innovate and streamline their production.

Understanding Aluminum Extrusion

Aluminum extrusion involves heating an aluminum billet to a pliable state and then pushing it through a die to create long lengths of aluminum with specific cross-sectional shapes. The process is akin to squeezing toothpaste out of a tube, where the die determines the final shape of the extruded product.

The Aluminum Extrusion Process

1. Preparation: The aluminum billet is preheated to enhance its malleability.

2. Extrusion: A hydraulic press pushes the heated aluminum through the die.

3. Cooling: The extruded aluminum is cooled using water or air to solidify its shape.

4. Cutting: Once cooled, the extrusions are cut to specified lengths.

5. Finishing: Additional processes such as anodizing or painting may be applied for enhanced durability and aesthetics.

This method allows for high precision and customization, making it suitable for a wide range of applications from architectural components to automotive parts.

Advantages of Choosing Aluminum Extrusion in Illinois

1. Customization and Versatility

One of the most significant advantages of aluminum extrusion services in Illinois is the ability to create highly customized profiles tailored to specific project requirements. This flexibility allows manufacturers to produce unique shapes that can enhance product functionality and aesthetic appeal.

- Wide Range of Applications: Aluminum extrusions can be used in various sectors including construction, automotive, aerospace, and consumer goods.

The ability to produce custom profiles means that businesses can innovate without being constrained by standard sizes or shapes. This leads to more efficient designs that can meet specific performance criteria.

2. Cost-Effectiveness

Aluminum extrusion is often more cost-effective compared to other manufacturing methods such as machining or casting. The ability to produce complex shapes without extensive secondary operations reduces overall material waste and labor costs.

- Efficiency in Production: High-volume production capabilities mean that businesses can benefit from economies of scale.

Moreover, the reduced need for additional machining or finishing processes not only saves time but also lowers production costs significantly. This makes aluminum extrusion an attractive option for companies looking to maximize their budget while maintaining quality.

3. Strength-to-Weight Ratio

Aluminum has an excellent strength-to-weight ratio, making it an ideal choice for applications where reducing weight without sacrificing strength is crucial. This property is particularly beneficial in industries like aerospace and automotive where weight reduction leads to improved fuel efficiency.

- Lightweight Nature: The lightweight nature of aluminum allows for easier handling during manufacturing and installation processes.

This characteristic also contributes to lower transportation costs since lighter materials are cheaper to ship. As a result, businesses can save money on logistics while benefiting from the performance advantages of using aluminum.

4. Corrosion Resistance

Aluminum naturally forms a protective oxide layer that enhances its resistance to corrosion. This feature is especially advantageous for products exposed to harsh environmental conditions, ensuring longevity and reducing maintenance costs.

- Durability: The durability of extruded aluminum products makes them suitable for outdoor applications where exposure to moisture and other corrosive elements is common.

This corrosion resistance means that products can maintain their structural integrity over time, leading to longer-lasting solutions that do not require frequent replacements or repairs.

5. Eco-Friendly Option

Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice for manufacturers looking to reduce their carbon footprint. Recycling aluminum requires only 5% of the energy needed to produce new aluminum from ore, significantly lowering environmental impact.

- Sustainability Practices: Many manufacturers in Illinois are adopting sustainable practices by utilizing recycled aluminum in their extrusion processes.

By choosing aluminum extrusion services that emphasize sustainability, businesses can align themselves with eco-friendly practices while also appealing to environmentally conscious consumers.

Why Illinois Stands Out for Aluminum Extrusion Services

Illinois has become a hub for aluminum extrusion services due to several factors:

- Proximity to Major Markets: Located centrally in the United States, Illinois provides easy access to major markets across the Midwest and beyond.

- Skilled Workforce: The state boasts a skilled workforce experienced in advanced manufacturing techniques, ensuring high-quality production standards.

- Established Infrastructure: With numerous suppliers and logistics options available, businesses can easily source materials and distribute finished products efficiently.

Additionally, Illinois has invested heavily in manufacturing technology and innovation, which further enhances its position as a leader in the aluminum extrusion industry. Companies benefit from access to cutting-edge equipment and techniques that improve production efficiency and product quality.

Applications of Aluminum Extrusion

The versatility of aluminum extrusion allows it to be used in various applications:

- Architectural Elements: Window frames, curtain walls, and other architectural components benefit from custom extruded profiles.

- Automotive Components: Lightweight structural components help improve vehicle efficiency.

- Consumer Products: Items such as furniture frames and electronic housings often utilize aluminum extrusions for their aesthetic appeal and durability.

- Industrial Applications: Machinery frames, conveyor systems, and structural supports are commonly made from extruded aluminum due to its strength and lightweight nature.

- Electronics Industry: Heat sinks made from extruded aluminum effectively dissipate heat from electronic components, enhancing performance and reliability.

The adaptability of aluminum extrusion means that it can meet the demands of various sectors while providing solutions that enhance product functionality and design aesthetics.

Innovations in Aluminum Extrusion Technology

Recent advancements in technology have further improved the capabilities of aluminum extrusion services:

- 3D Printing Integration: Some manufacturers are exploring ways to integrate 3D printing with traditional extrusion techniques, allowing for even more complex designs that were previously difficult or impossible to achieve.

- Advanced Die Design: Innovations in die design have led to more efficient production processes with reduced lead times while maintaining high precision levels.

- Smart Manufacturing Techniques: The adoption of smart manufacturing technologies enables real-time monitoring and optimization of the extrusion process, resulting in improved quality control and reduced waste.

These innovations not only enhance production capabilities but also allow manufacturers in Illinois to stay competitive in an ever-evolving market landscape.

Conclusion

Choosing aluminum extrusion services in Illinois offers numerous advantages over other manufacturing methods. From customization and cost-effectiveness to strength and environmental sustainability, aluminum extrusion proves to be a superior choice for various industries. As businesses continue to seek innovative solutions that enhance product performance while reducing costs, aluminum extrusion remains at the forefront of modern manufacturing practices.

By leveraging the unique benefits offered by Illinois-based extrusion services—such as access to skilled labor, advanced technology, and sustainability practices—companies can position themselves for success in today's competitive marketplace. Whether you're developing new products or optimizing existing designs, aluminum extrusion provides a robust solution that meets diverse needs while supporting growth and innovation within your organization.

FAQ

1. What industries benefit from aluminum extrusion services?

Aluminum extrusion services cater to various industries including construction, automotive, aerospace, electronics, and consumer goods due to their versatility and strength.

2. How does aluminum compare with other metals?

Aluminum is lighter than steel yet retains comparable strength, making it ideal for applications where weight reduction is critical without compromising structural integrity.

3. What are the common finishes available for extruded aluminum?

Extruded aluminum can be finished with anodizing, painting, or powder coating which enhances corrosion resistance and aesthetic appeal.

4. Is there a minimum order quantity for custom extrusions?

Many manufacturers have flexible minimum order quantities depending on the complexity of the design; some may even accept orders as small as one unit.

5. How long does the aluminum extrusion process take?

The lead time for aluminum extrusions can vary based on design complexity but typically ranges from two weeks after the final design approval up to several weeks if custom dies are required.

Citations:

[1] https://paramountextrusions.com/blogs/why-choose-custom-aluminum-extrusions

[2] https://dajcor.com/extrusion

[3] https://www.linkedin.com/pulse/advantages-aluminum-extrusion-process-

[4] https://eagle-aluminum.com

[5] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[6] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[7] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[8] https://glsmetals.com/custom-extrusions-aluminum

[9] https://thunderbird-metals.com

[10] https://dajcor.com/learning-centre/faq