Content Menu

● The Rise of Aluminum in Construction

● Advantages of Aluminum Extrusion Profiles

>> Strength and Durability

>> Design Flexibility

>> Energy Efficiency

>> Aesthetics and Customization

>> Low Maintenance

● Applications of Aluminum Extrusion Profiles in Windows and Doors

>> Sliding Windows and Doors

>> Casement Windows

>> Entrance Doors

>> Folding Doors

● The Manufacturing Process

>> 1. Ingot Casting

>> 2. Extrusion Process

>> 3. Heat Treatment

>> 4. Surface Treatment

● Sustainability and Environmental Impact

● Cost Efficiency

● Innovations in Aluminum Extrusion Profiles

● Case Studies

>> 1. High-Rise Residential Building in New York City

>> 2. Coastal Resort in Florida

>> 3. Sustainable Office Complex in London

● Future Trends

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of using aluminum extrusion profiles for windows and doors?

>> 2. How do aluminum extrusion profiles contribute to energy efficiency in buildings?

>> 3. Are aluminum extrusion profiles suitable for all types of climates?

>> 4. How do aluminum extrusion profiles compare to other materials like wood or uPVC in terms of cost and performance?

>> 5. Can aluminum extrusion profiles be customized for specific architectural designs?

● Citations:

In the ever-evolving world of construction and architecture, the choice of materials plays a crucial role in determining the quality, durability, and aesthetics of a building. When it comes to windows and doors, aluminum extrusion profiles have emerged as a popular and highly effective solution. This article will explore the numerous benefits and applications of aluminum extrusion profiles for windows and doors, providing you with valuable insights to make informed decisions for your next project.

The Rise of Aluminum in Construction

Aluminum has become increasingly prevalent in the construction industry, particularly in the manufacturing of windows and doors. Its versatility, strength, and aesthetic appeal have made it a preferred choice for architects, builders, and homeowners alike[1][2].

Advantages of Aluminum Extrusion Profiles

Strength and Durability

One of the primary reasons for choosing aluminum extrusion profiles for windows and doors is their exceptional strength-to-weight ratio. Unlike traditional materials such as wood or steel, aluminum profiles offer superior structural integrity without adding unnecessary weight to the building[1]. This characteristic ensures that your windows and doors will maintain their shape and functionality for years to come, even when exposed to harsh weather conditions.

Design Flexibility

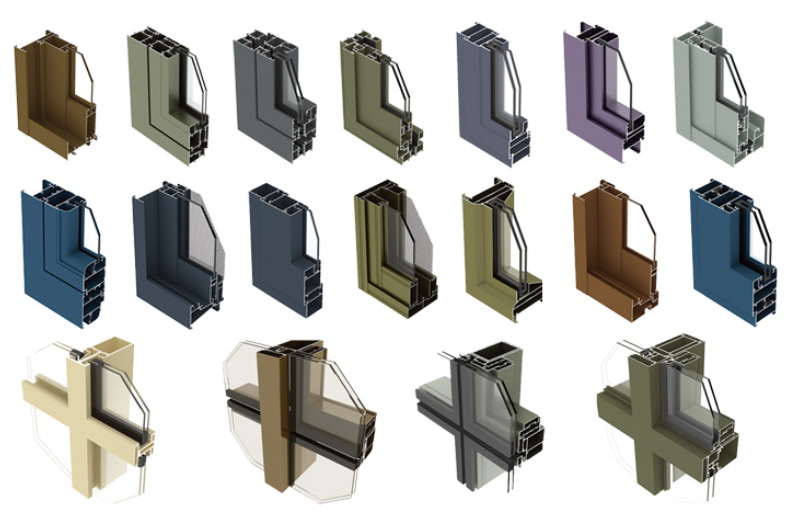

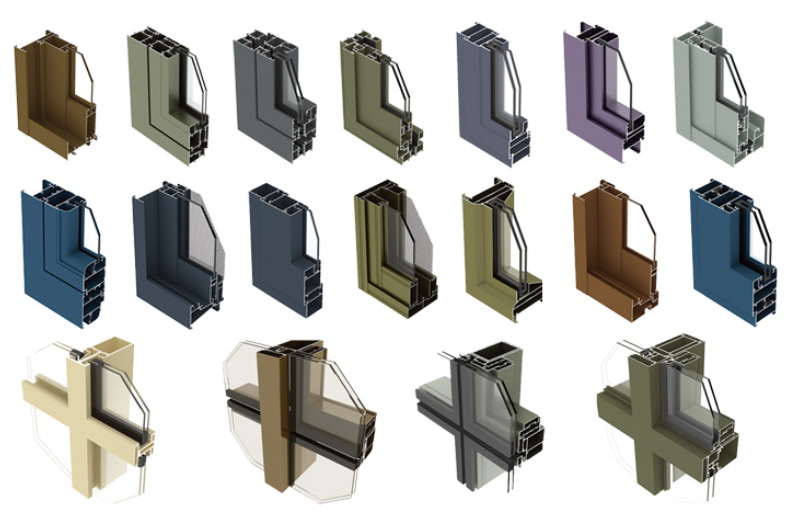

Aluminum extrusion profiles provide unparalleled design flexibility, allowing architects and designers to bring their most innovative ideas to life[1]. The extrusion process enables the creation of complex shapes and profiles, opening up a world of possibilities for unique and aesthetically pleasing window and door designs.

Energy Efficiency

In an era where energy conservation is paramount, aluminum extrusion profiles for windows and doors offer excellent thermal performance. By incorporating thermal breaks and innovative insulation technologies, these profiles help minimize heat transfer, resulting in improved energy efficiency and reduced utility costs[1][2].

Aesthetics and Customization

Aluminum extrusion profiles provide a sleek, modern appearance that can enhance the visual appeal of any building. With a wide range of finishes available, including anodized, powder-coated, and wood-grain effects, these profiles can be customized to complement any architectural style or color scheme[1][4].

Low Maintenance

Unlike wood, which requires regular painting and sealing, aluminum extrusion profiles are virtually maintenance-free. They resist corrosion, warping, and cracking, ensuring that your windows and doors remain in pristine condition with minimal upkeep[2].

Applications of Aluminum Extrusion Profiles in Windows and Doors

Sliding Windows and Doors

Aluminum extrusion profiles are ideal for creating smooth-gliding mechanisms in sliding windows and doors. Their strength and precision allow for effortless operation and excellent sealing properties[2].

Casement Windows

The rigidity and durability of aluminum profiles make them perfect for casement windows, providing excellent security and weather resistance[2].

Entrance Doors

Aluminum extrusion profiles are widely used in the manufacturing of entrance doors, offering exceptional strength, security, and aesthetic appeal[2].

Folding Doors

The lightweight yet robust nature of aluminum allows for the creation of large folding door panels that can seamlessly connect indoor and outdoor spaces[2].

The Manufacturing Process

Understanding the manufacturing process of aluminum extrusion profiles can help you appreciate the precision and quality that goes into these products.

1. Ingot Casting

The process begins with the preparation of aluminum alloy ingots, which are cast to the desired chemical composition and dimensions[7].

2. Extrusion Process

The ingots are heated to temperatures between 400 to 520 degrees Celsius and then extruded through a die using hydraulic presses with pressures ranging from 800 to 2500 tonnes[7].

3. Heat Treatment

After extrusion, the profiles undergo heat treatment to enhance their mechanical properties[7].

4. Surface Treatment

Finally, the profiles are subjected to surface treatments such as anodizing or powder coating to improve their appearance and durability[7].

Sustainability and Environmental Impact

Aluminum extrusion profiles for windows and doors contribute to sustainable building practices in several ways:

1. Recyclability: Aluminum is one of the most recyclable metals available, making these profiles an eco-friendly choice for modern architecture[3].

2. Energy Savings: The thermal efficiency of aluminum profiles helps reduce energy consumption in buildings[1][2].

3. Longevity: The durability of aluminum profiles means less frequent replacements, reducing waste and resource consumption over time[1][2].

4. Reduced Transportation Impact: The lightweight nature of aluminum profiles reduces transportation costs and energy consumption during the construction phase[3].

Cost Efficiency

While the initial cost of aluminum extrusion profiles may be higher than some traditional materials, they offer significant long-term cost benefits:

1. Reduced Maintenance Costs: The low maintenance requirements of aluminum profiles translate to lower overall expenses over time[3].

2. Energy Savings: Improved thermal performance leads to reduced heating and cooling costs[1][2].

3. Longevity: The durability of aluminum profiles means less frequent replacements, saving money in the long run[1][2].

4. Efficient Manufacturing: The extrusion process allows for high-volume production at relatively low costs[3].

Innovations in Aluminum Extrusion Profiles

The field of aluminum extrusion profiles for windows and doors is constantly evolving, with new innovations enhancing their performance and versatility:

1. Smart Window Integration: Aluminum profiles can be designed to accommodate smart home technologies, allowing for automated control of windows and doors.

2. Enhanced Thermal Breaks: Ongoing research is improving the thermal insulation properties of aluminum profiles, making them even more energy-efficient.

3. Nano-coatings: Advanced surface treatments are being developed to enhance the corrosion resistance and self-cleaning properties of aluminum profiles.

4. Biophilic Design: Aluminum profiles are being used to create larger, more open window and door systems that connect indoor spaces with nature, promoting well-being and productivity.

Case Studies

To illustrate the practical applications and benefits of aluminum extrusion profiles for windows and doors, let's examine a few case studies:

1. High-Rise Residential Building in New York City

A 50-story residential tower in Manhattan utilized aluminum extrusion profiles for its floor-to-ceiling windows. The profiles' strength allowed for expansive glass panels, maximizing views and natural light. The thermal efficiency of the profiles contributed to the building's LEED Gold certification.

2. Coastal Resort in Florida

A luxury resort on the Florida coast chose aluminum extrusion profiles for all its windows and doors due to their corrosion resistance and ability to withstand hurricane-force winds. The profiles' durability has significantly reduced maintenance costs and improved guest safety.

3. Sustainable Office Complex in London

An eco-friendly office development in London incorporated aluminum extrusion profiles in its curtain wall system. The profiles' recyclability and energy efficiency played a crucial role in achieving the project's sustainability goals and reducing its carbon footprint.

Future Trends

As we look to the future, several trends are likely to shape the use of aluminum extrusion profiles in windows and doors:

1. Increased Focus on Sustainability: The demand for environmentally friendly building materials will drive further innovations in recycled aluminum profiles and energy-efficient designs.

2. Integration with Smart Building Systems: Aluminum profiles will increasingly be designed to accommodate sensors, actuators, and other smart technologies for improved building management.

3. Customization and Personalization: Advanced manufacturing techniques will allow for greater customization of aluminum profiles, enabling unique designs tailored to specific architectural visions.

4. Enhanced Performance Standards: As building codes become more stringent, aluminum profiles will continue to evolve to meet higher standards for energy efficiency, security, and durability.

Conclusion

Aluminum extrusion profiles for windows and doors offer a compelling combination of strength, durability, energy efficiency, and aesthetic appeal. Their versatility and customization options make them suitable for a wide range of architectural styles and building types. As the construction industry continues to prioritize sustainability and energy efficiency, aluminum extrusion profiles are well-positioned to meet these demands while providing long-lasting, low-maintenance solutions for windows and doors.

By choosing aluminum extrusion profiles for your window and door projects, you're investing in a material that not only enhances the visual appeal of your building but also contributes to its overall performance and sustainability. As technology advances and environmental concerns grow, aluminum extrusion profiles will undoubtedly play an increasingly important role in shaping the future of architecture and construction.

Frequently Asked Questions (FAQ)

1. What are the main advantages of using aluminum extrusion profiles for windows and doors?

Aluminum extrusion profiles offer numerous advantages for windows and doors, including:

- Exceptional strength-to-weight ratio

- Excellent durability and resistance to corrosion

- Design flexibility for creating unique shapes and styles

- Energy efficiency through thermal break technology

- Low maintenance requirements

- Recyclability and sustainability

These benefits make aluminum extrusion profiles an ideal choice for modern construction projects[1][2][3].

2. How do aluminum extrusion profiles contribute to energy efficiency in buildings?

Aluminum extrusion profiles contribute to energy efficiency in several ways:

- Thermal breaks: Profiles can be designed with thermal breaks that minimize heat transfer between the interior and exterior of a building.

- Improved insulation: The profiles can accommodate double or triple glazing, enhancing overall thermal performance.

- Tight seals: Precision manufacturing allows for tight-fitting windows and doors, reducing air leakage.

- Reflective coatings: Aluminum profiles can be treated with reflective coatings to manage solar heat gain.

These features help maintain comfortable indoor temperatures and reduce heating and cooling costs[1][2].

3. Are aluminum extrusion profiles suitable for all types of climates?

Yes, aluminum extrusion profiles are suitable for a wide range of climates:

- Hot climates: The profiles' thermal break technology helps keep interiors cool.

- Cold climates: Their excellent insulation properties prevent heat loss.

- Coastal areas: Aluminum's corrosion resistance makes it ideal for salty, humid environments.

- Extreme weather: The strength of aluminum profiles helps them withstand high winds and severe weather conditions.

This versatility makes aluminum extrusion profiles a popular choice for buildings in various geographical locations[1][2][7].

4. How do aluminum extrusion profiles compare to other materials like wood or uPVC in terms of cost and performance?

When comparing aluminum extrusion profiles to wood or uPVC:

- Initial cost: Aluminum may have a higher upfront cost than wood or uPVC.

- Long-term value: Aluminum's durability and low maintenance requirements often result in lower lifetime costs.

- Performance: Aluminum offers superior strength, allowing for larger window and door sizes.

- Aesthetics: Aluminum provides a modern, sleek appearance that wood or uPVC may not achieve.

- Sustainability: Aluminum is highly recyclable, unlike uPVC.

While each material has its advantages, aluminum extrusion profiles often provide the best balance of performance, aesthetics, and long-term value[2][3].

5. Can aluminum extrusion profiles be customized for specific architectural designs?

Absolutely. Aluminum extrusion profiles offer extensive customization options:

- Shape and size: Profiles can be extruded into a wide variety of shapes and sizes to suit specific design requirements.

- Finishes: Aluminum can be anodized, powder-coated, or given wood-grain effects in numerous colors.

- Integration: Profiles can be designed to accommodate various hardware, glazing options, and smart home technologies.

- Performance features: Customization can include enhanced thermal breaks, sound insulation, or security features.

This flexibility allows architects and designers to create unique, high-performance window and door systems that meet their exact specifications[1][2][4].

Citations:

[1] https://www.fortune-alu.com/info-detail/aluminum-profiles-in-window-and-door-systems

[2] https://globalaluminium.com/application-of-aluminium-extrusion-profiles-for-doors-windows/

[3] https://nalbantal.com/en/importance-of-aluminium-extrusion-profiles/

[4] https://www.wellste.com/aluminium-profiles-for-windows-doors/

[5] https://www.youtube.com/watch?v=4QEv-O2gbjU

[6] https://www.youtube.com/watch?v=j81i23RbK2g

[7] https://www.tj-chinafreight.com/aluminum-window-profiles-the-ultimate-faq-guide/

[8] https://www.gdcalm.com/some-questions-about-aluminum-extrusion.html

[9] https://www.otalum.com/advantages-of-using-aluminium-window-extrusion-profiles-in-construction.html

[10] https://www.guangyaaluminium.com/architecture-aluminium-profile_c1