Content Menu

● Understanding Aluminum Extrusion Pivots

● Advantages of Aluminum Extrusion Pivots

>> Lightweight Yet Strong

>> Corrosion Resistance

>> Design Flexibility

>> Cost-Effective Solution

● Applications of Aluminum Extrusion Pivots

>> Furniture Design

>> Automotive Industry

>> Aerospace Engineering

>> Industrial Machinery

>> Architectural Elements

● Design Considerations for Aluminum Extrusion Pivots

>> Load Bearing Capacity

>> Environmental Factors

>> Precision Requirements

>> Integration with Other Components

● Manufacturing Process of Aluminum Extrusion Pivots

● Sustainability Aspects of Aluminum Extrusion Pivots

>> Recyclability

>> Energy Efficiency

>> Longevity

● Innovations in Aluminum Extrusion Pivot Technology

>> Smart Pivots

>> Advanced Alloys

>> 3D Printing Integration

● Case Studies: Successful Implementation of Aluminum Extrusion Pivots

>> Aerospace: Lightweight Aircraft Doors

>> Automotive: Innovative Seating Mechanism

>> Architecture: Sustainable Building Design

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of using aluminum extrusion pivots?

>> 2. How do aluminum extrusion pivots compare to other materials in terms of durability?

>> 3. Can aluminum extrusion pivots be customized for specific applications?

>> 4. What industries commonly use aluminum extrusion pivots?

>> 5. Are aluminum extrusion pivots environmentally friendly?

In the world of engineering and design, choosing the right materials and components can make all the difference in the success of a project. One often overlooked but incredibly versatile element is the aluminum extrusion pivot. These components offer a unique combination of strength, flexibility, and cost-effectiveness that can elevate your designs to new heights. In this comprehensive guide, we'll explore the many reasons why aluminum extrusion pivots should be at the top of your list for your next design project.

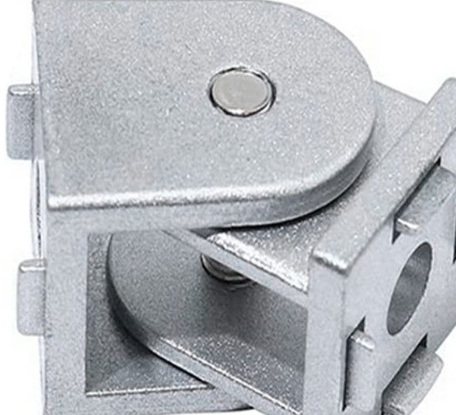

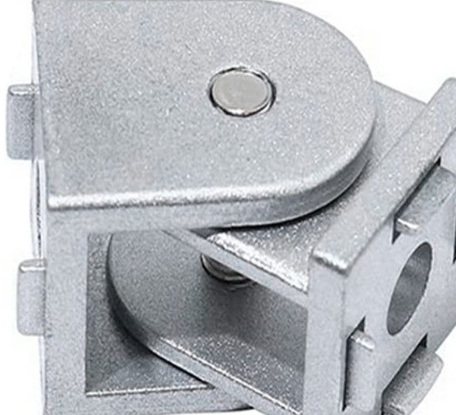

Understanding Aluminum Extrusion Pivots

Before diving into the benefits, let's first understand what aluminum extrusion pivots are and how they're made.

Aluminum extrusion pivots are components created through the extrusion process, where aluminum is forced through a die to create a specific cross-sectional profile. These profiles can then be cut, machined, and assembled to create pivoting mechanisms that are essential in various applications, from furniture to industrial machinery.

The extrusion process allows for the creation of complex shapes with tight tolerances, making aluminum extrusion pivots highly customizable and precise.

Advantages of Aluminum Extrusion Pivots

Lightweight Yet Strong

One of the primary reasons to choose aluminum extrusion pivots is their exceptional strength-to-weight ratio. Aluminum is known for being lightweight, yet when extruded, it gains significant structural integrity.

This combination of attributes makes aluminum extrusion pivots ideal for applications where weight is a critical factor, such as in aerospace or automotive industries.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This property ensures that aluminum extrusion pivots maintain their functionality and appearance over time, even in harsh environments.

Design Flexibility

The extrusion process allows for incredible design flexibility. Engineers can create custom profiles that integrate multiple functions into a single component, reducing the need for additional parts and simplifying assembly.

This flexibility extends to the creation of complex pivot mechanisms that can be tailored to specific project requirements.

Cost-Effective Solution

While the initial cost of aluminum extrusion pivots might be higher than some alternatives, their long-term value is undeniable. The durability, low maintenance requirements, and potential for integrating multiple functions into a single component can lead to significant cost savings over the life of a product.

Applications of Aluminum Extrusion Pivots

Aluminum extrusion pivots find applications across a wide range of industries and products. Let's explore some of the most common uses:

Furniture Design

In the furniture industry, aluminum extrusion pivots are revolutionizing the way designers approach movable components. From adjustable table legs to folding chairs, these pivots provide smooth operation and durability.

Automotive Industry

The automotive sector leverages aluminum extrusion pivots for various applications, including hood hinges, door mechanisms, and adjustable seating systems. The lightweight nature of these components contributes to overall vehicle efficiency.

Aerospace Engineering

In aerospace, where every gram counts, aluminum extrusion pivots play a crucial role in creating lightweight yet robust mechanisms for things like cargo doors, landing gear components, and interior fixtures.

Industrial Machinery

Industrial machines benefit from the strength and precision of aluminum extrusion pivots in applications such as conveyor systems, robotic arms, and packaging equipment.

Architectural Elements

In architecture, these pivots are used in window and door systems, providing smooth operation and weather resistance for large glass panels and movable walls.

Design Considerations for Aluminum Extrusion Pivots

When incorporating aluminum extrusion pivots into your design, several factors should be considered:

Load Bearing Capacity

It's crucial to calculate the expected loads and stresses that the pivot will encounter. While aluminum extrusion pivots are strong, they must be properly sized for the intended application.

Environmental Factors

Consider the environment in which the pivot will operate. While aluminum is corrosion-resistant, certain extreme conditions may require additional protective measures.

Precision Requirements

Determine the level of precision needed for your application. Aluminum extrusion pivots can be manufactured to tight tolerances, but this may affect cost and production time.

Integration with Other Components

Think about how the aluminum extrusion pivot will interact with other parts of your design. The flexibility of extrusion allows for creative solutions in component integration.

Manufacturing Process of Aluminum Extrusion Pivots

Understanding the manufacturing process can help you appreciate the versatility and quality of aluminum extrusion pivots.

1. Design Phase: Engineers create the profile design based on the specific requirements of the pivot.

2. Extrusion: Heated aluminum billets are forced through a die to create the desired profile.

3. Cooling: The extruded profiles are cooled to ensure dimensional stability.

4. Cutting: Profiles are cut to the required lengths.

5. Machining: Additional features such as holes, slots, or threads are added through CNC machining.

6. Surface Treatment: If required, the pivots undergo surface treatments like anodizing for enhanced durability or aesthetics.

7. Assembly: For complex pivot mechanisms, multiple extruded components may be assembled.

Sustainability Aspects of Aluminum Extrusion Pivots

In today's environmentally conscious world, the sustainability of materials is a significant consideration. Aluminum extrusion pivots offer several environmental benefits:

Recyclability

Aluminum is 100% recyclable and can be recycled indefinitely without losing its properties. This makes aluminum extrusion pivots an environmentally friendly choice.

Energy Efficiency

The production of recycled aluminum requires only 5% of the energy needed to produce primary aluminum, significantly reducing the carbon footprint of aluminum extrusion pivots.

Longevity

The durability and corrosion resistance of aluminum extrusion pivots mean they have a long lifespan, reducing the need for replacements and minimizing waste.

Innovations in Aluminum Extrusion Pivot Technology

The field of aluminum extrusion pivots is constantly evolving, with new innovations enhancing their capabilities:

Smart Pivots

Integration of sensors and actuators into aluminum extrusion pivots is leading to the development of smart pivots that can adjust their behavior based on environmental conditions or user inputs.

Advanced Alloys

Research into new aluminum alloys is producing extrusion pivots with even greater strength and lighter weight, expanding their potential applications.

3D Printing Integration

While not replacing traditional extrusion, 3D printing is being used to create prototypes and small-batch custom pivot components, accelerating the design process.

Case Studies: Successful Implementation of Aluminum Extrusion Pivots

Let's look at some real-world examples where aluminum extrusion pivots have made a significant impact:

Aerospace: Lightweight Aircraft Doors

A major aircraft manufacturer reduced the weight of their cargo doors by 15% by switching to a custom aluminum extrusion pivot system, resulting in improved fuel efficiency.

Automotive: Innovative Seating Mechanism

An automotive company developed a new adjustable seating system using aluminum extrusion pivots, providing greater comfort and flexibility while reducing overall vehicle weight.

Architecture: Sustainable Building Design

An award-winning office building utilized large-scale aluminum extrusion pivots for its movable glass walls, creating a flexible and energy-efficient workspace.

Conclusion

Aluminum extrusion pivots offer a compelling combination of strength, lightweight design, flexibility, and sustainability that make them an excellent choice for a wide range of applications. From furniture to aerospace, these versatile components are driving innovation and efficiency across industries.

As we've explored, the benefits of aluminum extrusion pivots extend beyond their physical properties. Their cost-effectiveness, design flexibility, and environmental advantages position them as a forward-thinking solution for engineers and designers looking to create products that are not only functional and durable but also sustainable.

By choosing aluminum extrusion pivots for your next design project, you're investing in a technology that offers proven performance, adaptability to future innovations, and alignment with global sustainability goals. As the demand for smarter, lighter, and more efficient products continues to grow, aluminum extrusion pivots are poised to play an increasingly important role in shaping the future of design and engineering.

Frequently Asked Questions (FAQ)

1. What are the main advantages of using aluminum extrusion pivots?

Aluminum extrusion pivots offer several key advantages:

- Lightweight yet strong construction

- Excellent corrosion resistance

- High design flexibility

- Cost-effectiveness over the product lifecycle

- Sustainability and recyclability

2. How do aluminum extrusion pivots compare to other materials in terms of durability?

Aluminum extrusion pivots are highly durable due to their:

- Natural corrosion resistance

- Ability to withstand repeated use without fatigue

- Resistance to environmental factors

- Low maintenance requirements

While they may not be as hard as steel, their strength-to-weight ratio and corrosion resistance often make them a superior choice for many applications.

3. Can aluminum extrusion pivots be customized for specific applications?

Yes, aluminum extrusion pivots are highly customizable:

- Custom profiles can be designed to meet specific requirements

- Various surface treatments and finishes are available

- Additional features can be integrated through machining

- Different aluminum alloys can be used for specific properties

This flexibility allows designers to create pivots that are perfectly suited to their application.

4. What industries commonly use aluminum extrusion pivots?

Aluminum extrusion pivots are widely used across various industries, including:

- Aerospace and aviation

- Automotive manufacturing

- Furniture design

- Industrial machinery

- Architecture and construction

- Consumer electronics

Their versatility makes them suitable for applications ranging from small consumer products to large industrial equipment.

5. Are aluminum extrusion pivots environmentally friendly?

Yes, aluminum extrusion pivots are considered environmentally friendly for several reasons:

- Aluminum is 100% recyclable and can be recycled indefinitely

- Recycling aluminum uses only 5% of the energy required to produce new aluminum

- The durability of aluminum pivots leads to longer product lifespans

- Lightweight nature contributes to energy efficiency in transportation applications

These factors make aluminum extrusion pivots a sustainable choice for environmentally conscious designs.