Content Menu

● The Advantages of Aluminum Extrusion

● Why Florida?

● Top Aluminum Extrusion Companies in Florida

● Applications of Aluminum Extrusions

● Quality Assurance in Aluminum Extrusion

● Emerging Trends in Aluminum Extrusion

● The Future of Aluminum Extrusion in Florida

● Conclusion

● FAQ

>> 1. What industries commonly use aluminum extrusions?

>> 2. How does the aluminum extrusion process work?

>> 3. What are the main advantages of using aluminum over other metals?

>> 4. Can I get custom designs from aluminum extrusion companies?

>> 5. What types of surface treatments are available for aluminum extrusions?

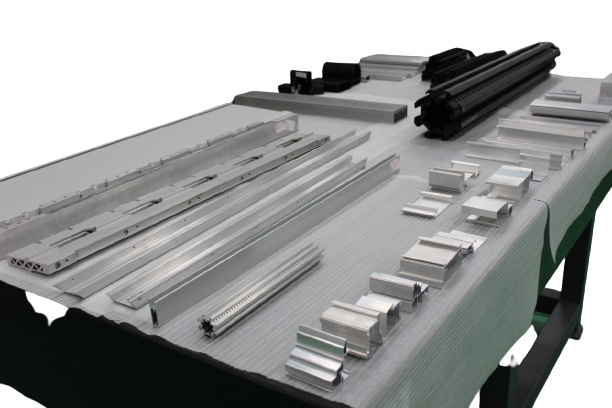

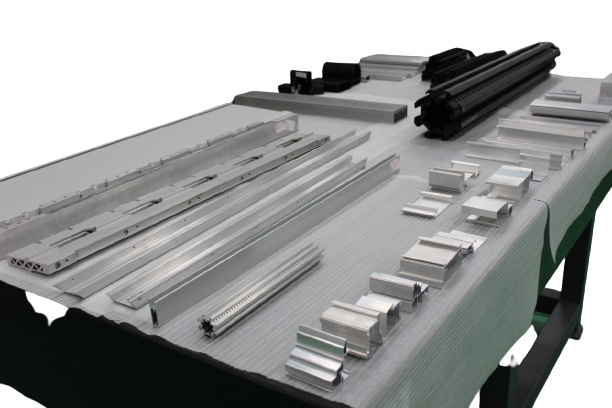

Aluminum extrusion is a manufacturing process that shapes aluminum alloys into desired profiles by forcing the material through a die. This technique is essential in various industries, including construction, automotive, aerospace, and consumer goods. Florida, with its growing industrial base and favorable business environment, is home to several reputable aluminum extrusion manufacturers. This article explores the reasons to choose aluminum extrusion companies in Florida, highlighting their benefits, capabilities, and contributions to various sectors.

The Advantages of Aluminum Extrusion

Aluminum extrusion offers numerous advantages that make it a preferred choice for manufacturers. Here are some key benefits:

- Lightweight and Durable: Aluminum has a high strength-to-weight ratio, making it ideal for applications requiring both strength and lightness.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion, making it suitable for outdoor and marine applications.

- Design Flexibility: The extrusion process allows for the creation of complex shapes and profiles tailored to specific needs.

- Cost Efficiency: With minimal material waste and high production rates, aluminum extrusion is a cost-effective solution for large-scale manufacturing.

- Sustainability: Aluminum is 100% recyclable without loss of properties, supporting environmentally friendly practices in manufacturing.

Why Florida?

Florida stands out as a prime location for aluminum extrusion manufacturing due to several factors:

- Diverse Industries: The state hosts a variety of industries that utilize aluminum extrusions, including aerospace, automotive, construction, and marine sectors. This diversity creates a robust demand for custom aluminum products.

- Skilled Workforce: Florida's educational institutions and training programs produce skilled workers proficient in advanced manufacturing techniques.

- Strategic Location: With access to major ports and highways, Florida manufacturers can efficiently distribute their products both domestically and internationally.

- Business-Friendly Environment: Florida offers favorable tax incentives and business regulations that encourage manufacturing growth.

Top Aluminum Extrusion Companies in Florida

Several notable aluminum extrusion manufacturers operate in Florida, each offering unique capabilities:

- Hydro Extrusion: With facilities in St. Augustine, Hydro is known for its extensive range of custom extrusions and commitment to quality. They offer advanced fabrication services like CNC machining and anodizing. Their plant is ISO 9001:2015 and ISO 14001:2015 certified, ensuring high standards of quality management and environmental responsibility.

- Zetwerk: This company specializes in custom aluminum extrusions with a focus on logistics and customer service. They provide comprehensive solutions from design to delivery, ensuring that clients receive exactly what they need on time.

- OD Metals: Recognized for their custom aluminum extrusions tailored to specific industry needs, OD Metals emphasizes high-quality materials and cost-effective solutions. Their expertise spans various sectors, ensuring they meet diverse client requirements.

Applications of Aluminum Extrusions

Aluminum extrusions are used across various sectors due to their versatility:

- Construction: Used in window frames, curtain walls, roofing systems, and structural components due to their lightweight yet strong nature. The growing trend toward sustainable construction practices further enhances the demand for aluminum extrusions in this sector.

- Automotive: Components such as chassis parts, heat exchangers, and body panels benefit from the durability and weight savings provided by aluminum extrusions. The automotive industry is increasingly adopting aluminum to improve fuel efficiency and reduce carbon emissions.

- Aerospace: Lightweight components are crucial for fuel efficiency; therefore, aluminum extrusions are extensively utilized in aircraft structures. Innovations in higher strength alloys are enabling even more applications within this sector.

- Consumer Goods: From furniture to appliances, aluminum extrusions provide aesthetic appeal along with functional benefits. Their ability to be finished in various ways allows manufacturers to create visually appealing products while maintaining performance standards.

Quality Assurance in Aluminum Extrusion

Quality assurance is paramount in the aluminum extrusion process. Manufacturers implement strict quality control measures at every stage of production:

1. Material Selection: Choosing the right alloy is critical. Common alloys used include 6061 (for structural applications) and 6063 (for architectural applications).

2. Precision Engineering: Advanced CNC machining ensures that extrusions meet precise specifications and tolerances.

3. Surface Treatments: Processes like anodizing or powder coating enhance the durability and appearance of the final product.

4. Testing Standards: Rigorous testing ensures that products meet industry standards for strength, corrosion resistance, and dimensional accuracy.

Emerging Trends in Aluminum Extrusion

The aluminum extrusion industry is continuously evolving with emerging trends that enhance manufacturing processes:

- Technological Innovations: Advances such as rapid quench systems improve cooling efficiency during production, leading to better product quality. These systems ensure uniform cooling of extrusions as they exit the press, reducing deformations like straightness issues.

- Artificial Intelligence Integration: AI is being integrated into various aspects of the extrusion process. Predictive maintenance powered by AI can significantly reduce downtime by anticipating equipment failures before they occur.

- Sustainable Practices: The industry is making strides toward sustainability by reducing carbon emissions throughout the value chain—from mining bauxite to recycling scrap aluminum. This commitment aligns with global efforts to combat climate change.

The Future of Aluminum Extrusion in Florida

The future looks promising for aluminum extrusion manufacturers in Florida. As industries increasingly prioritize sustainability and lightweight materials, the demand for aluminum products is expected to rise significantly.

- Growth Projections: The global aluminum extrusion market is projected to grow from $90 billion in 2022 to $170 billion by 2030 at an annual growth rate of approximately 8%. This growth reflects the increasing need for lightweight materials across various sectors such as construction and automotive industries.

- Innovation Focus: Companies are investing heavily in research and development to create higher strength alloys specifically designed for demanding applications like automotive components where performance is critical.

Conclusion

Choosing an aluminum extrusion manufacturer in Florida offers numerous advantages ranging from cost efficiency to sustainability. With a diverse industrial landscape and skilled workforce, Florida stands out as a key player in the aluminum extrusion market. Companies like Hydro Extrusion, Zetwerk, and OD Metals exemplify the high-quality production standards available in the state. As industries continue to evolve towards more sustainable practices, the role of aluminum extrusions will undoubtedly expand further.

FAQ

1. What industries commonly use aluminum extrusions?

Aluminum extrusions are widely used in construction, automotive, aerospace, marine applications, consumer goods manufacturing, and more due to their versatility and strength-to-weight ratio.

2. How does the aluminum extrusion process work?

The process involves heating an aluminum billet until it's malleable, then forcing it through a die to create specific shapes or profiles. The resulting extrusions are then cooled and cut to length.

3. What are the main advantages of using aluminum over other metals?

Aluminum is lightweight yet strong, resistant to corrosion, highly malleable allowing complex shapes to be formed easily; it also supports energy-efficient designs due to its recyclability.

4. Can I get custom designs from aluminum extrusion companies?

Yes! Many aluminum extrusion manufacturers offer custom design services tailored to meet specific customer requirements across various applications.

5. What types of surface treatments are available for aluminum extrusions?

Common surface treatments include anodizing (for enhanced corrosion resistance), powder coating (for aesthetic finishes), mill finishes (for raw appearances), among others tailored for specific needs.